Top ranking of the best mounting foams in 2022

In the process of repair and construction work, both beginners and professional repairmen and builders invariably deal with such a type of universal insulating material as mounting foam (another name for it is one-component foam).

This type of polyurethane sealant perfectly fills any cracks, voids and cavities, and also has such characteristics as heat and sound insulation, low electrical conductivity, moisture resistance, fire resistance. The hardened polyurethane foam becomes hard, porous and light, but at the same time this substance is often very sensitive to ultraviolet radiation, therefore it turns yellow and collapses under the influence of sunlight.

Content

Types of mounting foam

There are several types of this building composition, differing in the principle of use and in relation to the temperature conditions under which repairs are carried out.

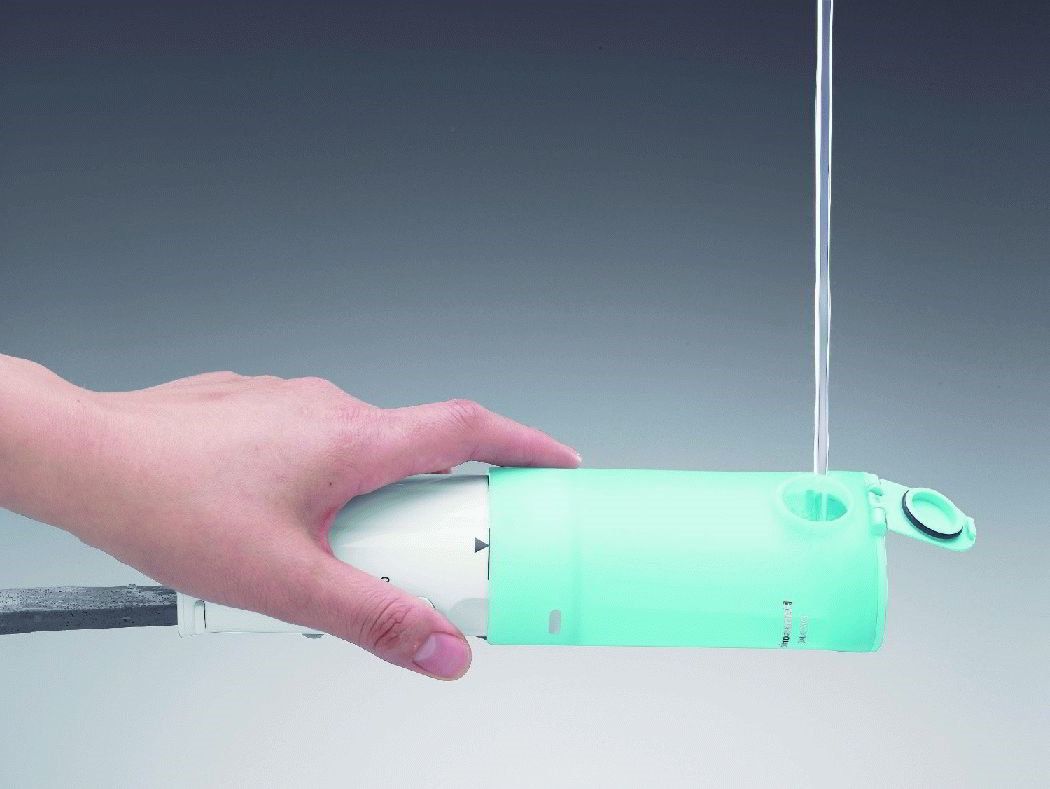

- Professional foam. Usually it is used with a special mounting gun. It differs in the density of the composition, and the secondary expansion of this sealant is almost absent. You should never use professional foam for minor home repairs, as its yield from a bottle is 3 times higher than household foam.

- Semi-professional. This is a household foam that needs to be used in one go and does not require a gun as the can is fitted with a tube. The density of the composition is lower than that of professional foam, and the secondary expansion is greater, therefore, for serious work, such as the installation of windows, window sills and doors, this composition is not suitable.

- Summer composition. They can work at temperatures from +5 to +35 degrees.

- Winter foam. Its composition differs from summer, the sealant can be used during severe frosts, as it can withstand temperatures down to -20 degrees.

- All season. It combines the characteristics of winter and summer and can be used at temperatures from -10 to +30 degrees.

- Fire-fighting. On the cans you can see the marks - B1, B2, B3. These are designations for the combustibility of the material, where B1 is refractory, B2 is self-extinguishing, and B3 is a combustible substance. Of course, type B1 is preferable, which has a special fire-fighting composition and retains all its properties at high temperatures.

How to choose mounting foam?

When choosing a sealant, you should focus on several basic requirements for foam:

- Elasticity. The higher the quality of the foam, the more elastic it is;

- Shrinkage. In other words, the decrease in foam upon drying, which should be minimal;

- Structure. The composition should be thick and tenacious enough to adhere well to any surface and not drain;

- Frost resistance. The hardened substance should not crumble and crack at low temperatures if construction and repair work is carried out outside the premises;

- Porosity. The foam should not be too porous, otherwise the heat and sound insulation properties of the material are reduced;

- Extension. During the exit of the foam from the cylinder, as well as during its complete solidification, the expansion of the substance occurs, which should be minimal. Otherwise, excessive expansion of the foam may, for example, distort the door frame when installing the doors;

- Freezing speed. The speed and performance of the work as a whole depends on this indicator.

- The weight. A container with a quality undiluted composition should have a mass of approximately 910 grams.

Mounting foam rating

There is a wide variety of types of sealant from different manufacturers, but there are actually not so many compositions that have firmly won positive reviews and user popularity. Unfortunately, very often there are low-quality compounds that not only do not cope with their basic duties, but are also dangerous to health, as they contain harmful toxins. That is why it is very important to make the right choice, which guarantees high-quality repairs without harm to health.

Moment Mounting

A very popular company, whose mounting foam is professional and household, as well as all-weather - it is used at any temperature. With its main function - filling voids and sealing seams - it does a good job. Suitable for finishing work. The average cost is 320 rubles.

- the composition is dense and homogeneous;

- adheres well to various types of surfaces;

- economical consumption;

- Can be used for both interior and exterior repairs.

- strong secondary expansion;

- low-quality foam is often found;

- not suitable for thermal insulation;

- fragility, over time darkens and collapses.

Makroflex

Another popular manufacturer whose products are highly economical. The mounting foam of this company is most often all-weather, has good adhesion to building materials, in addition, it is moisture resistant. The composition of the sealant is characterized by uniformity of mass, shows minimal secondary expansion. Mounting foam of this brand is suitable for the installation of windows and doors, for the repair of plumbing, as well as for the usual sealing of joints, creating sound insulation. The cylinder is convenient in that it can be used with a special pistol. The average cost is 200 rubles (for a cylinder with a volume of 0.75 liters).

- good indicators of heat and sound insulation;

- composition is non-toxic;

- high service life;

- fire resistance;

- availability.

- defective products are often found;

- when dried, strong shrinkage occurs;

- sensitive to direct sunlight.

MAXFORTE SoundFlex

Our rating includes a new generation of mounting foam MAXFORTE SoundFlex, which is designed specifically for soundproofing window and door mounting joints, elastic filling of expansion joints in building structures, crevices and voids. It has a high density and low expansion. SoundFlex foam has an increased level of elasticity and the ability to stretch and regain its original shape after compression. The product provides a significant reduction in the vibration load between building structures and becomes a damping layer that dampens vibrations. The average price is 590 rubles.

- The foam takes its original shape at any degree of compression (up to 75%);

- Increased elasticity without damaging the structure;

- High product density;

- Mounting foam with a very high degree of adhesion to building materials such as concrete, wood, metal and artificial surfaces;

- First-class vibroacoustic properties: vibration reduction up to 90%;

- Application temperature from -10°C to +35°C;

- Sound insulation of joints 65 dB (joint 10 mm).

- Does not tolerate exposure to ultraviolet rays.

soudal

The mounting foam of this company is gaining popularity due to its quality characteristics and good properties. There are three types - summer, winter (maximum operating temperature -20 degrees) and, produced separately, fire-resistant. At the same time, the composition of the sealant does not contain toxic substances and does not have a strong odor. The material is very dense in structure, has a minimum number of pores, due to which shrinkage does not occur after the sealant dries. It dries quickly and, most importantly, evenly.Often used for professional window installation. The average cost of this mounting foam is 350 rubles.

- high quality;

- the ability to work at low temperatures;

- large foam output;

- good waterproofing performance;

- shows weak secondary expansion;

- Adheres well to various types of surfaces.

- does not tolerate sun exposure (it is necessary to cover the cured foam with paint to protect it from ultraviolet radiation, otherwise it will darken and crack over time).

Penosil

Another brand that is growing in popularity. The mounting foam of this company has a lot of positive reviews, it is chosen by beginners and professionals, praised by those involved in home repairs and construction. The sealant is characterized by density and uniformity of the composition, shows a large volume of output, and the secondary expansion is reduced to the minimum possible. Reliable, suitable for the installation of serious structures, perfectly fills cavities, gaps and seams. Since the composition has no smell, it is comfortable and pleasant to work with it. There is also a special type of this foam sealant, which is a cross between foam and glue. The average cost is 220 rubles.

- reliability and high quality;

- there is no shrinkage during solidification of the material;

- large output volume;

- has a white tint;

- ideal for interior renovations.

- not well suited for outdoor work;

- does not tolerate temperatures below -5 degrees;

- in hot weather (from +35 degrees and above), the sealant does not foam, it flows down the surface.

A very popular polyurethane foam that has earned first place in terms of the number of positive reviews, professional repairmen and builders. Differs in high profitability and quality. It is produced in two types - a winter version, and with increased fire resistance. The structure of the composition is dense, fine, retains volume, shrinkage during solidification does not occur, as well as secondary expansion. Thanks to such useful properties, the sealant shows itself perfectly when installing windows and doors, repairing heating and water supply systems, and performing thermal insulation work. The average cost is 230 rubles.

- the composition of the mounting foam does not contain toxic ingredients;

- the sealant has good adhesion to all building materials;

- great for interior work;

- With the help of this mounting foam, pipes can be installed.

- does not tolerate exposure to ultraviolet rays;

- when used for outdoor work shows fragility.

Popular manufacturing companies

Despite the variety of products offered by the market, there are not so many manufacturers of truly high-quality polyurethane foam. Unfortunately, there are many more companies that produce low-quality sealants without the use of technological knowledge and equipment that meets modern standards.

High popularity

- Firm Soudal - has factories in countries such as Belgium, Slovenia, Poland. The mounting foam of this company has a good structure, output volume, is durable, does not darken and does not crack over time.

- Estonian manufacturer Krimelte (Penosil brand products) - good value for money, as well as a variety of sealant options for different occasions.

- Trademark TITAN - from the manufacturer Orion (Spain, Turkey, Poland). The products of this company foam well, have no secondary expansion, but begin to deteriorate after a year.

Average Popularity

- The moment of installation is an inexpensive and high-quality product with low toxicity.

- Ultima - has an affordable price, easy to use, but at the same time has a low level of efficiency.

- Axton - odorless, quickly hardens, but has poor adhesion and high porosity of the structure.

Mounting foam with low popularity

- Makroflex (from the Estonian company Henkel) - inexpensive, quickly hardens, but the foam consumption is uneconomical, the composition does not tolerate ultraviolet light, and also has a high level of expansion.

- Greflex - does a good job of sealing, but the composition often has additional unwanted impurities.

- Boxer is a budget mounting foam for home repairs, not suitable for outdoor use.

Areas of application of polyurethane foam

So, the use of polyurethane foam, as you can already see, is quite wide, it is:

- isolation and sealing;

- insulation of rooms (sealing of cavities and cracks with foam);

- sealing cracks in the roof;

- filling cavities around various structures, door frames, window openings, as well as fixing window and door blocks;

- filling voids and cracks at bends or joints, as well as around water and heating pipes;

- gluing to the walls of insulating, insulating and other materials;

- soundproofing, (including treatment of bathtubs to avoid unnecessary noise during use);

- boat repair (sealing holes and cracks).

The modern market offers a wide variety of mounting foam, which differs in scope and conditions of use. It is best to opt for the highest quality material, which will not only provide comfort during work, but also guarantee reliability and durability.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131652 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127693 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124520 -

The best men's sneakers in 2022

Views: 124034 -

The Best Complex Vitamins in 2022

Views: 121941 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2022

Views: 113396 -

Ranking of the best wood paints for interior work in 2022

Views: 110320 -

Rating of the best spinning reels in 2022

Views: 105330 -

Ranking of the best sex dolls for men for 2022

Views: 104367 -

Ranking of the best action cameras from China in 2022

Views: 102217 -

The most effective calcium preparations for adults and children in 2022

Views: 102012