Rating of the best air coolers for 2025

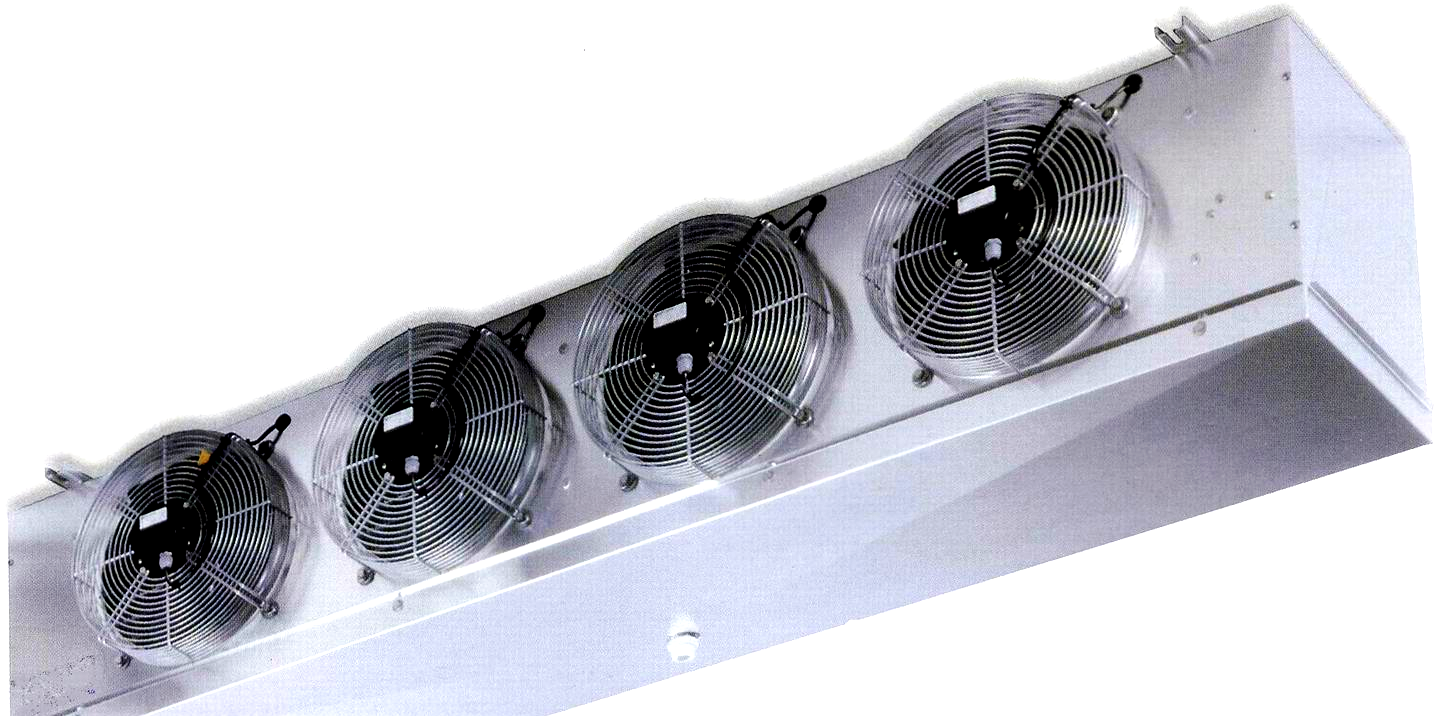

The heat exchange unit, whose task is to cool the air, is called an air cooler. The best models of air coolers will be discussed below.

Content [Hide]

Installation

Before installing such equipment, it should be noted that the installation of duct coolers is carried out exclusively in a horizontal position. This position contributes to improved condensate drainage. When using water as the main substance, it is recommended to carry out installation in heated rooms (plus temperature). Also, manufacturers and numerous users advise using a siphon (hydraulic valve) to avoid unpleasant odors.

It should be noted that the distance to the bend should not be less than the diagonal of the selected cooler model.

Connecting the air outlet and preventing it from freezing

In order to prevent irreparable things from happening, during the installation process, you must adhere to some rules:

- The liquid is drained at sub-zero temperatures if it does not contain antifreeze.

- The climatic conditions for each of the regions are different, therefore, when choosing an antifreeze refrigerant, its temperature must be below the indicated limit.

The main selection parameters and functionality of duct air coolers

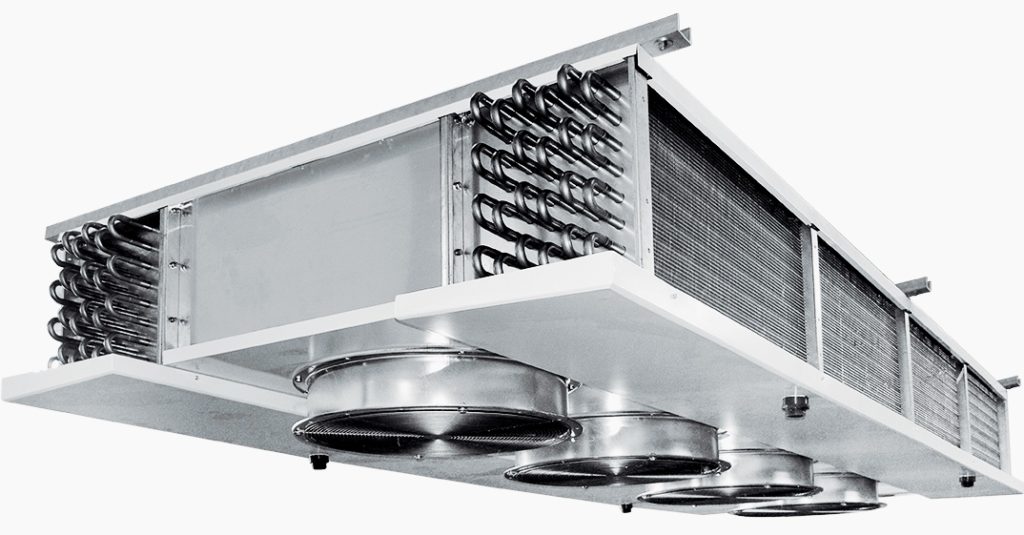

As with the principles of operation of other cooling devices, it is very straightforward. Inside the device, air from the room enters forcibly (is sucked in), where it comes into contact with the evaporator, or rather, its surface. The laying of such communications is carried out at the initial stage of construction. After the air masses are cooled to a certain temperature and distributed throughout the premises. Any material can be inside the evaporator. Often we are talking about freon, which can be found in refrigerators.

However, water coolers should not be ignored either.The main mistake when choosing a material is the lack of sufficient information regarding the compositions used. Freon structures are able to cool the flow faster and more efficiently. However, structurally they are somewhat more complicated. In addition, they differ significantly in cost. Freon leakage can not only harm human health, but also lead to many other unpleasant consequences.

Other important selection criteria include:

- Ease of installation.

- Reliability in use.

- Low noise during operation.

- If necessary, other structures can be used to help absorb noise.

- In a short period of time, the device is able to pass a huge amount of air through itself.

- Compactness.

- The ability to install units in the ventilation structures of buildings and structures.

In the kit you can find a drop eliminator and a heat exchanger. Rapid air exchange guarantees a regular supply of fresh air to rooms where people are. Structurally, it consists of a huge number of copper tubes, inside which the selected substance circulates. Dimensions of the device may vary depending on the capacity of the cooling device and customer requests. The drip catcher consists of plastic plates that collect condensate in a tray specially placed below.

Features of choice

You should pay attention to the fact that a high-quality step-by-step instruction will allow you to do the installation yourself (on your own). However, this is not recommended if a person does not have the necessary amount of skills and knowledge. Otherwise, the design safety index will be low.The best manufacturers recommend that when choosing a model of an industrial design cooling unit, pay special attention to some aspects.

| What to pay attention to first | What to pay attention to second |

|---|---|

| Fluid and air flow. Applicable to water air coolers. | Device weight. |

| Power indicator. | Outlet temperature. |

| Types of popular models. For home or industrial premises. | A measure of the fluid pressure inside a structure. Applicable for aqueous media only. |

Channel options are mounted in residential buildings. However, if necessary, industrial samples can also be purchased. Thus, the building will be provided with more intensive cooling of large rooms or free spaces. There are several types of structures and they are divided according to their characteristics, performance and installation method (ceiling). Design and appearance will play any role only if the installation is carried out in a public place (floor) where everyone can see it. Color also does not carry any functional load. You can get acquainted with brands and the opinions of customers in one of the many online stores.

Water or freon?

A feature of coolers with freons is the presence of freons in a compressed form inside the heat exchanger. When repairing a complete disassembly will not have to be done. It is enough to check the tubes inside which freon is compressed. This contributes to the start-up of the compressor and condenser equipment. Often, filler grades 22, 410 and 407 are launched into the design. The main feature of such freon is the ability to cool air masses of any volume in a short time.The negative characteristics include the tendency to complete freezing.

Water structures are filled with liquid. Glycol is used as an auxiliary component. In addition to the function of cooling, such an installation can dehumidify the environment. Installation is carried out in channels of rectangular and round section. In terms of efficiency, they are inferior to freon ones, but they are much more comfortable in operation. It is worth paying attention to this in order not to make mistakes when choosing high-quality and reliable equipment.

Rating of quality water systems

Water structures are used in channels that have a rectangular or circular cross section. The filling is identical to that used in popular freon models. It should be noted that it is possible to manufacture the structure according to individual measurements in case the dimensions of the channels do not belong to the typical category. In order to place an order, you will need to contact the brand representatives by phone or fill out the proposed electronic form.

WHR-W 1000 x 500/3 Shuft

votes 0

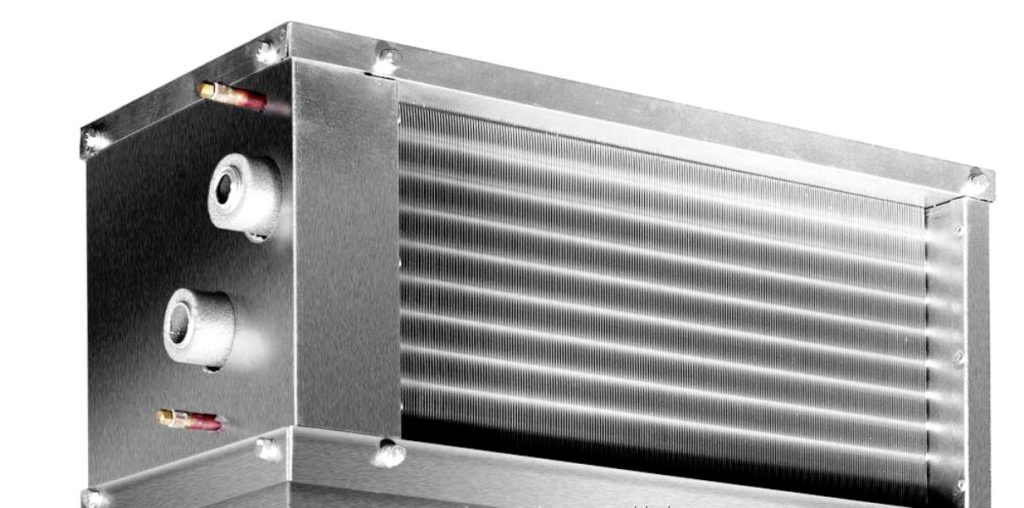

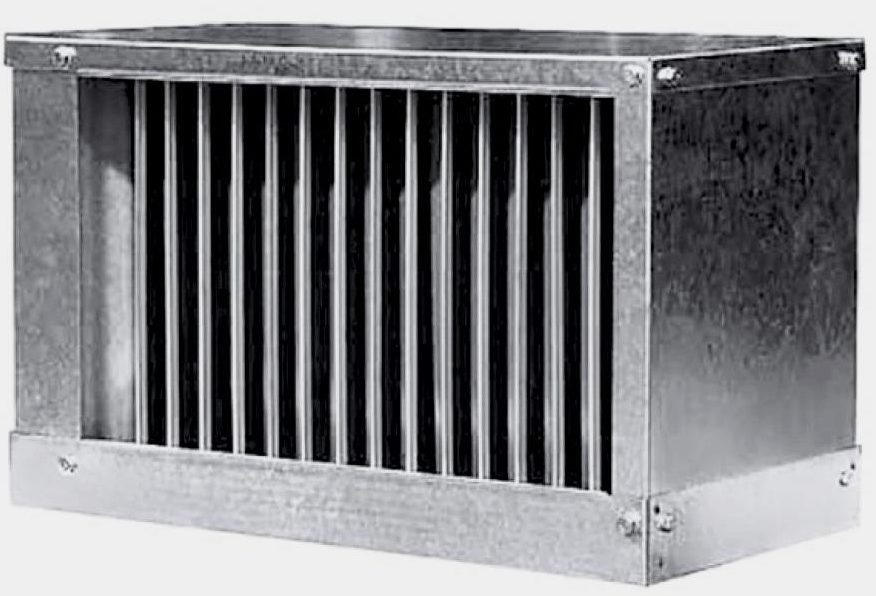

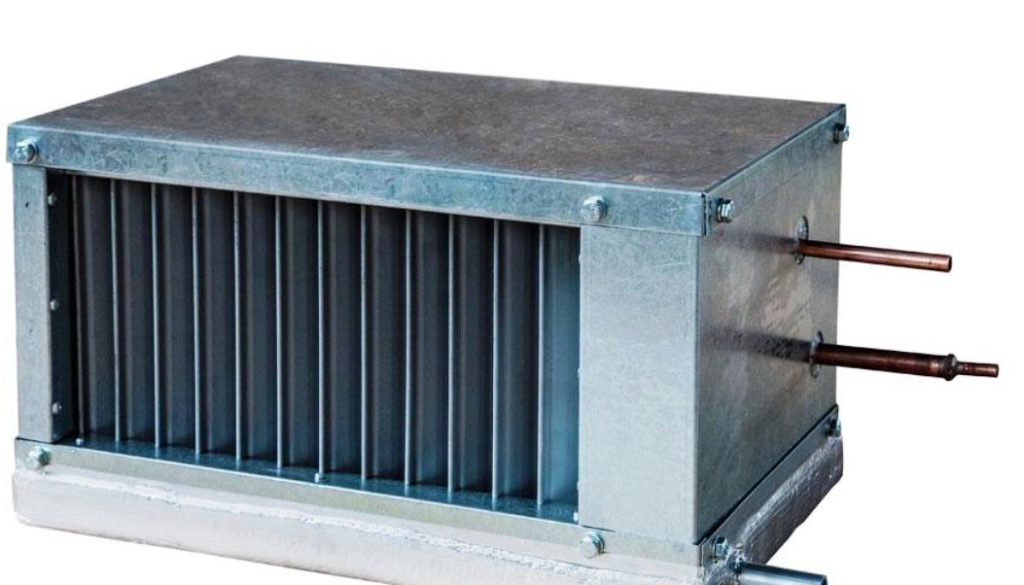

Installation is carried out in rectangular channels in industrial, public and residential premises that need to suppress the supplied air masses. The housing is made of high quality galvanized sheet steel. The heat exchanger is made of copper pipes. Three-row execution is considered standard. The approved pitch is 2.1 mm. Thus, the manufacturer managed to increase the heat transfer rate and optimize the weight and dimensions with insignificant aerodynamic resistance of the heat exchanger. The pipes are mechanically expanded to increase heat transfer. In addition, they are connected to the fins.

Solders with silver elements are used for soldering rolls, which guarantees a high strength result.Any composition can be used as a coolant. The permissible operating pressure inside the system is 16 bar. Production tests are carried out at a pressure of 24 bar. For the manufacture of the drop eliminator, segments of a plastic profile are used with a step of 33 mm and a width of 100 mm. The profile has a curved section, which allows you to retain the required amount of moisture.

The accumulated moisture is displaced to the pallet made of galvanized steel. Its outer part is made of heat-insulating materials. The refrigerant is supplied in the standard way. By changing the coolant, the temperature is regulated to the set indicators. Often, such a function is realized by mixing the heated and cold streams in the mixer assembly.

The average price of a product is 33,000 rubles.

- three-row execution;

- built-in type pipes;

- eight standard sizes;

- heat-insulating material that covers the outer part of the pallet;

- the heat exchanger is made of copper and aluminum;

- installation in a common channel;

- fin pitch 2.1 mm;

- body made of high-strength steel (galvanized).

- not identified.

RW 100-50

votes 0

Time-tested household model from a popular manufacturer. It is used for cooling air masses and other safe (non-explosive) liquids and gases, which do not contain harsh abrasive, fibrous and sticky impurities. Installation is carried out in a rectangular duct duct. Non-freezing compositions or water can be used as a heat carrier. It should be noted that the maximum pressure inside the system will be 1.5 MPa.

Can be purchased at a price of 47,000 rubles.

- universality;

- efficiency;

- acceptable cost;

- ease of use;

- fast installation;

- no need to purchase auxiliary equipment and components.

- a small selection of coolants.

CHV 90-50

votes 0

The water type cooler is made on the same principle as other popular models. The tension pitch between the aluminum plates is 2.1 mm. The diameter of the used copper tubes is 1 cm. A high-strength galvanized sheet is used for the manufacture of the body. If necessary, if the system is made to order, then the buyer can choose stainless steel instead of galvanized sheets. With the help of SUMX nodes, the device is adjusted. The system is designed in such a way that the rate of temperature drops of the transported air masses will be dt 10°С, and liquid surges 6/12°С. Calculations and selection of components that are offered to the customer in the form of a comparative table are carried out by REMAK. Execution "left" — standard.

You can buy in any online store for 39,000 rubles.

- efficiency;

- price;

- high quality materials;

- famous brand;

- several stages of testing;

- installation method.

- left-hand execution in the direction of the droplet eliminator and the movement of air masses as standard (other variations on request).

PBAR 1000×500-3-2.5

votes 0

It is used for cooling air masses in systems with a rectangular cross section. For the manufacture of the case, sheet steel is used, which is covered with a protective layer of zinc. Inside there is a heat exchanger, which consists of many copper tubes with aluminum fins, as well as a droplet separator and a drain pan. The fins have a pitch of 2.5 mm. There are auxiliary flanges on both sides of the body.With their help, additional elements of duct ventilation are attached. The condensate leaves through a galvanized pipe, which is presented in the form of a branch pipe. Its thread is ½. Permissible pressure inside the system is 3.0 MPa. During production, the structure is tested under conditions of 3.3 MPa.

It is recommended to additionally install a siphon in the process of connecting to the drain of the cooler pan. This will help to avoid the appearance of unpleasant odors in the premises.

How much does the kit cost? About 54,000 rubles.

- ergonomics;

- efficiency;

- the ability to order a custom-made system, according to individual measurements;

- structural strength.

- not identified.

PGK 100-50-3-2.0

votes 0

The model does not belong to the budget category. Based on the description provided by the manufacturer, the unit is installed in rectangular ducts. One of the best and highest quality samples on the market. For the manufacture of used sheet steel, which is covered with a protective layer based on zinc. Also noteworthy is the presence of aluminum fins on copper pipes. The kit includes a drain valve and an air release valve. The pallet is made of stainless steel, which is equipped with a special pipe that is responsible for removing moisture. Permissible pressure indicator - 16 bar or 1.6 MPa. Hydraulic connections can be on the right side and on the left. The model can be ordered online. If necessary, you can conclude a contract with subsequent maintenance. There are also two service hatches in the hull.

The price of the kit is 173,000 rubles.

- ease of installation;

- auxiliary structural elements are included;

- it is possible to manufacture equipment according to individual measurements;

- high service life;

- The equipment has stood the test of time.

- price.

CWK 400-3-2.5

votes 0

Water type air cooler. It is used for installation in round systems (air ducts). The zinc layer has become an excellent addition to the sheet steel from which the body is made. As in many other popular models, the heat exchanger is equipped with aluminum fins on copper pipes. For subsequent maintenance and technical inspection, service hatches are used, which are equipped with the hull. Accession is carried out directly to the air duct by means of flanges equipped with rubber seals. The coolant temperature should not exceed 150°C. Working pressure - 1.6 MPa. It is this unit that is better to buy, based on numerous reviews.

Price - 98,000 rubles.

- price-quality ratio;

- high strength equipment;

- excellent baseline performance;

- durable case;

- service maintenance.

- the complexity of the installation work.

AVA 400

votes 0

The design is used for rectangular channels. The main task is to cool the air that enters the ventilation system of the building. However, such a product does not provide for the presence of aggressive impurities in the system. Mounted in a rectangular ventilation opening. It is recommended to use antifreeze or water in the complex.

Cost - 48,000 rubles.

- in the kit you can find a special drop catcher, which is made of many plastic plates that trap fumes;

- high-strength steel (galvanized) is used for the manufacture of the body;

- the supply can be either right or left;

- 9.52 mm copper tubes are used for cooling, aluminum plates are used as their fins, which are strung on them.

- installation complexity.

WLO 100-50

votes 0

A water type device that can be mounted in rectangular channels. Lamellas (aluminum plates) with a thickness of 0.2 mm are used for the manufacture of the case. The nesting gap is 2.5 mm. Tubes of 9.52 mm pass through them. It should be noted that the manufacturer placed the tubes in a checkerboard pattern. For quick removal of moisture, the system is equipped with a special tray and a nozzle with a drop catcher. It is recommended to use non-freezing mixtures. However, water can also be used. The rectangular-shaped air cooler is considered efficient, due to the copper-aluminum plate type heat exchanger, which has a three-row design. This type of fixture is often used in ventilation ducts.

Cost - 42,000 rubles.

- installation complexity;

- requires regular care;

- some elements are covered with auxiliary protection against corrosion;

- many accessories.

- not identified.

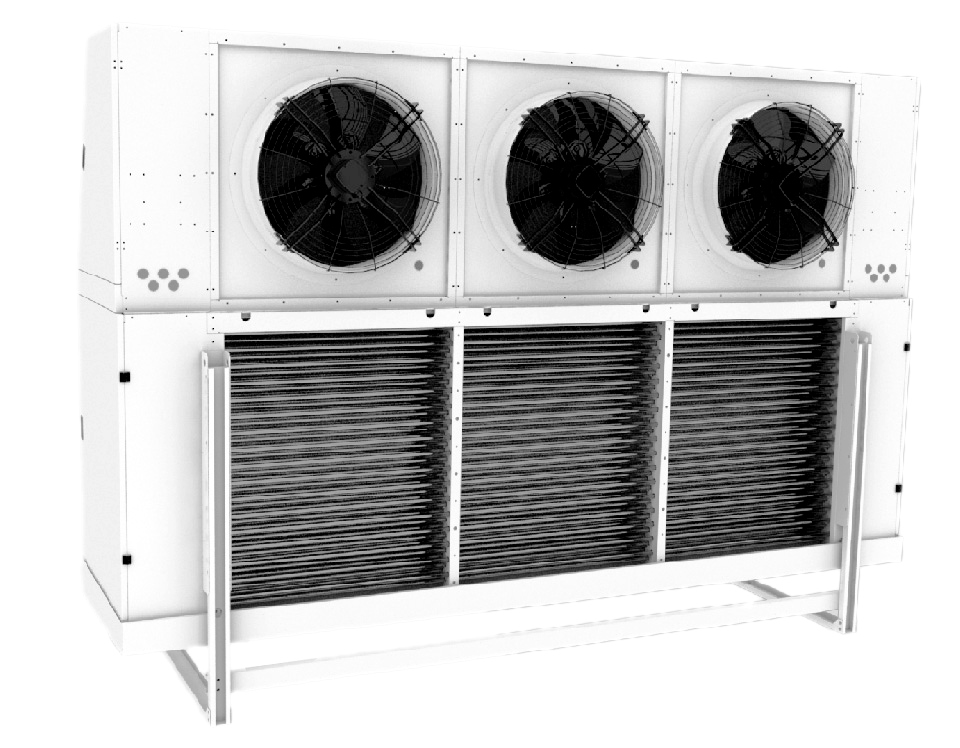

Rating of the best freon air coolers

A freon-type cooler is a complex system based on a heat exchanger, which is located in the supply ventilation system. The main purpose of new products is the cooling of air masses by means of freon. Being in the heat exchanger circuit, it is gradually compressed, which puts the compressor unit into operation. The following brands are often used:

- 410.

- 22.

- 407.

When choosing a cooler, several selection criteria should be followed simultaneously. Thus, the required and calculated parameters, as well as the volume of air consumed, are taken into account.

FLO 100-50

votes 0

The device is mounted in rectangular channels. It is an efficient heat exchanger based on the use of aluminum plates or lamellas, each of which is 0.2 mm thick. Attachments have a gap of 2.5 mm. The diameter of the tubes (copper) that pierce them is 9.52 mm. They are arranged in a checkerboard pattern, which leads to an increase in the efficiency index. Like any other system that is used for cooling or heating, condensate is generated during operation. The kit comes with a profile drip catcher, a special tray equipped with a pipe, which is responsible for removing accumulated moisture. Thus, the manufacturer managed to significantly increase not only the operational life of the device itself, but also the system in particular. Gas (freon) R407C, R410A and R22 is used as the main substance.

Price - 53,000 rubles.

- quality assembly;

- follow-up service;

- inexpensive, but high-quality components;

- high-strength materials;

- operational period;

- efficiency indicator.

- difficult replacement of individual components.

DXRE 100-50-3-2.5

votes 0

The cooling structure is often installed for arranging centralized cooling of air masses in ventilation systems. Installation is also possible in private houses, for zonal or individual cooling of individual rooms. The model cannot be classified as inexpensive, but the unit is able to cope with multidirectional flows, which cannot be said about many other products. This became possible due to the fact that the installed heat exchanger is able to turn over.

Price - 192,000 rubles.

- admissible indicator of working pressure - 28 bar;

- high-strength sheet steel is used for the manufacture of the body;

- in the presence of an auxiliary aluzinc or anti-corrosion coating of the body;

- the droplet separator can be installed in any direction;

- the same design can be used for arranging right-hand and left-hand connection;

- aluminum fins on copper heat exchanger tubes;

- ease of removal of the pallet;

- possible self-service in the future;

- the pallet is made of stainless steel;

- eight sizes.

- price.

OF 100-50

votes 0

Model for arranging rectangular channels of air conditioning systems for supply air flows. It should be noted that aggressive liquids should not be present in the flows. Mounted in rectangular air ducts. The manufacturer allows the use of substances such as R410A, R22 and R407C. A drop catcher is made of small plastic plates. It is responsible for trapping condensate and is mounted behind the cooler. The remaining moisture is placed in the tray, which is located at the bottom of the device. Additionally, it is thermally insulated and equipped with tubes to improve condensate drainage. Evaporation occurs due to inert gases. Coolers are installed in a horizontal position.

The cost of the kit is 51,000 rubles.

- the surface of copper tubes, whose diameter is 9.52 mm, has a protective coating in the form of aluminum silvering;

- the tubes are staggered;

- the body is galvanized and made of high-strength steel (sheet);

- the product belongs to the category of three-row, and has the ability to carry out the left-hand and right-hand supply of the substance;

- for greater protection, a thermostat can be installed (it will help to avoid freezing of the substance).

- the impossibility of self-installation.

PBED 800×500-3-2.1

votes 0

This type of duct cooler is used to cool air masses in systems with a rectangular cross section. The body consists of high-strength steel sheets, which are additionally coated with zinc. Inside there is a heat exchanger, which consists of copper tubes with aluminum fins. Also inside the structure you can find a droplet separator and a drainage pan. Finning with a pitch of 2.1 mm. On both sides there are flanges that are used to attach the remaining elements of duct ventilation. Installation is carried out in such a way that condensate can freely flow into the drain. You will need TPB to manage follow-up work.

Price - 43,000 rubles.

- zinc pipes for draining condensate;

- works with gases such as R410A, R407C and R22;

- allowable pressure indicator 3.0 MPa;

- checking equipment at each stage of production;

- it is possible to install a solenoid valve, a viewing window and other devices.

- siphon installation is required (however, this is rather a recommendation).

Vento CHF 80-50 / 3L-BE

votes 0

votes 0

A direct type device, which consists of a complex of copper tubes, the diameter of which is 1 cm. Aluminum plates are stretched over them in increments of 2.54 mm. Based on the project, the product is connected to the compressor and condenser unit. Calculations are carried out by specialists, so the risk of errors in the project is excluded.

Cost - 42,000 rubles.

- durable case made of stainless or galvanized steel (at the request of the customer);

- allowable temperature difference of air masses 10°С;

- equipped with a branded (durable) drop catcher.

- it is possible to use only R22 refrigerant, at which the evaporation temperature will be 5 ° C;

- execution - left;

- Auxiliary cooling circuits will need to be installed.

RF 100-50

votes 0

Water-type design, which is used to cool air masses and other non-explosive gas mixtures (non-fibrous, non-sticky). Also, the composition should not include harsh abrasive substances and impurities. Installation is carried out in channels of rectangular section. R407C and R22 can be used as the main substance. The recommended evaporation temperature is +5°C.

Price - 60,000 rubles.

- robust housing made of galvanized steel;

- protective layer;

- necessary components are provided by the manufacturer.

- not identified.

WHR-R 1000×500 / 3 Shuft

votes 0

It is mounted directly in ventilation ducts with a rectangular cross section. It is recommended for the arrangement of industrial, public and residential buildings and structures that require forced cooling of the supplied air masses. The case is made of high-strength galvanized steel (sheet). The heat exchanger is manufactured according to standard technology in a three-row version. The fins have a pitch of 2.1 mm, which made it possible to optimize weight and size indicators and increase heat transfer under the condition of insignificant resistance (aerodynamic). The material supply is standard.

Sellers ask for an average of 41,000 rubles for the goods.

- eight sizes;

- three-row execution;

- fin pitch 2.1 mm;

- for draining and removing air masses, built-in pipes are used;

- protective and heat-insulating coating of the surface of the pallet (drainage);

- installation is carried out in the channel;

- copper-aluminum heat exchanger;

- galvanized body.

- not identified.

Conclusion

Often, the installation of air coolers is carried out in a horizontal position. Installation features allow you to carry out all the necessary manipulations on your own, without the involvement of professionals. However, in the absence of the necessary skills, it is recommended to seek help from a specialized company that provides guarantees for the work done.

The main thing is to monitor the temperature regime inside the system, the indicator of which should not exceed + 30 ° С. The percentage of humidity should not exceed 43%.

Before installation, it is necessary to check the place near which combustible and explosive substances should not be located. Access to the hatch and the system itself should not be blocked either. Furniture items should be at some distance from the viewing window. Indoor air must be clean. The service life of the device will be significantly reduced if the premises are smoky or heavily smoky. Sticky and fibrous additives also have a negative impact on equipment life.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131654 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127694 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124521 -

The best men's sneakers in 2025

Views: 124037 -

The Best Complex Vitamins in 2025

Views: 121942 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2025

Views: 113398 -

Ranking of the best wood paints for interior work in 2025

Views: 110321 -

Rating of the best spinning reels in 2025

Views: 105332 -

Ranking of the best sex dolls for men for 2025

Views: 104370 -

Ranking of the best action cameras from China in 2025

Views: 102218 -

The most effective calcium preparations for adults and children in 2025

Views: 102013