Rating of the best floor insulation for 2025

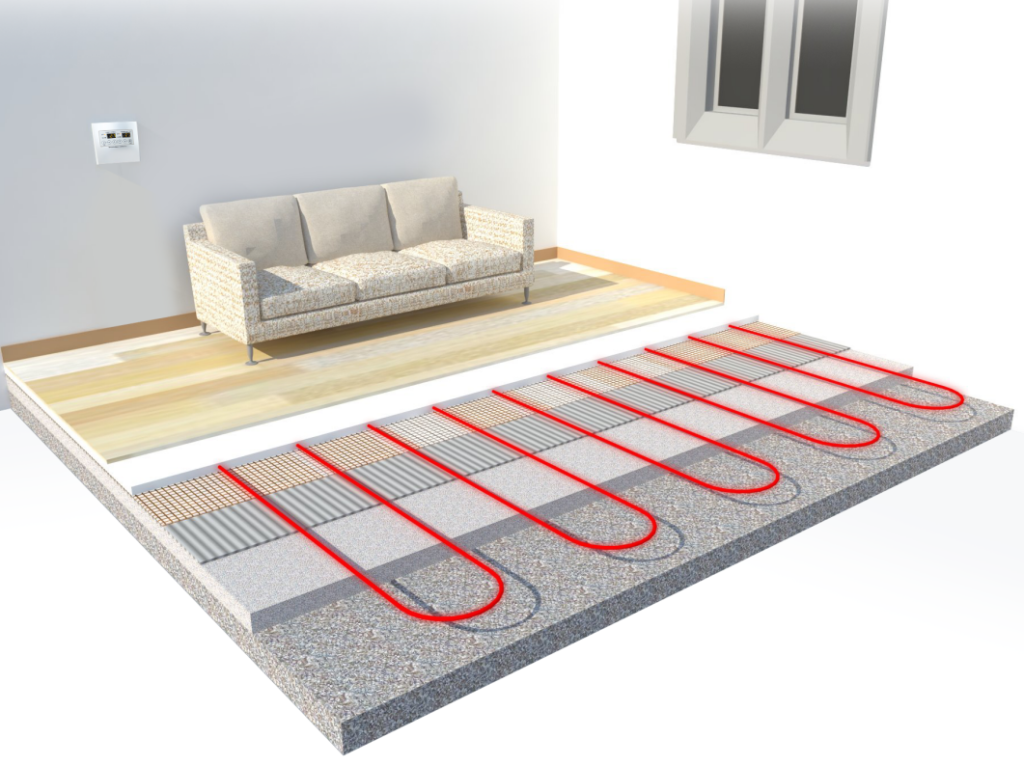

Most often, the owners of private houses and apartments located on the ground floor are engaged in floor insulation. And this is not surprising, because up to 30% of the heat goes through the flooring. Residents of the 2nd and higher floors are less concerned about this problem, because their heat transfer from the floor covering is about 5%. However, any homeowner tries to keep the heat in their premises and at the same time save on their heating. That's why, most modern homeowners pre-lay the cost of arranging a warm floor during repairs or when building a detached house. Underfloor heating in the modern world is equipped with special heaters, which are not only able to retain heat, but can also act as a soundproof screen.Thus, a responsible owner, as they say, "kills two birds with one stone" - minimizes heat loss through the floor and significantly reduces the noise load on the organisms of their households.

Content [Hide]

Appointment of insulation

The decision to insulate the floor on the first floors of apartment buildings or in private buildings, in principle, should not be in doubt, because the room will remain warm, and finances will be saved. However, in high-rise buildings, some owners, on the contrary, insulate not the floor, but the ceiling, and this decision is based on the simplest laws of physics. Heated air always rises, therefore, it must be preserved by insulating the ceiling. On the one hand, this option seems to be correct. However, the heat still escapes through the floor, which is facilitated by the cold floor slab. In the rooms described above, you may encounter a situation where the flooring is cold at any time of the year.In addition, steam condensate seeps into the concrete from below, and even with very dry room air, it can easily lead to the formation of fungus and rot, and in cases where the floor is covered with a laminate or parquet board, it can also lead to their deformation. At the same time, concrete, which already contains condensate in its pores, will take heated air from the surrounding space in order to evaporate the accumulated moisture molecules. Again, simple physical laws apply. It can be seen from this that the whole problem is easier to solve with the help of a floor insulation that has a vapor barrier function. The main thing is to be able to correctly choose its type correctly.

Existing types of floor insulation

On the modern building materials market, floor insulation is sold in the form of slabs (mats) or rolls, they can also be poured into containers or bags, and even contained in cylinders in a liquid state. Such a variety will make it easy to find the perfect solution for any base: for a “floating” screed or floor on concrete, with or without a frame, or for a draft base.

Existing materials can be grouped according to the form of manufacture, the principle of operation and the type of raw material from which they are produced.

Classes according to the form of manufacture

The general classification and characteristics for this grouping criterion are as follows:

- Rolled - the material itself has a length of more than 2 meters and is supplied in the form of a tightly twisted roll. Accordingly, only thin insulation with elastic properties can be twisted, such as: polyethylene foam, polystyrene foam, cork or bitumen cork. It is also possible to twist loose soft materials that have a low density, such as mineral wool.Roll insulation, due to its flexibility / elasticity, is capable of insulating bases with irregular geometry (excluding cork material), while the number of butt joints will be minimal, and this, in turn, will increase the degree of thermal protection. A huge advantage of rolled material is the presence of a layer of foil in it (which is rarely found, for example, in sheet material and is completely absent in liquid-free-flowing types).

- Sheet - these include all heat-insulating monolithic materials having a length of up to 2 meters (mats or plates), capable of maintaining their dimensions over a long period of time. They can be easily mounted, however, if the base has indentations and bulges, then multiple trimming will be required. In turn, multiple trimming means an increase in the number of seams that will have to be processed (glued) in excess of the existing ones, otherwise heat losses cannot be avoided.

- Loose - their range is represented by ordinary sawdust, expanded clay, foam glass, ecowool. They are easy to fill in a pre-prepared space, and can also be applied directly to the ground, on a rough wood floor or on concrete floors. Their advantage is the budget cost, and the disadvantage is the need for a large amount of this insulation.

- Liquid - they are various polymer mixtures that, when in contact with oxygen, create a foamed solid material (polyurethane foam / penoizol). Their advantages include the ability to insulate the most complex (in terms of geometry) bases, and the disadvantage is the high price and the need for special equipment for their application.

- Combined - they stand apart in this group and are represented by polystyrene concrete and expanded clay concrete, supplied in bulk form (immediately ready for use). Their undoubted advantages include: low weight, low cost, the ability to purchase all components separately, excellent heat-saving properties, and they are also a good alternative to a cement-sand screed.

Classes by type of functioning

There are only 2 such classes - these are “preventing” and “reflecting”. The essence of their action is as follows:

- Preventive - their working function is based on materials with low thermal conductivity, through which heat transfer is reduced. They are considered the most common type of insulation, which may contain both synthetic (inorganic) substances and natural (organic) ones. The presence of mixed substances is also acceptable.

- Reflective - their principle of operation is that heat is retained by returning it back to the entire volume of the room (i.e. infrared waves return). In this case, lavsan or foil can act as reflectors. This flooring solution is considered ideal, but expensive.

Classes by type of raw material

This classification should be considered in a little more detail. It includes two positions - heaters on an inorganic base and on an organic one. The latter include banal sawdust and you should not thoroughly disassemble this option. Of greater interest are inorganic materials due to their complexity, application specifics, and widely varying properties.

polyurethane foam

It is produced in a liquid state (it has the abbreviation PPU) or in the form of elastic soft plates - they are called foam rubber. For floors, the first option is used, i.e. PPU, because it has record low heat transfer properties. Among other things, it has certain advantages:

- The possibility of obtaining a material with the necessary characteristics for maintaining heat, which can be done right at the installation site - there are about 30 recipes;

- It is distinguished by increased strength - up to 10 kilograms per square centimeter in the process of compression, and up to 19 kilograms per square centimeter in bending;

- It has increased adhesive qualities with almost any type of building materials (except polyethylene), which simplifies the process of application to the treated surface (there is no need to mount the crate);

- Long service life - can maintain operational parameters for more than 30 years;

- Low own weight, which greatly facilitates the load on the floor;

- The drop-like method of application will fill various areas with complex geometry on the treated surface;

- Connecting seams, as an element of installation, are generally absent;

- Multifunctionality - application can be carried out both on logs and on a screed;

- The material itself practically does not absorb moisture, because. is very dense (degree of absorption is about 2%), which makes it possible not to carry out waterproofing work during interior decoration.

At the same time, PPU has its own disadvantages:

- Its operational and thermal insulation parameters are extremely dependent on the need to comply with the installation technology - the slightest deviation from the finishing order can lead to marriage and uselessness of the material;

- PPU has a flammability class "G2", which means that when ignited, the material will emit acrid smoke that is dangerous to human health. This problem is especially relevant for finishing wooden houses, so a second non-combustible layer must be applied to them;

- Thermal insulation properties are lost under direct exposure to ultraviolet rays;

- PPU, although it cannot serve as food for rodents, however, pests easily make holes in it, violating its overall functionality;

- PPU is a rather expensive material recommended for laying only by professionals (on average, laying one square meter by a specialist with a layer thickness of 10 millimeters will cost from 1300 rubles).

IMPORTANT! For self-assembly, it is better to use disposable kits - they are designed for a small amount of work.

Styrofoam

This type of raw material can be divided into two types - the actual polystyrene foam itself (aka polystyrene) and its extruded version. Their raw materials are the same, but the production technologies differ.

Styrofoam usually insulates the floor under the screed (by pouring sand-cement mortar directly into the insulation with a layer of 3-5 centimeters), or it is laid between the lags. In this case, the thermal insulation layer on top is covered with OSB sheets or plywood. This type of insulation has a number of significant advantages:

- A good heat-shielding level is created;

- Insulation has increased strength - it perfectly holds the mass of the cement screed;

- It has a reduced own weight, thus reducing the load on the floor;

- It has sufficient moisture resistance, which allows the use of such a coating on the first floors of buildings with a basement below;

- Reasonable price as a result.

Speaking of cons, it is worth mentioning:

- When heated to more than 30 degrees Celsius, toxic styrene will be released, and when burned, toxic substances;

- Not resistant to rodent activity.

Extruded polystyrene foam (abbreviated as EPS) differs from polystyrene foam in color and manufacturing technology. The color will depend on the desire of the manufacturer. It can, like polystyrene, be used both between lags and under a screed. However, unlike its counterpart, it has additional advantages:

- Shows improved heat retention properties - with a smaller layer thickness it is able to retain the same heat volume;

- Wide operating temperature range - from -50 to +75 degrees Celsius;

- They have a different molecular structure that makes the plates much stronger and tougher;

- It has a higher price - about 4500 rubles per cubic meter.

Polyethylene foam

It is a traditional representative of materials for floor insulation. Its price belongs to the budget category, but practicality does not suffer, because. PPE is usually supplied with one or two layers of foil as a reflective base (lavsan can also be used). The thickness of the insulation varies from 2 to 10 millimeters, while the thickness of the foil layer does not play a significant role. Nominally, 2 millimeters of polyethylene itself and 15 micrometers of foil are enough to retain 95% of heat. The reflective layer makes polyethylene foam one of the main materials used under the screed when installing cable electric, film or infrared floor heating. In this case, the cable is laid directly under the screed, the film - under the rod, the infrared is laid directly under the heater itself. The laying process is always carried out with the foil side up.

The main advantages of PPE include:

- Small thickness, which allows you to save free volume in a room with a low ceiling;

- Small own weight - reduction of loads on the floor;

- Durability - the possibility of re-use during the implementation of repair work;

- Long service life;

- Ease of installation, accessible even to a non-specialist;

- Low cost.

Among the shortcomings, it is possible to single out:

- Easily deforms with strong pressure;

- Low degree of rigidity;

- Low level of coupling with different bases (difficult to stick);

- High current conductivity, which requires grounding of the foil part when arranging an infrared "warm floor".

Insulation selection questions

The presence on the market of many options for floor insulation makes a potential buyer carefully work on the choice. In order for the choice to be correct, it is necessary to determine the main criteria, as well as to study the requirements for the base on which the insulation will be applied.

Main criteria

First of all, you should not limit yourself to just a couple of the main technical characteristics of the insulating material, because in this case, of course, the price will be lower, but the quality will obviously suffer. Thus, it is necessary to take into account all the nuances in a complex and come to the "golden mean". Below are the most important options to choose from:

- Thermal conductivity - this is the main indicator for all heaters (measured by W / (m-K)). The higher the number on the package, the worse it will keep the heat in the room.

- Durability - the optimal service life should coincide with the service life of the floor covering, and if a “floating screed” is used, then this period should not be less than 30 years. Otherwise, you will have to go to additional costs, because. the insulation will lose its properties before the onset of a similar moment at the coating;

- Mass - this indicator is extremely important for private development and apartments in old houses, of which there are many in both Russian capitals and in other cities. First of all, the weight limit is associated with the subfloor (wooden base) under the finishing flooring in private houses, and in apartments - with a plank floor, which was previously laid on powerful I-beams;

- The degree of fire resistance is another important indicator. It is most preferable to purchase materials with the "NG" index, i.e. non-combustible. In the case when the floor is made of concrete or brick, it is possible to be content with material indexed by the 1st or 2nd degree of flammability (respectively, "G1" and "G2"). However, such materials should not emit toxic substances when ignited;

- Degree of sound insulation - any kind of heat-insulating material is able to interrupt noise waves. Some materials do this to a greater extent, others to a lesser extent. For private households, you can get by with lower rates, but for owners of premises in apartment buildings, the issue will be much more relevant;

- Strength - it is important when arranging according to the "floating floor" or "floating screed" systems;

- The thickness of the insulation is an indicator, although a minor one, but it plays a big role if the ceilings in the room being finished are too low. Therefore, with low ceilings, the thinnest and most practical material is selected;

- Cost is the most important parameter, however, to which attention should be paid last, and only after analyzing all of the above criteria.

Material selection tips for various substrates

Properly selected insulating floor covering is the key to successful preservation of heat in the home.

For wood floor:

- The mass of the insulating coating should be as small as possible when applied to a rough wood floor;

- For a wooden floor, due to its increased flammability, a heater marked "NG" or "G1" should be selected;

- The coating must have increased moisture resistance, otherwise it will be necessary to produce additional waterproofing of the floor base, regardless of what the base is - wood flooring or soil;

- Based on the foregoing, it can be seen that for a wooden floor it is preferable to use foam, polyurethane foam, polystyrene concrete or expanded clay concrete. It is possible to use other types of thermal insulation, however, the degree of their effectiveness will depend on the type of foundation: tape, screw or pile.

Under the screed is perfect:

- Vermiculite;

- Extruded foam;

- Expanded clay;

- Foamed polyethylene;

- Ecowool;

- glass wool;

- Basalt wool.

Rating of the best floor insulation for 2025

For wooden floor

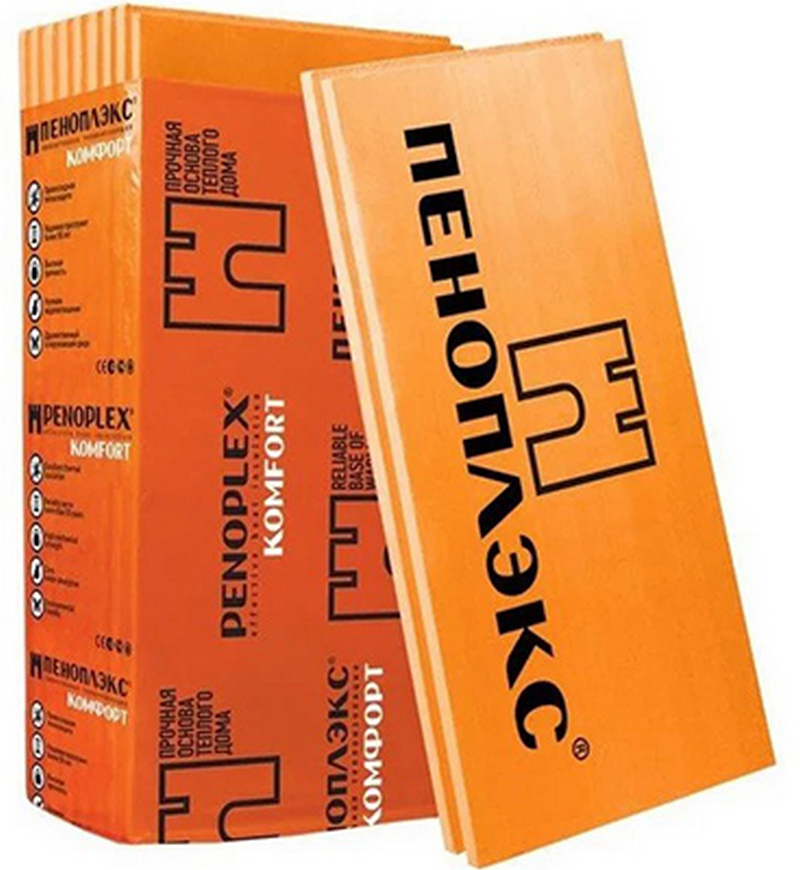

2nd place: "Penoplex Comfort"

votes 0

This sample is presented as a quality base for finishing not only the floor, but also the walls with the ceiling. Perfectly will be suitable for external and internal works. Available in tile form in various sizes, making installation easy and effortless. Resistant to a wide range of operating temperatures - from -50 to +75 degrees Celsius. It has a good density, which means a sufficient ability to retain heat.Relevant for work on interfloor ceilings in an apartment building. Has no unpleasant odors. The starting price is from 1200 rubles.

- Large coverage area with one sheet;

- There is waterproofing;

- Ease of installation;

- Service life - up to 40 years.

- Not resistant to rodents.

1st place: TechnoNIKOL Rocklight

votes 0

This sample is supplied in the form of slabs, which for stone wool means a significant simplification of the laying process. Plates are slightly susceptible to combustion and are able to withstand temperatures up to +870 degrees Celsius. Soundproofing properties are significantly expanded, which is achieved due to the increased density of the entire structure. Perfect for laying between lags, linoleum or parquet, as well as massive boards. The model is weakly subject to compression deformation and practically does not absorb moisture. It will quite cope with the retention of heat on the lower floors in houses with a basement. The starting price is from 1400 rubles.

- Prevents putrefactive processes;

- Absolutely not susceptible to mold;

- Large range of manufactured sizes.

- Relatively large weight of one plate (from 10 kg).

For concrete floor

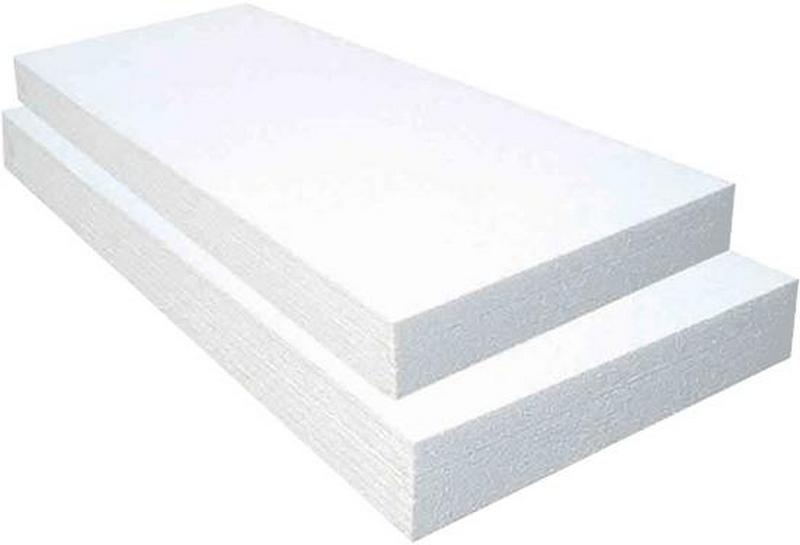

2nd place: "Foam PSB S-15"

votes 0

The sample is widely used in the insulation of residential premises, because it consists of foam material. In its composition, sound and heat insulating components are correctly distributed, due to which it has gained great popularity. However, the dimensions of the sheets are rather big - from 3 square meters, but they are cut with ease and with virtually no waste. It is characterized by special strength, therefore it is not subject to compression deformation.Can be used in any environment: dry, normal, wet. Nevertheless, the sheets are thick, so in rooms with low ceilings, use will not be justified. The starting price is from 300 rubles.

- Has sufficient vapor permeability;

- Has a non-porous structure;

- Density increased;

- Use in different climatic zones is possible.

- Thick and large sheets often require trimming.

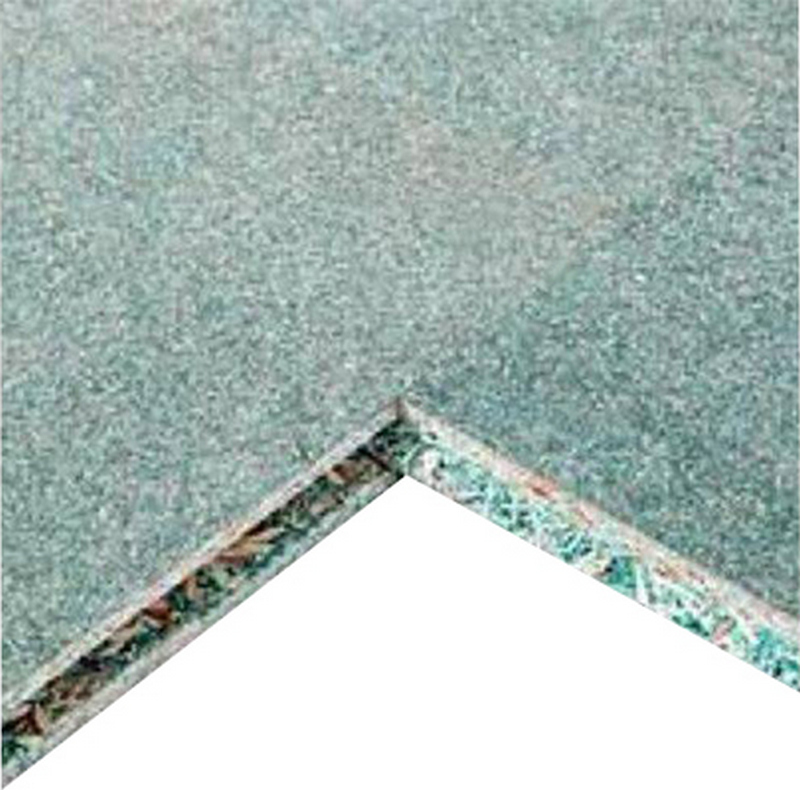

1st place: "QuickDeck chipboard moisture resistant Plus"

votes 0

This sample is extremely easy to install, because each of its sheets has docking grooves on both sides. It perfectly resists moisture, respectively, they can insulate floors in baths, bathrooms and bathrooms. The main distinguishing characteristic is complete environmental friendliness, which allows its use in special premises (kindergartens, hospitals, sanatoriums). Heat dissipation is at an average level, and sound insulation is considered sufficient. With its small thickness, it has a high density. It is extremely flammable and almost does not emit formaldehyde. The starting price is from 1800 rubles.

- Convenient laying technique due to the existence of grooves;

- There is no unpleasant odor - environmental friendliness parameter;

- You can work on vertical and horizontal surfaces;

- Possible exterior finish.

- Not suitable for laying under the screed.

For "warm floor"

2nd place: Thermo

votes 0

It is intended for the arrangement of "warm floors" in order to reduce heat loss throughout the room.The structure is presented from several layers - a foil coating on one side and foamed polyethylene on the other. Thanks to this design, moisture is extremely difficult to penetrate through all layers, which means ultra-reliable waterproofing. Supplied in rolls one meter wide. Completely resistant to decay, and therefore to premature wear. A fire safety function has been implemented - after a short burning, it fades on its own. During smoldering, it does not emit harmful substances. Has a long service life. The starting price is from 14,000 rubles.

- Reliable waterproofing;

- Sufficient noise reduction;

- Easy to cut.

- Extremely thin, requires careful assembly.

1st place: Isolon 500 3020 AV/AH

votes 0

Completely universal sample, the most popular model for the equipment of "heat-insulated floors". It is produced in thin sheets of a standard area (2 sq.m.), which allows you to quickly and efficiently complete the finish. It is fully aimed at saving heat costs and is able to evenly distribute heated air throughout the serviced premises. Due to its low weight, unnecessary load on floor coverings is completely eliminated. The functions of moisture protection and vapor permeability are present. The starting price is from 1750 rubles.

- Leaks in the design of the "warm floor" are completely excluded;

- Holds and distributes heated air well;

- Not afraid of direct ultraviolet rays.

- Overcharge.

Instead of an epilogue

An analysis of the modern Russian market for floor insulation has established that the most popular samples presented on it are of domestic origin. In most cases, this applies only to the most common types of insulation - on a wooden floor, on a crate and on a concrete base. If we are talking about high-tech arrangement of "warm floors", then the Western manufacturer is completely "hosting" here. At the same time, it is worth noting that our materials in the standard segment have a cost several times lower than their similar counterparts, but in terms of quality they are not inferior to them one iota. On the other hand, there are very few Russian materials for arranging "warm floors", and their price is very "biting". Therefore, in this area, a potential buyer will opt for a foreign product.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131650 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127690 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124518 -

The best men's sneakers in 2025

Views: 124032 -

The Best Complex Vitamins in 2025

Views: 121939 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114979 -

The best paint for gray hair - top rating 2025

Views: 113394 -

Ranking of the best wood paints for interior work in 2025

Views: 110318 -

Rating of the best spinning reels in 2025

Views: 105328 -

Ranking of the best sex dolls for men for 2025

Views: 104365 -

Ranking of the best action cameras from China in 2025

Views: 102215 -

The most effective calcium preparations for adults and children in 2025

Views: 102011