Ranking of the best roll groovers for 2022

In today's world, pipelines are the safest way to move gaseous, liquid or viscous substances. Ensuring proper transportation of these substances through pipes is possible only if the installation of the pipeline system itself is of high quality. And for the installation of such a system, a lot of different equipment is used. Not the last place in this group is occupied by a device called a groover. It is with its help that special gutters are created in the pipes, by deformation of the material under high pressure. This tool is most often presented as a special machine, through which the installation of pipes from various metals is carried out:

- Of stainless steel;

- aluminum;

- Copper, etc.

These devices are designed to create special grooves in the material or make grooved joints.The indicated connections are used in cases where it is not possible or simply undesirable to solve the problem with the help of electric welding equipment. The process itself is quite simple, and even a non-professional can cope with it - it is enough to carefully read the instructions for the machine and do everything exactly in accordance with the recommendations. The result will be a significant time saving during the final installation work.

Content [Hide]

Grooving technology

Grooving (grooving) is carried out by means of support and knurling rollers, which deform the tubular material (i.e., press it slightly inwards) by applying an increased pressure force.At the same time, the rotational mechanism of the machine is engaged in the rotation of the pipe itself, and the rollers at this time create a groove-groove of a set width and depth.

The rollers of the machine are made of high strength steel, which indicates a minimal risk of premature wear when involved in the work process. As a rule, in addition to the main set of rollers, which is mandatory attached to the roll groover, it is possible to purchase special roller sets designed to work with pipes of other sizes and diameters.

Standard portable grooving machines are capable of grooving 2-6 inches in diameter. Separately, you can buy a roller kit for such a machine, which can work on ultra-small groove diameters - up to 1 inch. At the same time, it is quite easy to find commercially available sets of rollers (rollers) for non-standard sizes, for example, 1.1/4 or 1.1/2 inches.

The step-by-step principle of the roll groover is as follows:

- The pipe cut to the desired size is prepared properly (they clean the surface from large burrs, and it is quite possible to use a conventional pipe cutter for cutting);

- Then, the resulting part is clamped along one of the ends and set in a position in which the rolled axis becomes perpendicular to the end;

- When the lever is turned, the roller will move and it will gradually enter the material, thus deepening and deforming the pipe. Thus, a groove with a semicircular cross section will be created;

- The feed step and the turning speed are determined empirically (experimentally) and depend on the pipe material, its plastic properties, and directly on the available diameter;

- When the required depth of the groove is found, the feed stops and 2-3 check turns of the roller in the groove are performed (this operation is necessary to eliminate the occurrence of roughness on the surface of the resulting profile);

- The entire procedure is considered completed as needed.

Structural Features of Roll Groovers

Most roll grooving machines have the same design and include:

- Leading roller rotating the billet pipe;

- Rolling disk, which, pressing against the pipe, deforms it and creates the required profile at the end point;

- Swivel operator arm;

- An additional set of rollers for creating grooves of various diameters;

- A set of thread-cutting devices (optional).

The main advantages of using groovers

The modern market is able to provide a wide range of tools for creating grooves in a pipe, both domestic and foreign. But so far, mankind has not come up with any other, more efficient and high-quality ways to perform the operation in question, except for the use of roll-grooving machines. They can be used directly on the construction site (fortunately, there are portable models) when pipes need to be connected in a short time. However, this is necessary for those situations where the use of an electric welding machine is not possible (for example, due to safety regulations or due to a lack of electricity). Grooving machines themselves are made from durable and high-strength steel, which means they have a long service life. If we draw direct parallels between the advantages of grooving and the use of electric welding, then the first method will be more beneficial due to a number of obvious “pluses”:

- To use a machine for rolling grooves, there is no need to issue a work permit for work (electric welding requires this, because it belongs to the type of fire hazardous work);

- There is no need to fence the place of work with non-combustible materials in order to prevent possible fires (unlike electric welding, the knurling machine does not spark during operation);

- Significant savings in financial resources and working time;

- To use the machine does not require special training and skills;

- The resulting connection will be as reliable as a welded one.

NOTE. Manual portable roll groovers are a compact device for sleeve mounting pipes. The collars themselves are made from wear-resistant and heat-resistant materials, which ensures the reliability of integration and overall safety in the operation of a full-fledged piping structure.

Existing types of groovers

In addition to the fact that machines can be portable and stationary, they can be further subdivided into mechanical and electric (hydraulic):

- Electric (or hydraulic - the result of the work is the same) - in situations where it is necessary to process products made of high-strength stainless steel or when the pipe being processed has a significant diameter, it becomes very, very difficult to manually control the creation of a groove in such a workpiece. The operation of such machines is fully programmable and automated; they are completely silent and able to work without operator supervision. All applied efforts are carried out due to the action of high pressure oil, which is located in the hydraulic cylinder.

- Mechanical devices - they have a slightly different design and are made in the form of a separate module of a semi-automatic thread rolling machine.The work is carried out as follows. The original product is fixed in the support of the machine. The knurling roller, located on the moving tool head, is placed against the line of the axis of the intended groove, and then the roller is mechanically screwed. At the same time, the tubular product begins its rotation. Excess metal exits into a chute located on the side of the tool head, and in the case of working with metals with increased ductility, it is dumped and distributed along the entire pipe axis.

IMPORTANT! The mechanical method of creating grooves is most preferably used on the basis of repair shops or in assembly shops of industrial production. Here the whole question lies in the payback indicator - this process is characterized by increased productivity, it can even be automated, and it is practically unlimited in the types of working materials. This shows that for domestic use, due to their high price, such machines are not economically viable.

Service Features

Although roll-grooving machines in their total mass (not counting full automatic machines) are not high-tech and complex equipment, it will not be superfluous to follow some rules when operating them:

- It is necessary to constantly monitor the state of the surface of the rolling roller - it should not have cracks;

- It is desirable to lubricate the roller more often - this will reduce the negative impact of the friction process;

- When servicing (replacing spare parts, for example), only tested and certified equipment and tools should be used (especially true for branded models);

- Rollers should only be used for materials for which the manufacturer has intended them to be processed;

- It is required on a periodic basis to clean the side grooves of the knurling machine from cut burrs and small chips;

- During operation, the device must be in a stable position on a flat surface;

- During processing, the tubular product should not slip - in order to avoid such a situation, if the pipes are too long, a vice or clamp should be used.

Groove connections

Grooving for grooved joints is used in cases where it is necessary to perform an easy and simple connection of pipes in the shortest possible time, and electric welding is not possible for a number of reasons. The rollers for grooved joints are made of high-strength steel, which makes it possible to create grooves by deforming the tubular product, namely, by pressing it inward with increased pressure. At the same time, the formed groove will always comply with state standards regarding coupling joints. This method will be indispensable when it is required, for example, to integrate a fire extinguishing system in a warehouse environment - in this situation, the deployment of large-scale welding is simply not economically feasible.

Groovelock concept

This is the name of the connection by means of a special coupling (clamp) - that's what it is called gruvlok. He himself (grovelock-coupling) is a cuff and a connecting clamp-clamp. Typically, the cuff is made from a wear-resistant rubber-based polymer, which further increases the tightness of the joint. At the same time, the clamp-clamp is attached to the bolts screwed into the pipe in two parts of the groove. The process is to install the clamp into pre-created grooves, which are then tightened with bolts.Non-welded grooved couplings are divided into rigid and flexible (they are also “soft”). In the modern domestic market, they are represented by several popular brands, among which are Dinancy and Viktaulik.

Advantages of a groove joint

As a positive aspect of the use of coupling joints, installation professionals note their extremely simple installation / dismantling, which clearly makes subsequent repair and maintenance of the pipeline easier. At the same time, they point to undeniable savings in the cost of work. The structure of the split fittings makes it possible to save up to 55% of labor hours compared to the same welding. Separately, professional installers single out the factor that there is no need to have various permits when working on objects with a certain category of fire and explosion hazard (i.e., wherever electric welding is generally prohibited by law). From this it can be seen that all the "pluses" of coupled detachable joints consist in obtaining a very flexible pipeline structure as a result, in which the requirements for the coincidence of the axes of the elements can be significantly reduced, which in general will give increased resistance to vibration effects. At the same time, it should be noted that the compensation of the thermal expansion factor of the pipe is increased on quick-release clamps. This circumstance is most relevant in a situation where a major fire has occurred at the facility. An additional positive point to be mentioned is the installation/self-centering of the connected pipes. With a grooved joint, the whole structure can be dismantled in the shortest possible time using ordinary wrenches. The same factor has a positive effect on the process of permanent maintenance, cleaning and maintenance.

Conditionally, and summing up, it is possible to outline the following undoubted advantages of the groove lock:

- Installation and dismantling of such connections is easy and simple. Maintenance, repair and cleaning of such pipe connections will become less labor intensive and economically less expensive.

- Execution of the entire complex of works in a short time - such integration of pipes, as a rule, saves labor hours by half (including for installation) in comparison with electric welding;

- Ease of use. Typically, a groovelock joint is used when integrating fire extinguishing systems at a site. As practice shows, the installation of such systems is a complex process, especially since the result must be accepted by state supervisory authorities (Gospozhnadzor of the Ministry of Emergency Situations of the Russian Federation). The use of welding will significantly slow down the whole process as a whole (obtaining permits, organizing fire safety at the work site, etc.);

- Grooved connections are characterized by a long service life (about 30 years minimum) and high vibration resistance;

- During this connection, it is easy to compensate for angular bends.

Grooving clamps - knurling channels

In fact, until recently, the regulatory framework of Russian legislation in the field of construction allowed the use of the described connections without any special restrictions (everything was regulated by the old SNiP from 1985). But this type of connection was not very common in our country, and in the CIS as a whole, where local legislation was reduced to the "former Soviet denominator."This can be largely explained by the lack of effective production tools, and even more so, the lack of clear standards for pipe preparation - for example, in the process of rolling grooves, significant deviations from the proper standards were allowed during pipe rolling. However, today, this issue is regulated by law and it is possible to produce grooving standards only in accordance with the norms of the Code of Practice No. 73.13330 of 2012. Thus, the knurling of grooves can be carried out in any conditions - from a small workshop to the conditions of a large industrial facility, subject to compliance with state requirements.

Detachable joint of steel pipes with galvanization without welding

Most professionals have long been aware of the main provisions of clause 4.6 of the aforementioned "Code of Rules" - "... the use of welding when connecting pipes made of galvanized steel is unacceptable ...". Simply put, the basis for this ban is that “when boiling a galvanized pipe, the zinc will completely burn out, and only bare metal will remain, from which (for example, in a conventional water supply system) the water will acquire a characteristic rusty tint.” In addition, galvanized piping will corrode twice as fast as a socketed connection. From this it can be seen that the best solution would be a grooved joint based on clamp-type couplings and without the use of connecting threads and welding. All you need to apply is a groove lock - a special crimp collar!

Ranking of the best roll groovers for 2022

Manual models

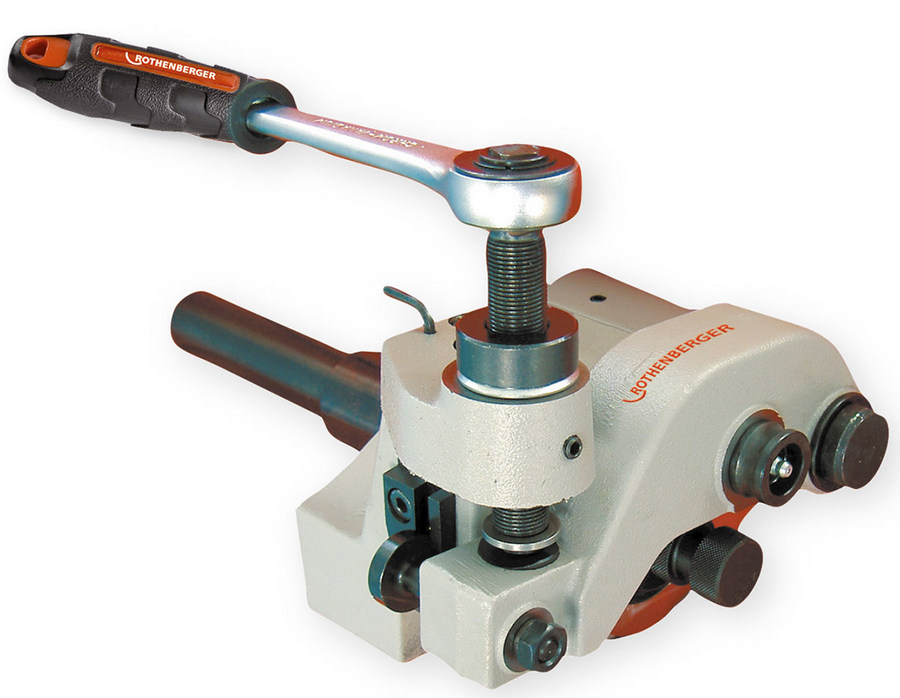

3rd place: "ROTHENBERGER SUPER-EGO 887 887010200"

votes 0

The machine is perfect for working on ordinary pipes and pipes with thin walls, which can be useful when installing heating appliances. The body of the device is made of high-strength aluminum. The result of the processing of pipe sections will be their high-speed connection in the absence of welding. The device is equipped with a special limiter that provides smooth adjustment. The included ratchet expands the possibilities of fine tuning.

| Name | Index |

|---|---|

| Manufacturer country | Spain |

| Max Diameter | 150 mm |

| Minimum Diameter | 50 mm |

| Roller set | 2-6 dm |

| Total weight, kg | 0.66 |

| Price, rubles | 8700 |

- Sharing with the carving machine is possible;

- The adjustment system will ensure a constant groove depth;

- The rollers are made of hardened steel.

- Limited functionality.

2nd place: “HONGLI GC02 1.1/4″- 6″ 503204”

votes 0

Very simple and easy to use portable model. One person does all the work alone. The installed body of the machine has an increased margin of tensile strength. Changing rollers for knurling is quick and does not require special knowledge. Working elements are resistant to mechanical damage.

| Name | Index |

|---|---|

| Manufacturer country | China |

| Max Diameter | 1.25 dm |

| Minimum Diameter | 6 dm |

| Roller set | No |

| Total weight, kg | 22.7 |

| Price, rubles | 68400 |

- Convenient for single operator operation;

- Relatively light weight;

- Extended range of processed pipes.

- Rollers are not included (purchased separately).

1st place: "BREXIT BrexGROOVER 6UV"

votes 0

A versatile device that is compatible with many third-party cutting machines, which is why it has such a high price. The chute adjustment system is greatly simplified, making it easy to maintain a constant depth. Due to its low weight, the machine is extremely mobile and very easy to carry.

| Name | Index |

|---|---|

| Manufacturer country | Belarus |

| Max Diameter | 51 mm |

| Minimum Diameter | 152 mm |

| Roller set | 2-6 dm |

| Total weight, kg | 11 |

| Price, rubles | 122500 |

- Extended compatibility;

- Light weight;

- Precise roller adjustment.

- High price.

Combined segment

3rd place: "REKON RG-8 Combo 020108"

votes 0

This machine copes well with any kind of steel, especially stainless steel. At the same time, it works well with soft metals, such as aluminum. The whole structure can work both with the application of muscular effort and with the help of the Turbo 501 electric motor. The depth of the roll groove can be fixed. Easy to transport, for which there is a special handle.

| Name | Index |

|---|---|

| Manufacturer country | Great Britain |

| Max Diameter | 8 dm |

| Minimum Diameter | 0.75 dm |

| Roller set | ¾-8 dm |

| Total weight, kg | 10.5 |

| Price, rubles | 100500 |

- Small dimensions;

- Extended service life;

- Works on both hard and soft materials.

- Not identified (for its segment).

2nd place: "RIDGID 975 33033"

votes 0

This machine is also able to work both manually and from the power drive "ReedGuide 300". The type of groove application is machine-driven.The device is equipped with an automatic tracking regulator, which means enhanced fixation of the pipe during operation, as well as a reduction in time spent during re-installation. The structure itself is made of high-strength wrought iron.

| Name | Index |

|---|---|

| Manufacturer country | USA |

| Max Diameter | 6 dm |

| Minimum Diameter | 1.25 dm |

| Roller set | ¾-6 dm, 1.1/4-1.1/2 dm |

| Total weight, kg | 12 |

| Price, rubles | 107000 |

- Light weight and dimensions - easy transportation;

- High accuracy of operations;

- Work with almost any kind of materials.

- Not detected.

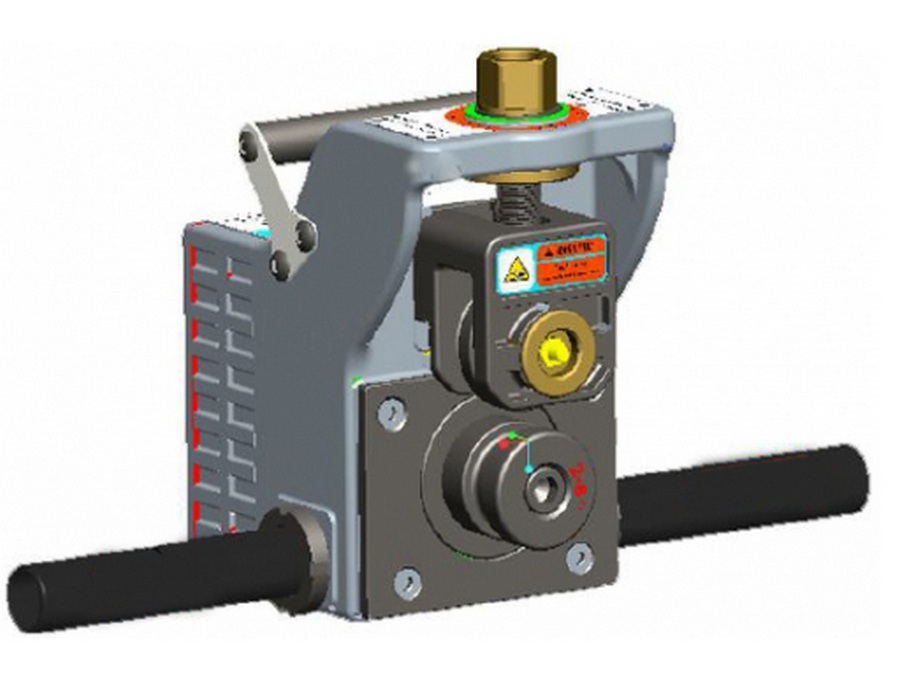

1st place: "RIDGID 916 48307"

votes 0

The manufacturer positions this device as semi-professional and recommends using it in large-scale industries and workshops. The model is characterized by high accuracy when performing operations. It shows itself perfectly in working with soft metals of various hardness - copper, aluminum, steel. At the same time, it can work with cutting machines and power drives of its brand.

| Name | Index |

|---|---|

| Manufacturer country | USA |

| Max Diameter | 6 dm |

| Minimum Diameter | 2 dm |

| Roller set | 2-6 dm |

| Total weight, kg | 15 |

| Price, rubles | 125000 |

- Cam type feed system - a minimum of muscular effort from the operator;

- Adjustment of the grooves performed with a screw;

- Ease of maintenance.

- The lack of a special handle gives some inconvenience during transportation.

hydraulic samples

3rd place: VOLL V-Groover 6 2.24006

votes 0

A professional sample used on construction sites and in production workshops.An excellent solution for the installation of various industrial pipelines, including the installation of fire extinguishing systems. The knurling rollers are made of high strength steel, which means an extended service life. Powered by a 450W high power motor.

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| Max Diameter | 6 dm |

| Minimum Diameter | 1.25 dm |

| Roller set | All existing |

| Total weight, kg | 80 |

| Price, rubles | 110000 |

- Excellent equipment;

- Professional performance;

- Better value for money.

- Not detected.

2nd place: "SUPER-EGO ROGROOVER 1500001987"

votes 0

A very highly specialized model, specially designed for the manufacture of piping for fire sprinkler systems. It has a very powerful, but at the same time low-noise electric motor. The stability of the device is ensured by four special legs.

| Name | Index |

|---|---|

| Manufacturer country | Spain |

| Max Diameter | 2 dm |

| Minimum Diameter | 12 dm |

| Roller set | 2-12 dm |

| Total weight, kg | 130 |

| Price, rubles | 330000 |

- Quiet motor;

- Good equipment;

- Fine tuning.

- Narrow specialization.

1st place: "RIDGID 918 57092"

votes 0

The presented sample is capable of processing pipes not only from soft and hard materials, but also from plastic. However, such operations will require appropriate consumables. A powerful hydraulic piston installed in the structure will help to do all the work quickly and accurately. Only one operator is required for the entire complex. The model is equipped with the original mounting kit for the compact carriage.

| Name | Index |

|---|---|

| Manufacturer country | Spain |

| Max Diameter | 2 dm |

| Minimum Diameter | 12 dm |

| Roller set | Sold Separately |

| Total weight, kg | 37 |

| Price, rubles | 402000 |

- Ability to work with any materials;

- Good equipment;

- Powerful hydraulic piston.

- Overcharge.

Instead of an epilogue

An analysis of the modern domestic market of the equipment in question showed that most of the presented goods are produced by high-quality European brands, therefore they have a very high price. At the same time, the Russian manufacturer is represented only in the segment of professional and semi-professional equipment, which indicates some positive trends for Russian firms. It is worth noting that few people need equipment for grooving at home, therefore, it is purchased exclusively by manufacturing enterprises. From this we can conclude that even a very hefty price will allow the device to quickly pay off in a relatively short period.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127688 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124516 -

The best men's sneakers in 2022

Views: 124030 -

The Best Complex Vitamins in 2022

Views: 121937 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2022

Views: 113393 -

Ranking of the best wood paints for interior work in 2022

Views: 110318 -

Rating of the best spinning reels in 2022

Views: 105327 -

Ranking of the best sex dolls for men for 2022

Views: 104363 -

Ranking of the best action cameras from China in 2022

Views: 102214 -

The most effective calcium preparations for adults and children in 2022

Views: 102010