Ranking of the best wood sanders in 2025

Wood sanders are used to give the wooden surface a perfect smoothness. These devices are able to clean any surface of the tree without damaging the board. They can polish parquet, furniture as high as possible. Our ranking of the best wood grinders will help you choose the right machine.

Content [Hide]

Types of grinders

The choice of construction tools of this type is much wide. There are the following types of grinders for working with wood:

- deltoid;

- corner;

- Orbital (eccentric);

- Vibrating;

- Brush;

- Tape.

deltoid

This type of grinder is used for restoration work. It can be applied in hard-to-reach places (for example, for parquet polishing). Such a machine can still grind window frames and furniture corners.

There are high frequency vibrations here. In this it is similar to a vibratory grinder. The sanding sheets are attached with Velcro. This allows you to process products with a curved surface.

Additional functions:

- Vibration adjustment;

- Dust removal channel;

- The swivel mechanism allows you to rotate 120 degrees.

Corner models

For home use, this type of machine is chosen most often. Bulgarian is another name for the corner model. The grinder grinds absolutely all types of wooden products, they can cut stone or metal. The power of the model and the diameter of the disk play a key role.

- 6000 revolutions per second - the maximum speed of rotation of the disk;

- Power ranges from 600 to 1000 watts.

For the processing of a particular material, its own nozzle in the form of a disk is designed. Petal discs grind wooden surfaces. A feature of the grinder is a protective cover. It is not recommended to remove it.

This tool must be used carefully, because if the tree is damaged, the fragments scatter and injure soft tissues, falling on the body.For safe work with a grinder, it is necessary to wear gloves and goggles to avoid damage. Discs, the size of which does not correspond to the characteristics of the tool, are strictly forbidden to use.

Such devices can regulate the number of revolutions. The tool has a soft start. Disc wear is reduced thanks to the automatic balancing system. Often, additional handles are included with the grinder.

Orbital

Design feature: the grinding plane rotates around an axis. The axle also rotates. This allows you to make fine grinding at high tool speeds. Grinds convex or convex products. These devices clean wooden rounded elements: railings, columns, and also process putty in cars. To make it easier to do the processing of curved surfaces, it is necessary to attach additional nozzles made of elastic material. A grinding wheel is attached to the sole of the tool. Dust is collected in a dust collector or in a vacuum cleaner bag.

Such units consume from 150 to 750 watts of energy. This will depend on the product model. Several brands have additional features:

- braking system;

- An electronic circuit is provided for soft start;

- Additional handle.

Eccentric machines have a wide range of applications. Can be used for fine matting of lacquered surfaces and coarse rust removal. For these models produce:

- Woolen caps;

- Polishing sponges;

- Sanding cloths.

With these additions, you can bring any surface to the desired state. The orbital type is used for both final sanding and polishing wood products.

Vibrating

In such models, the largest fluctuations occur. The maximum oscillation frequency is 20 thousand per minute.

Professional devices are equipped with speed controllers. This feature gives you the chance to adjust the grinding speed to the specific material. These models are unique in their kind. Power ranges from 180 to 700 watts. A more “finer” quality of grinding prevents damage to materials by careless movements. There are two ways to attach paper with abrasive:

- The paper is clamped in a vise;

- Attaches with Velcro.

Almost all vibratory grinders have holes with a dust channel. A vacuum cleaner hose is fixed on it, or a dust collector bag is installed.

In addition to wooden products, vibration grinders process metal and stone products. Such a device even grinds plastic if it is set at low speeds. But this is if the device is equipped with a vibration speed controller. Wooden products are ground with fine-grained sandpaper, and metal and glass products are treated with felt.

Brush

They are used to remove old layers of paint or rust. In their application, brush machines are similar to tape machines. At home, they clean boards and parquet with their help.

Brush sanders must meet the following criteria:

- Weight about 4 kg;

- It should be possible to install abrasive cloths.

Here, a metal brush is used as a nozzle. This allows you to quickly process large volumes of products.

Tape

Such models are used for continuous grinding of large surfaces. Capable of handling rough surfaces:

- plastics;

- Rusty metal products;

- Not planed boards.

Rarely used for polishing work.

This type of grinding machine has a heavy bottom platform and a large weight.Sandpaper can be transported along the platform without much effort. The operator only needs to move the apparatus evenly over the surface. Unnecessary indentations may occur if the operator brakes the machine in one place. Power ranges from 500 to 3000 watts. From 70 to 600 meters per minute is the speed of the tape apparatus.

Stepped and smooth speed controller have professional models. For work in various conditions, additional handles are provided in the kit. There are two ways to dispose of dust in these models. It accumulates in a dust collector or is displayed in a construction vacuum cleaner.

To prevent damage to materials, the belt sander can be operated together with a special frame. To fix the machine in a static position, an additional stand that acts as a vise helps. Thus, LSM is fixed upside down. This position allows you to sharpen cutting tools.

The belt sander has two varieties:

The first type performs the functions of a file.

The second - makes the surface treatment with a brush, not sandpaper.

The bristle of the brush has different types: they are classified from soft woolen to hard iron.

Which model is better to choose

To decide which machine to choose, you need to determine how often it will be used on the farm. If you plan to use it constantly, then it is better to choose a professional model instead of a household one. They are more powerful than usual and are made of the highest quality materials. Perhaps their only drawback is the high price.

Take a budget household tool if you plan to use it infrequently.Such machines are safe to operate for approximately 20 hours per month. It is not recommended to work with them for more than 3 hours a day to avoid breakage. Such a device has a weak power. A pause of 15 minutes must be done so that the cheap device does not overheat. However, such models are low cost and light in weight.

Which skins are suitable for grinders

The first sandpaper, namely it is used for processing materials in grinders, was made from shark skin. Such references are recorded in Chinese manuscripts in the 13th century. Since then, sandpaper has undergone many upgrades. The first modern version of sandpaper looked like this: sand, along with broken glass, was glued to paper. The modern abrasive was invented by Briton John Walkey in 1833. He later patented a whole series of this paper.

In its modern form, abrasive powder is attached to paper or fabric. To form an abrasive layer, use:

- Small diamond chips;

- Pomegranate;

- Silicon carbide.

Grit is the main characteristic of sanding paper.

A system of markings and certifications has emerged. The finest sandpaper is the "M" series, and the largest is the "H" series.

How to use a wood sander

The operating rules are detailed in the technical sheet of the device. Each tool has its own characteristics, therefore, before work, you need to carefully study everything.

General security measures:

- In order not to injure the eardrum, it is necessary to use headphones that absorb noise during work;

- If the device has damage to the network cable or mechanical damage, then it cannot be started;

- Do not work near flammable or combustible materials when processing metal parts;

- To protect against dust, you need to use construction glasses made of glass that does not break;

- To protect the respiratory organs from dust, it is necessary to wear a respirator;

- Wear construction gloves to protect your hands from injury.

Popular angle grinders

AEG WS 11-125

votes 0

Characteristics:

- Power - 1.1 kW;

- Weight - 2.4 kg;

- Cable - 4 meters;

- It costs 4500 rubles.

- cheap;

- Light;

- Powerful (despite its low power consumption);

- Great for renovation work.

- Not suitable for industrial work;

- Has few features.

Bosch GWS 12-125 CIE

votes 0

Suitable for both work and home. It has many advantages, but it is also quite expensive. It has a speed stabilization system, overload protection, speed control. Differs in high-quality German assembly.

Characteristics:

- Weighs 2.3 kg;

- Power - 1200 watts;

- The price is 9000 rubles.

- Light;

- Monofunctional;

- Quality German grinder;

- Has pretty good power.

- Overcharge.

Metabo WEV 10-125 Quikc

votes 0

The company occupies a leading position among manufacturers of electric tools. The model is relatively inexpensive, has a good build quality.

Characteristics:

- It costs 7500 rubles;

- Rotation speed - 10500 rpm;

- Power - 1 kW;

- Weighs 2.1 Kg.

- Light;

- Powerful.

- Relatively expensive.

Makita GA5030

votes 0

The only advantage of this model is that it is made by a good brand. Despite its low performance, the model is fully consistent with the price.

Characteristics:

- Cable - 2.5 meters;

- Energy consumption - 720 W;

- Weighs 1.4 kg;

- It costs 4000 rubles.

- cheap;

- Famous brand;

- Light;

- Practical.

- Short cable;

- Has few features;

- Low power.

Bosch GWS 15-150 CIH

votes 0

This model has a large number of features, including a good safety system that prevents injury. Jammed drive protection instantly shuts off the power. The special handle promotes convenient work. Also, manufacturers took care of reducing the level of vibration. This is the most expensive model of the Bosch series.

Characteristics:

- It costs 15 thousand rubles;

- Weighs 2.3 kg;

- Rotation speed - 9300 rpm;

- Power - 1500 watts.

- Light;

- Has many features;

- Has additional accessories for comfortable work.

- High price.

DIOLD MSHU-1,2-150

votes 0

Many users are satisfied with this tool. Despite the fact that it has average technical characteristics, the device is a competitive grinding tool. It loses to foreign manufacturers in many respects.

Characteristics:

- Weight 2.7 kg;

- 6800 rpm - rotational speed;

- Power - 1200 watts;

- It costs 2500 rubles.

- Low price;

- Light;

- Good power.

- Suitable for home work only;

- High energy consumption.

Models of belt grinders

Bort BBS-801N

votes 1

A cheap tape machine that has additional handles. Designed for rough cleaning. You can select the optimal operating mode. This budget option is recommended to use a short period of time.

Characteristics:

- Rotation speed - from 120 to 260 meters per second;

- Power - 800 watts;

- Included - dust collector, brushes, 3 tapes;

- Weighs 3.1 kg;

- It costs 3400 rubles.

- Low cost;

- Has additional tools in the kit;

- Relatively good power.

- Designed for draft work only;

- Can only be used for 10 minutes without a break.

Makita 9911

votes 0

Polishes paint and varnish coverings and polishes roughnesses. The function of smooth adjustment of the rotation speed allows you to get a high-quality result on any surface. If you adjust the tool correctly, you can achieve a high and high-quality grinding result.

Characteristics:

- The tape rotates at a speed of 75 to 270 meters per minute;

- It costs 7700 rubles;

- Has a dust bag;

- Power - 650 watts.

- Low price;

- With the right settings, it works like a professional;

- Works on any surface.

- Weak power.

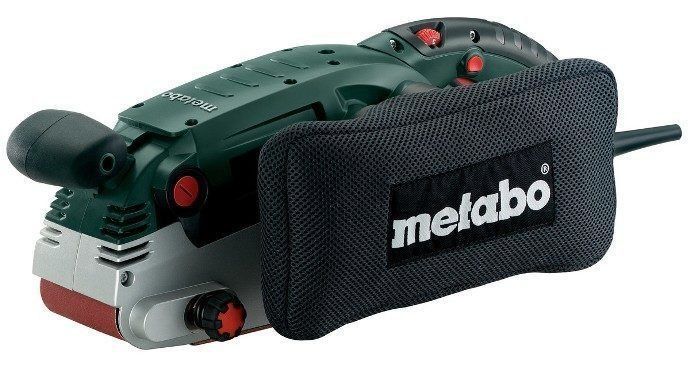

Metabo BAE 75

votes 0

The advantage is the engine management system. This device ensures stable rotation of the tape on any surface and at any speed. Even a novice carpenter will easily figure out the functionality of the model, it is also popular among professional builders.

Characteristics:

- Rotation speed - 450 rpm;

- It costs 16300 rubles;

- Weighs 4.9 kg;

- Has a dust bag

- Power - 1010 watts.

- Multifunctional;

- High rotation speed;

- High engine power;

- Long ribbon;

- Convenient control location;

- Smooth start;

- Automatic electronic control.

- High price;

- Heavy.

Interskol PShM-32/130

votes 0

This budget-friendly belt sander is perfect for:

- Dry polishing of paintwork materials;

- Grinding smooth drops;

- Removal of single-layer coatings.

During operation, the Velcro fastener securely holds the abrasive sheet. This tool is contraindicated to regularly subject to intensive loads.

Characteristics:

- It costs 1618 rubles;

- Weighs 0.9 kg;

- Has a set of sanding paper;

- Power - 130 watts;

- Ergonomic body.

- Very low price;

- Ultralight;

- Has additional features.

- Too weak power;

- It is not advisable to work outdoors.

Models of vibratory grinders

Makita BO3711

votes 0

Characteristics:

- Power 190 watts;

- Weighs 1.6 kg;

- 22 thousand vibrations per minute;

- It costs 4000 rubles.

- Has a speed controller

- Light;

- Works without noise;

- Almost no vibration;

- budget model.

- Short wire;

- Weak power.

Fiolent MPSH 4-28

votes 0

Characteristics:

- Weighs 2.5 kg;

- Price - 4000 rubles;

- 6000 vibrations per minute.

- High performance;

- Powerful;

- Does not vibrate;

- Reliable construction;

- Light.

- Case missing.

Makita BO3700

votes 0

Characteristics:

- Weighs 1.4 kg;

- Power - 180 watts;

- It costs 3400 rubles;

- The oscillation frequency is 20 thousand per minute.

- Light;

- Does not vibrate;

- Has a rag vacuum cleaner;

- Practically does not heat up;

- Does not create excessive noise.

- Not identified.

Bosch PSS 200AC

votes 0

Characteristics:

- Weighs 1.6 kg;

- Price - 3430 rubles;

- 24,000 platform oscillations per minute;

- Rotation speed - 12 thousand revolutions per minute;

- Power - 200 watts.

- There is a special suitcase for storage;

- Comfortable;

- There is a plastic container;

- Light.

- Weak power;

- Inconvenient fastening of the skin.

Conclusion

The grinder is an essential item in the home and professional environment.Such devices can be used both for home repairs and in enterprises. Grinders come in different types. The most popular are Bulgarians.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131651 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127690 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124519 -

The best men's sneakers in 2025

Views: 124033 -

The Best Complex Vitamins in 2025

Views: 121940 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114980 -

The best paint for gray hair - top rating 2025

Views: 113395 -

Ranking of the best wood paints for interior work in 2025

Views: 110318 -

Rating of the best spinning reels in 2025

Views: 105329 -

Ranking of the best sex dolls for men for 2025

Views: 104366 -

Ranking of the best action cameras from China in 2025

Views: 102216 -

The most effective calcium preparations for adults and children in 2025

Views: 102011