Rating of the best bushings for 2025

Sleeve bushings are used in various machines and equipment. Properly selected and made of high-quality material, the sliding sleeve will last a long time and increase the time before the next repair. In the article, we will analyze the recommendations on how to choose the appropriate option for the price and technical parameters. And also what types of bushings are, and which company is better to purchase under various conditions.

Content [Hide]

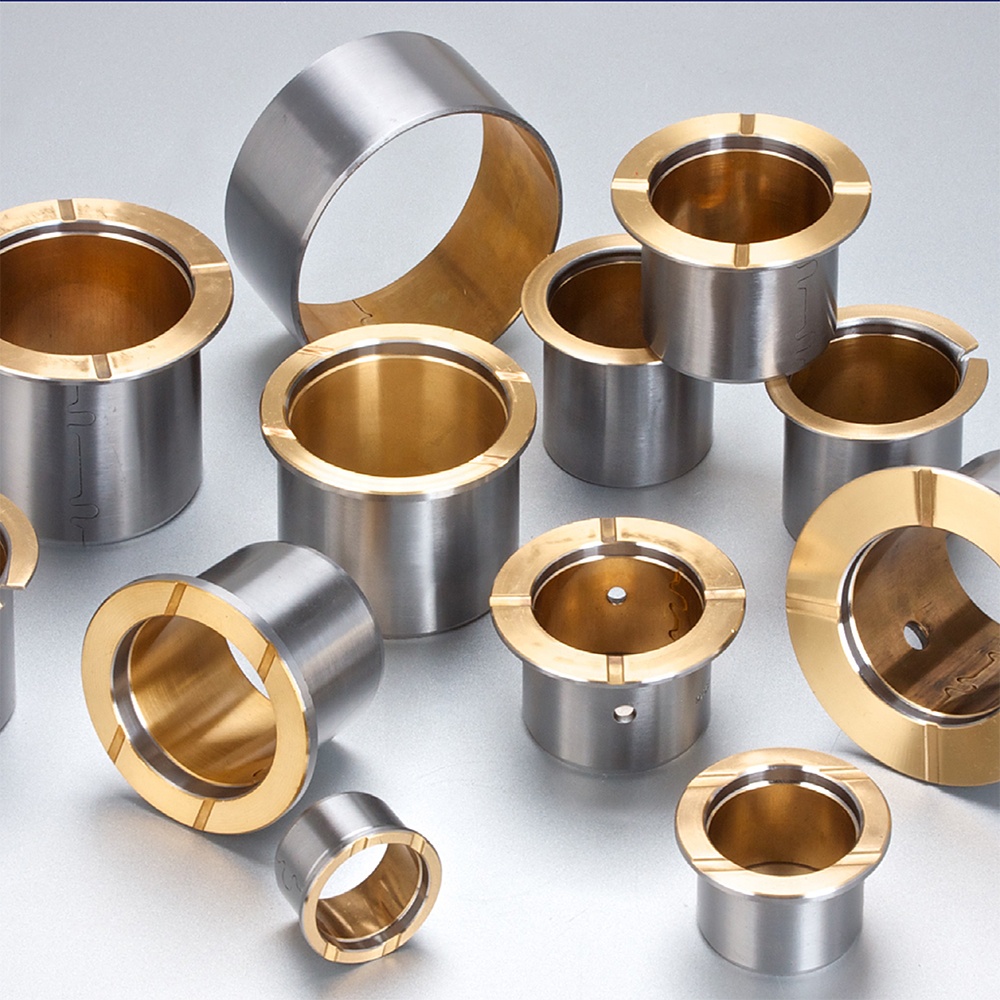

Description

Sliding sleeve - a tubular ring that is installed between the seat in the housing and the shaft. Designed to separate elements that should not be in contact with each other. The sleeve is able to withstand medium loads of the radial type. Such parts are referred to as radial plain bearings.

The bushings are simple in design, work well even in adverse conditions (temperature changes, pollution), but at the same time they may not withstand long rotation at high speed. Easier to maintain than plain bearings and more compact than rolling bearings, with lower load capacity and high friction torque.

They have found wide application in various spheres of human life. They are used in hydraulic type mechanisms, in rotating and rotary mechanisms of industrial equipment, in the mining industry, etc.

Pros:

- the ability to work at high speeds;

- withstands heavy loads;

- installation accuracy;

- the ability to work in aggressive environments.

Minuses:

- in most cases, enhanced lubrication is required;

- it is difficult to fit the required type;

- significant linear dimensions.

Classification

- By production method:

- sintered (powder metallurgy method is used for production. They have a porous structure);

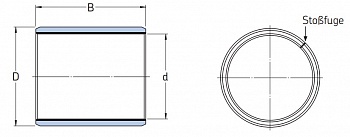

- rolled (folded into a ring from a flat sheet, while a slot remains. The thinnest);

- machined (turned from a workpiece).

- Finished part shape:

- cylindrical (represent a pipe of equal diameter);

- shouldered (for the most part, the parts are of the same diameter, and towards the end they have an extension in the form of a washer (shoulder).

- According to the material of manufacture:

- steel;

- bronze;

- polymeric;

- cast iron;

- made up of multiple materials.

- For service needs:

- serviced (they have nipples for supplying grease. The nipples must be periodically filled with grease);

- maintenance-free (do not require lubrication. They are easier to operate, but have a shorter service life).

- By size:

- metric dimensions (in the beginning is the abbreviation PCM);

- inch dimensions (the designation is PCZ);

- with an additional designation (if B / E designations are present, then the part operates at temperatures from -200 to + 250 degrees Celsius, the designation M indicates that the operating temperature is from -40 to +100 degrees Celsius, while they can provide electrical insulation of parts);

- with flange (designated PCMF).

Polymer sleeves

PBC linear polymer bearings are very popular, their main advantages are:

- vibration absorption;

- chemically resistant composition;

- small mass;

- may have magnetic properties;

- there are options with a built-in seal function, with a cavity to retain grease, etc.);

- universal, they are used in various fields;

- regulate electrical insulation and electrical conductivity;

- can work without lubrication;

- resistant to edge loads;

- can resist ionizing radiation.

Let's look at the properties in more detail:

- Self lubricating, maintenance free. In their composition, they have lubricants in a balanced proportion in the composition of the polymer itself. The microfibers are worn down during operation and thus provide optimal glide.

- Long service life. The polymers have a homogeneous structure, which eliminates the appearance of grooves that reduce the service life. There is no abrasive wear of the shaft, because contains no glass fibers.

- Close to each other static and dynamic coefficients of friction. Continuous operation is carried out even at minimum speeds, and with minimal noise. And if a lubricant is used, then the coefficient of friction will be even less.

- High non-shrinkage. Such bushings do not absorb water, this makes it possible not to take into account the possible change in dimensions during installation. The fiber seal significantly reduces thermal expansion or contraction and improves fit at high temperatures.

- Wear resistance. Such parts have minimal wear even under constant heavy loads.

- Resistant to heavy loads. They withstand great pressure and effort, including edge loads. If you choose the right material, then high pressure is acceptable.

- They have a wide operating temperature range. Depending on the type of material, they can operate at temperatures ranging from -200 to +250 degrees Celsius. However, when buying, you must take into account this indicator, it is indicated in the technical characteristics of the product.

- Improved thermal conductivity. They have an improved fit on the body, thereby providing a higher rotational speed during continuous operation. This is achieved through fiber reinforcement.

Top Producers

- b-ring. A fairly large American manufacturer, factories operate in China, but are guided by Swedish quality standards in production. All products are divided into 3 lines, according to the mileage, and, accordingly, according to the price range. Such spare parts are not often counterfeited, they are of high quality.

- ISB. Italian brand founded in 1981.The company is focused on the middle price segment, which is why their products are very popular in many countries. Of course, such a part cannot fully replace the bushing of an expensive brand, but it copes with its task quite well. A wide range of products also favorably distinguishes the company in the aftermarket.

- INA. German company founded in 1946. Currently part of the Schaeffler Group. Buyers evaluate products at a level above average, the company is constantly improving its potential, updating equipment and introducing innovative developments into production. All spare parts have a large margin of safety.

- SKF. The company was founded in 1907 in Sweden. Today it is the largest manufacturer of bearings, lubrication systems and other spare parts. In Russia, the activities of this company are represented by a subsidiary of CJSC SKF, which has subsidiaries in several major cities of the country.

Criterias of choice

Tips on what to look for when buying:

- Vehicle type. You need to know exactly which type is suitable for your equipment. When ordering, you need to specify such indicators as: car brand, car model, specifications and type of the desired part.

- The best manufacturers. More and more new manufacturers are entering the market, offering innovative new products. The functionality of such components is the same, but the price may vary several times. Carefully study the sales market, long-running firms have a lot of reviews about their products, you can use them to determine which manufacturer does the job efficiently.

- Where could I buy. You can buy it at a car dealership, or order online at an online store.When buying on the site, carefully study the proposed documentation, correlate all sizes and dimensions, only after that place an order. Upon delivery, check the conformity of the delivered goods with the declared.

- Price. Inexpensive (budget) options have the same functionality as more expensive bushings from well-known brands. It’s not worth overpaying for fame, choose the right part based on your needs and capabilities.

- Kinds. Be sure to select the exact dimensions (length, width, height) and the appropriate type of bushings (with or without a collar; bronze or steel, etc.).

- Material. The quality of the material directly affects the durability of the part. Therefore, be sure to check the compliance of the part with quality standards before buying. The seller is obliged to provide you with the necessary certificates.

Rating of quality bushings for 2025

The rating includes the best bushing models, according to buyers. The popularity of models, review and consumer reviews were taken as the basis.

The best models from a domestic manufacturer

HDB-10 (SF-1)

votes 0

The part has an increased load capacity, high slip and low coefficient of friction. Lightweight and compact material, minimum overall dimensions and ease of installation allows you to install the part quickly and efficiently. Used for a wide range of hydraulic applications. Average price: 30 rubles.

- ease of installation;

- low level of vibration, noise, environmental pollution;

- low resolution and high conductivity.

- not identified.

| Characteristics | Description |

|---|---|

| Manufacturer | CJSC SMS |

| Dimensions (mm) | 28x32x20 |

| Load capacity (N/mm2) | 140 |

| Operating temperature (degrees) | -195 to +280 |

Sleeve sleeve VTS-101

votes 0

The company produces components for industrial enterprises in Russia. The production time depends on the quantity of the order and its complexity, and averages 7 days. The average price range is from 40 rubles to 3,000 rubles.

- for mass production;

- optimal price;

- reliable manufacturer.

- not identified.

| Characteristics | Description |

|---|---|

| Manufacturer | CPM |

| Material | alloy steel |

| Dimensions | will offer any size according to the scheme of the client |

BrO5S25 (OOO OZIL)

votes 0

The term of production of the plug under the order makes 3-20 days. A variety of services offered and an acceptable pricing policy favorably distinguishes this manufacturer from competitors in the market. Average price: from 85 rubles.

- durability;

- uniqueness;

- wide functionality.

- long production time.

| Characteristics | Description |

|---|---|

| Manufacturer | OOO OZIL |

| Type of | bronze, brass, copper |

| Type of casting | centrifugal chill mold |

OOO "YAZSA"

votes 0

The Yaroslavl Plant of SpetsAgregatov will manufacture various types of bushings, including sliding bushings, from various materials (polymer, steel, bronze, etc.). Dimensions (length, width, height) are provided by the customer, or standard sizes are taken. All products comply with international standards (DIN; ASME; ANSI). The price will depend on the dimensions and parameters required by the customer.

- quality assurance;

- modern technologies;

- a large assortment.

- not identified.

| Characteristics | Description |

|---|---|

| Manufacturer | OOO OZIL |

| Type of | bronze, brass, copper |

| Type of casting | centrifugal chill mold |

The best models from a foreign manufacturer

ISB KU2015SF1SN23 (PCM202315E)

votes 0

The bushing is used for cars, agricultural machines, motorcycles. Bronze-plated steel body for durability. Brand origin: Italy. Cost: 58 rubles.

- self-lubricating;

- wide application;

- high operating temperature.

- not identified.

| Characteristics | Description |

|---|---|

| Inner diameter (mm) | 10 |

| Outside Diameter (mm) | 23 |

| Width (mm) | 15 |

PCMF 101209 E

votes 0

The company from Sweden manufactures high quality products at a fairly low cost. Flanged model made of composite with PTFE. Average cost: 44 rubles.

- wear-resistant;

- high quality material;

- with flange.

- hard to find on the market.

| Indicators | Meaning |

|---|---|

| Inner diameter (mm) | 10 |

| Outside Diameter (mm) | 12 |

| Width (mm) | 9 |

| Weight (g) | 3 |

EGB 2030-E40-B-Y

votes 0

Maintenance-free part, with bronze base. Brand: INA. It is intended for the perception of jointly acting external loads, such as axial load and axial load. Has the ability to self-install. Cost: 236 rubles.

- famous brand;

- low creep deformation;

- high wear resistance.

- price.

| Indicators | Meaning |

|---|---|

| Inner diameter (mm) | 20 |

| Outside Diameter (mm) | 23 |

| Width (mm) | 30 |

| Weight (g) | 25 |

| Production material | bronze |

PCM 505540 E

votes 0

The detail has wide application in various fields of activity. With proper and timely maintenance, it will last a long time, thereby increasing the life of the machines. Cost: 700 rubles.

- wear resistance;

- great functionality;

- famous manufacturer.

- price.

| Indicators | Meaning |

|---|---|

| Inner diameter (mm) | 50 |

| Outside Diameter (mm) | 55 |

| Width (mm) | 40 |

| Weight (g) | 12.8 |

| Technical description | without flange |

ISB KU1625SF2 (PCM161825M)

votes 0

Bronze coated steel bushing. Used in mining and metallurgy. Outer diameter: 18mm, inner diameter 16mm, width 25mm. Brand country: Italy. Model without flange. Cost: 55 rubles.

- durable, due to the bronze coating;

- optimal price;

- reliable manufacturer.

- without flange.

| Indicators | Meaning |

|---|---|

| Max speed (m/s) | 2.5 |

| Hole diameter (cm) | 0.4 |

| Load capacity (N/mm²) | 70 |

| Maximum dynamic load (N/mm² * m/s) | 22 |

| Friction coefficient without lubrication | 0,05-0,25 |

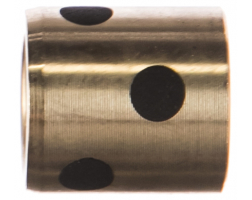

ISB BNZ101415BG1

votes 0

A bushing without a flange is used in the mining industry, shipbuilding, for hydraulic turbines, etc. Brass products are quite durable, less susceptible to corrosion. Withstands temperatures up to 300 degrees, and a maximum load of 100 N / mm². Cost: 864 rubles.

- high resistance to corrosion;

- small coefficient of friction;

- ease of installation.

- not identified.

| Indicators | Meaning |

|---|---|

| Inner diameter (cm) | 0.14 |

| Outside Diameter (cm) | 0.1 |

| Width (cm) | 0.15 |

| Material | brass/graphite/bronze |

ISB KF1007SF1SN

votes 0

Model made in Italy, with flange. It is used in hydraulic vehicles (cars, motorcycles, agricultural machines). Production material: steel (with bronze coating). Operating temperature range: -195°C to +280°C. Cost: 127 rubles.

- famous brand;

- high quality material;

- great wear resistance.

- not identified.

| Indicators | Meaning |

|---|---|

| Inner diameter (mm) | 10 |

| Outside Diameter (mm) | 12 |

| Width (mm) | 7 |

| Flange diameter (mm) | 18 |

| Weight (g) | 3 |

In the article, we examined the popular models of sliding bushings, how much each option costs, and which one is better to buy. We also sorted out mistakes when choosing, and what to look for when buying.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127688 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124516 -

The best men's sneakers in 2025

Views: 124030 -

The Best Complex Vitamins in 2025

Views: 121937 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2025

Views: 113393 -

Ranking of the best wood paints for interior work in 2025

Views: 110318 -

Rating of the best spinning reels in 2025

Views: 105327 -

Ranking of the best sex dolls for men for 2025

Views: 104363 -

Ranking of the best action cameras from China in 2025

Views: 102214 -

The most effective calcium preparations for adults and children in 2025

Views: 102010