Ranking the best forklifts for 2022

A definite impetus to the creation of forklifts was the First World War. It was precisely because of the lack of manpower that several European and American companies developed independently, and in the late 1920s introduced the modern forklift to the world.

At the time of 2022, the forklift market provides a fairly large assortment, which, in turn, allows the buyer to choose the most suitable option that will fully satisfy his selection criteria.

However, a large assortment can also present some difficulty in choosing, especially for buyers who are not experts in this industry. That is why, in addition to the review of loaders, we provide you with detailed information about their characteristics and parameters, which will facilitate the choice.

Content [Hide]

Selection criteria: what to look for when choosing

From our review, you will learn what a forklift is and what types there are, as well as consider in detail the following characteristics, the knowledge of which affects the correct choice:

- engine types;

- load capacity;

- lifting height;

- building height;

- fork size;

- number of wheels;

- tire type;

- transmission type;

- counterweight;

- optional equipment;

- safety;

- price.

What is a forklift?

Forklifts, or stackers as they are also called, are a type of warehouse, floor, self-propelled equipment that is necessary for stacking, unloading, processing, loading and moving various types of goods using attachments (forks).

The scope of this technique is diverse: the loader is used in workshops, terminals, warehouses, agriculture, as well as construction sites, large logistics centers, industrial enterprises and other industries that need to optimize and simplify loading and unloading operations.

Features to look out for when choosing

engine's type

First of all, warehouse equipment in the form of a forklift is divided into 2 types of engines: internal combustion engines and electric ones.

The electric motor type forklift is an environmentally friendly equipment that produces minimal noise and is quite economical to use. The loader is powered by a battery. The battery is being charged from the mains.

To the advantages of the electric forklift described above, one should add a sufficiently long period between maintenance and the scope of use: low-temperature warehouses, the pharmaceutical industry, fire and explosion hazardous premises and other premises that exclude the possibility of using forklifts with an internal combustion engine.

The disadvantages of the electric motor include difficulties with the battery. In the event of a battery failure, there is no possibility of its repair, only the replacement of individual elements is available. Also, the battery requires daily maintenance, and a separate, special room is required to charge it.

Let's move on to internal combustion engines, which in turn are divided into 4 types:

- Petrol. The gasoline engine loader is characterized by low cost, minimal sensitivity to the quality of the injected fuel, ease of operation, low maintenance costs and the ability to install gas equipment.

The disadvantages are the emission of exhaust gases into the atmosphere and a lot of noise during operation. - Gas. A gas engine can significantly save on fuel costs and minimize the release of hazardous substances into the atmosphere. There are two types of fuel for gas forklifts: CNG - natural gas methane compressed to a pressure of 200-250 bar and LPG - liquefied propane-butane gas.

- Gas-petrol. The combined type of engine provides a high level of autonomous operation, a wide scope of use (suitable for both warehouses and open areas).

- Diesel. The main advantage of a diesel engine is high power, reliability and low consumption. Its cost is slightly higher than gas, gasoline and electric counterparts. Of the significant disadvantages - this is a high sensitivity to the quality of the fuel being poured, a decent amount of exhaust emissions and a fairly high volume during operation.

load capacity

The load capacity of forklifts is divided into 4 classes:

- Small - from 1 to 4 tons.

- Average - from 4 to 10 tons.

- Above average - from 10 to 16 tons.

- Heavy - more than 16 tons.

You should pay attention to the fact that when choosing the load capacity of the loader, it is worth considering the "residual" load capacity. The minimum weight reserve must be at least 500 kg. So, if the mass of the lifted load is 1,000 kg, then the nominal value must be at least 1,500 kg.

lifting height

The maximum vertical lifting height is 8 meters. The standard lifting height is mainly used - 3 meters. For lifting over 8 meters, two-section masts of the "standard" and "duplex" types and three-section "triplex" types are used. Duplex and Triplex masts are free-swinging, which is ideal for working in confined spaces, as there is no need to raise the other sections.

Construction height

Headroom is the maximum height of the vehicle with the carriage lowered and the mast not extended.

When buying a forklift for a warehouse, be sure to take into account the height of doorways, arches, and based on the dimensions, choose the required building height.

Fork size

The forks have a length of 700 to 1200 mm. Mostly in warehouses, pallets are used to move cargo. It is on the basis of the dimensions of the pallets that the dimensions of the forks are chosen.

Number of wheels

Loaders are four-wheel and three-wheel, with single and dual wheels.

Tricycle wheels are placed in the shape of a triangle - their advantage is a high level of maneuverability in tight spaces.

Tire type

There are 3 types of tires:

- Bandage – low profile tires with low ground clearance, which can only be used on perfectly smooth and even surfaces.

- Solid cast or as they are also called superelastic - have a high level of rigidity and strength, but weak depreciation. This type of tire is suitable for use indoors, where there is a risk of hitting glass, metal chips, nails and other objects that threaten the integrity of the tire.

- Pneumatic - a high level of grip with the road surface allows the use of these tires on open areas with uneven surfaces.

Transmission type

Transmission is automatic and manual. An automatic transmission wins significantly, since the gear shift occurs during operation, and with a manual transmission, it is necessary to stop the stacker (aka loader).

Counterweight

The counterweight is an important part of the stacker, as it is responsible for the balance between the loader and the load, and also acts as engine protection. A counterweight is installed on the back of the machine.

Note that the maximum available weight of the lifted load is directly proportional to the weight of the counterweight.

Optional equipment

In addition to the standard equipment, forklifts also have additional equipment that increases the efficiency of transport. Below is an example of some additional equipment:

- tilting forks - necessary to change the vertical angle of inclination up to 50 degrees. This addition allows you to transport bulk and long loads using a bucket;

- side shift of the carriage - allows the carriage to move left and right relative to the mast. The addition is very useful and in demand, as it allows you to drink maximum accuracy when placing the load in a horizontal position;

- fork positioner - the add-on allows you to change the distance between the forks by moving them in and out.

Safety

The work of an operator on a forklift is quite dangerous.In the course of work, he can be injured when working at high speed, in cramped conditions, or when carrying heavy loads, shifting the center of gravity, hitting the load on the cab roof, and other similar situations.

To avoid possible injury, the forklift cab must comply with international ROPS / FOPS safety standards.

How much should specialized transport cost

By choosing specialized equipment for a few days, you can save. And if you want to get high-quality transport that will last a long time and will guarantee safety when interacting with it, you should forget about saving. Having saved once, the buyer will have to spend a lot of money on further repairs and the purchase of parts for him.

Top Producers

Forklifts are imported into Russia from the USA, European countries, China and Japan. General statistics show that the following companies supply the largest number of imported vehicles:

- JAC is a Chinese company with 20 years of experience. Consists of the 5 largest automobile factories in China;

- KOMATSU is a Japanese company founded in 1921. Engaged in mechanical engineering;

- TOYOTA is a Japanese company founded in 1937. It is the largest automotive corporation;

- JUNGHEINRICH is a German company founded in 1953. Engaged in the production of warehouse equipment and lifting and loading equipment;

- TCM, a Japanese company, was the first in Japan to develop a forklift. Year of foundation: 1949;

- HELI, a Chinese company founded in 1958, has been ranked among the 20 largest manufacturers of floor-standing special equipment.

It is also worth highlighting the high quality of the delivered loaders from the Japanese automaker Nissan, founded in 1933, and the automotive company Mitsubishi, founded in 1870.

The best electric forklifts

TOYOTA 7FB30

votes 10

| The price will come out | about 1,300,000 rubles |

| Cargo capacity | up to 3 t |

| lifting height | up to 3 m |

| reversal | 2.43 m |

| Dimensions | 124 x 279.5 x 217 cm |

| Engine | 1DZ-II, with a volume of 2486 cubic meters. cm and a power of 44 kW and 2600 rpm |

| Producing country | Japan |

TOYOTA 7FB30 is a representative of a Japanese company that combines high quality and affordable price.

This model has a high level of maneuverability, thanks to a turning radius of 2.2 m. The battery life of the vehicle is 8 hours, with a battery capacity of 370 Ah and a voltage of 80 V. With an electric motor power of 11.9 kW, the maximum load capacity is 3 tons .

The 7FB30 allows the installation of optional equipment in the form of V, FV and FSV masts, full swivel fork and roll paper grab, cross carriage and tilt forks.

- affordable price;

- good maneuverability;

- compact dimensions;

- the possibility of installing an additional device;

- long work without recharging.

- missing.

Series STILL RX60

votes 4

| average price | 2,300,000 rubles |

| Maximum cargo capacity | from 2.5 to 3.5 t |

| Speed | up to 21 km/h |

| Battery voltage | 80 V |

| wheels | four-point, superelastic |

| Work position | sitting |

| Produced | in Germany |

| Height | maximum 7.6 m |

| Turn | 2.1 m |

Specialized cars of the STILL RX60 series with single-engine front-wheel drive, made in Germany and are of high quality.The model is very maneuverable, the turning radius is 2.1 m. The power will be enough to load a load weighing 2.5-3.5 tons (depending on the model) to a height of 7.6 m.

A battery with a voltage of 80 V will delight the consumer with long-term operation, as the manufacturer has taken care of the return of up to 20% of energy thanks to the recovery system.

Operation of the RX60 is simple and intuitive. In addition to the standard configuration, the model supports many additional options, including grippers and attachments.

STILL RX60 is suitable for work with bulky cargo, both in a warehouse and for open areas. You can transport goods in any weather conditions, because all important systems are protected from moisture, which eliminates the possibility of getting wet.

Separately, it is necessary to highlight the high quality of the brake system, which is characterized by slow wear.

- simple control;

- small turning radius;

- return of energy;

- support for additional equipment;

- moisture protection;

- high lifting height;

- wear resistance of the brake system.

- not detected.

TCM FB30-8

votes 7

| Total weight | 3 530 kg |

| Battery capacity and voltage | 450 Ah, 72 V |

| Position for work | sitting |

| average cost | 2,512,000 rubles |

| Cargo capacity | 3 t |

| Dimensions | 358 x 122.5 x 207.5 cm |

| Engine power (traction, lifting) | 11.9 kW, 14 kW |

| Speed | up to 15 km/h |

| lifting height | up to 6 m |

| Tire type | pneumatic |

The autonomy of the TCM FB30-8 reaches 8.5 hours, which was made possible thanks to the use of a recuperation system during braking. The model perfectly will be suitable for work in small rooms, thanks to the good maneuverability and compactness.

The maximum load capacity is 3 tons, which the car can lift to a height of 6 meters. The speed limit eliminates the possibility of skidding the rear during the work process. Additional safety is provided by the anti-roll system.

- Speed Limit;

- ease of management and maintenance;

- good maneuverability;

- economical charge consumption;

- compact dimensions;

- anti-skid system.

- not found.

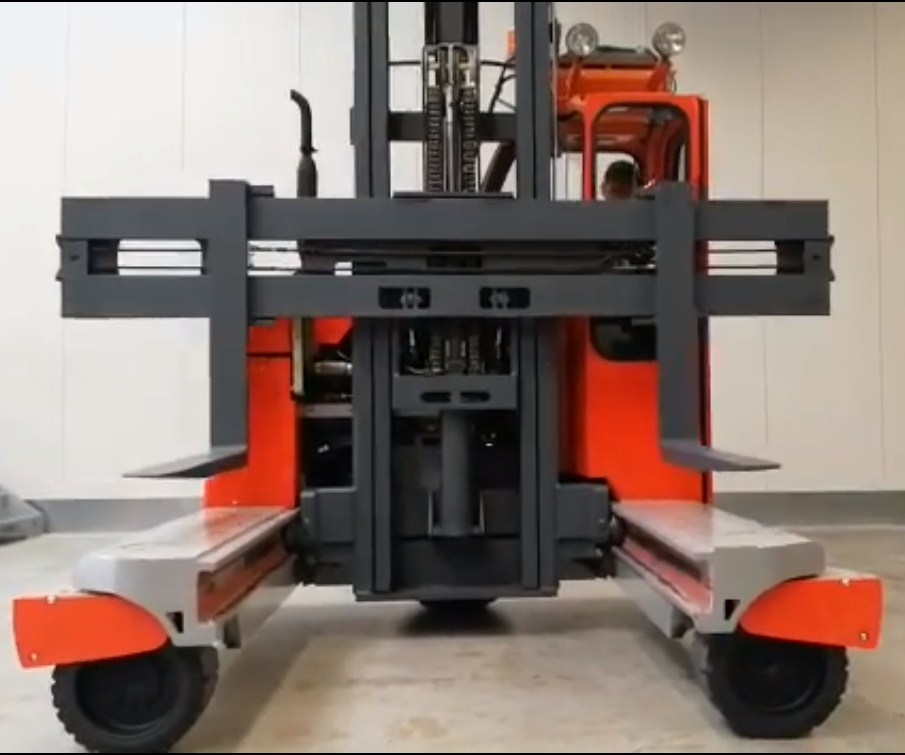

HUBTEX DS 27

votes 3

| Price | from 4,300,000 rubles |

| lifting height | up to 6 m |

| Load weight | up to 2.7 t |

| Number of wheels | 3 |

| Producing country | Germany |

HUBTEX DS 27 is a universal electric transport capable of working in all directions. Three large wheels with 4 way valves allow the stacker to be used both indoors and outdoors with uneven surfaces.

The model is suitable for working with both standard loads and long ones.

Management is carried out in a standing position. For greater comfort, the operator's backrest is adjustable and a low step is available.

- universality;

- ergonomics;

- excellent all-round visibility;

- noiselessness at work.

- not detected.

The best diesel forklifts

TOYOTA 8FD30

votes 6

| The price will come out | about 1,300,000 rubles |

| Cargo capacity | up to 3 t |

| lifting height | up to 3 m |

| reversal | 2.43 m |

| Dimensions | 124 x 279.5 x 217 cm |

| Engine | 1DZ-II, with a volume of 2486 cubic meters. cm and a power of 44 kW and 2600 rpm |

| Producing country | Japan |

The Japanese stacker differs in good endurance and reliability. With the maximum possible load capacity of 3 tons, it is able to lift the load to a height of 3 m. Fuel consumption is quite economical.

TOYOTA 8FD30 has a small turning radius of 2.43 m, which allows it to be used in small spaces. The model is unpretentious in work and will last for many years, subject to timely maintenance.

- unpretentiousness in service;

- efficiency at work;

- small dimensions;

- durability and maneuverability;

- acceptable price.

- missing.

KOMATSU FD20T-17

votes 6

| Cargo capacity (t) | maximum 2 |

| Lifting height (m) | maximum 3 |

| Control | sitting |

| Tires | pneumatic |

| Produced | in Japan |

| Average price (in rubles) | 1375000 |

| Turning radius (m) | 2.19 |

| Drive unit | manual |

| Voltage, battery capacity (V, Ah) | 12, 64 |

| Engine | Komatsu 4D94LE |

| Speed, power (rpm, kW) | 2 200, 34.2 |

| Tank capacity (l) | 58 |

With its low cost, KOMATSU FD20T-17 has a fairly powerful engine with economical fuel consumption and provides fast movement with large loads. The maximum load capacity and lifting height is 2 tons and 3 m.

The model is distinguished by good maneuverability, high-quality assembly, durability and reliability.

- ease of operation;

- low cost;

- small turning radius;

- efficiency and economy;

- durability.

- not detected.

HYUNDAI 50D

votes 2

| Produced | in South Korea |

| average price | 2,150,000 rubles |

| Maximum cargo capacity | 5 t |

| Model, power and engine speed | D4DD, 70 kW, 2300 rpm |

| Max Speed | 26.6 km/h |

| Control type | sitting |

| lifting height | 2.9 m |

| Dimensions | 330 x 174 x 220.8 cm |

| Tire type | pneumatic |

| turning radius | 3.02 m |

In Russia, HYUNDAI 50D is very popular, as it is endowed with a number of good technical characteristics that allow it to be easily used outdoors in any weather.

The equipment has a high build quality, excellent maneuverability and high performance in work. The maximum load capacity is 5 tons.

- affordable price;

- high performance and efficiency;

- good maneuverability;

- reliability and durability;

- adaptation to different weather conditions.

- not found.

Best Diesel LPG Forklift

HUBTEX DQ50D

votes 2

| Price | from 4 910 990 rub. |

| Produced | in Germany |

| Maximum load lift | 5 t |

| lifting height | maximum 4.56 m |

| Construction height | 3.2 m |

| Tires | superelastic |

| The weight | 7.4 t |

| Mast | standard |

| Dimensions | 260 x 223 x 320 cm |

HUBTEX DQ 50 D is a versatile solution for transporting and handling bulky and long loads both indoors and outdoors. The stacker is available for purchase in gas and diesel versions.

This model combines a reach truck, a forklift and a side loader. Such versatility was achieved thanks to a special design: a frame-type mast extends horizontally. Also a distinctive feature is the separate drive of each wheel.

- excellent maneuverability and performance;

- structural strength;

- possibility of purchase in diesel and gas version;

- separate drive for each wheel;

- multifunctionality.

- not detected.

Conclusion

The ranking presented the best diesel, gas and electric type forklifts. After reading our review, you can choose the most suitable model for yourself.For more detailed information, it is better to contact a specialist in order to exclude possible errors when buying.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131654 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127694 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124521 -

The best men's sneakers in 2022

Views: 124037 -

The Best Complex Vitamins in 2022

Views: 121942 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2022

Views: 113398 -

Ranking of the best wood paints for interior work in 2022

Views: 110320 -

Rating of the best spinning reels in 2022

Views: 105332 -

Ranking of the best sex dolls for men for 2022

Views: 104370 -

Ranking of the best action cameras from China in 2022

Views: 102218 -

The most effective calcium preparations for adults and children in 2022

Views: 102013