Rating of the best vibration mounts for machine tools and equipment for 2025

During the production of many technological processes, working equipment tends to vibrate. They are an inevitable phenomenon that affects both the quality of work or products, and the wear resistance of the working equipment itself. In order to reduce their negative impact, it is necessary to use special equipment aimed at damping vibrations.

In the vast majority of cases, fluctuations occur due to the operation of machine tools. Ventilation systems, supply of various liquids, other power plants create waves of different frequencies in their work. It is these waves that “shatter” the molecular structure of surrounding objects. Therefore, the main engineering task will be the creation of compensation elements, which will have a destructive effect on the waves and prevent their propagation. To perform the described tasks, special devices are used, called vibration mounts (they are also vibration cushions or compensators).

Content [Hide]

- 1 General conditions for the use of vibration supports

- 2 General information about vibration supports

- 3 The principle of operation of vibration mounts

- 4 Structural components of the vibration support

- 5 Existing types of vibration isolation supports

- 6 Benefits of using vibration pads

- 7 Adjustment Options

- 8 Questions of competent selection of vibration support

- 9 Rating of the best vibration mounts for machine tools and equipment for 2025

- 10 Instead of an epilogue

General conditions for the use of vibration supports

These include:

- The obvious presence of vibrations with destructive characteristics, which are formed periodically and have their own frequency;

- Orientation of vibrations - destructive waves are clearly directed and pass through the base of the machine or its working elements;

- The presence of characteristic vibrations during the production process, reflected on the surface of the base (floor, foundation), and in the worst case, the appearance of obvious cracks;

- Appropriate ratio of the weight of the machine equipment and the support - the latter must not only withstand the weight of the machine, but also not harm it on its own.

General information about vibration supports

The supports, as well as the equipment on which they are mounted, must comply with certain technical characteristics, the first of which can be called the mass of the machine (it is also a statistical load). Other parameters should be determined individually for each specific case, taking into account all the features of the operation of the equipment, and even more so - the requirements established by its manufacturer regarding vibrations.

ATTENTION! The use of vibration isolation supports is appropriate only on those surfaces that have a relatively even and solid base!

To integrate the supports on the equipment, there must be regular mounting points - the so-called "paws" with holes of the required diameter. The machines on which the supports are mounted must meet the requirements of stability, because such an integration method eliminates a rigid hitch with the base. This is true for frame-truss and column structures, as well as for equipment that is exposed to wind blowing.

It should be noted that the use of vibration mounts does not guarantee the absorption of vibrations by 100% - such a result can only be achieved using a whole range of measures aimed at eliminating sources of destructive vibrations.

The principle of operation of vibration mounts

Their main function is to prevent the spread of vibrations in all directions - both from the protected object (power plant, pressing machine, liquid transfer system) into the interior of the room where it is located, and to suppress return waves from the walls of the room to the protected object. Simply put, vibration absorption is the same noise reduction, which in both cases is a variation of vibration isolation.

In total, there are two options for vibration isolation:

- Active - represents a counteraction to oscillations that are created by the equipment itself, for which they are opposed by the same oscillations, only reversed in phase. At the same time, active insulation is divided into shock-absorbing insulation and periodic vibration insulation. Any equipment, be it a machine tool or a press, is by all means a source of vibrations of the two above-mentioned types - mechanical-based drives and their various types of mechanical action are capable of creating shock and vibration loads that propagate in all directions and at the same time “hit” the very placement room. Building codes and regulations No. 2.07.01 of 1989 regulate the degree and types of permissible vibrations in industrial premises, however, in some cases, the limits may be based on the specification of the equipment used or the general arrangement of the production premises (for example, proximity to high-precision machines and their similar precision devices)

- Passive - this protection is the protection of machines from destructive vibrations from the outside and potential additional energy sources are not used for it.For this type of vibrations, it is characteristic that the frequency of their excitation is indefinite, and their very formation is polyharmonic in nature. In this case, the equipment itself (measuring stand, machine tool, feeding system) becomes the object of the destructive impact, and at the same time its accuracy decreases, while at the same time worsening other performance indicators. When using passive vibration isolation, it is necessary to avoid dry contact (friction) that may occur between the foundation and the protected object, bypassing the protective element.

In a theoretical view of both these types of vibration isolation, they are almost indistinguishable, therefore the level of their measurement is similar and is determined for both types in the same way. In the general case, it can be represented as a transmission coefficient, which will show what part of the vibrational energy was transferred through the vibration damper.

Structural components of the vibration support

Due to the fact that the most common type of vibration mounts are rubber-metal, it makes sense to designate its main working elements:

- A shock absorber made on the basis of metal and rubber (rubber element plus flange);

- Washers in the amount of two pieces;

- Nuts - top and bottom;

- Tire;

- Stud with a square hole for a key.

As a rule, all parts made of metal have an anti-corrosion coating. The operating conditions for these products are the same as for industrial premises in which people work. However, it should be noted that rubber parts are badly affected by exposure to high temperatures - from +60 degrees Celsius. At the same time, they can crack when the ambient temperature drops sharply.

Existing types of vibration isolation supports

The main advantage of using components for vibration compensation is that in this way it is possible to reduce the cost of improving the conveyor. After all, now you do not have to create a separate foundation for each apparatus and calculate its weight to take into account working vibration processes. For proper operation, you just need to choose the right type of vibration pads from good material. To date, there are several such components that differ in technical parameters:

- Rubber - are the most common extinguishing elements in the entire market. Both real and synthetic rubber can be used for their production. When choosing them, it is important to pay special attention to the specific gravity. You should also take care of the environmental conditions - such products are afraid of too high (possibility of melting) and too low (possibility of cracking) temperatures;

- Rubber-metal - in addition to the rubber elements, a metal base is also installed in order to increase the maximum load. With the help of a metal base, you can control the level of absorption and the lifting height of the unit. In addition, the metal will to some extent perform protective functions, taking on the residual impact and preventing damage to the protected equipment;

- From solid metal - the scope of such pillows is limited to supermassive machines. Traces of deformation from absorbed vibrations may well appear on them, while their performance will not be reduced. However, they are a good conductor for transmitting high frequency vibrations. The shock-absorbing parts can be springs or springs.

NOTE.There are also cork and felt vibration pads, but their effectiveness is extremely low, so they are only used to adjust the height of the equipment or are used as spacers. It is also possible to include gaskets made of lead or asbestos in the same group.

Benefits of using vibration pads

With proper selection of vibration mounts, the protected equipment can be provided with the following preferences:

- There is no need to equip protection for each machine - by installing the compensator once, it will cover the entire foundation of the room;

- The number of repairs, the need for which will be caused by the impact of negative vibrations, will decrease significantly;

- Improved working conditions directly for equipment operators;

- The floor covering will be less subject to wear and tear;

- The noise produced by the devices during operation will be significantly reduced;

- The quality and accuracy of the devices will increase;

- The service life of the equipment will be significantly extended.

Adjustment Options

It is always worth leveling the base on which equipment with compensators is installed - all sharp changes in floor level must be leveled. Thus, a uniform weight distribution of the equipment will be set, which can always be adjusted by tightening the nut on the vibration damper. As a rule, the technical data sheets for pillows indicate the minimum and maximum number of loads in exact values that the support can withstand without serious damage. From here it is necessary to distribute the mass of the protected equipment to a certain number of reference points.

Questions of competent selection of vibration support

These devices must be selected taking into account many individual characteristics of the protected units.To do this, it is worth deciding on the following questions:

- Available types of vibrations that can threaten the protected equipment - the frequency of their occurrence, frequency and average and maximum strength;

- The mass of the protected unit - the heavier it is, the more powerful compensator it will need. To obtain more accurate indicators, the weight of the apparatus should be taken into account along with the weight of the workpiece (material) installed in it;

- Orientation and nature of oscillations - the summed vector of the direction of the resulting vibrations should be taken into account. As a rule, the vibration isolation product is mounted under the base of the protected unit, however, in some cases, the vibration pad must be placed vertically on the wall;

- Ambient conditions in the room - you should always take into account the endurance of the vibration support, because it can be "afraid" of very high or very low temperatures;

- Possibility of unintentional contact with aggressive substances and stability in case of contact of the vibration cushion with them without loss of operational properties - we mean chemical acids, molten substances, industrial oils, etc.

IMPORTANT! You should also take into account the issue of the safety of the vibrator itself - with a high draft, oscillations at low frequencies will be optimally isolated, however, the impact of external forces in the form of, for example, hydro-electric connections will be quite noticeable.

The most optimal professionals consider the following operating conditions for vibration cushions:

- All linings made on a rubber base are equally and evenly covered and compressed;

- The nut has a maximum passage and a minimum distance from the vibration cushion cover to the frame;

- The machine is lowered along the hairpin as low as possible in order to eliminate the critical effects of resonance.

Rating of the best vibration mounts for machine tools and equipment for 2025

Budget options

3rd place: "PCA-60"

votes 0

A good sample with high-quality vibration isolation. Suitable for machines small in size and weight, able to provide sufficient protection for the working unit. It is supplied in various versions and can vary in height. The design consists of heavy-duty steel and natural rubber. It has its own low frequency in the region from 10 to 15 Hertz.

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| Material | Galvanized steel/natural rubber |

| Maximum load, kg | 110 |

| Minimum load, kg | 30 |

| Stud in diameter, mm | 10 |

| Step height, mm | 1/2,5 |

| Dimensions, mm | 22x80x110 |

| Natural frequency, Hz | 15 |

| Price, rubles | 505 |

- budget cost;

- Triple height level;

- Low natural frequency.

- Little variation in usage.

2nd place: "LME 80 M10"

votes 0

This product is distinguished by its structural strength and is adapted for non-foundation placement. Leveling (by means of a 12 mm bolt) after installation is characterized by increased accuracy. Along with a good suppression of vibrations, it can significantly reduce noise in the production room. Components are made of steel and synthetic (nitrile) rubber. Natural frequency is set in the range from 25 to 100 Hz.

| Name | Index |

|---|---|

| Manufacturer country | China |

| Material | Steel/synthetic rubber |

| Maximum load, kg | 350 |

| Minimum load, kg | 10 |

| Stud in diameter, mm | 80 |

| Step height, mm | 8 |

| Dimensions, mm | 33x80x110 |

| Natural frequency, Hz | 25 |

| Price, rubles | 690 |

- Leveling accuracy;

- Large maximum load;

- Rugged housing.

- Not detected.

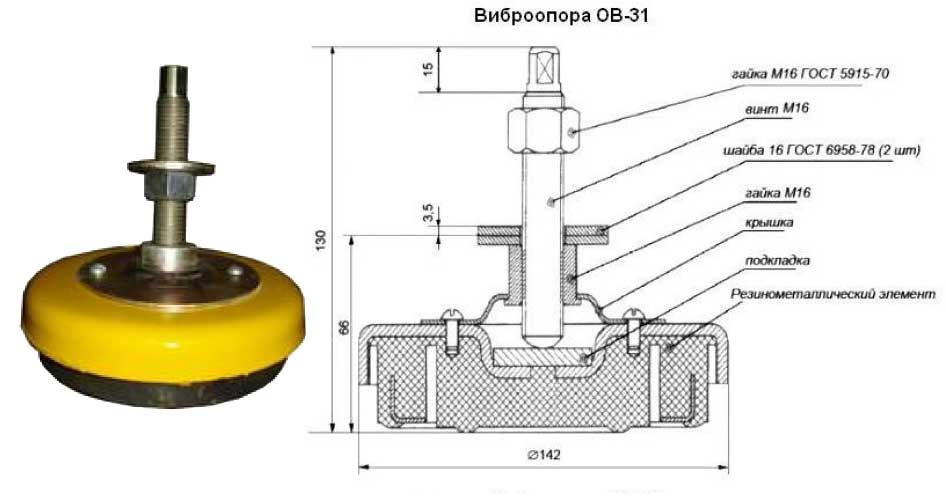

1st place: "OV-31 M16"

votes 0

This device is designed to protect industrial units and machine tools of medium and small dimensions, which have rigid beds of normal and high accuracy. The product already belongs to the class of powerful devices, because it is able to withstand a large machine weight. The height adjustment limit is set to 15 millimeters, the diameter of the stud is set to 16 millimeters.

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| Material | Steel galvanized |

| Maximum load, kg | 4570 |

| Minimum load, kg | 250 |

| Stud in diameter, mm | 16 |

| Step height, mm | 15.6 |

| Dimensions, mm | 33x142x130 |

| Natural frequency, Hz | 100 |

| Price, rubles | 720 |

- Increased load;

- High-quality case;

- Noise cancellation capability.

- It does not have an anchor fastening to the foundation.

Middle price segment

3rd place: "Groz RU59500048"

votes 0

This unit is used for soundproofing and vibration isolation of machine tools on rigid beds of increased and normal accuracy. By fine adjustment it is possible to achieve the best result. The case and working elements are characterized by increased strength, the device itself is made of composite materials. Maximum load up to 500 kilograms.

| Name | Index |

|---|---|

| Manufacturer country | India |

| Material | Composite |

| Maximum load, kg | 500 |

| Minimum load, kg | 25 |

| Stud in diameter, mm | 14 |

| Step height, mm | 15 |

| Dimensions, mm | 45x45x150 |

| Natural frequency, Hz | 50 |

| Price, rubles | 1600 |

- Good value for money;

- Ability to withstand a sufficient load;

- Composite materials were used in the construction.

- Not found.

2nd place: "EM 1.55 M16"

votes 0

This model is specially adapted to limit recoil and mitigate shock loading during high vibrations.Efficiency of action is reached at the expense of a strong design of the case. The dimensions of the device are extremely small and it is very easy to install. Particular strength is noted along the horizontal plane. Additionally, the vibration mount is protected against corrosion.

| Name | Index |

|---|---|

| Manufacturer country | Lithuania |

| Material | Galvanized steel/natural rubber |

| Maximum load, kg | 190 |

| Minimum load, kg | 10 |

| Stud in diameter, mm | 16 |

| Step height, mm | 5 |

| Dimensions, mm | 13x20x13 |

| Natural frequency, Hz | 8 |

| Price, rubles | 2100 |

- Anchoring to the foundation;

- 5 step shift;

- Used natural rubber.

- Low natural frequency.

1st place: "EPC 05-60 M16"

votes 0

This model is very easy to integrate under the base of the working unit, its functional rubber element is protected by a steel cover. The entire body is protected from the risk of corrosive processes. The stability of the fastening is ensured by the anchor connection. The construction uses galvanized steel and natural rubber. The product has a high natural frequency.

| Name | Index |

|---|---|

| Manufacturer country | Italy |

| Material | Galvanized steel/natural rubber |

| Maximum load, kg | 820 |

| Minimum load, kg | 200 |

| Stud in diameter, mm | 16 |

| Step height, mm | 16.4 |

| Dimensions, mm | 160x108x50 |

| Natural frequency, Hz | 10 |

| Price, rubles | 3000 |

- Protecting the rubber element with a steel cover;

- Ease of installation;

- Large maximum load.

- Not detected.

Premium models

3rd place: "C 2040 M10"

votes 0

An excellent sample from a European manufacturer is distinguished by a special quality performance. Able to create both passive and active vibration isolation.The same applies to noise cancellation. Shock loads are effectively damped. Integration is provided on a foundationless basis. Users note high resistance to tensile deformation. At the same time, the fixture is guaranteed to retain its performance properties under tension, shear and during pressure.

| Name | Index |

|---|---|

| Manufacturer country | Germany |

| Material | Stainless steel/synthetic rubber |

| Maximum load, kg | 75 |

| Minimum load, kg | 10 |

| Stud in diameter, mm | 30 |

| Step height, mm | 16.4 |

| Dimensions, mm | 76x76x38 |

| Natural frequency, Hz | 75 |

| Price, rubles | 4000 |

- Rubber of the increased elasticity;

- Hardened stainless steel body;

- Increased stud depth.

- Low maximum bearing weight.

2nd place: "LME 230 M24"

votes 0

This sample will be able to provide a reliable level of noise and vibration isolation for ultra-large industrial units. Thanks to its high-strength housing, precise leveling and foundationless placement, operation efficiency reaches up to 95%. The design provides for the presence of a rubber damper and a protective plate made of leveled steel. Fastening - anchor, carried out using a bolt of 12 millimeters.

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| Material | Galvanized steel/synthetic rubber |

| Maximum load, kg | 7500 |

| Minimum load, kg | 4500 |

| Stud in diameter, mm | 229 |

| Step height, mm | 12 |

| Dimensions, mm | 54x66x180 |

| Natural frequency, Hz | 25 |

| Price, rubles | 4100 |

- Reinforced housing;

- Increased level of maximum load;

- Decent price.

- Not detected.

1st place: "CP 2090"

votes 0

The product is able to suppress vibration and noise fluctuations both actively and passively.Shock loads are reliably restrained by damping. Installation is provided on a foundationless basis. Users note the high tensile strength of the equipment. The ability to maintain operational properties under excessive pressure, shear and stretching has been fixed. The rubber part is made from synthetic rubber (chloroprene), which is characterized by increased elastomericity.

| Name | Index |

|---|---|

| Manufacturer country | Germany |

| Material | Stainless steel/synthetic rubber |

| Maximum load, kg | 75 |

| Minimum load, kg | 10 |

| Stud in diameter, mm | 30 |

| Step height, mm | 16.4 |

| Dimensions, mm | 76x76x38 |

| Natural frequency, Hz | 75 |

| Price, rubles | 4300 |

- The design uses a special type of rubber;

- Resistance to mechanical stress;

- Anchor method of fastening.

- Not detected.

Instead of an epilogue

The conducted market analysis found that the vast majority of popular vibration mounts are made on the basis of rubber, because it is thanks to it that these devices combine the ability to endure excessive loads, combined with sufficient power in terms of vibration damping. In addition, they, having a sufficiently high level of plasticity, perfectly absorb vibration waves and at the same time have a long service life. At the same time, other supports made on the basis of rubber compounds and metal do not lag behind them in terms of performance.

Among other things, vibration mounts are designed not only to protect working units, but also to reduce operating noise in production facilities, and this already indicates the creation of additional comfortable conditions for human operators.Thus, the vibration mount is an indispensable part of any industrial workshop, where it is required to provide proper working conditions for personnel and ensure the safety of equipment.

If we talk about the economy and the brand component of the current market of vibration mounts in Russia, then you can see that the price for them has a rather large spread. The simplest models start at 500 rubles, and the most expensive ones cost about 5000 rubles. The manufacturer is represented mostly by Asian brands, whose products, although they have some variability (for example, an increased hairpin pitch), do not differ in quality, durability and efficiency. The domestic manufacturer has densely occupied the middle price segment, where it presents devices whose design has not changed for more than 30 years, however, is still capable of performing the tasks assigned to it with high quality. It is worth noting that samples from countries with developing economies also found themselves in the same segment, showing their quality quite well, for example, from India.

Regarding the higher price segment, models from a European manufacturer completely reign there. Indeed, their prices are quite “biting”, however, they have advanced functionality, advanced technologies are used in their design on an ongoing basis, and wear resistance and service life are significantly increased.

Summing up, it is possible to draw the following conclusion: for super-massive industrial machines, only vibration mounts from the premium segment should be purchased, because the rest simply cannot cope. For medium and small businesses (small workshops for one or two machines), domestic models are suitable.Regarding Asian samples, we can say that they will be able to cope with their task, but not for long.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131654 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127694 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124521 -

The best men's sneakers in 2025

Views: 124039 -

The Best Complex Vitamins in 2025

Views: 121942 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2025

Views: 113398 -

Ranking of the best wood paints for interior work in 2025

Views: 110321 -

Rating of the best spinning reels in 2025

Views: 105332 -

Ranking of the best sex dolls for men for 2025

Views: 104370 -

Ranking of the best action cameras from China in 2025

Views: 102219 -

The most effective calcium preparations for adults and children in 2025

Views: 102014