Rating of the best cleanup circles for the grinder for 2025

Removing rust, as well as removing paint from metal surfaces or walls, usually requires a lot of effort and a huge amount of time. Therefore, in the modern world, this process cannot do without the use of a special power tool. This type of work will help facilitate the "grinder" (aka angle grinder or angle grinder), equipped with special nozzles. Usually, for such operations, specialized discs are used for stripping or peeling, however, the final stages of processing can be carried out with both grinding and sharpening devices - everything will depend on the material to be processed.

Content [Hide]

- 1 Grinding and peeling discs

- 2 Grinding discs

- 3 Grinding discs

- 4 Selection of discs for specific jobs

- 5 Specifics of disc marking for angle grinders

- 6 Additional accessories required for cleaning work

- 7 Rules for changing circles on the instrument

- 8 Problems arising during operation

- 9 Rating of the best cleanup circles for the grinder for 2025

- 10 Instead of an epilogue

Grinding and peeling discs

Their working part is a steel cup or some combination of two disks, on the edge of which brushes, twisted cutters or standard metal wire are integrated. This design is suitable for removing traces of corrosion and rust, as well as layers of various coatings (for example, dried cement, polymer or paintwork). These devices will become indispensable when repairing the bodies of various car models, equipment or building units. The strength and section of the wire element will determine the level of processing. Grinding discs can be coated with abrasive or diamond, and their edges are similar to those of grinding wheels. Therefore, they are easy to remove plaster and other coatings applied to stone or concrete with a high level of adhesion of the finish.

Paint strippers

It is preferable to remove the paint with the help of brush discs - they gently clean the surface, pass over irregularities better, and also do almost no harm at the junction or adhesion of the treated objects. Wire brushes are considered a little more aggressive - they are better for removing paint applied to hard coatings, because they have little elasticity and do not interact well with bumps. To effectively remove the coatings, these nozzles will require the tool to work at high speeds and it is desirable that the tool itself, in order to be more stable, is not very light. At the same time, high speeds and the weight of the tool will adversely affect the operator (hand fatigue will come faster).

Nozzles for removing coatings from metal surfaces

For peeling work on metal surfaces (usually this is the removal of rust and traces of corrosion), specialists use brushes. They look like a classic brush made of twisted / non-twisted wire, installed in a metal glass or integrated into a disk based on a similar wire.

IMPORTANT! Work with brushes for metal should only be done in special protective clothing, because during processing, small pieces of wire can come off the nozzle and fly into the operator.

Depending on the type of roughing work to be carried out, the stiffness and thickness of the brushes should be properly selected. It must always be remembered that the wire installed on the disc leaves scratches on the surface to be processed. Therefore, to remove a coating, for example, from a car body, they must be used with caution. But when removing rust in hard-to-reach and invisible places, they can be used with effort.For gentle grinding of metal, it is preferable to use special wheels based on silicon carbide fibers (XCS) - as a standard they are black. Also, wear-resistant discs made using Clean and Strip technology (made of nylon threads and blue in color) are suitable for gentle work. These wheels are made in two versions - for angle grinders and for drills. Their distinctive feature is that after work the circle is not clogged with the removed material and does not cause damage to the treated surface in the form of scratches. At the same time, it will perfectly remove welding spatter, traces of rust, hardened sealant drops and anti-corrosion coating. Due to the high resistance to wear, Clean and Strip wheels can be used until they are completely abraded.

To remove coatings from metal surfaces, you can also use a petal nozzle for an angle grinder. The petal disc is a circle with sandpaper glued to its surface, which is cut out in the form of petals. For roughing purposes, sandpaper with a large grain size is used. For the final (finishing) work, emery petals with fine grain cutting are selected. However, such circles tend to wear out quickly, and their surface is quickly clogged with the remnants of the removed coating, but it is very easy to replace or restore them.

Nozzles for stripping wall coverings

In order to carefully remove the paintwork from the walls, you should use brushes on a thick twisted wire. This method is the most effective, but it creates a lot of dust. From this it is clear that in the process of work the operator must use goggles and a respirator. In addition, it is preferable to equip the angle grinder with a special vacuum cleaner with equipment that would cover the brushes.Also, thick twisted wire will do an excellent job of removing old primer, plaster or putty from the walls.

To remove the paint coating from concrete walls, nozzles in the form of a bowl are used. During this process, the “grinder” must be held at an angle so that the tool does not penetrate into the surface, and the paint layer is still removed. At the same time, it is possible to carry out final work on leveling the surface and removing the resulting sagging on the wall with a thick screw brush.

Grinding discs

Such discs are directly designed for rough metal processing. They can clean welds, chamfer cut iron objects, and also grind tools (chisels, drills, etc.), in the case when there is no grinder at hand.

IMPORTANT! To work on these discs, the angle grinder speed must be set to a minimum and must not exceed the recommended values \u200b\u200bspecified on the label.

Usually, these circles are used on small models of "grinders", because it is easier to clean metal with them. Grinding discs differ from cutting discs in their thickness (at least 5 millimeters) and they have a recess in the center, which facilitates the processing of the desired object.

Grinding discs

They are used for polishing and grinding various surfaces such as plastic, wood or metal. In this process, a petal-type grinding wheel is most often used, on which sandpaper in the form of petals is glued. However, for the purposes of grinding, and not stripping, it is possible not only to glue the petals, but simply to attach them to a simple Velcro. For polishing purposes, you can use special circles that look like felt pads. All-cloth discs are also suitable.

Selection of discs for specific jobs

For deburring, deburring and roughening wood floors or ceilings in new buildings, use grinding wheels marked P150 or 180 - they are best suited for general tasks.

For final and wet processing, apply:

- Models marked P240 and 280 - they will easily achieve smoothness when removing varnish or paint. This is especially true for objects with which a person is constantly in contact, for example, furniture in a bath.

- Abrasives marked P400, 600 and 1000 will help create an almost mirror-like surface on plastic, ceramic or metal products. They will not leave special scratches on bumpers and headlights of cars, and will perfectly process metal elements of furniture and even dishes.

- Wheels marked P1200, 1500, 2000 and 2500 will add a matte finish to an already painted body surface, windshield or any mirrored surface.

For cleaning polishing, you will need to use special wheels with special materials:

- Vulcanite - they are made on a rubber base, to which crystalline ingredients are added. They have a high heat capacity, so they are able to perfectly process metal. For example, through them you can renew things made of stainless steel, plumbing or dishes.

- Felt - made of compacted fabric, which actively fights against chips and cracks, deep abrasions and scratches on wood, plastic, metal or glass-ceramic. Perfectly clean polishes. Easily help to get rid of traces of wipers on the front glass of the car. They are used even in aviation and railway transport.

- Foam rubber - made on the basis of polyurethane foam.Circles can be different with respect to their own rigidity and are marked with colors - white, orange, blue and black. Perfect for removing scratches and chips on painted surfaces. They also fight smudges very well - just apply a little paste on the foam rubber and walk over the problem area.

- Woolen - the basis for them is synthetic or sheep wool. Ideally suited for tough cleaning - perfectly removes traces of oxidation and scratches from painted surfaces. They are used in conjunction with abrasive paste, but require a slightly larger amount of it than foam rubber. Usually used for stripping car bodies after painting, but may leave haze and holograms.

- Fur - structurally consist of soft villi, which become sharp during rotation. These wheels are suitable for final cleaning and give shine and gloss to the treated surface. The main and main competitor of foam rubber discs in this direction;

- Felt - made of felted wool and suitable for removing defects from metal objects, while cleaning the surface and giving it a glossy finish. In addition to body work, they can be used in special professional areas - polishing of surgical instruments, measuring instruments, mechanical engineering elements and precision parts of other mechanisms.

Specifics of disc marking for angle grinders

Together with the barcode of the country of manufacture and the scope of application, the marking of discs for the "Bulgarian" contains the following information:

- Characteristics of the working coating (diamond, abrasive, etc.);

- Dimensions - diameter of the outer edge, diameter / thickness of the nozzle hole (in millimeters), etc.;

- Angular speed (maximum);

- Rotation speed (limit);

- Angle of work (permissible);

- List of operations that are prohibited to perform in this circle;

- Pictograms and icons indicating security measures;

- Expiration date and release date.

IMPORTANT! In addition to the information available on the circle, when making a purchase, you should ask the seller about the compliance of the selected product with Russian standards, as well as inquire about the production technology of the circle itself.

Additional accessories required for cleaning work

Any work on cleaning or peeling surfaces must be performed with the proper level of comfort for the sake of their own quality. Therefore, it will not be superfluous to purchase additional equipment for the grinder:

- Construction vacuum cleaner or dust collector - they are designed to collect and accumulate working dust. After work, a filled waste container can simply be thrown into the trash, and cleaning, as such, may not be required at all.

- Dust outlet - often supplied with a grinder (usually with expensive models). You can also purchase it separately to connect the tool to the vacuum cleaner hose, thereby saving yourself from getting dust on your clothes during work.

- Protective gaskets - an optional element, but desirable, because. designed to protect the working sole of the "grinder" from premature abrasion.

- Replaceable Velcro - they are used alternately to fix various equipment elements on the platform of the working unit.

Rules for changing circles on the instrument

Due to the fact that the disks for angle grinders have the status of consumables, sooner or later they will have to be replaced. They are fixed on the grinder spindle by means of a clamping flange (or nut) with an M14th thread.A special open-end wrench supplied with the tool, equipped with a one-sided pin, is just designed for fastening operations. Below is a step-by-step instruction for attaching a circle:

- It is necessary to de-energize the tool (by disconnecting the battery or pulling the plug out of the socket);

- By pressing the button located in the front of the housing, fix the spindle of the grinder (the spindle is fixed in a fixed position after the stopper enters the hole of the disk located in the gearbox after pressing the button);

- Next, you need to insert the pins of the key into the clamping flange (or rather, into its holes);

- Holding the latch with one hand, with the other hand, turn the key to the left until the nut moves. Then it can already be unscrewed without the help of a key and removed from the shaft.

- Then you can replace the equipment, after removing the old one (if dust and dirt have accumulated inside the casing, then you need to remove the lower flange and use a steel brush to clean the dirt from all bearing surfaces);

- The next step is to return the flange to its place. It must be fixed properly, all grooves on the flange and spindle must necessarily match;

- Then it is required to place a gasket over the flange (lower). It is not necessary to install it, but it is desirable, because it will help to easily unscrew the clamping nut in the future when you need to replace the equipment;

- Fix the new circle by setting it with the marked side (the side with the information sticker) facing out;

- Install the gasket on top of the abrasive wheel (if the gaskets were not immediately supplied with the grinder, then you can purchase them at a hardware store or you can make them yourself from cardboard or thin tin);

- In the end, it is necessary to screw the flange onto the shaft by hand. The nut should be tightened until it stops until it stops turning without a key. Then, while clamping the stopper, you need to tighten the nut with a wrench, but not more than 1/4 turn, otherwise the circle may be deformed.

- Upon completion of all the above steps properly and in the correct order, the replacement will be considered successful.

IMPORTANT! The clamping flange must always be unscrewed in a direction that is directly opposite to the rotation of the shaft!

Problems arising during operation

It is very easy to increase the service life of a disk - it is sometimes necessary to run it idle, i.e. by air. The incoming air currents will cool the circle and remove some thermal stresses between the working area and the center.

The most common problem encountered when working with angle grinders is the rapid wear of their working area. This is mainly due to incorrect tool selection, increased feed (pressure) speeds, or the general condition of the grinder drive. When there are “beats” in it, the life of the circle is instantly reduced, and in some situations that are relevant for large amplitude fluctuations, it can even collapse. Therefore, in order to avoid such circumstances, the wheel should be used at the recommended speeds with gentle pressure, and any presence of beats should immediately entail the repair of the unit.

With accelerated erasing of the cleaning segments, it is better to simply replace the disc - it is probably not suitable for the material being processed.If the equipment is chosen correctly, but the erasure still occurs prematurely, then the working element needs to be cooled more often, because it can overheat during a long period of operation. A clear sign of overheating can be a change in color at the base of the disk - a blue tint appears.

An immediate replacement of the circle should also follow when obvious bundles appear on its surface. The reason for this may be work with non-core materials or high work intensity. Often, such defects appear during working distortions. Thus, during operation, it is desirable to periodically stop the apparatus.

The operation of the diamond disc is prohibited if the “grinder” has radial or lateral beats, or uneven rotation occurs, or an unauthorized decrease / increase in the speed of circulation. Under such circumstances, the device must be repaired or it is better to use a new one.

You can increase the disk usage resource by following a few simple rules:

- It is necessary to use discs with a large diameter, since in this case the total load on the surface will decrease;

- The angle grinder must be powerful, which will ensure the stability of the output speed;

- It is necessary to correctly select the wheel in accordance with the material being processed;

- Permissible speed should not be exceeded.

Rating of the best cleanup circles for the grinder for 2025

Lower price segment

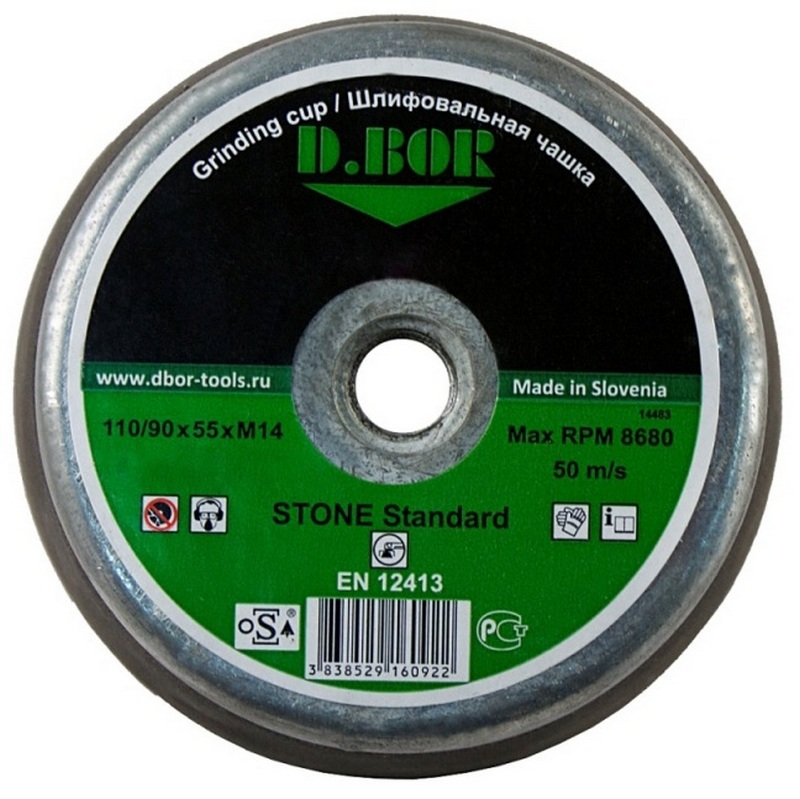

2nd place: "STONE Standard D.BOR D5-F11-C60P-110-M14"

votes 0

The standard cup technology disc is designed to remove a variety of coatings from hard surfaces. The installation diameter corresponds to the M14 nut.The grit is fully adapted to the declared type of work and is large. Dimensions - 60x110x55 millimeters with a weight of 800 grams. The brand is from Slovenia. The recommended retail price is 850 rubles.

- Sufficiently durable material of manufacture;

- Universal mounting diameter;

- Also suitable for grinding operations.

- Small equipment - only one disk.

1st place: "TRIO-DIAMOND 390002"

votes 0

An excellent cup shaped cleaner specifically designed for hardwood, softwood, plastics, aerated concrete and sand-lime bricks and sandstone. It has tungsten soldering applied to the working edge of a flat shape. Can be used for both rough and fine work. It can also be used to decorate various surfaces. Dimensions - 10x200x150 millimeters, weight - 280 grams. The brand is from China. The recommended retail price is 1100 rubles.

- Versatility (work with different materials);

- Possibility of design application;

- Small mass.

- Not detected.

Middle price segment

2nd place: "Bosch 1.608.600.234"

votes 0

An excellent sample from the world famous European brand. Used for processing metal surfaces. It has a maximum diameter of 110 millimeters, which means high wear resistance (because the risk of overheating is significantly reduced). The grit is coarse, respectively, the circle is suitable for rough processing. Dimensions - 110x110x55 millimeters with a dead weight of 680 grams. The brand is from Germany. The recommended retail price is 1300 rubles.

- Max Diameter;

- coarse grain;

- Overheat resistance.

- Narrow specialization.

1st place: "Disk Alpha 770-045"

votes 0

This disc is made of Pobedit, which means its increased strength and wear resistance. It is used for rough grinding work on hard wood, foam concrete, fiberglass and composite materials. As part of the design toolkit, it can process artificial stone and animal hooves. In some cases, it is possible to use on brick and gas silicate blocks. Completely NOT SUITABLE for metal surfaces and hard stones. It is forbidden to work with the end part of the circle. The disk itself is made of high-strength steel, tungsten carbide grains, which are tightly soldered to the body, act as abrasive parts. To achieve maximum effect, it is recommended to properly regulate the speed - the softer the material, the higher it can be (and vice versa). Dimensions - 125x125x22 mm with a weight of 280 grams. The birthplace of the brand is Russia. Retail price for sale - 1500 rubles.

- Tungsten inclusions in the working part;

- Variety of materials for processing;

- Winning base structure.

- There are critical restrictions on the processed materials.

Premium class

2nd place: "Bosch 2608600364"

votes 0

This tungsten carbide grinding wheel is designed exclusively for use on Bosch angle grinders. Coarse-grained coating of hard alloys is applied to the surface. With its help, aerated concrete, fiberglass, hard and soft woods are perfectly processed.It is also allowed to work with sand-lime brick, plastic, sandstone, leather and rubber with varnish. Coarse dispersion allows you to perform a wide range of tasks. The use of the native exhaust hood will make the performance of all operations absolutely devoid of any dust. Dimensions - 150x120x20 millimeters, weight - 270 grams. The brand is from Germany. The price for retail stores is 3100 rubles.

- Universal concave circle;

- Application for design tasks is allowed;

- Quality manufacturing.

- Not found.

1st place: "EIBENSTOCK 37108000"

votes 0

This tungsten carbide disc is of special quality and is designed for fine work. Ideal for use on soft wood surfaces and for removing thin layers of paintwork. Differs in high wear resistance and the strong case. Dimensions - 130x130x10 millimeters with a dead weight of 100 grams. The brand is from Germany. The price set for retail chains is 4100 rubles.

- Strong base structure;

- Tungsten carbide abrasive coating;

- Long service life.

- Narrow specialization.

Instead of an epilogue

An analysis of the state of the current market for roughing and grinding wheels for grinders has established that there is no particular shortage when choosing this toolkit. In any specialized hardware store, their wide range is presented at the proper level, and it is not difficult to choose the right circle according to technical parameters and price index.Regarding the price limits - the lower price segment is occupied mainly by Asian samples, which are characterized by their fragility, but at the same time quite adequately perform their functions for the allotted service life. The middle price segment is divided between European and Russian manufacturers, while domestic enterprises still lose in terms of "price-quality". The upper segment is occupied exclusively by proven Western brands, the cost of which is often too high. The reason for this is the use of innovative technologies in manufacturing and "big names". In addition, the price of such discs may increase due to the extended configuration and use only with native angle grinders. However, they are not in great demand.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131648 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127687 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124515 -

The best men's sneakers in 2025

Views: 124030 -

The Best Complex Vitamins in 2025

Views: 121936 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2025

Views: 113393 -

Ranking of the best wood paints for interior work in 2025

Views: 110317 -

Rating of the best spinning reels in 2025

Views: 105326 -

Ranking of the best sex dolls for men for 2025

Views: 104362 -

Ranking of the best action cameras from China in 2025

Views: 102214 -

The most effective calcium preparations for adults and children in 2025

Views: 102009