Rating of the best vibration isolation hangers and fasteners for 2025

One of the main disadvantages of living in a multi-storey high-rise building can be called with great confidence the almost zero level of sound insulation. Moreover, if the house is an apartment building, then each of the residents has their own idea of an acceptable volume level: some people are not averse to starting deafening repairs starting on weekend mornings, some people are not embarrassed by loud music right in the middle of the night. And if these examples are most often episodic, then the sounds of neighbors' steps will be constant companions of living in such a dwelling. However, this problem has a solution in the form of installing a soundproofing system for each specific apartment, with the help of which the owner will not only not interfere with his neighbors, but will also save his family from extraneous sounds.And the leading role in such a system will be played by vibration isolation hangers and fasteners (also referred to as vibration hangers and vibration fasteners).

Content [Hide]

general information

The main purpose of such suspensions and fasteners is to increase the overall sound insulation performance, that is, to effectively absorb sound vibrations coming from inside the room and not transmit vibrations received from outside into the room. This is especially true for plasterboard ceilings. In the process of installing such a ceiling sheet, the frame is first assembled, and then it is sheathed. At the same time, an air gap appears between the frame and the skin, which is not only an excellent acoustic conductor, but it is also capable of amplifying sound vibrations by several times. As a rule, this issue is solved by simply filling the voids with mineral wool or other soundproofing materials. However, this method does not fully solve the issue, because the frame itself is also capable of transmitting sound vibrations, sinceit is attached to the ceiling by means of suspensions, and those, in turn, are usually made of metal, which makes them an additional excellent sound conductor. This is where vibration isolation fasteners and suspensions will come to the rescue.

The whole essence of the secret of the effectiveness of these devices lies in their special design and they consist of:

- Directly the most direct suspension - it is mounted on a frame profile;

- Fasteners - this is the element that is responsible for fixing the suspension directly on the ceiling;

- Gaskets made of elastic metal - this is what distinguishes the vibration isolating suspension from the standard one, because it is the main shock-absorbing part, which is responsible for damping vibrations and general noise absorption.

There are also vibration suspensions, the fastening elements of which are coated with an anode solution - these samples have increased strength indicators.

Vibration-isolating fasteners / hangers widely used today are usually able to withstand a load of 20-30 kilograms, however, there are also heavyweight models that can withstand masses of 40 kilograms or more.

Before starting the installation of the ceiling, simple calculations should be made regarding the number of vibration suspensions that will be required for reliable sound insulation. Specialists are inclined to use the following ratio: for every 15 square meters, on average, from 40 to 50 vibration suspensions are required.

It is worth remembering that vibration isolation fasteners / suspensions are the most important element of the ceiling structure in the room. Mankind has not yet invented to extinguish sound vibrations in a different, less expensive way. The simplicity of the design of these devices suggests that it is quite possible to make them yourself.However, in inept hands, such an initiative can result in low efficiency of the entire system, coupled with a short overall service life.

Choice between partial and full soundproofing

Different engineering solutions will affect the suppression of extraneous sounds in different ways.

Partial soundproofing may be carried out on one or more surfaces. At the same time, it has a point of concentration of efforts, concentrating on a certain direction from where the sound comes from. In this case, the sound-absorbing material is laid inside the ceiling frame, which is fixed on vibration suspensions.

IMPORTANT! It must be remembered that different materials will deal with unwanted acoustic waves in different ways: drywall and gypsum-fiber sheets (GCR) will absorb sound, and cork, mineral or foam fillers will reflect it.

Complete soundproofing is a complex solution, in which not only the ceiling is insulated, but also the walls with the floor. Such an arrangement of the premises will make it possible to get rid of even the indirect transmission of acoustic vibrations. The main disadvantage of this scheme is that it will significantly reduce the amount of usable living space in the room, since frame structures will be installed everywhere. In addition, with full insulation, the floor will be made in a “floating” format, which means the thickening of the floor covering itself by an average of 50-80 millimeters. Naturally, such a coating will completely dampen the noise from running children or moving furniture, and the sound insulation index will reach the limits of 15 - 18 decibels at an acceptable 10. As practice shows, such a decision will be justified with large areas of the apartment and if the owners have expanded financial opportunities.

Application of partial sound insulation in various types of buildings

- Panel houses - their load-bearing structures are more than prone to a high level of indirect sound transmission, because they successfully propagate not only over floors, but also reflect from surfaces that have the same structure. For example, it is precisely because of this that the sound of the included drill is perfectly distinguishable in any room. It is worth noting that soundproofing the ceiling alone without additional wall insulation will not give a positive result.

- Brick houses - they have a heterogeneous structure of walls and ceilings, which is why the transmission of indirect noise is noticeably worse. In such apartments, it is quite possible to get by with only soundproofing the ceiling.

- Monolithic-frame buildings - they have a slightly different situation, in which powerful vibrations are transmitted from compacted floors to thin partitions. It is also preferable to combine wall and ceiling insulation here.

Design features of vibration isolation suspensions

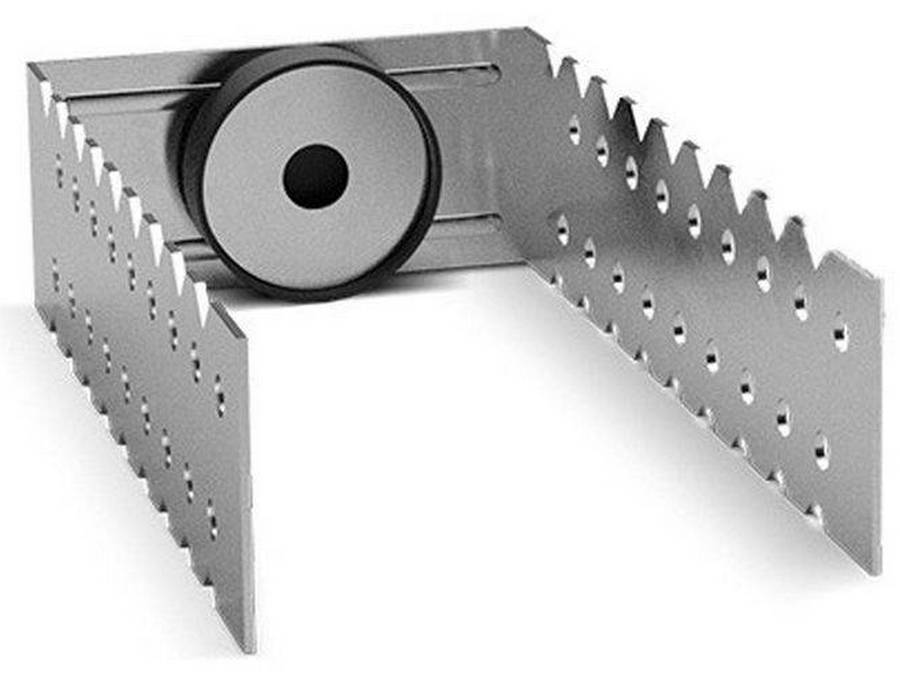

The vibration suspension is a U-shaped profile structure, on the upper crossbar of which a special insert made of an elastic material is installed. Usually such material is polyurethane, rubber or ordinary rubber. It is this soft base that takes on the impact of the sound wave and dampens it. The whole process of impact lies in the fact that the force of the acoustic wave is significantly wasted to compress the elastic gasket, rotate the hinge, and in the future its forces are simply not enough to affect the protective structure itself. The efficiency of the gasket directly depends on its thickness - the thicker it is, the greater the vibration amplitude it is able to extinguish.As a rule, the vibration suspension is fixed with an anchor to the wall / ceiling, and the reverse part is attached to the frame with self-tapping screws.

The main advantages of using vibration suspensions

The great popularity of these devices among the population is due to the following important advantages:

- Effectively prevent the penetration of extraneous low-frequency noise into the room due to their highly active vibroacoustic characteristics;

- Simple design for easy installation;

- Multifunctionality (suspensions can be used for both ceiling and wall sound insulation);

- They have confident moisture resistance, have increased anti-corrosion characteristics, their design implies an increased operational resource.

Existing types of fasteners / hangers for vibration isolation

The modern market of finishing materials is able to provide the buyer with a wide range of these devices. They can differ in the type of fastening, in the place of use, dimensions, as well as in the materials and dimensions of the insulating washers.

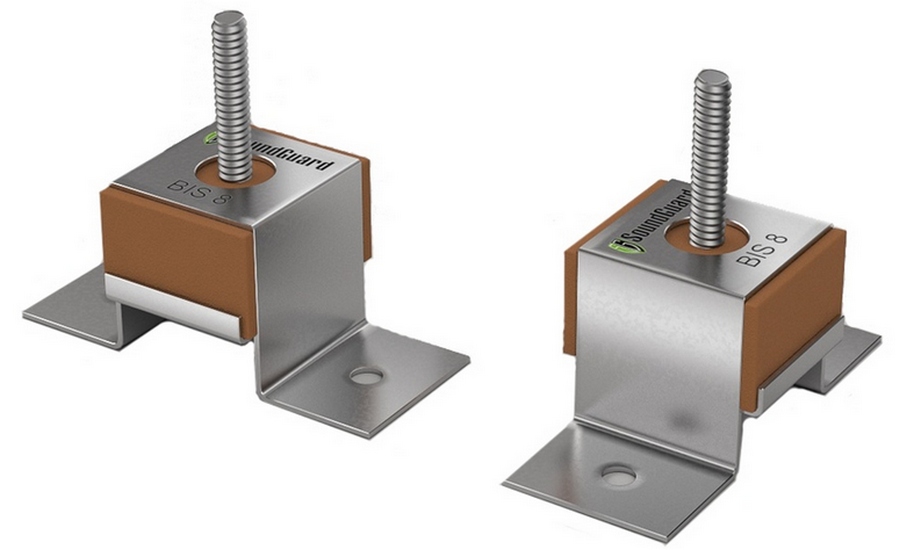

Among finishing specialists, it is generally accepted that the best option for the type of fastening is a box-shaped vibro-suspension. Its design is designed to absorb acoustic waves as successfully as possible, almost completely preventing their penetration to the ceiling surface or plasterboard wall. The main disadvantage of this variety is that before installation it will be necessary to set the studs on the profile as accurately and scrupulously as possible. In addition, their cost is far from small.

In terms of their dimensions, vibration hangers for drywall sheets can be standard, used for mounting on a profile with a width of 6 centimeters, and can be made in the economy class for a narrow profile, where their width will be 4.7 centimeters. Absorbing washers are usually represented by products made of rubber, polyurethane or rubber. All described devices must withstand a maximum load of up to 30 kilograms. Their adjustment can be carried out through holes that are located on the sides of their U-shaped design.

Do-it-yourself hanging devices for vibration isolation

The simplicity of the design of suspensions / fasteners allows you to make them yourself, despite the fact that the technology is quite simple, and the end result may not be inferior in efficiency to factory samples. For the whole procedure, you only need perforated metal plates and pieces of porous rubber. The required number of hangers must be calculated in advance, based on the area of the room to be isolated (about 40 pieces per 15 squares). For the direct manufacture of vibratory fasteners, it is necessary to bend a perforated metal plate into the shape of a rectangle (U-shaped view), and fix a rubber gasket in the center. The final step will be the usual bending of the edges of the plate. In order to increase efficiency, it is worth installing not one, but several gaskets for each mount - this will improve the quality of sound damping and prevent the further spread of vibrations to the drywall sheet as much as possible.

At the end of the procedure for the production of suspensions, it is worth testing them. To do this, the vibration suspension is fixed on a small wooden block, after which they need to hit the floor well.Immediately after the impact, one should carefully observe the vibrations that the plates produce. The faster the vibrations of the edges of the structure die out, the better the vibration isolation properties and the overall ability to dampen the vibration of the entire system as a whole will be.

Problems of competent choice

When choosing factory samples of hangers / fasteners, you should pay attention to their strength. The vibro-suspension has a significant load of supporting gypsum boards, coupled with an insulating material, and they also need to hold a layer of putty. Budget options for these devices are usually designed to hold weight up to 12 kilograms, standard ones are already designed for 15 or more. The "heavyweight" options are adapted to a weight of 40 kilograms for the wall and 30 kilograms for the ceiling. Also, the high-quality functioning of the fasteners will depend on the thickness and area of the elastic washer - the larger it is in volume, the better the insulation will be. The same parameter will also depend on the elasticity of the material: for example, for greater efficiency, rubber gaskets should be preferred over conventional rubber gaskets.

Some features of the installation of gypsum boards and vibration suspensions

Installing the drywall construction itself will consist of several steps:

- Production of measurements of the ceiling area - here you need to use the construction level and determine the lowest angle. Next, it is necessary to measure the distance from it that will be required to install the lamp and soundproofing material.

- Installation of frame guide profiles - on metal structures that will be joined to the ceiling, you need to stick adhesive tape for sealing.Thanks to this operation, it is possible to significantly reduce the risk of noise bridges, and this, in turn, will favorably affect the insulating characteristics of the entire structure as a whole.

- The markup designation consists in marking the junctions of jumpers and rack rails. At the same time, the future position of the vibration suspensions is marked.

- This is followed by the procedure for directly fastening the suspensions and lowering their working edges.

- Then you need to install the carrier rails and secure them with hangers.

- The final stage will be the laying of the insulation material on the frame and its subsequent sheathing.

In principle, the installation, as well as the general operation of the vibration suspension, differ little from the use of a standard direct attachment. The main thing here is to choose the right fixing material, which should be fully combined with the type of ceiling used. The connections of the vibration hangers themselves with the frame profile should be carried out using self-tapping screws or press washers. As a result, it should always be remembered that in the conditions of an apartment building, when using vibration suspensions, 100% sound insulation can never be achieved. However, their use can make the life of apartment residents much more comfortable in conditions of the lowest possible extraneous noise.

Rating of the best vibration isolation hangers and fasteners for 2025

"Sonocrepe Protector PRO"

votes 0

A simple and affordable option. Designed exclusively for ceiling mounting. The applied lightweight metal allows you to successfully dampen sound waves. The installation procedure is simple and uncomplicated. The elastic cap is made on a rubber basis.

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| Material | Cink Steel |

| Estimated load | 40 kg |

| Scope of application | Ceiling |

| Price, rubles | 150 |

- Improved sound insulation;

- Increased load weight;

- Small price.

- Limited scope.

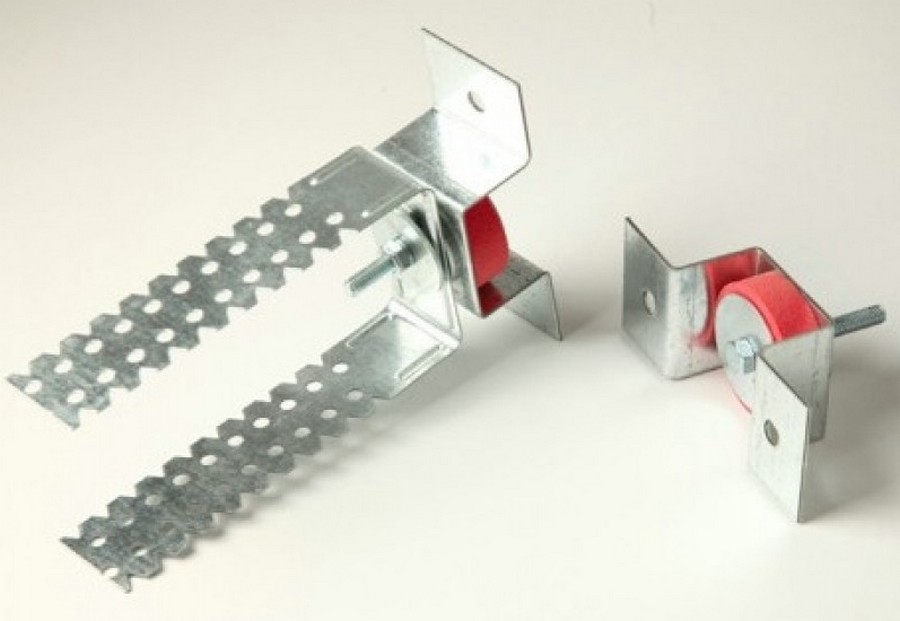

"Sonocrepe Protector" (62x30x125)

votes 0

The sample has a galvanized body, characterized by improved durability. Additional tabs between the body of the gimbal and the elastomeric washer prevent their unwanted contact, as a result of which they do not fray. It is possible to adjust it according to the thickness of the profile base.

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| Material | Cink Steel |

| Estimated load | 40 kg |

| Thickness | 1 mm |

| Scope of application | Ceiling and walls |

| Price, rubles | 100 |

- Versatility (ceiling and walls);

- Specialized design;

- Improved acoustic wave suppression performance.

- Not found.

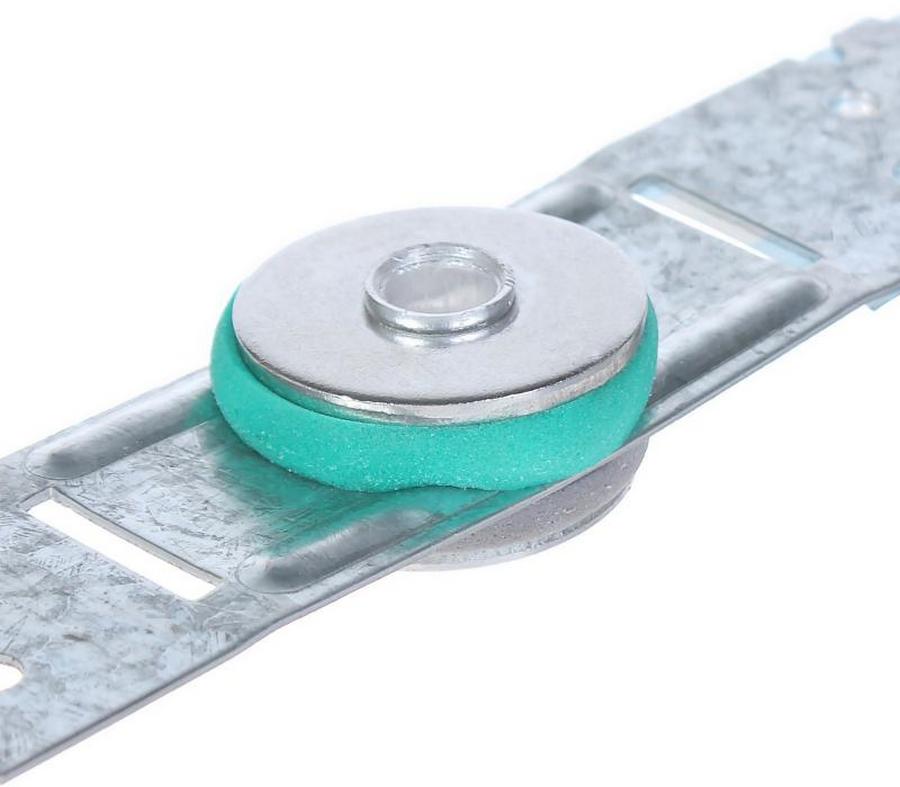

"Ultracustic"

votes 0

The model is intended for use as a reinforcing element in an already finished frame. Proper placement will increase sound insulation by an additional 25%. The model uses a combination of two elastomer washers at once - 6 and 12 mm.

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| Material | Steel |

| Estimated load | 15 kg |

| Thickness | 0.9 mm |

| Scope of application | Ceiling and walls |

| Price, rubles | 110 |

- Multifunctionality;

- Acceptable price;

- Specialized design.

- It is recommended to use as an additional element.

Vibrofix SPU

votes 0

This vibrosuspension can be used for both household and industrial needs. In particular, it can be used to provide sound insulation of cinema halls, recording studios, technical transformer rooms. Differs in special reliability.Austrian-made Silomer superelastic material was used as a rubber gasket.

| Name | Index |

|---|---|

| Manufacturer country | Austria |

| Material | Cink Steel |

| Estimated load | 12 kg |

| Thickness | 1.5 mm |

| Scope of application | Ceiling and walls |

| Price, rubles | 390 |

- Innovative technologies are used;

- The scope of application is extremely wide;

- The thickness of the antennae is extremely increased.

- Overpriced for a small set.

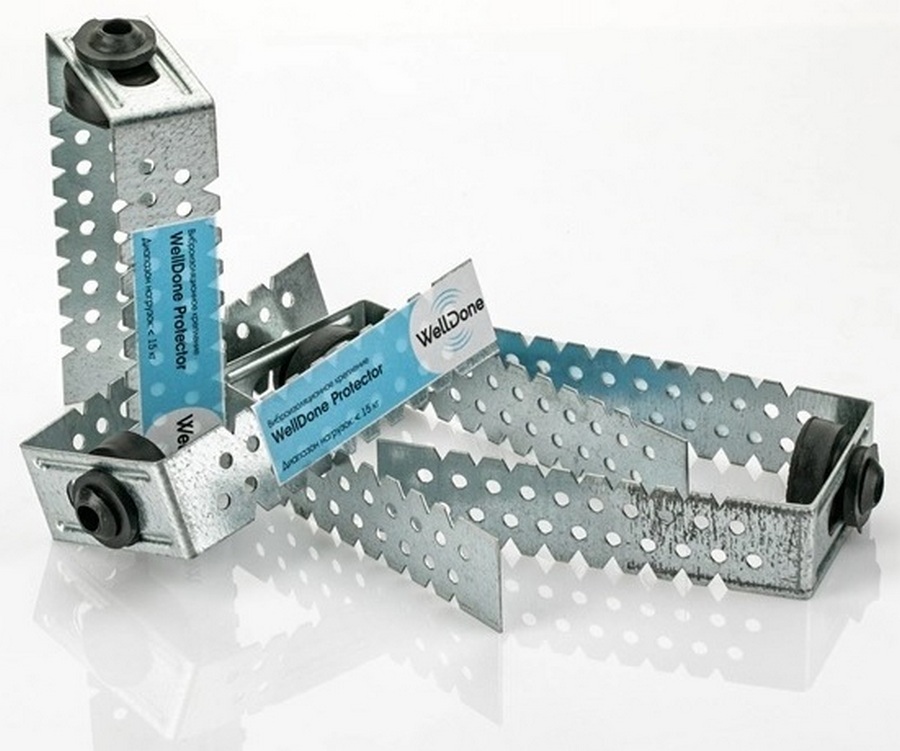

Well Done Protector

votes 0

The product is specially designed for vibration decoupling of frame systems on larger areas. The elastomer used in the design is made of aviation rubber, which allows you to achieve maximum effect. Fastening between the wall and the profile is carried out by means of a supporting fastener, which means an increased degree of reliability.

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| Material | Cink Steel |

| Estimated load | 40 kg |

| Thickness | 2 mm |

| Scope of application | Ceiling and walls |

| Price, rubles | 790 |

- Double fastening security;

- Application of improved elastic washer;

- Good kit.

- Extremely high price!

Instead of an epilogue

The analysis of the vibro fastener market shows that the Russian consumer is more focused on the domestic manufacturer. This situation can be explained by the simplicity of the product design, which is why it is absolutely not necessary to chase global brands. You can buy fasteners / hangers at any hardware store or on the Internet site, since the variety of types is very wide.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127688 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124516 -

The best men's sneakers in 2025

Views: 124030 -

The Best Complex Vitamins in 2025

Views: 121937 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2025

Views: 113393 -

Ranking of the best wood paints for interior work in 2025

Views: 110317 -

Rating of the best spinning reels in 2025

Views: 105326 -

Ranking of the best sex dolls for men for 2025

Views: 104363 -

Ranking of the best action cameras from China in 2025

Views: 102214 -

The most effective calcium preparations for adults and children in 2025

Views: 102010