Rating of pumps for heating systems in 2025

In the modern world, in private country and country houses for living in cold conditions, a heating system is installed based on the movement of hot water. Such pumps are circulating, that is, the water in the pipeline constantly circulates using the same pump. The choice of such a circulation pump is a very significant task, the solution of which determines the service life, the quality of heating and the reliability of the entire system.

Content [Hide]

- 1 Pump design

- 2 Types of pumps for heating systems

- 3 Pump installation

- 4 15 best models of pumps for heat supply

- 4.1 BELAMOS BRS 25/4G

- 4.2 Oasis CR 25/4

- 4.3 UNIPUMP UPC 25-40

- 4.4 KM RS25/4G-180

- 4.5 Grundfos UPS 32-40 180

- 4.6 WWQ CN 25/60-180

- 4.7 JEMIX WRF-50/12

- 4.8 Valtec VRS 25/4 130

- 4.9 Grundfos ALPHA1 L 25-60 180

- 4.10 Grundfos UPS 25-80 180

- 4.11 Grundfos ALPHA2 25-60 180

- 4.12 Grundfos UPS 25-60 180

- 4.13 Oasis CN 25/4

- 4.14 VORTEX TsN-25-4

- 4.15 Grundfos UPS 25-40 180

- 5 Characteristics of the first five models of pumps for heat supply

- 6 How to choose the right pump for the heating system

- 7 Conclusion

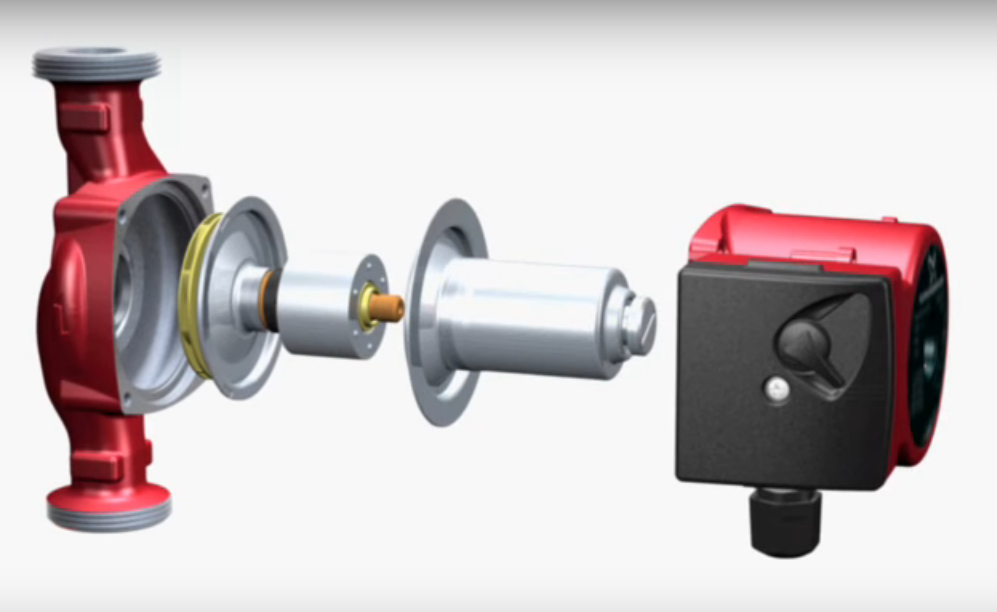

Pump design

Before proceeding with the selection of a pumping device, it is necessary to understand the principle of operation and design of the circulation pump for the heating system. The main purpose of the pumping unit is the forced pumping of water or other heat carrier through the pipeline. This heat supply system with a pump must provide a constant temperature of a certain value, which is evenly distributed in the room.

The composition of the pump for heating systems includes:

- Electrical engine;

- rotation rotor;

- Working wheel;

- frame.

Two impeller disks with blades, which are located opposite to each other, during rotation, convert the energy of the movement of the liquid into pressure. In this case, the aqueous medium cools the rotor shaft and continues to move in a given direction. This principle circulates fluid in a closed and closed piping system. The efficiency of this heating system directly depends on the circulation pumping equipment. The rotor is hermetically sealed with a cast iron or stainless steel housing from the electric motor and all electronics in order to exclude the possibility of water or antifreeze entering the equipment control system.

Types of pumps for heating systems

To select the right pumping equipment, you need to know what type it belongs to. There are two types of pumps for heating systems: with dry and wet rotors.

Dry Rotor

The electric motor of this type of pumping unit does not have direct contact with the aqueous medium, which it forces to circulate through the pipeline. The mechanical seal isolates the pump part of the circulation pump from the electric motor with the utmost hermeticity. The advantage of this type of pump is its high efficiency (more than 80% efficiency). Dry rotor units are used to ensure the movement of a large volume of liquid, in most cases in centralized heating systems. The pump components are cooled by an air system, the use of which slightly increases the noise level during operation of the unit.

wet rotor

The design of this type of pumping equipment provides for the presence of both the impeller itself and the rotor of the electric motor in a watery environment, which in turn ensures cooling of the constantly moving parts of the unit. The advantages are long-term operation, low operating noise and small pump size. Easily installed and built into the pipeline, which eliminates the possibility of unnecessarily calling a service engineer. Of the minuses of such structures is a low efficiency (efficiency from 30 to 50%). Glandless pumps are mainly used for autonomous heat supply of private houses, as well as apartments.It is worth emphasizing that this type of pumping equipment is intended only for the heating system, and not for supplying drinking water.

Pump installation

For the highest quality and reliable installation of pumping equipment, you must follow a few simple rules:

- The expansion tank is mounted at a height of 1 meter above the highest point of the heating system;

- The heating system must be equipped with an air outlet.

- The heating system must have a backup pipeline in case of unforeseen emergencies.

Also, to install the pumping unit, you must comply with simple conditions:

- Approximately 10 m of pipeline consumes approximately 0.6 m of pump head. It follows from this that a head of 60 m will ensure the movement of fluid in a pipe 100 m long;

- The average speed of movement of the heat carrier is about 1.5-2 m/s;

- The smaller the pipe diameter, the more pumping equipment will be required to circulate the aqueous medium.

At the initial stage of installation of the heating system, it is necessary to prepare all the constituent components for installation, stock up on the necessary tools, and calculate the threaded connections to the pump unit. It is recommended to install a cleaning filter before the pump, which will help to prevent dirt and sand from entering the system. The direction of the circulating fluid must match the direction of the arrow, which is shown on the body of the pumping equipment. It is desirable to install shut-off valves at the joints of the pipes of the pipeline for convenient repair of the heating system. Glandless pumps are installed only in a horizontal position, while dry rotor pumps are installed both horizontally and vertically.

15 best models of pumps for heat supply

BELAMOS BRS 25/4G

votes 0

In fifteenth place is the surface pump BELAMOS BRS 25/4G, used for the circular movement of various aqueous media in closed systems for supplying heat to rooms. It is very popular, as it has the best price and quality. The body of the pumping unit is cast and made of cast iron. Ceramic sealing devices provide a very high and reliable tightness. This model of the pump can be installed both in a private house and in an apartment of a multi-storey building.

- Protection category ip44;

- Reliable pressure.

- Fasteners of poor quality.

Oasis CR 25/4

votes 0

In the fourteenth place is the Oasis CR 25/4 surface heat supply pump, the throughput of which allows you to avoid significant heat losses by adjusting the circulation of hot liquid. It works quite quietly, which allows you to install the pump in a variety of places, without being afraid to hear extraneous sounds. The inclusion of a certain power mode of the unit will allow you to adjust the operation of the pumping equipment according to the conditions of the heating system. The design with a wet rotor allows this model to perform its work for quite a long time.

- Blocking current present;

- Simple assembly work.

- There are defective fasteners.

UNIPUMP UPC 25-40

votes 0

In thirteenth place is the heating pump unit UNIPUMP UPC 25-40 with a wet rotor, the use of which is to ensure the forced circular movement of an aqueous medium through a closed pipeline at high temperatures.The equipment has the ability to mechanically switch 3 power levels with a 3-position switch. The coolant can be water of low hardness, non-flammable liquids without solid additives or impurities with mineral oils.

- Big power;

- 3 operating modes.

- Big mass.

KM RS25/4G-180

votes 0

In twelfth place is the KM RS25/4G-180 surface heat supply pump. The unit is intended for heat supply by forced movement of a clean aqueous medium through a closed pipeline. The pump device is installed in the heating system in two positions: horizontal and vertical. The three speeds of the electric motor regulate the speed of the rotor shaft, which allows the pressure in the circuit to be varied. The design of the pump has a system of protection against ingress of solids and particles from 1 mm.

- Two installation positions;

- Power adjustment.

- For clean water only.

Grundfos UPS 32-40 180

votes 0

In eleventh place is a single-stage pump unit Grundfos UPS 32-40 180 with three speeds and a horizontal shaft. Switching speed modes affects the rotation speed of the impeller. The electric motor is equipped with an overheating protection system if the moving parts of the pump are blocked. The design of the pumping unit eliminates the presence of glands, because the rotor is hermetically sealed from the stator. It has an optimal ratio of price and quality, which, of course, is a competitive advantage.

- Convenient installation;

- Quiet pump operation.

- Unreliable fixture.

WWQ CN 25/60-180

votes 0

In tenth place is the surface pumping unit WWQ CN 25 / 60-180, which is installed in suburban private houses to ensure circular pumping of the heat carrier in heat supply systems by pressurizing pipelines. With the help of a built-in centrifugal mechanism, the circulation pump can easily cope with loads. The pumping equipment is equipped with a safety system in which the operation of the pump stops in case of overheating of the electric motor.

- 3-speed operation;

- Overheat protection.

- Short network cable.

JEMIX WRF-50/12

votes 0

In ninth place is the circulation pump JEMIX WRF-50/12. Glandless rotor unit, which provides cooling of the bearings, significantly low noise level, long duration of operation and operation. The design of this pumping equipment differs from the versions of other models of pumps by a flanged connection to the pipeline of the heating system. Such a circulation pump can be used for heating both a small cottage and a house with more than two floors.

- High power;

- Big pressure.

- The need to weld counter flanges to the pipeline.

Valtec VRS 25/4 130

votes 0

In eighth place is the pump circulation unit Valtec VRS 25/4 130. The body of this model is made of cast iron, other important components, such as the rotor shaft, bearings, fasteners, and so on, are ceramic with a mirror finish. The pump is installed in various positions, both horizontal and vertical, but on condition that the rotor shaft must be horizontal. The unit withstands watery medium temperatures up to 110 0C at a maximum pressure of 10 bar. The wet rotor design cools itself by the pumped liquid.

- Small cost;

- Sealed fasteners.

- Short power cord.

Grundfos ALPHA1 L 25-60 180

votes 0

In seventh place is the surface pump for heating systems Grundfos ALPHA1 L 25-60 180. This product is used for forced pumping of an aqueous medium through a pipeline. The device is installed in two positions: horizontal and vertical. But the shaft on which the impeller is fixed must not be installed vertically. The pump has a night mode, which is turned on with one button. There is also a mode of automatic adjustment of the pumping unit to the conditions of the heating system.

- performance adjustment;

- Dust protection.

- Low power.

Grundfos UPS 25-80 180

votes 0

In sixth place is the Grundfos UPS 25-80 180 circulation pump. This model is used in heat supply systems with 3-stage regulation, the design of which provides for a wet rotor, which provides lubrication and cooling of ceramic bearings located on the shaft. Thanks to this, the pump runs silently, and the service life of the device is also increased. A modern electric motor saves electrical energy.

- High power;

- Easy adjustment of performance and pressure.

- High price.

Grundfos ALPHA2 25-60 180

votes 0

In fifth place is the pump unit for heating systems Grundfos ALPHA2 25-60 180. The advantages of this pump are low noise and construction quality.It is very easy to install and operate, which allows it to be integrated into the heating system of an apartment in a residential multi-storey building. This pumping equipment is equipped with both manual and automatic adjustment systems for optimal operation of the pump in the heating system. The design of the pump is so high quality and reliable that the manufacturer gives a guarantee of 5 years of uninterrupted operation of the product.

- Low noise performance;

- Convenient installation.

- High price.

Grundfos UPS 25-60 180

votes 0

In fourth place is the Grundfos UPS 25-60 180 pump unit. This model is a pump consisting of a horizontal shaft and a single-acting impeller with a wet rotor. The design of the product provides for small size and weight. The operation of the pump is quite quiet and consumes a significantly small amount of electrical energy. Pumping equipment has 3 speeds, switching of which changes the rotation speed of the electric motor shaft, which in turn regulates the pressure in the pipeline.

- Silent;

- Three speeds;

- Small dimensions and weight.

- Not found.

Oasis CN 25/4

votes 0

In third place is the circulation heating pump Oasis CN 25/4, which provides forced circulation of a watery medium in heating systems. This unit is excellent in that it can be used to provide space heating over 100 square meters. A very compact and lightweight pump consumes not so much electrical energy, it makes noticeable sounds during operation. The wet rotor design lubricates and cools all moving parts of the machine.

- Small amount of electricity consumed;

- Easy installation, dismantling.

- Noisy.

VORTEX TsN-25-4

votes 0

In second place is the circulation pumping device VORTEX TsN-25-4, the purpose of which is the forced circular pumping of cold or hot liquid in the heat supply systems of houses and apartments. This equipment is convenient to use in centralized heating systems. The pump is very convenient in operation, economical in power consumption, easy to install. It works quite silently, has small dimensions, and is operated for a long time.

- Long trouble-free operation;

- Small price.

- The declared characteristics sometimes do not correspond to the real ones.

Grundfos UPS 25-40 180

votes 0

In the first place - pumping equipment for heating systems Grundfos UPS 25-40 180. Among the leaders among sales of pumps for heating systems. This model of pumping units has been produced in Serbia for more than 15 years, and during all this time it has not lost interest in itself. The pump has a mechanical adjustment system, is characterized by simple operation and reliable design. The downside of the unit is that it is often faked and sold as a low quality pump. To solve this problem, the manufacturer has created a database on the official website, with which you can check the authenticity of products by entering the serial number.

- Good pressure;

- High performance.

- The possibility of counterfeit products.

Characteristics of the first five models of pumps for heat supply

| Manufacturer | Grundfos | Knight | Oasis | Grundfos | Grundfos |

|---|---|---|---|---|---|

| Model | UPS 25-40 180 | TsN-25-4 | CN 25/4 | UPS 25-60 180 | ALPHA2 25-60 180 |

| Pump type | circulation | circulation | circulation | circulation | circulation |

| Rotor type | wet | wet | wet | wet | wet |

| Performance | 2.93 cubic meters per hour | 3 cubic meters per hour | 3.6 cubic meters per hour | 4.35 cubic meters per hour | 2.8 cubic meters per hour |

| pressure | 4 m | 4 m | 4 m | 6 m | 6 m |

| Power | 45 W | 72 W | 72 W | 60 W | 34 W |

| Housing material | cast iron | cast iron | cast iron | cast iron | cast iron |

| Thread diameter | 1 1/2" | 1 1/2" | 1 1/4" | 1 1/2" | 1 1/2" |

| Liquid temperature | from 2 to 110 deg. | from -10 to 110 deg. | from -10 to 110 deg. | from 2 to 110 deg. | from 2 to 110 deg. |

| The weight | 2.6 kg | 3 kg | 2.68 kg | 2.6 kg | 2.1 kg |

How to choose the right pump for the heating system

The circulation pump is designed for periodic movement of the coolant through the pipeline: water or antifreeze, which ensures the optimum ambient temperature in the room. Choosing the right pumping equipment can significantly save on the consumption of gas and electricity.

When choosing a circulation pump for heating systems, it is necessary to take into account the main and auxiliary characteristics of the unit.

Main characteristics

- Power

Basically, the power of the heat pump is in the range of 60-300 watts. This is the main characteristic that you should pay special attention to, since it determines the overall temperature scheme of the heating system. When choosing a pump, it is not recommended to focus on units with maximum power, since pumping equipment is not designed to move a large number of cubic meters of hot liquid for heating large areas of premises.

- Performance

Productivity is the amount (volume) of fluid moved over a certain period of time.This characteristic directly depends on the power of the pumping equipment and the diameter of the pipeline of the heating system.

- pressure

Head, in its essence, is hydraulic resistance. Its value is measured in meters and indicates to what height the pump can raise the entire volume of liquid.

Auxiliary characteristics

- Connection dimensions

The dimensions of the connection and installation of the pump in the heating system are mainly selected based on the diameters of the pipelines and the dimensions of the unit itself.

- Temperature

Since the pump is designed to provide heat to residential premises, its pipeline must withstand high temperature loads. This characteristic must be coordinated with the temperature characteristics of the heating boiler and pipes used in the heating system.

Conclusion

In 2025, heating pumps are very popular and widespread due to the fact that they are easy to install and operate without the help of service engineers. A diverse range of models and a huge range of pump characteristics provide any apartment, country cottage, private house, cottage with high-quality and reliable heat supply, which is so necessary for a comfortable and cozy holiday on picturesque cold winter evenings.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131651 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127690 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124519 -

The best men's sneakers in 2025

Views: 124033 -

The Best Complex Vitamins in 2025

Views: 121939 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114980 -

The best paint for gray hair - top rating 2025

Views: 113395 -

Ranking of the best wood paints for interior work in 2025

Views: 110318 -

Rating of the best spinning reels in 2025

Views: 105329 -

Ranking of the best sex dolls for men for 2025

Views: 104366 -

Ranking of the best action cameras from China in 2025

Views: 102216 -

The most effective calcium preparations for adults and children in 2025

Views: 102011