Rating of the best protective coatings for SUVs for 2022

The more difficult the obstacles and the worse the environment, the higher the risk of damaging the body to the metal base, thereby starting the corrosive process. The factory paintwork does not help out even off-road, which is why drivers have to use auxiliary protection.

The most effective are considered to be funds on a polyurea and polyurethane basis. These are the ones we will consider in the ranking of the best protective coatings for SUVs for 2022.

Content

Types of protective polymer coatings for the body

The polymer solution forms a thick and rough layer during application. There are two types of polymer solutions on the market:

- Compositions based on polyurea.

- Protective compositions based on polyurethane.

Polyurea products

Developed three decades ago and turned out in the 90s. product of commerce technology "sprayed polyurea elastomeric coatings", despite the inharmonious name, made a splash in the market of protective technologies.

As it turned out, polyurea (polycarbamide) is best suited for protecting car bodies:

- Durable, scratch-resistant, withstands powerful impacts and is not afraid of vibration.

- Elastic - does not crack during deformation and stretches several times.

- In case of a traffic accident, it does not burst, and during application it lays down evenly and thoroughly sticks to surfaces of various form factors and appearance. The polymer also adds additional hardness to the components.

- ECO-clean and refractory - there are no solvents in the composition, so it is possible to apply the material on car bodies and use it inside the car without fear for your own health.

- It dries quickly and can be used under any conditions. A number of layers are applied without prior drying. Immediately after spraying, the car is serviceable.

- The elastomer also serves as an additional noise insulator and repels water. A car that has been treated with a polyurea compound is not as prone to contamination as others.

Polyurea-based products effectively protect SUVs both completely and their individual components.Of course, the composition is imperfect, and there are some application details, but there are significantly more pluses than comparative minuses.

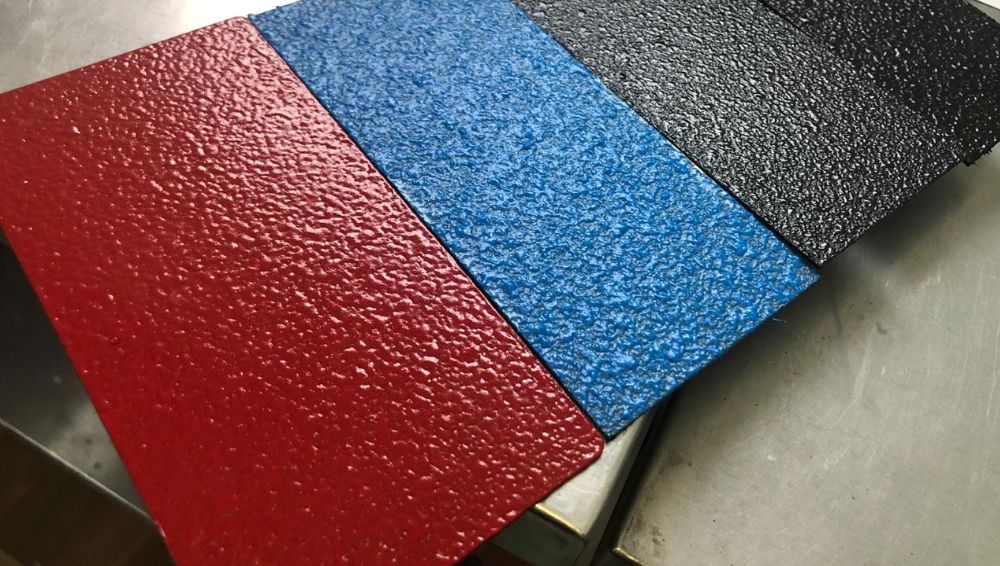

In appearance, the car, its parts or parts (for example, bumpers, anti-gravel belt, sills, hood ends, etc.) look like they are covered with "shagreen" - a protective layer that is slightly rough to the touch and looks like hard rubber.

The volume and magnitude of roughness are adjusted by a specialist in the process. The thickness of the layer, as a rule, ranges from 1-5 mm. The optimal layer is considered to be from 2 to 3 mm, however, the door ends cannot be processed, since the doors will not be able to close.

The color is not only black, but almost any. Experts say that by applying a duplicating layer, the coating can be painted even in metallic. It is worth noting only that the pimply composition of the material does not imply a special brilliance. In addition, it should also be taken into account that if the car is not completely painted, then it becomes quite difficult and not always possible to choose the right color for the protected components under the “native” color scheme.

Smooth and rough surfaces shine and look different, so it is better to resort to the help of specialists who have the proper experience.

The car is prepared for treatment with a polyurea-based composition in exactly the same way as for painting: the damaged areas are cleaned, dried and primed.

The polymer has rather high adhesive properties (sticks) and it can be applied even on "native" paint. However, this is done only if there are no damages and signs of corrosion on the machine, otherwise it is necessary to clean it to a metal or plastic base.

If a protective layer is applied to swollen paint or rust, a bubble will form and it will not be possible to correct it. It is also worth noting that after an accident or other damage to the “armor”, it cannot be repaired even partially. In order to preserve the waterproofing and the absence of seams, it is necessary to re-treat the body component or section completely, having previously cleaned the previous layer from them.

It is quite difficult to clean the body or certain parts of the car from the composition based on polyurea, since the material has high adhesive properties. That is why it is worth considering in advance that the protective layer will remain on the vehicle forever.

For the same reason, “shagreen leather” is usually applied to SUVs and pickup trucks, for which the protective layer adds value, and not to passenger cars. In the United States, where polyurea coatings have been around for a couple of decades, the state automobile society has found that the price of a car that has been treated with an elastomer is halved when sold.

This is not devoid of logic, since the risk that the car is rotten is reduced significantly.

The polyurea composition, when compared with polyurethane-based protective agents, cannot be applied by hand with a roller or brush. That is why you will have to resort to the help of specialists.

Experts recommend that a manufacturer of "armor" with a certificate of quality act as a specialist, since there are many nuances and trifles in this matter.

In addition to the fact that you will need expensive equipment with dispensers, heated hoses, a recirculation type pump, a productive compressor and a spray gun, well-chosen coating elements are also needed.In addition, a person who has all the specific skills to use the mentioned equipment is also important.

It is for this reason that there are few companies with many years of experience in this field. The most important thing here is with many years of experience, because it is not difficult to purchase equipment and advertise a company today. It is much more difficult to collect a case of work done and earn positive comments, as well as the trust of motorists.

Polyurethane-based products

For most car owners, such “armor” is known as “anti-gravel”. It is in high demand, there are also enough manufacturers.

The key advantage of this type of protective composition is the ease of application. Any driver can cover his own car, pickup truck body, power kit, etc. with the help of such a tool, since the main skill is the experience of using a brush, spray gun or roller, and an ordinary garage is ideal as a processing room.

The key disadvantage of such “armor” is that the polyurethane-based protective layer dries for a long time and for this period it must be protected from pollution and rain. They protect polyurethane-based paints from the same types of aggressions as the polyurea-based products discussed above: corrosion, rust, aggressive salt, UV rays, chemicals and mechanical damage.

When compared with the same polyurea compounds, the output polyurethane layer is thinner and stronger.

It's worth noting that polyurethane-based "armor" will cost less, so if you don't prefer aggressive riding, then maybe you should take a closer look at these compounds.

The best polyurea products

There are quite a large number of companies that provide services in the field of applying polyurea-based elastomeric coatings. Let's consider the best of them.

1 place. LINE-X

The most common brand of protective coatings for car body in the Russian Federation based on polyurea from the United States. The company began its activity in the development of the composition more than 30 years ago and has been engaged in the processing of cars for about 20 years.

In the world, the company has an impressive network of departments, and the first workshops of the brand opened in Russia about 5-8 years ago. During this time, their composition has become not only a protective coating, but a branded component of SUVs and pickups.

Bodies and car parts are covered with "armor", consisting of two components based on aromatic polyurea with an eternal guarantee.

The average price is 1000 rubles per kilogram.

- easy to wash and clean;

- protects against corrosion;

- multicolor;

- impressive warranty period;

- preserves the original appearance of the vehicle.

- hard to find for sale.

2nd place. BRONIX

Polymer made in Europe. Companies that cover cars and their components with "armor" of this brand use two types of polyurea:

- Aliphatic.

- Aromatic.

The warranty period for the performed processing is 3 years. The composition guarantee ranges from 5-10 years (it all depends on the company). However, in the context of the phrase “composition guarantee”, it means that during the specified time it will not collapse and will not lose its physical characteristics.

Color changes are not covered by the warranty period.

The average price is calculated individually and depends on the type of work.

- protects against scuffs;

- protects against mechanical damage;

- protects against the influence of water, gasoline, salt and various chemicals;

- protects against corrosion;

- anti-slip coating.

- not detected.

3rd place. Z PRO

To process a car, a tool is used that consists of three components marked Standart, released by a company from Switzerland - Huntsman, but modified. By order of the official distributor of the Protek company, an elastomer adapted to the conditions of the Russian winter is imported into the Russian Federation.

The average price is calculated individually and depends on the type of work.

- made on the basis of pure aliphatic and aromatic polyureas;

- has a maximum threshold of resistance to ultraviolet rays;

- protects car bodies from corrosion and abrasive wear;

- used in the construction industry for finishing steel and concrete tanks.

- not detected.

4th place. Bullet Liner

This is a protective type polymer coating developed on the basis of high quality polyurea. The Bullet Liner brand was created by Burtin Labs. The founder of this brand, CEO K. Barten, was the creator of the "armor" Line-X, discussed before.

In 2015 Accella Polyurethane Systems acquired Burtin Polymer Laboratories. Using innovative chemical materials and hardened resourcefulness, Bullet Liner technology has been created and improved for over 30 years.

The long history associated with polyurethane-based protective coatings determines the brand's commitment to making high-quality polyurea compounds for vehicles and supplying them to the automotive market. The company's products are tested not only in laboratory conditions, but also tested in the most severe environmental conditions.

The average price is calculated individually and depends on the type of work.

- high-strength elastic coating;

- impressive polymerization speed, which is 10 seconds;

- excellent sound insulation;

- resistance to acids, solutions and UV rays;

- high adhesive properties.

- not detected.

5th place. Rubber Paint HELMET

Exclusive high strength polyurea protective compound. This agent with excellent chemical-physical properties is applied by conventional spraying. After processing, a matte type film with shagreen is formed on the surface. The layer thickness ranges from 0.5 to 2 mm, it all depends on the processing method and the number of layers.

The tool is used to protect the bodies of special equipment, SUVs and all-terrain vehicles. The composition can be applied to different surfaces:

- metal;

- polymeric;

- composite;

- plastic;

- concrete;

- wooden.

Important! It is forbidden to apply the product on 1K primers.

The composition is easily applied with an anti-gravel type gun. The can is screwed directly onto the gun. It is also possible to treat the surface with a paint sprayer with a nozzle from 2.5 mm, a brush or a roller. Depending on the processing method, the surface can be shagreen or smooth.

The average price is 2,900 rubles.

- processing does not require special equipment;

- there is no need to pre-prime the surface;

- dries to the reinforcement assembly within 2 hours at a temperature of 20 degrees Celsius;

- complete polymerization occurs after 5 days.

- not detected.

The best products based on polyurethane

Consider the best polyurethane-based products from various manufacturers.

1 place."AKTERM Avtoarmor"

A tool that has absorbed the best properties of the compositions of various brands. During its development, the experience of using various similar tools was taken into account. The creators of AvtoBrony tried to combine the best aspects in the products, which are typical for polyurethane protective coatings from various manufacturers.

A polyurethane-based protective agent was created directly in order to protect parts of car bodies that are operated in difficult conditions. They process the body elements of trucks, SUVs and other vehicles.

"AKTERM AvtoBronya" will also be an excellent choice for vehicles used in normal conditions. Among other things, this tool is used in the construction industry. With its help, metal surfaces are protected from corrosion and the influence of external factors.

The average price is 1,300 rubles.

- high-strength composition;

- excellent resistance to chemical influences;

- attractive decorative look;

- durability about 15 years;

- ready to apply, no solvent needed;

- quickly reaches the required level of strength;

- reduces noise and vibration threshold;

- protects from UV rays;

- repels water.

- the maximum packing is only 0.8 l;

- hard to find for sale.

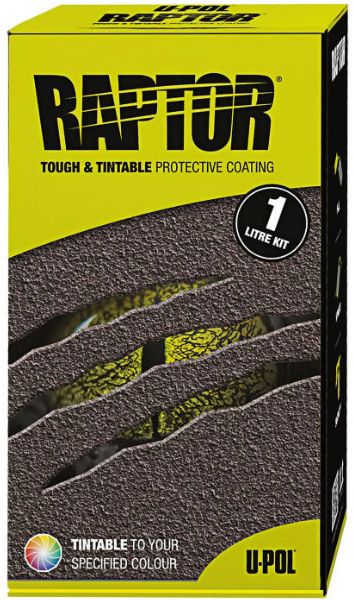

2nd place. RAPTOR

Protective layer consisting of two components. Sold in sets, which include 4 bottles of product and 1 container of hardener. The kit is enough to process 10 sq.m. with one layer. The drying time between layers is 3 hours, and full polymerization and achievement of the required level of strength occurs after 3 weeks. However, it is allowed to use the vehicle (part) already 10 hours after treatment.

The average price is 1,500 rubles.

- high resistance to abrasive damage;

- the material transfers impressive tensile loads;

- protects the body from chopping blows;

- scratch resistance;

- prevents enlargement of incisions.

- after processing it is impossible to apply varnish;

- the product looks like shagreen, so the aesthetics of the appearance of the vehicle deteriorate;

- if it is not properly painted, then there is a high probability of chipping.

3rd place. Herculiner

Unique coating based on polyurethane with rubber granules. It is applied to the body of trucks in 3 simple steps using a brush or roller (included). After drying, the agent guarantees a reliable, wear-resistant and anti-slip layer.

The proprietary water-free formula, when compared to water-based products, allows the coating to properly adapt to the surfaces to which it is applied. Due to its exclusive qualities, the coating is able to adhere to almost all types of surfaces or substances.

This tool is used to treat wooden, metal, concrete, aluminum, asphalt, rubber, fiberglass and plastic surfaces, including polyvinyl chloride. Herculiner prevents rust by sealing the surface and is resistant to gasoline, chemicals, solvents and oil.

The average price is 5,000 rubles.

- modified coating based on polyurethane;

- wear-resistant base;

- particles adhere to each other;

- forms an anti-slip layer;

- contact with moisture in the air for the best drying.

- some motorists considered the price tag too high.

4th place. BROWNER

As a result of polymerization, a reliable elastic coating is created, which consists of 95% polyurethane and 5% polymer additives. The composition protects the treated surface from external influences.

The protective coating is available in 3 varieties:

- "Bronyator HARD" - the largest shagreen, which is applied using an anti-gravel gun.

- "Bronyator STANDARD" - a medium pebble, which is applied with an anti-gravel type gun, or a small pebble, applied with a spray gun.

- "Bronyator SUPER" - a coating applied with a spray gun and forming a smooth mirror layer on the surface. At the same time, this modification meets all the parameters of the standard one.

The range of the brand also includes a protective tinted primer applied to a painted or unpainted metal surface before a protective coating. The primer is a protective and adhesive coating, as well as the tone of the tinted surface. Thanks to these features of the soil, the consumption of a protective coating is saved.

The average price is 1,200 rubles.

- perfectly applied to a porous and smooth surface;

- the possibility of processing from a smooth surface to large shagreen;

- a liter of layer processes about 3 sq. m surface;

- availability;

- protects from aggressive environment.

- not detected.

5th place. NOVOL COBRA

Protective coating with structural effect based on 2K polyurethane resins. It stands out from competitors with a sufficiently high degree of mechanical strength and scratch resistance. Protects the car body from the effects of aggressive environment factors, gasoline, water, oils and salt.

It has good soundproofing and vibration qualities, and the surface structure gives an anti-slip effect. In the basic version it is produced in black, and in the modification for painting it makes it possible to achieve any color by adding 10-15% base or acrylic paint.

Experts recommend buying the SPECTRAL BASE or SPECTRAL 2K variety.

The average price is 2,000 rubles.

- high degree of protection;

- forms a surface resistant to scratches, stains and thinners;

- the coating is characterized by increased resistance to all weather conditions: moisture, high and low temperatures, ultraviolet rays, salt water;

- easy and quick to apply;

- you can choose the thickness of the structure.

- not detected.

Conclusion

Autopaint protects the car body from most of the negative effects of the external environment. Painting improves the primary parameters of the machine, protecting it from corrosion and damage. The protective coatings considered in this rating are in some way a preventive measure for the destruction of the body, which will last a very long time.

Attention! The above information does not serve as a call to purchase. Before you purchase a protective coating for an SUV, be sure to consult with a specialist.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131651 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127690 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124519 -

The best men's sneakers in 2022

Views: 124033 -

The Best Complex Vitamins in 2022

Views: 121939 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114980 -

The best paint for gray hair - top rating 2022

Views: 113395 -

Ranking of the best wood paints for interior work in 2022

Views: 110318 -

Rating of the best spinning reels in 2022

Views: 105329 -

Ranking of the best sex dolls for men for 2022

Views: 104366 -

Ranking of the best action cameras from China in 2022

Views: 102216 -

The most effective calcium preparations for adults and children in 2022

Views: 102011