Welding best inverters, rating 2022

Thanks to welding machines, welders have greatly facilitated their work, this is mainly due to modern inverters. Such a modern device has made a big leap in the work with electric welding of metals.

Content

About welding inverters

Of all the power tools, the most popular and frequently used is the welding machine. The inverter today works in many industries, it is applicable both for welding window grilles, building barbecues, and repairing water pipes, installing a fence in a country house and others. With such a welding machine, you can not only connect metal, but also quickly cut it, it is in demand where a grinder is not suitable for cutting. A modern inverter is important for dismantling the foundation, old buildings, as well as removing iron, warming threaded connections.

- The construction is lightweight;

- More convenient than other models;

- Small size;

- It is easier to learn how to work than with other devices;

- Conforms to European standards EN 61000-3-12, which is important for welding;

- You can safely work from a standard outlet, and the wiring in the house will not burn out for sure;

- Welding will be beautiful.

Inverters are slightly more expensive than conventional welding machines, however, they have become the most relevant in the world and are suitable for different jobs. Such a device operates at high frequencies, has a complex electronic filling, thanks to which welding is better controlled. It can work with metals of very different thicknesses, as it has a current adjustment, the arc will burn more stable than other types of welding, and the pulse amplitude is regular.

How to choose an inverter

It is better to buy modern inverters only from ours or European ones, since most of the Chinese products are of poor quality. It is required to take into account the country of the manufacturer, as there will be breakdowns, and there are currently no spare parts for Asian equipment or it is difficult to get them. Also, be sure to know what to look for, the main thing is the temperature indicator during operation, which should be indicated in the characteristics of the inverter. It is better not to use the device where there is a lot of dust, dust easily enters the product through a fan for cooling.

The most important characteristics when choosing a device

-

- Total running time at max. current, this is the ability to work as long as possible at maximum operating values;

- The operating voltage of idling, the larger it is, the faster the welding arc is formed, usually it is 40-80 V;

- Arc Force, such a function will automatically regulate the currents, increasing them when required;

- Anti-sticking, serves to recognize the moment of sticking of the working electrode to the metal;

- Hot start, this function is required when working with electrodes of terrible workmanship and welding rusty metal;

- Of even greater importance is the price indicator, the size of the product;

- Before the purchase itself, find out the reviews on the network, check the quality of workmanship and the moments when the inverter fails.

Before purchasing a welding inverter, you should clarify whether it is required for a home or for construction and major work. Find out right away which model will be the best so that the unit functions as long as possible and does not cost much.Modern welding machines can be clearly divided into three groups, they can be household, special or industrial, each group has its own characteristics. The inverter is today the most fashionable welding machine, although its price is not so small. To buy the best models, consider which company the product is of better quality, and not just its cost.

The most affordable inverters

Aurora Vector 2200 MMA

| SPECIFICATIONS | |

|---|---|

| WELDING CURRENT: | 20-220 A. |

| INPUT VOLTAGE: | 230 V. |

| POWER: | 8.40 kVA. |

| ELECTRODE DIAMETER: | 1.60-5 mm. |

| DEGREE OF PROTECTION: | IP21S. |

| DIMENSIONS: | 323x126x193 mm. |

| THE WEIGHT: | 4.3 kg. |

The welding inverter of the Vector line is designed for manual arc welding with a coated electrode, and is also used to work with carbon steel, stainless steel and various alloys. This model is ideal for construction, repair and installation work.

Due to the high power ratings, the welding inverter produces a strong and stable arc. The peculiarity of the device lies in the ease of adjusting the welding mode, so the device is suitable for beginners.

The average price is 8,900 rubles.

- increases the welding current when the electrode touches the surface to be treated in automatic mode, which makes it possible to immediately ignite the arc and carry out work;

- reduces the welding current at the moment of electrode sticking in automatic mode, which makes it possible to separate and preserve the integrity of the electrode without piercing;

- increasing the welding current during operation at the moment of separation of the metal drop from the electrode in automatic mode, which reduces the risk of electrode sticking and increases the stability of the arc;

- adapted to domestic operating conditions;

- the presence of protection against overheating;

- the ability to interact in networks with a high supply voltage spectrum.

- not detected.

ZUBR Master MMA SA-250K

| SPECIFICATIONS | |

|---|---|

| WELDING CURRENT: | 20-250 A. |

| INPUT VOLTAGE: | 160-230 V. |

| POWER: | 8.40 kVA. |

| ELECTRODE DIAMETER: | 1.60-6 mm. |

| DEGREE OF PROTECTION: | IP21. |

| DIMENSIONS: | 260x110x175 mm. |

| THE WEIGHT: | 4.4 kg. |

This small model is designed for manual arc welding using fusible electrodes. Electronic components and microprocessor-type current control, lightness, compactness, as well as good parameters and instant adjustment favorably separate this model from competitors.

The average price is 8,100 rubles.

- compactness;

- stable arc;

- smooth adjustment of the welding current in a wide range;

- economical consumption of electrical energy;

- high rate of efficiency.

- not detected.

Interskol ISA-160/7.1

Interskol ISA-160/7.1 is a welding inverter available, ideal for welding. The product has such an important advantage as working with a rapidly changing current, even with large network drawdowns up to 150 V, the arc is kept in the electrode here. It works great, it is mobile and comfortable, and it comes with a special strap, so that the product can be easily carried around. Even if the air temperature is high, this machine will not become very hot, so it can work for a long time without interruption, which is often required. For work, you may need to purchase special cable mounts, a wire for the inverter.

Characteristics:

- Device: welding inverter;

- Type: manual arc welding MMA;

- Current for work: 20-160 A;

- Operating output voltage 170-242 V;

- Power phase: one;

- Output currents: constant for work;

- Power 8.2 kVA;

- Duration at max. currents 100%;

- Electrode with a diameter of 1.60-4 mm;

- Class F insulation;

- Anti-stick;

- Hot start.

Video review of characteristics:

- The seam is beautiful;

- Reviews are mostly excellent;

- Affordable price;

- The quality is higher than expected;

- There will always be stability;

- Works without difficulty;

- Holders are comfortable;

- The functionality is perfect;

- Assembly;

- There are required options.

- The button for operating the device is located inconveniently;

- The anti-stack is terrible;

- The anti-seize at the electrode is weak;

- Terminals;

- The design is small, although this is not a minus;

- Serious minuses are not noticed in the network.

Bottom line: The inverter apparatus is used to operate in the MMA mode with DC current when using piece standard electrodes. The average price for the Internet is from 5223 rubles, although in city stores the cost reaches up to 7000, Interskol products will be the most inexpensive high-quality models.

Resanta SAI-220

Resanta SAI-220 is the equipment of the Latvian company, assembled in China. The welding inverter has a duration indicator of 70%, that is, it works up to 7 minutes when the loads are maximum. This is an excellent performance indicator, as other products will be able to work up to 6 minutes. The mass of this device is only 5 kg, which is less than that of other designs, it is easy to operate, there are no problems with the purchase of spare parts when the product breaks down.Such an inverter is the best in terms of quality and price, today Resanta has become fashionable in the CIS countries, the product can be easily bought at a low price, this popular model is one of the best.

Characteristics:

- Product type: welding inverter;

- Welding arc manual MMA;

- Current for welding: 10-220 A;

- One phase;

- Idling 80 V;

- Operating time with max. current;

- Electrode diameter up to 5 mm;

- Hot start;

- Protection degree IP21;

- The package contains two cables.

How to use the device - in the video:

- Small weight;

- Minimum dimensions;

- Seam quality;

- The arc is caught immediately;

- Works products without interruption for a long time;

- The electrode ignites perfectly;

- The price is reasonable;

- Works with electrodes 1-5 mm;

- Smooth seams;

- Enclosure protection class IP21.

- Power and amperage are too high;

- The power wire is weak;

- The strap fastening is terrible;

- Regulator knob;

- There is no case for work;

- The amperage adjustment is too easily confused.

Bottom line: The inverter has all the required functions, the mass is small and there will be no problems with the operation of the device, the price is reasonable, and the quality is excellent. The cost of this popular model is 5,600 rubles, while in a city store the price is up to 6,500 rubles.

FUBAG IR 200

The FUBAG IR 200 inverter provides welding at an output voltage of 150 V, which is a great advantage. This quality is required to work in difficult conditions, where there are difficulties with electricity, there is no current stability. For this device, a standard electrode with a diameter of 1-5 mm is used. The ignition is excellent, a light touch of welding to the metal is enough for work, and the arc is even, stable.The product is compact and light in weight, the only drawback is the short cable included in the package, in addition, the fan installed here is too noisy. It is required to regularly clean the device from dust, and it is better to do it consistently, often.

Characteristics:

- Work at rated welding current;

- Welding current 5-200 A;

- Operating output voltage 150-240 V;

- Operating time at max. current 40% or more;

- There are all additional features;

- Afterburner and anti-sticking;

- Network 220 V;

- Current in operating mode 5-200 A;

- MMA current at PV 74 A;

- Weight 4.68 kg.

Video review of the welding machine:

- Efficiency - 85%;

- Burning is stable;

- Welding voltage does not jump;

- Electronic drift of metal small-drop;

- The seam is finely scaly, precise;

- Cooling system;

- Indicators are conveniently located;

- The mass is small;

- The cost is reasonable.

- The working PV is small and reaches 40% at maximum current;

- The working current quickly decreases when falling in the network;

- The earth cable is too short;

- There are few cons in the network.

Bottom line: The inverter has all the required functions, provides excellent welding, you can safely work with the product even with little experience. The average price is 12,000 rubles, the quality of the device is ideal, therefore it is among the inexpensive and best.

The best expensive models

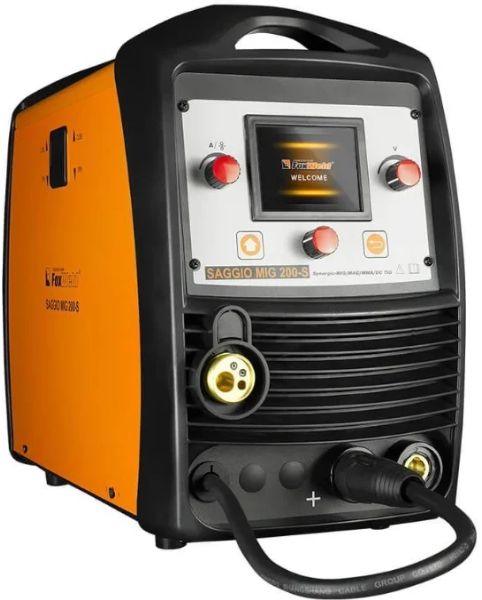

FoxWeld Saggio Mig 200-S

| SPECIFICATIONS | |

|---|---|

| WELDING CURRENT: | 10-200 A. |

| INPUT VOLTAGE: | 187-253 V. |

| POWER: | 7.90 kW. |

| ELECTRODE DIAMETER: | 1.60-4 mm. |

| DEGREE OF PROTECTION: | IP21S. |

| DIMENSIONS: | 557x242x437 mm. |

| THE WEIGHT: | 17 kg. |

This is a new universal welding inverter, which is made using innovative IGBT technology, which makes it possible to perform the following types of welding:

- semi-automatic;

- manual;

- argon-arc.

The model makes it possible to adjust the characteristics independently or with the help of synergy. The synergistic control system makes it possible to adjust the apparatus for specific purposes in a short time. The settings and mode are displayed on a digital type LCD screen, which makes it possible to improve the regulation procedure. This model is able to save the parameters of the specified welding settings for their reuse. The design of the circuit guarantees high dynamic arc parameters, excellent surface welding and excellent efficiency.

This is a 1-phase welding inverter that operates from a 220-volt network at a frequency of 50 Hz. The device is intended for repair, suitable for workshops and small manufacturing enterprises.

The average price is 71,800 rubles.

- stylish appearance;

- compactness;

- rich functionality;

- manual and synergistic adjustment of electric welding characteristics;

- informative and practical PU;

- informative LCD screen.

- not detected.

Telwin TECHNOLOGY TIG 230 DC-HF/LIFT VRD

| SPECIFICATIONS | |

|---|---|

| WELDING CURRENT: | 10-220 A. |

| INPUT VOLTAGE: | 190-253 V. |

| POWER: | 6 kW. |

| ELECTRODE DIAMETER: | 1.60-4 mm. |

| DEGREE OF PROTECTION: | IP23. |

| DIMENSIONS: | 430x176x340 mm. |

| THE WEIGHT: | 14.8 kg. |

This model is compatible with electrodes whose diameter does not exceed 4 mm, which makes it possible to interact exclusively with dense metal in the form of a sheet. Thanks to the practical control panel, the functioning of the device can be easily adjusted.

The advantage of this model lies in the rich configuration, which is needed for electric welding. The reliable case with ventilation guarantees high-quality protection of internal components, and the comfortable handle facilitates carrying of the device.

The average price is 85,200 rubles.

- an ergonomic handle is provided on the upper part of the body, which makes it possible to comfortably transport the device;

- compact dimensions;

- lightness.

- not detected.

ELITECH AIS 300SYN

| SPECIFICATIONS | |

|---|---|

| WELDING CURRENT: | 15-300 A. |

| INPUT VOLTAGE: | 342-418 V. |

| efficiency: | 85%. |

| ELECTRODE DIAMETER: | 1-6 mm. |

| DEGREE OF PROTECTION: | IP21S. |

| DIMENSIONS: | 600x240x430 mm. |

| THE WEIGHT: | 29 kg. |

This is a powerful device capable of welding surfaces with wire and hand-held stick electrodes. The system effectively tolerates high loads. This welding inverter is also equipped with synergic PU.

The relative lightness and small dimensions of the device make it possible to transport the model without much difficulty, and a reliable case protects the internal components from damage.

The average price is 46,000 rubles.

- has support for 3 operating modes;

- two digital screens;

- a light weight;

- small sizes.

- not detected.

Cedar ALPHAMIG-350S

| SPECIFICATIONS | |

|---|---|

| WELDING CURRENT: | 40-350 A. |

| INPUT VOLTAGE: | 323-437 V. |

| POWER: | 13 kW. |

| THE DIAMETER OF THE WIRE: | 0.80-1.20 mm. |

| DEGREE OF PROTECTION: | IP21S. |

| DIMENSIONS: | 942x500x690 mm. |

| THE WEIGHT: | 55 kg. |

This is an industrial model of a semi-automatic type, designed for powerful high-quality electric welding.The welding inverter works together with a small but powerful 4-roll feeder. This machine will be a good choice for electric welding of large structures, so it is often used in construction, production and repair work.

The device is equipped with a "smart" control system, which allows the welder to quickly prepare the device for work. In addition, this model makes it possible to independently adjust the wire feed speed in synergistic mode, optimizing the welding parameters for a specific type of material and operating conditions. The device has dust and moisture protection, which makes it possible to use it in the most critical conditions.

Important! The giving open or closed device is bought separately.

The average price is 81,000 rubles.

- excellent indicators of welding power and current make it possible to weld with wire;

- design features of the modular type significantly increase the scope of application, which makes it possible to cook and adjust the characteristics at a distance from the current source;

- availability of synergistic management;

- there is a 4-roller wire feeder that guarantees smooth and uninterrupted wire feeding;

- an integrated socket for the gearbox with heater is provided.

- not detected.

TSS TOP TIG MMA-250P AC DC

| SPECIFICATIONS | |

|---|---|

| WELDING CURRENT: | 10-250 A. |

| INPUT VOLTAGE: | 187-253 V. |

| POWER: | 8.50 kVA. |

| ELECTRODE DIAMETER: | 1-4 mm. |

| DEGREE OF PROTECTION: | IP21. |

| DIMENSIONS: | 470x220x400 mm. |

| THE WEIGHT: | 17 kg. |

This is a compact and easy-to-use model, with which you can cook with manual electrodes.Due to the small dimensions and good PV, you can use the device for electric welding of any level of complexity.

The advantage of this welding inverter is the ability to interact with both alternating and direct current. This facilitates work during construction, where there is often no permanent connection to the electrical network.

The average price is 42,800 rubles.

- compactness;

- lightness;

- reliable body;

- durability;

- wide range of settings.

- not detected.

Awelco SMARTMIG 2200

| SPECIFICATIONS | |

|---|---|

| WELDING CURRENT: | 20-200 A. |

| COIL LOCATION: | Internal. |

| OUTPUT CURRENT TYPE: | Constant. |

| ELECTRODE DIAMETER: | 1.60-5 mm. |

| DEGREE OF PROTECTION: | IP21S. |

| DIMENSIONS: | 630x250x440 mm. |

| THE WEIGHT: | 16.1 kg. |

This is a microprocessor type control model, which is suitable for welding in 3 modes. The first (MIG-MAG) mode is semi-automatic arc welding under shielding gas conditions. That is why the welding inverter we are considering is most in demand in service stations, since it does not reduce the reliability and corrosion resistance of sheets of thin metal surfaces. In addition, the made welding seam does not need to be cleaned from scale and flux.

The second (MMA) mode is manual arc welding with stick electrodes at direct current. Working in this mode makes it possible to quickly and firmly weld metal parts, creating a high-quality seam or welding points. For this reason, this device is often used in almost any type of construction work, for industrial purposes to create metal structures, as well as in everyday life.

The third (TIG) mode is a non-melting tungsten argon-arc type welding, which is ideal for working on steel surfaces containing alloying elements, as well as for processing non-ferrous metal coatings.

The average price is 50,450 rubles.

- microprocessor type control;

- three working modes;

- the formed welding seam does not need to be cleaned from scale and flux;

- quickly and efficiently welds metal parts.

- not detected.

EWM PICO 162

EWM PICO 162 is an expensive welding inverter, operating currents are small here, and wires of 30 m or more will not cause difficulties in operation. If other models will stop welding on their own due to a voltage drop, then this device welds even in this case with very high quality of the seams.

The device works perfectly, this device is a single-phase professional, it is available for operation even for those who do not know about MMA and TIG. The inverter is used for welding with stable current and has work adjustment, is portable and can be carried on the shoulder with a belt. Manual welding is carried out with special rod electrodes, and TIG Liftarc is also carried out, protection works here, so that random current fluctuations will not lead to difficulties.

Characteristics:

- Device: welding inverter;

- Current adjustment range: 10-150 A;

- Idle: 105 V;

- Network with a frequency of 50-60 Hz;

- Maximum power 5.5 kVA;

- Efficiency 86%;

- Weight 5.1 kg;

- Protection class IP 23;

- Class A EMC standard;

- One-button control.

- Welding type: MMA and TIG;

- Welding currents 10-160 A;

- The duration at maximum currents is 35%;

- Welding maximum 100 A;

- Operating current input 138-265 V;

- One phase power supply from the network;

- Maintainability.

- The price is big;

- If the product has breakdowns, then it will take a long time to wait for spare parts;

- The terminals here are rather weak;

- There were few cons.

Bottom line: An ideal inverter, the arc is smooth, and the current is clear, the welding seams will be even and of high quality, there are practically no minuses except for the price. The cost of an average product is from 39,000 rubles.

Fubag INMIG 200 PLUS

Fubag INMIG 200 PLUS is a universal product for welding, it realizes the possibilities of arc manual, argon and semi-automatic welding. The device works even at different current values, max. the current is 200 A, and the minimum threshold already depends on the type of welding. There are many technical trivialities, and a number of additional features, notable for their quality.

The inverter is manufactured by a German company and embodies world achievements, the difficulties in this area are taken into account. The operating current ranges here are large 86-256 V, the model is easy to operate and has ideal characteristics. The main advantages are the unique workmanship and safety, working with the inverter will be pleasant, comfortable.

Characteristics:

- Item Type: Inverter;

- Dimensions are minimal;

- Weight 6.4 kg;

- High class insulation;

- The level of protection is great;

- There are hot start, arc force and anti-stick;

- Welding current 5-200 A;

- Input currents 150-240 V;

- The temperature range is large.

More about the device - in the video:

- Versatility;

- Lots of features;

- Dimensions are minimal;

- Protection;

- Large range of welding currents;

- Single-phase power for work;

- The product is excellent;

- Welding goes without difficulty;

- Can be easily cooked.

- The product does not remember the settings of the employee;

- Difficulties with wire feed in idle mode;

- The price is not small;

- Indication;

- The model is one of the best, so the minuses on the network were few for sure.

Bottom line: Fubag inmig 200 works perfectly, and the build quality is excellent, traditional for Germany, is the epitome of the achievements of this century. The average price of an inverter is today 33,000 rubles on the Internet.

AuroraPRO SPEEDWAY 175

SPEEDWAY 175 is the flagship among AuroraPRO's line of best semi-automatic inverters, this is a universal product for gas MIG-MAG welding with a special wire, used for manual welding and argon arc welding. Such a modern special semi-automatic device has a synergistic control, the operating parameters can be easily adjusted with one handle.

The factory control of the device is adjusted manually, the product will be indispensable in the work of professionals when it is required to do specific complex tasks. The product is used both in everyday life and in production, indispensable for car service. It gives excellent results when welding metals, in semi-automatic mode it masters workpieces with a thickness of 8-10 mm or more.

Characteristics:

- Item Type: Inverter;

- Network 220 V;

- Frequency 50-60 Hz;

- Universal use MMA, MIG-MAG, TIG DC;

- Power 6.9 kW;

- Idling 56 V;

- Welding current 50-175 A;

- Two-four-stroke control mode;

- VR function;

- Arc stability;

- Digital bright display.

- Synergy management;

- Manual correction;

- High-quality unique metal welding;

- Easy polarity change for work;

- Power unit based on IGBT;

- Diagnosis is easy and simple, works when using LEDs;

- Automatic protection;

- Rich equipment;

- Ergonomic beautiful design;

- Lots of new additional features.

More about the advantages of the device - in the video:

- Argon arc welding is difficult to master;

- Price;

- There are few cons in the network, there are only good reviews.

Bottom line: Aurora's product is one of the best inverters available today, has a range of welding methods, excellent design ergonomics, and perfect workmanship. The average price is 34,000 rubles.

Svarog PRO ARC 160 (Z211S)

The modern product Svarog PRO ARC 160 Z211S is the latest product that uses high technologies developed back in 2014. The company that created Svarog is known in the country, their equipment has become very fashionable today. This design has many advantages, such as ease of current adjustment, and thanks to the range, it is already possible to work with electrodes up to 3 mm for welding metal with a thickness of 5 mm. The design is ergonomic, the model is light and has a digital display, there is a plastic handle for product delivery. The design of Svarog is practical in operation, has extensive functionality, the product is reliable and designed for a large range, there are many additional functions.

Characteristics:

- Device type: welding inverter;

- MMA and TIG welding;

- Welding current 10-160 A;

- Total input current 187-253V;

- One phase;

- Idling 63 V;

- Power 7.20 kVA;

- Electrode with a diameter of 1.50-3.20 mm;

- Arc ignition through touch;

- Hot start;

- fast and furious;

- Efficiency 85%.

Overview of PRO series inverters:

- Convenient adjustment;

- There is a fan to work;

- Ideal for domestic work;

- The price is reasonable;

- Cooks with electrodes clearly;

- Build quality;

- Small dimensions;

- Minimum weight;

- Warranty 5 years;

- The design is good;

- Compactness.

- There is a guarantee here, only its conditions are too special;

- The case is missing;

- No shipping strap;

- An extension cord is often required;

- The model is one of the best, so there are few cons on the network.

Bottom line: The device cooks perfectly, the seam is smooth, and the work goes without splashes, the inverter is quite light and compact, the assembly is perfect. The average price is 11170 rubles.

Manual Arc Welding Inverter

Aurora Orion 160.3

| SPECIFICATIONS | |

|---|---|

| WELDING CURRENT: | 20-160 A. |

| INPUT VOLTAGE: | 230 V. |

| POWER: | 6.80 kVA. |

| ELECTRODE DIAMETER: | 1.60-4 mm. |

| DEGREE OF PROTECTION: | IP21S. |

| DIMENSIONS: | 450x272x360 mm. |

| THE WEIGHT: | 9 kg. |

Welding inverters of the Orion line are designed for manual arc welding with a coated electrode, as well as for welding of argon-arc type with contact ignition of the arc. The devices are in demand for working with carbon steel, stainless steel and various alloys, therefore they are often used in construction, repair and installation.

High power ratings of the devices guarantee a strong and stable arc, and due to the use of powerful IGBT type transistors and instantaneous diodes as the key electrical components of the model, the stabilized current is transformed into high-frequency alternating current supplied to the primary winding of the step-down ferrite transformer. The high-frequency alternating current received on the secondary winding is transformed into direct current.This mechanism of action makes it possible to use a smaller power transformer, which significantly reduces the weight of the equipment.

The average price is 12,600 rubles.

- the presence of the option "adjustable arc force" increases the welding current during the separation of the metal drop from the electrode;

- the “anti-stick” option reduces the welding current when the electrode sticks in automatic mode;

- maximum current during arc ignition for a smooth start;

- the ability to disable the VRD option, which guarantees safe work for the welder in critical conditions;

- high-quality quick-release welding cable connections.

- not detected.

Quattro Elementi Multi Pro 1700

| SPECIFICATIONS | |

|---|---|

| WELDING CURRENT: | 10-165 A. |

| THE DIAMETER OF THE WIRE: | 0.60-0.80 mm. |

| POWER: | 4.90 kW. |

| ELECTRODE DIAMETER: | 1.60-4 mm. |

| OUTPUT CURRENT TYPE: | Variable. |

| NUMBER OF POWER PHASES: | 1. |

This model is designed for semi-automatic electric welding, work with fusible coated electrodes, as well as welding of argon-arc type. Small and high-quality in use, the device will be an excellent choice for the home. The welding inverter complies with modern technical requirements and quality standards, guaranteeing a long-term and safe life cycle.

A small mass, high output power and a long-term operation cycle were achieved through the use of German-made instantaneous bipolar transistors.

The average price is 14,400 rubles.

- the section of the extension is 3x2.5 mm;

- the wire feeder is ergonomically placed inside the housing for easy transport;

- the welding gun is connected to the device;

- will be an excellent choice for working with low-carbon, heat-resistant, stainless and other steels containing alloying elements.

- not detected.

NEON VD-203

| SPECIFICATIONS | |

|---|---|

| WELDING CURRENT: | 30-200 A. |

| WORKS AT TEMPERATURE: | -40 to 40 °C. |

| POWER: | 6.40 kW. |

| ADDITIONAL FUNCTIONS: | Anti-stick. Hot start. Arc force. |

| DIMENSIONS: | 390x174x324 mm. |

| THE WEIGHT: | 8.2 kg. |

This model is designed for manual arc welding using stick electrodes. The digital type screen shows the characteristics of the welding current and voltage, which makes it possible to most favorably adjust the device and control its operation. The device provides the anti-stick, hot start and arc force functions, which greatly facilitates the work process and saves the welder's time.

The average price is 22,700 rubles.

- wide range of operating voltage;

- overheating protection;

- automatic type switch;

- digital welding voltage and current indicator;

- the presence of options "anti-stick", "hot start" and "arc afterburner";

- perfectly proved itself when working in conditions of low and high temperatures;

- presence of a shoulder strap.

- not detected.

FUBAG IR 200

The welding inverter has a maximum operating current of 200 A, which gives the ability to cook and cut metal with all electrodes up to 5 mm evenly. The product has a large operating range, and its action is maintained even if the current drops to 150 V, which is important in welding.There is such an important working function as anti-sticking, as well as afterburner and hot start, a welder with little experience can work with this design.

The only negative is welding at maximum current, when every 4 minutes it takes 6 minutes. for cooling. The inverter can be ideally suited for both professional work and for welding at home. Unique transistors are installed for this series, and the module is suitable for complex welding.

Characteristics:

- Device type: welding inverter;

- Welding arc manual;

- Welding currents 5-200 A;

- Input currents 150-240 V;

- One phase;

- Idling 65 V;

- Work 20.8-28V;

- Power 8.8 kVA;

- Operating time at max. current is 40%;

- Electrode with a diameter of 1.6-5 mm;

- Efficiency 85%;

- The insulation is excellent.

- Equipment;

- Light;

- Famous brand;

- There are all required functions;

- Works without difficulty;

- There is protection against dust and condensation;

- Works great even with low current;

- Even an inexperienced welder can work with this device;

- Welds with old UONI electrodes;

- Anti-stick.

- A strap is installed, not a handle, although it is also convenient;

- Needs to be cleaned regularly.

Bottom line: An ideal quality welding inverter, to improve performance, there are all modern features, such as anti-sticking and others. The average price is 5130 rubles.

Resanta SAI-220A

Inverters with the Resanta brand have become relevant today, as this product is distinguished by quality and price. This model is one of the best and has a high max. current 220 A. Due to its unique performance, it can weld with electrodes up to 5 mm, welds massive structures, and cuts easily.Such a unit provides high currents and works for a long time, since the PV coefficient is 70%, which is important for work. This design had all the special functions, that is, anti-sticking, afterburner, hot start.

There is one drawback here - it will be difficult for a welder with little experience to work, unlike other welding structures. The product has an operating current range of up to 260V, the inverter requires careful storage, the technical general characteristics here are ideal. The company is one of the best modern manufacturers in the world, whose equipment is relatively cheap.

Characteristics:

- welding inverter;

- Welding arc manual;

- Current 10-220 A;

- One phase;

- Idling;

- Operating time at max. currents 70% exactly;

- Electrodes up to 5 mm;

- Start hot and anti-stick;

- The package is excellent;

- Minimum size.

- Can be used at high welding currents;

- Performance will be excellent even with strong and frequent current drops;

- The price is affordable;

- The power is big;

- Light model;

- Decent welding;

- Value for money;

- The case is not made of plastic, so it lasts a very long time;

- Input machine;

- Special working cables.

- The current regulator has a weak twist;

- The case is missing;

- The scale at the current adjustment knob is terrible;

- The manufacturing material of the welding fan is weak;

- The mass wire design is unfortunate here;

- There are cons, although for this price the product is excellent.

Bottom line: The workmanship is excellent and the price is affordable, can easily weld large structures, cuts metal perfectly. The average price is 5759 rubles, the quality of this inverter is excellent, there are few comments.

Inverters, their advantages and disadvantages

The welding inverter is a convenient and compact special tool for welding metals. Modern equipment can be used both by qualified specialists with great experience and with little. Professionals will say that the best unit is one that operates with direct current, works with various types of electrodes and where there are required functions, such as hot start, anti-sticking. In addition, the device has such an important element as greater stability when the current drops. If an employee is interested in the issue of quality, as well as how much the model costs, then it is better for him to take into account the rating of this article.

Main characteristics:

- Power. This characteristic is indicated in the document for the design, this is the welding current at which the inverter operates without interruption and overheating, when buying structures for welding, make a current reserve of 50% exactly.

- Duration of general workloads. It is a characteristic of the product in the rotary short-term mode.

- Power supply current range. If welding takes place outside the city, then the mains current may have strong deviations from the required value, it is better to use the unit, taking into account a jump of 10-20% on average.

- Additional qualities. Requires ARC FORCE, HOT START and ANTI STICK for convenience.

Today, inverters have taken the best positions as leaders among welding equipment, which is due to their advantages, products that are easy to transport and efficient in operation. Among the technical main advantages, such characteristics as low weight of the equipment, economical indicators of the electricity used, which are better than conventional transformer welding, are important.

The splash zone of working sparks is reduced, welding currents can be adjusted, and the product works immediately from the moment it is started. The seam will be of high quality, the inverter itself is safe and easy to use. If you want to buy the best inverters, then consider the ratings of quality devices on the Internet.

Among the minuses is the cost, which is more than 2 times than that of older devices. Another disadvantage is expensive repairs, if the power module breaks, it will cost 30% of the price of the inverter. The device works without strong overloads, it is also necessary to take into account the stability of the current at the place of work. A modern device has such a weak factor as dusting, that is, it is afraid of dust, in addition, it is advisable not to work at low temperatures.

Welding modern technologies are ideal, the device for welding has become more economical and better, which even a welder with little experience can handle. If you are thinking about which inverter to buy and how to choose it, then consider the main selection criteria indicated here in the article.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131651 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127690 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124519 -

The best men's sneakers in 2022

Views: 124033 -

The Best Complex Vitamins in 2022

Views: 121939 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114980 -

The best paint for gray hair - top rating 2022

Views: 113395 -

Ranking of the best wood paints for interior work in 2022

Views: 110318 -

Rating of the best spinning reels in 2022

Views: 105329 -

Ranking of the best sex dolls for men for 2022

Views: 104366 -

Ranking of the best action cameras from China in 2022

Views: 102216 -

The most effective calcium preparations for adults and children in 2022

Views: 102011