Rating of the best liquid thermal insulation for 2022

Building a house is not an easy task. And here it is not only a matter of choosing a suitable site, drawing up a house plan and erecting walls. It is important to make the house warm and cozy. The choice of material for thermal insulation is an important component of construction. If earlier it was easier to make a choice, because the assortment was not so great. Now technology has taken a step forward, the old technique has been replaced by a replacement in the form of liquid thermal insulation.

Content

What is liquid thermal insulation

Liquid thermal insulation, or as heat paint is also called, is one of the types of insulation, often used to insulate walls, pipes, roofs, and facades. By its consistency, this material resembles mastic or sour cream. Such a heater is applied in several thin layers, before applying a new layer, it is necessary to wait for the previous one to dry completely. After drying, each layer will resemble foam, this reaction occurs due to contact with air.

The basis of thermal paint is usually made of acrylic, as well as various additives in the form of microspheres of ceramics, glass or silicone. A certain type of additive is suitable for its field of application. Due to the presence of spheres that contain air, heat is reflected. The presence of acrylic guarantees the stability of liquid thermal insulation.

Types of liquid thermal insulation

Liquid thermal insulation can be divided into two large groups. The first group of goods includes heaters, which are thermal paints, and the second group includes heaters with foam filler. Let's look at the features of each group.

- Thermal paint

When applied, the thermal paint forms a film that has thermal conductivity. This is ensured by its structure, which contains various fillers. The method of its application is quite simple and does not differ from conventional paint coating. But one layer will not be enough, because. it can easily wear off or be destroyed by the environment. Therefore, for a good thermal effect, at least 10 layers of paint are required. Such a heater is applied to any surface, does not require additional skill and anyone can handle it. When working inside the building, it is better to use protective masks.The paint dries quickly enough, but several layers are required, and during the entire process you can inhale the chemicals that make up the paint, which can adversely affect your health.

- Foam insulation

In appearance, they resemble mounting foam. The basis of such thermal insulation incorporates a polymer, which, upon air contact, forms a dense material. It is applied with the help of special spray guns, when applied it seems liquid, but due to its high density it quickly adheres to the material. After 30 minutes after application, it begins to form a light crust, and after a few hours it begins to harden. This type of insulation is often used by construction companies, it does not have a negative impact on health.

Rules for applying liquid thermal insulation

Wall insulation

For wall insulation using liquid materials, a heater with ceramic components is more suitable. Water-based liquid ceramic heaters are ideal for interior wall coverings, and for exterior facades, a lacquer-based option is suitable. With the help of such material, you can easily insulate hard-to-reach places and do the work yourself.

Before starting work, prepare the surface. To do this, you need to remove all the irregularities and, if necessary, plaster using a dry gypsum mixture. After you need to apply a primer. When the wall is fully prepared, you should start mixing liquid insulation. Mix it immediately before application and follow the manufacturer's instructions. Thermal paint is applied in several layers, it is allowed to form a new layer after the previous one has completely dried. Also, the layer of paint should be about 1 mm thick.The number of layers depends on the material and thickness of the walls. You can apply the product with a foam roller or spray, then there will be a uniform coating.

For external wall insulation, it is necessary not only to level the surface, but also to get rid of mold and fungus, then treat it with a special antiseptic. After that, the wall is primed. When the primer dries, you can proceed to thermal insulation. The weather during work should be warm, in the presence of wind, rain, it is forbidden to apply thermal paint. The layer of applied paint should be no more than 1 mm. In the work it is recommended to use a brush or a spray gun. Each layer dries for about 24 hours. Complete drying of the final layer depends on the number of applied layers.

Floor insulation

To reduce heat loss, it is allowed to insulate the floors with liquid thermal insulation, this option goes well with the underfloor heating system. But this method can be used in rooms where there is no floor heating.

Before starting work, clean dust and dirt, remove all irregularities. Then a primer is applied in the form of acrylic impregnation. After it has completely dried, you can apply thermal paint. It is best to use a spray gun here. You need to keep it at a distance of 50 cm from the floor, you should work at one angle. Then the paint will have a uniform distribution over the entire area of the floor.

Pipe insulation

Liquid thermal insulation is used for insulation of pipelines in the gas and oil industries, as well as for water supply pipes. Such a coating reduces heat loss, and also provides protection against chemical and mechanical influences. For this, a special line of thermal paints is produced, designed for pipes.

Before starting work, remove dirt and rust, then prime the pipe.After the primer has completely dried, you can begin the process of warming. Ceramic thermal paint is applied with a brush or a special sprayer. It is necessary to apply about 5 layers, each layer dries about 4-5 hours. After that, the pipe is covered with a special enamel.

Selection rules

First of all, you should decide on the place of application of thermal paint. Usually, a jar with a product is labeled by the manufacturer. Carefully look at what surface this product can be applied to.

Carefully inspect the contents of the jar. It should be homogeneous, there should be no plaque or any inclusions. It is desirable that the color be white, but light shades of gray or beige are allowed. Otherwise, the product will not meet the declared qualities.

The density of the product must not be ignored. A low indicator of this criterion will give a large heat transfer. In addition, you should familiarize yourself with the service life and interaction with external environmental indicators. For example, ultraviolet, fire or water.

Not all liquid thermal insulation has an easy application method. Make sure that the product not only meets the desired protection and density indicators, but is also convenient to use.

Since there are a large number of manufacturers of this insulation on the market, it is better to give preference to a time-tested brand. So you can be sure of the quality and reliability of the purchased product.

The best liquid thermal insulation

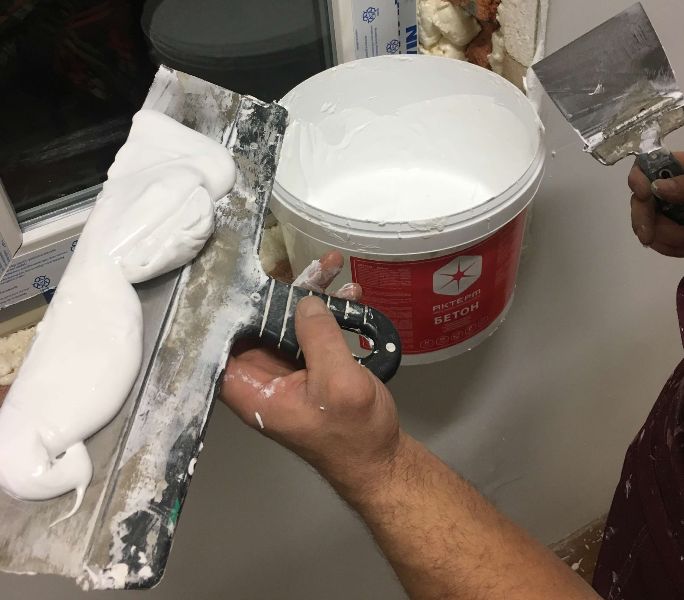

AKTERM Concrete™

This is an ultra-thin liquid thermal insulation based on water dispersion. Suitable for:

- insulation of basements, loggias and balconies;

- isolation of facades and seams between panels;

- insulation of "breathing" concrete, brick and lime surfaces;

- protection of the floor and walls from freezing;

- internal wall insulation;

- insulation and insulation of slopes on windows.

It is used instead of foil in underfloor heating systems.

Consumption of liquid thermal insulation - 1l / 1m2, if applied with a layer of 1 mm. By the way, overspending is allowed if the surface is too porous. Before using AKTERM Beton™, experts advise first applying an acrylic primer to the surface. The color after complete drying is white.

The coating dries at room temperature - a day. After that, decorative plaster is applied, wallpaper is glued or the surface is painted with decorative water-based paint. When the heat-insulating layer dries, the coating will withstand temperatures from -60 to +150 degrees Celsius.

AKTERM Concrete™ is applied in a millimeter layer at a positive temperature of 7-45 degrees Celsius. If the surface area to be treated is small, then experts recommend using a brush or spatula to apply liquid thermal insulation.

For the treatment of large rooms, experts advise applying liquid thermal insulation using airless spray units. AKTERM Beton™ is produced in plastic buckets of 2,5,10 and 20 liters.

The average cost for 10 liters is 3,550 rubles.

- the material does not exfoliate, even if stored for a long time;

- liquid insulation is immediately ready for use (no need to mix the material with anything else);

- dries in half an hour to the degree of tack;

- in small rooms it is applied with a roller, spatula or brush;

- the composition does not contain organic substances and volatile components - the material is fireproof and non-toxic.

- not detected.

Armor Wagon

Liquid ceramic thermal insulation "Bronya Universal" is suitable for insulation of metal, wood, concrete, plastic coatings.This tool has found wide application in the insulation of various pipelines. It is used for thermal insulation of water supply, heat pipes, ventilation ducts, furnaces, various containers or tanks. It is also applied to prevent the formation of condensate.

The recommended application layer is 0.5 mm, drying between each layer should be at least 24 hours. The product is applied with a brush, a special spray gun or a spatula. If you apply "Armor Universal" with a thickness of 1 mm, then the consumption is 1 liter per 1 sq.m. You should also take into account the possible overspending, which can be up to 30%. This parameter depends on the method of application and the level of skill.

Work with this heat-insulating material should be carried out at a temperature not lower than +5 degrees. If the work is carried out indoors, then the temperature there should be + 7- + 120 degrees. If "Bronya Universal" is applied to a surface whose temperature is above +60 degrees, then the product must be diluted with water in a ratio of 1 to 1. After the thermal insulation has completely dried, the room can be operated in a temperature range of -60-+120 degrees.

This heat insulating agent is available in plastic buckets of 5, 10 and 20 liters. It is also produced in two versions: low-flammable and non-flammable.

The average cost of a low-combustible option for 5 liters is 1,500 rubles, and a non-combustible one is 1,600 rubles.

- Suitable for all surfaces;

- A small percentage of overspending;

- Convenient application;

- It is produced in two groups according to the degree of flammability.

- Not suitable for operation at temperatures above 140 degrees.

Armor Nord

A distinctive feature of this liquid insulation from the Bronya company is the possibility of application at negative air temperatures. The minimum allowable application temperature is 35 degrees. "Bronya Nord" is suitable for warming any surfaces, including plastic, wood, brick and metal.

The manufacturer recommends applying Bronya Nord with a brush, roller or sprayer. The applied layer should be no more than 1 mm, drying between layers should be at least 24 hours. Consumption for this application will be equal to 1 liter per 1 sq.m. Before starting work, this thermal paint should be brought into working condition with a solvent.

After complete drying of the thermal insulation, the product can be used. Let's say the temperature regime is from -60 to +70 degrees. If the product is planned to be operated at higher temperatures, then you should choose the Bronya Zim thermal paint. This insulation after polymerization can be operated in temperature conditions from -60 to +90.

"Bronya Nord" is packaged in metal buckets of 10 and 20 liters. Also, this modification of thermal insulation has two degrees of flammability: low-flammable and non-flammable.

The average cost of a low-combustible version with a volume of 10 liters is 3,900 rubles, and a non-combustible one is 4,200 rubles.

- A budget option for thermal paint, which can be applied at a negative temperature;

- Has two degrees of combustibility;

- Can be applied with any tool;

- Slight overspending when applied to large surfaces.

- A product coated with "Bronya Nord" cannot be operated at temperatures above +70 degrees;

- Not available in small quantities.

Green Planet Thermoshield Standard

Liquid thermal insulation "Thermoshield" is used to quickly solve the problems of insulation. "Thermoshield" can be applied to any surface that "does not breathe". For example, glass, plastic, metal, etc. This tool will help to cope not only with thermal insulation, but also help in the fight against rust, fungus or mold.

Basically, "Thermoshield" is used for insulation of pipelines, metal structures, roofs, tanks, as well as for thermal insulation of plastic window frames and refrigeration units.

The consumption of thermal insulation "Thermoshield" is 1 liter per 1 sq.m., when applying a layer of 1 mm. This tool can withstand 10 cycles of frost resistance. After complete drying, they will retain their properties at temperatures from +5 to +150 degrees.

The average cost of a 1 liter bucket is 380 rubles.

- Suitable for application on any surface;

- Does not collapse under the influence of the environment;

- Not toxic;

- Not combustible.

- The maximum packing volume is 10 liters.

Magniterm Standard

This insulation brand "Magniterm" is suitable for working with any surface. It is usually used for thermal insulation of pipes, roofs, walls, and various containers. After complete drying, the surface becomes matte. The materials used in the manufacture of "Magniterm Standard" are made in France and Sweden. It is also worth noting that, unlike other models of heaters, it does not have a water base, but a silicone one.

The ambient temperature when applying "Magniterm Standard" should not be lower than +5 degrees. After complete polymerization, the product can be applied in a temperature range from -60 to +200 degrees.The average consumption when applying a layer with a thickness of 1 mm is 0.8 l/sq.m. Packing is made in plastic buckets of 10 liters.

The average cost is 3300 rubles.

- Silicone base;

- Consumption is less in comparison with analogues;

- It will help to reduce expenses during the heating season by 40%.

- Packed in buckets of only 10 liters.

Teploplus

Liquid thermal insulation from the company "PolymerPromKraska" consists of a water-based acrylic base with the addition of ceramic filler. "TeploPlus" is suitable for both internal and external insulation work. This tool is used for warming products or structures made of metal, brick, concrete, wood.

Layer 1 mm thick. corresponds to mineral wool 50 mm thick. after complete drying of the finishing layer, the product can be operated in a temperature range from -60 to +260 degrees. The layer formed by thermal insulation "TeploPlus" will create a thermal barrier, as well as reflect heat, thereby maintaining the set temperature. When applied to pipes, condensation will be prevented and frost protection will appear. Also, the substances that make up TeploPlus will protect the surface from the appearance of mold or fungus.

"TeploPlus" is completely safe for the environment, non-toxic and odorless.

The average cost of "TeploPlus" with a volume of 10 liters is 3000 rubles.

- The product after coating can be operated in a wide temperature range;

- Has no smell;

- Environmentally friendly product;

- Suitable for application to any coating.

- No.

Conclusion

When it comes to the choice of insulation material between thermal paint and standard options in the form of glass wool, it is worth considering not only the price of the goods. You should also take into account the ease of doing the work, the time spent on the process. In addition, with the help of heat paint, you can easily reach hard-to-reach places. Liquid insulation is packaged in different volumes, which simplifies the purchase of the required quantity.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127688 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124516 -

The best men's sneakers in 2022

Views: 124030 -

The Best Complex Vitamins in 2022

Views: 121937 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2022

Views: 113393 -

Ranking of the best wood paints for interior work in 2022

Views: 110317 -

Rating of the best spinning reels in 2022

Views: 105327 -

Ranking of the best sex dolls for men for 2022

Views: 104363 -

Ranking of the best action cameras from China in 2022

Views: 102214 -

The most effective calcium preparations for adults and children in 2022

Views: 102010