Rating of the best air ducts for 2025

A quality ventilation system should be in every home. Due to it, a regular influx of fresh air is carried out, which eliminates stagnation indoors and the formation of mold. Laying of ventilation ducts is carried out at the stage of building construction. The movement of flows occurs through ducts. Based on the designated functionality, devices may differ in material, parameters and design.

Content [Hide]

Why are they needed and what are

In the process of planning the ventilation structure, attention should be paid to the air channels. The reliability of the entire complex will depend on the correct choice, equipment reliability, efficiency and installation of the device. Air ducts are a type of channels that are used for laying ventilation. Due to them, air masses move in a certain direction.

Thanks to properly installed equipment and components, oxygen enters the premises located in private houses and industrial facilities, and pollution and exhaust air masses are removed.

The best manufacturers have made sure that the user himself can regulate the flow rate and pressure indicator through valves. To solve the main problems, several ways to solve them have been identified:

- Supply and exhaust design. According to buyers, it is considered one of the most effective ways to solve the problem. To do this, you need to lay two channels at a respectful distance from each other. One of them will remove polluted masses, while the second will supply fresh air.

- In the second case, clean air will enter the premises through windows, doors or specially equipped openings. To remove contaminated masses, a separate exhaust channel is installed and used.

Often, when arranging a ventilation system, several types of air ducts are used simultaneously. In the complex, they represent a full-fledged network with a huge number of branches, shafts and branches.

Requirements and selection criteria

The designed and installed air circulation structure must cope with the designated tasks and functions. To do this, you must adhere to some requirements. Among them:

- Indoors, the device should occupy a minimum amount of usable space.

- Fit and existing interior.

- Compliance with the norms regarding thermal insulation.

- Another recommendation is to create such an installation that could withstand the operating pressure inside the structure, taking into account a small margin of safety.

- Performance. Mounted devices must not interfere with the passage of a certain volume of oxygen at a strictly designated speed (calculated in each case separately).

- During operation, there will be a characteristic aerodynamic noise that inevitably occurs during the operation of systems of this type. Even the best and most expensive models are not able to eliminate this inconvenience. However, the noise figure should not exceed the norm (sanitary) established by the state.

- The design must be completely sealed. Otherwise, its effectiveness will be significantly reduced.

Depending on the installation location and other subtleties, other requirements may be imposed on the equipment, which are mandatory.

Feature overview

To date, the buyer has access to many different solutions for building a complete ventilation system. A modern online store offers over a hundred different solutions that allow even an uninitiated person to purchase a high-quality design. In order not to make mistakes when choosing, you should listen to the opinion of experts. Products vary in:

- method of insulation (popular models are equipped with insulation initially, in other cases, manipulations are carried out after installation is completed);

- section diameter;

- sizes;

- channel cross-sectional shape;

- material of manufacture;

- hardness index.

However, when calculating the budget, it is necessary to understand that in addition to the ducts themselves, auxiliary components, maintenance and installation costs will be needed. It should be noted that despite significant costs, further savings are obvious. The main materials are often used:

- stainless steel (stainless steel);

- steel (galvanized);

- plastic;

- corrugated pipes;

- aluminum.

Advantages and disadvantages of materials

In the process of arranging the system, it is possible to use various materials. Often the choice stops on plastic or steel structures. The first option for kitchen hoods is not recommended, since significant heating is implied during operation. For achievement of the maximum indicator of efficiency combination of materials is possible.

| Construction type | Flaws | Advantages |

|---|---|---|

| Flexible | Fragile and fragile items. Soot, fumes and dust massively accumulate on the surface. Due to the presence of a corrugated surface, the flow rate is reduced. | Operation at temperature range -30°С - +120°С. Possibility of taking any form. Compress and stretch to desired length. |

| Plastic | Materials are classified as fire hazardous. Low temperatures lead to the destruction of the structure due to the fact that the material becomes brittle. | Durability at an affordable cost. Increase in speed due to the presence of smooth walls. Low noise level. Ease of installation due to low weight of key components.High aesthetic value. |

| metal | Significant weight of the product, which complicates the installation process. During the installation process, you will need specialized tools (expensive) that will make it possible to achieve tight connections. High noise. | UV resistant. Tolerance to significant temperature changes. High speed of transportation of air masses due to the presence of a smooth surface. Does not contribute to the accumulation of dirt. High strength and service life. |

Rating of high-quality air ducts with a flexible duct

There are corrugated and spiral. Lightweight structures, the frame of which consists of steel wire. The walls are covered with polyester or foil. Installation belongs to the category of simplified, due to the ease of transportation and connection. Corrugated products are able to stretch and shrink a huge number of times and bend at different angles. The disadvantages include poor soundproofing qualities, delays in the passage of air masses and a low indicator of structural strength.

ERA 15-PF 150 mm, round

votes 3

This popular model will be needed for the installation of exhaust and supply ventilation systems. High-strength plastic is used as the main material, which belongs to the category of fireproof (flammable). The frame of the spiral type consists of steel wire. In subsequent use, the design proved to be safe. Country of origin - Russia. In addition, it should be noted that finding auxiliary components and replacing individual components is somewhat easier when it comes to a domestic brand. You should also pay attention to the fact that the price of such products will be more profitable than foreign analogues.

The average price is 500 rubles.

- movement of air masses up to 30 m/s;

- wall thickness - 0.12 mm;

- operating temperature range -30°С — +100°С;

- excellent compression ratio.

- the novelty is not made of particularly durable materials;

- additional care and cleaning is required.

ERA 12.5 PF 125 mm

votes 0

An inexpensive model is also used for the installation of exhaust and supply structures. Flame-resistant plastic is used as the main raw material. For the manufacture of the frame part, steel wire was used. Recognized as completely safe for apartments and private houses. It is this model that is better to buy for arranging round ventilation ducts. With its help, you can adjust the process of airing a room of any type, size and location.

Special attention deserves a special type of plastic, which is based on a polymer of vinyl chloride (thermoplastic). It should be noted excellent resistance to various solvents, acids, oils (mineral) and alkalis. In air, the raw material is not subject to the combustion process. The frost resistance index is insignificant -15 ° С. Withstands heating up to +66° (without visible deformation).

You can buy a kit for 480 rubles.

- movement of air masses at a speed of 30 m/s, but not more;

- wall thickness 0.12 mm;

- operating temperature range -30°С — +100°С;

- excellent compression ratio;

- PVC flexible elements;

- spiral frame based on high-carbon steel wire.

- for fastening structures to each other, you will need auxiliary devices of the same diameter and from the same brand.

ERA 10-PF 100 mm

votes 0

Flexible and round air duct, related to the budget segment.It is considered an integral element of any exhaust and supply ventilation. Like many other flexible conduits, safe plastic is used for manufacturing, as well as a spiral-type steel frame, which consists of high-carbon wire. Recognized as completely safe for both private houses and storage facilities.

What is the price? 210 rub.

- operating temperature range -30° - +100°С;

- ease of installation (assembly);

- elasticity of key components of the system;

- small weight of air ducts;

- if necessary, you can use the "triple lock".

- connecting elements of the appropriate diameter, based on numerous reviews, are best purchased together with flexible channels.

ELIKOR VG-1

votes 0

A flexible type air duct used to create high-quality air conditioning systems for rooms of various types, sizes and locations. The product is corrugated, flexible, with a channel diameter of 150 mm. It should be noted that the air duct is aluminum, round and corrugated. Accessories can be ordered online if needed. It is enough to first read the description of the product on the manufacturer's website, and choose the kit that best suits the dimensions and has the necessary functionality.

The price of the kit is 800 rubles.

- designed to remove polluted air from the premises;

- the material is corrugated and is characterized by increased elasticity;

- complete set;

- excellent technical characteristics;

- appearance;

- if necessary, individual components can be replaced.

- for installation you will need a clamp, a fitting with a grate.

ISO 203

votes 0

It should be noted that the product is insulated, so its cost is more than justified.Diameter - 20.3 cm. The set consists of an air duct with a length of 10 m. For the manufacture of a similar design, an air duct of the FDA series is used, an auxiliary heat-insulating layer based on polyester non-woven fiber. The thickness of the padding polyester is 2.5 cm. The outer cover is made of a metallized film and a polymeric laminated tape. It should be noted the ease of installation in the process of connecting to oval and round channels. As a binding component, in the process of lamination, a composition based on synthetic polymers is used. The combustion process will not release toxic gases. It is this company that is better to buy an air duct for your own home.

Price - 1700 rubles.

- total weight 8.8 kg;

- operating temperature range -30°С — +140°С;

- the flow rate declared by the manufacturer is 30 m / s (average);

- product thickness 30MKM+25mm+30MKM;

- pressure indicator 2500 Pa.

- price.

Aluminum flexible 12.5 VA

votes 0

The design belongs to the category of flexible. It is used for the arrangement of air conditioning and ventilation systems, exhaust, as well as durable structures. The basis is aluminum foil - a lightweight, flexible material that is able to cope with the tasks. A triple lock is used for connection. Spiral hinged design.

Cost - 150 rubles.

- operating temperature range -30°С — +300°С;

- foil 80 microns thick;

- the main material is aluminum foil;

- ease of installation;

- elasticity;

- light weight.

- to attach individual components, special fasteners are required.

Rating of the best models with a hard channel

Sound insulation and strength indicators are maximum.Mounting methods, weight and cost are almost the same.

ERA 511-VP

votes 0

A quality product from a renowned manufacturer. The model is suitable for systems with a rectangular cross section. It is used for arranging exhaust and supply ventilation systems. In the presence of special connecting elements, it is possible to attach the structure to previously installed equipment. It should be noted that the selected elements must have the same cross section. They belong to the category of inexpensive, besides, they are easy to repair later. PVC is used as raw material. Based on the declared characteristics, elements with a diameter of 55x110 mm are the most popular. Belongs to the category of hard channels.

Cost - 230 rubles.

- main material - PVC (white);

- element width 110 mm;

- element height 55 mm;

- rectangular section;

- the diameter can be 110 mm, 1000 mm, 100 mm or 500 mm;

- can be used to design flat systems;

- length 50-2000 mm;

- The package contains 35 elements placed in a thermal bag.

- you will need an auxiliary kit with the appropriate cross section.

Vents 8020

votes 0

Flat channel, which is used for rooms for various purposes. With it, you can easily equip supply and exhaust ventilation. Ceiling mounting is allowed, provided that the ceiling will need to be lowered to a minimum. Offered in white. Made from PVC. The permissible length of the channels is 2 m, 1.5 m, 1 m and 0.5 m. The channels can have the following cross section:

- 204x60 mm;

- 120x60 mm;

- 110x55 mm.

Tees, angles and other auxiliary elements are used as connecting elements.

Price - 640 rubles.

- rectangular shape;

- hard type air duct;

- PVC (light weight);

- it is possible to create flat channels;

- suitable for arranging any type of premises;

- ease of installation work.

- not identified.

ERA 320-VP

votes 0

Straight section device 60x204 mm. It is used for arranging exhaust ventilation and supply air. Structures are classified as rigid. The surface of the model is smooth, which affects the resistance of air masses. The noise figure is significantly reduced. During operation, there will be no extraneous sounds. A well-thought-out model allows you to assemble a system of any shape and level of complexity. For the manufacture of high-quality plastic is used, characterized by resistance to aggressive environments and impact resistance. Also, the product is immune to atmospheric phenomena. The material is practically not subject to combustion and is able to withstand significant temperature changes.

Price - 430 rubles.

- neutral white color;

- high strength plastic;

- fireproof;

- shockproof;

- weather resistant;

- low noise level.

- you will need auxiliary connecting elements of a certain size (diameter).

ERA 12.5-VP 125 mm

votes 0

Scope - the creation of exhaust and supply ventilation in buildings and structures for various purposes. The surface of the elements is smooth, which favorably affects the resistance of air masses. The noise level during operation is low. The declared design features allow you to create a ventilation system of any shape, size and level of complexity.For manufacturing, high-quality plastic is used, which guarantees a high rate of resistance to aggressive environments, impact resistance and the ability to withstand any weather conditions. The material is hardly flammable and is able to withstand significant temperature changes.

Cost - 320 rubles.

- country of origin - Russia;

- light weight;

- PVC as main material;

- excellent indicators of quality and resistance to external factors;

- allows you to make a design of any complexity.

- for installation, connecting devices of a certain diameter are required.

ERA 15-VP 150 mm

votes 0

Such an air duct will make an excellent exhaust or supply ventilation, which can be installed in buildings and structures of any size and purpose. If necessary, you can always purchase additional elements and install in an existing system, thereby expanding it or improving it. However, this will require structures of the same type and size. With their help, you can collect round channels of any length.

Cost - 400 rubles.

- brand registration country - Russia;

- high-strength white PVC;

- the possibility of choosing the optimal diameter;

- the length of the channel will be 0.5-2 m;

- a triple lock is used for connection;

- operating temperature range -30°С — +100°С;

- ease of installation;

- light weight.

- additional fasteners will be required.

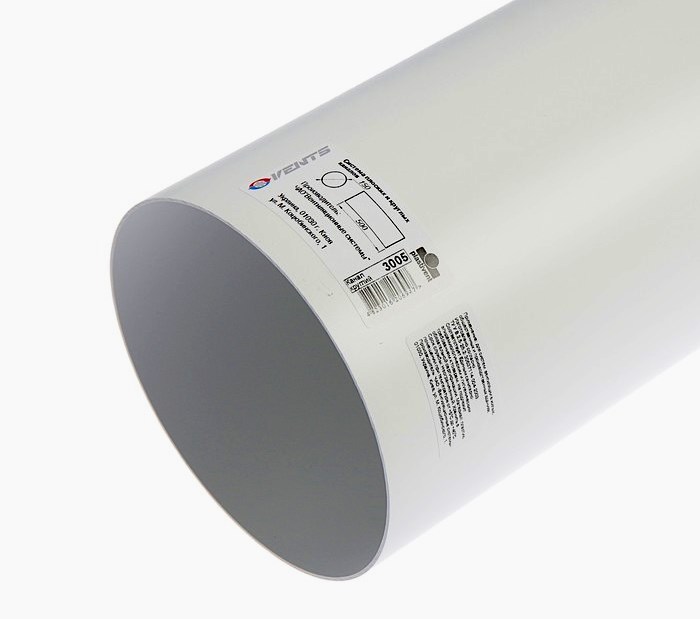

Vents 3005 150 mm

votes 0

Plastic elements with a round cross section, which are used to equip ventilation systems in medium and small-sized rooms.Also, with the help of the Vents 3005 model, you can connect an extractor hood in the kitchen. For connection, auxiliary elements with a diameter of 100-200 mm will be needed. The manufacturer uses white PVC as the main material. It has a length of 0.5 m. The diameter of the outer part is 153 mm. Inner diameter - 150 mm.

Price - 200 rubles.

- supplied in thermal packaging;

- if necessary, the manufacturer makes independent calculations and design of the future ventilation system;

- acceptable cost;

- structural strength;

- operational period;

- ease of installation;

- neutral color;

- light weight.

- not identified.

Requirements regarding the installation of air ducts

Before proceeding with the design and installation of the ventilation system, experts advise you to familiarize yourself with such regulatory documents as SP 60.13330 and SP 73.13330.2012. Based on the content, we can come to the following conclusions:

- If it is planned to lay through the walls, you will need to use special adapters and metal sleeves.

- Places where elements come into contact with the ground (ground floors or basements), as well as concrete structural elements, then the choice should be made in favor of rigid pipes.

- Semi-rigid and flexible elements should not be used if their vertical segment will have a length of two floors or more.

- No sagging of individual elements, as well as sleeves, should be observed.

- During the installation of flexible products, they must be in a fully expanded (stretched) position.

It should be noted that in order to install an effective exhaust system in the kitchen in an apartment building, it is possible only on the top floor.We are talking about the connection of air ducts to a source of natural ventilation. Otherwise, the installation of forced ventilation is prohibited. It is also not superfluous to entrust all the necessary calculations to professionals who are better versed in the intricacies of the upcoming manipulations.

Conclusion

Forced type of ventilation allows you to eliminate extraneous odors, toxic fumes and moisture from the room. This type of device is considered to be the best solution for a private home. When installing products in apartment buildings and high-rise buildings, special requirements apply, which should be familiarized with at the initial stage of planning the system. The outlet for the hood is connected to a common duct system, so stagnant air masses are released into the street. For each type of building, different laying schemes are used, the design of which should be handled by specialists.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127688 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124516 -

The best men's sneakers in 2025

Views: 124030 -

The Best Complex Vitamins in 2025

Views: 121937 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2025

Views: 113393 -

Ranking of the best wood paints for interior work in 2025

Views: 110317 -

Rating of the best spinning reels in 2025

Views: 105327 -

Ranking of the best sex dolls for men for 2025

Views: 104363 -

Ranking of the best action cameras from China in 2025

Views: 102214 -

The most effective calcium preparations for adults and children in 2025

Views: 102010