Rating of the best pipe cutters for plastic and metal pipes for 2025

For independent installation of systems, the presence of a pipe cutter is the main condition. It helps to quickly and accurately cut pipes of a given length. The cuts are smooth and neat, which greatly facilitates the work of plumbers and installers.

Content [Hide]

- 1 Short description

- 2 Main characteristics

- 3 Manufacturing materials

- 4 Fixture dimensions

- 5 What are

- 6 How to choose

- 7 Rating of the best pipe cutters for plastic and metal pipes for 2025

- 8 Conclusion

Short description

To cut such elements, you can use a hacksaw for metal. But the result is of poor quality: there is no cutting accuracy, there are numerous burrs on the end. You have to additionally align the edges, using specialized tools for this purpose. In addition, a hacksaw cannot always be used, as there is a special material that is not suitable for these procedures. Precise 90-degree cuts are achieved by using only a pipe cutter.

When carrying out perpendicular cutting with equipment, the ends of the workpieces are smooth and of high quality. Its performance indicator far exceeds the capabilities of a hacksaw. Devices are widely used in the construction of new facilities, the dismantling of obsolete heating and water supply systems, and the replacement of damaged areas. With their function, they cope "excellently".

It is considered the best tool when working in close proximity to explosive objects or where there is no possibility of connecting to the electrical network.

Main characteristics

A review of designs shows that they all have design differences, but they have two principles of operation:

| View | Description |

|---|---|

| Orbital | The movement of the cutting part occurs in a circle. The fixed part wraps around the tool and rotates. Requires a large free space for the operation of the device.The furrow gradually deepens until the end of the cut. Used for cutting special material in installed pipeline. |

| Stationary | It is supposed to have a special machine. The device is stationary, and only the part rotates. Copes with significant product diameters. The method is used in the production of a large volume of material. |

The devices differ in the following parameters:

- Drive type.

- Weight and dimensions.

- The principle of work.

- Structural features.

- Functional.

- Area of use.

- performance indicator.

- Manufacturing materials.

For industrial purposes, devices with a non-mechanical principle of operation are used:

- Laser. Special CNC machines are used. They perform the main task - at high speed they carry out accurate cutting at various angles.

- Plasma. Most often, an automatic CNC machine is used, which operates in conjunction with software. Quickly and efficiently cut out and make figured cutting of products from different alloys.

- Cumulative. It is based on the use of the jet of the same name, which is involved in the upcoming action. It is used to work with steel elements, the diameter of which reaches 1500 mm, with a thickness of 30 mm or less.

Manufacturing materials

The body of the equipment is made of the following materials:

- impact-resistant plastic;

- zinc alloy;

- composition based on aluminum;

- tool steel.

In order to resist corrosion, individual elements of the body can be coated with a protective layer based on chromium or a special coloring composition (powder). The steel structure is assembled from individual elements, which are also subjected to a procedure such as hardening.This provides significant stability of loaded and rubbing against each other nodes. Chrome-plated components are not afraid of moisture, have a good wear resistance, are resistant to corrosion, and have an excellent appearance. Cutting elements can be steel, tool or made from a special steel grade (alloyed).

Fixture dimensions

The weight and size of the selected device depend on where the tool will be used and what maximum diameter of the elements will have to be cut. Scissors for 42 mm products have an average weight of 300 to 500 grams, their length is from 250 to 350 mm. As for electrical devices, their mass and dimensions depend on the engine and the mechanisms for fixing product fragments.

After reviewing the data given in the product passport, the buyer can identify information regarding the minimum and maximum diameter of structures that the selected unit is able to handle. The pre-installed ratchet mechanism will help to cope with thin copper walls, however, the diameter of the working raw material should not exceed 42 mm. Electric and pneumatic models work with a diameter of up to 1500 mm, roller - 50 - 100 mm, cutting - up to 100 mm.

What are

The best manufacturers produce popular models of the following types:

- Manual. Needed for do-it-yourself repairs at home. Can handle a small amount of work. Differ in compactness, ease, noiselessness, mobility.

- Electrical. They work with an electric motor. Performance is essential. Used to perform a large amount of work in a limited period of time. Requires a power source, which limits the range of its capabilities.Rechargeable models are independent of electricity. The noise level is superior to similar products.

- Hydraulic. The main feature is high power. The work uses hydraulic fluid, so the models are heavy and have limited mobility. In most cases, stationary devices are produced, but mobile options can also be found on store shelves. One of the varieties is electro-hydraulic devices. Operate in tandem with an electric drive.

- Pneumatic. They are powered by compressed air pumped by a compressor unit. Efficient device with low noise level.

Tools differ in the principle of operation, and therefore they are divided into the following types:

- Roller. They are used for fixed products in a limited space. The cutting element is rollers, the number of which varies from one to four. Single rollers are designed for products with a diameter of up to 50 mm, four rollers can cope with a diameter of up to 100 mm.

- Guillotine. The main difference is to ensure uniform blade pressure over the entire cross-sectional area. The main purpose is for polypropylene structures, as it guarantees the absence of deformation of the product during the cutting process. Popular models are available with lever and screw feed.

- Incisal. The main task is to cut thick-walled or thin-walled polymer and metal pipes. As a cutting part there is a rotating disk.

- Scissors. Scissor pipe cutters are used for reinforced plastic and plastic structures. Visually resemble scissors for metal. A distinctive feature is the presence of sponges with an adapted cylindrical profile. A blade is used as a cutting element - a sharpened blade.It is not recommended to use when working with thin-walled and metal products.

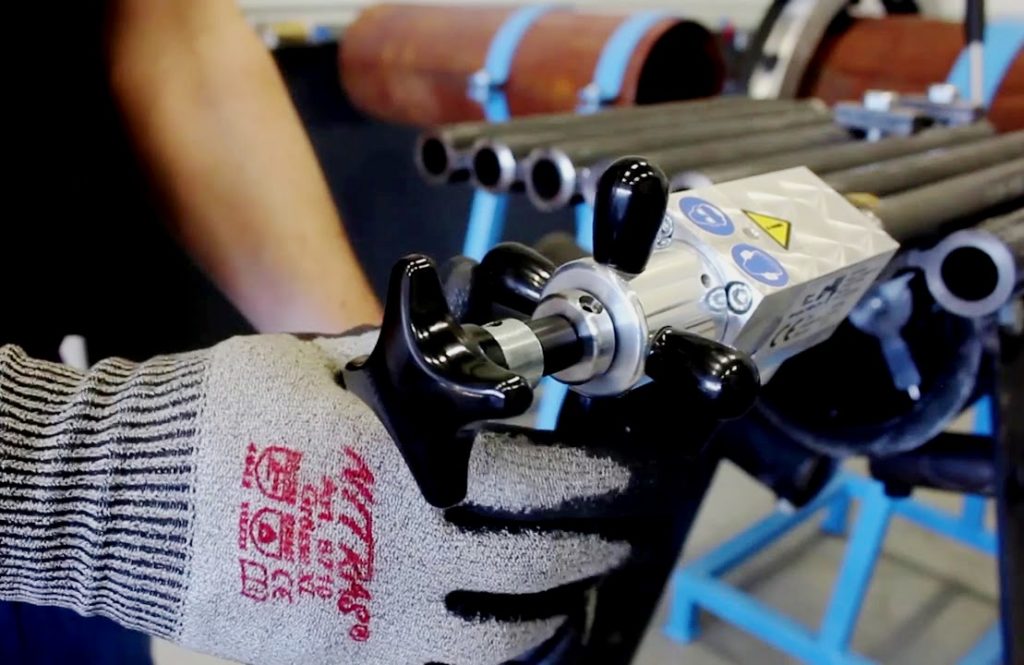

- Telescopic. Roller type. Also called universal. In addition to the cutting rollers, there are guides and a carriage, which makes it possible to work with products of various sizes. The possibility of adjustment allows the tool to be used for stainless corrugated products. The best manufacturers have launched the production of telescopic models with a built-in deburrer.

- Ratchet. A subspecies of a scissor tool. The principle of operation is the closing of several handles. Thanks to special gear racks, after the end of the cut, the blade returns to its original position.

- Orbital. They are floor or desktop electric machines on which workpieces are fixed by means of clamping jaws. They work with products made of non-ferrous and ferrous metals, plastic and stainless steel. Detachable and non-detachable models are available.

- Chain. Recommended for work with fragile compositions: concrete, cast iron, ceramics. The basis of the design is a chain, where the links are connected using cutting rollers, making the cutting process high-quality and uniform.

- With clamp type latch. They are distinguished by the presence of a rigid type of fixation, which is located along the entire diameter. Rollers are used as a cutting element, which can be replaced if necessary. This made it possible to increase the service life declared by the manufacturer. The adjustable handle makes it possible to use the unit in hard-to-reach places. Scope of use - cutting pipes with large dimensions and thick walls.

- C-shaped minipipe cutters. The cutting part is disks. Able to work in confined spaces. Differs in ease, convenient form, compactness.Able to make a cut in any hard-to-reach place.

How to choose

Everyone has their own criteria for choosing a pipe cutting device. Which one is better to buy depends on many factors. If you review the rating of quality products, you may be surprised at the variety of equipment for copper, aluminum, steel and other types of pipes. What matters is how much the item costs. But, according to buyers, this criterion is not fundamental.

The recommendations of experts boil down to the following: if you carry out professional activities using metal-plastic pipes, then you should buy a pipe cutter - scissors with a ratchet mechanism. Roller models do an excellent job with metal products.

The advice of professionals is as follows: you should not save on such a tool. Budget options cannot be characterized by high service life and quality. What should you pay attention to in order to avoid mistakes when choosing? First of all, special attention should be paid to the raw materials from which the product case is made, as well as to the basic set of device functions. It is advisable to choose a steel case. It is more practical, has high wear resistance. Which firm is better depends on the preferences of the buyer.

Rating of the best pipe cutters for plastic and metal pipes for 2025

For steel pipes

Kraftool 23410-42

votes 0

A popular German company that has launched the production of high-quality scissor and rotary pipe cutters. The device is equipped with a hardened blade that does not dull, so sharpening is not required. Sufficient strength makes it possible to operate it for a long time, without replacing modules. The handles have rubber inserts that do not allow the device to slip out of the hands.

The average price is 3600 rubles.

- ergonomics;

- convenient locking mechanism;

- does not slip;

- lack of dangling brackets;

- durable;

- reliable;

- convenient to use;

- an indispensable assistant in the repair of plumbing.

- significant price.

Ridgid 35 S 29963 (6 – 35 mm)

votes 0

Produced for cutting mainly steel products. It is distinguished by the strength of the roller, which is able to cope with high-alloy metals, without edge jamming. The presence of reinforced "lips" makes it possible to cope with increased loads. The device works with pipes with a diameter of 6 to 35 mm. Its light weight (400 g) allows it to be used continuously for 5-6 hours. At the same time, the hands practically do not get tired. The thick clamping screw stays still even if the palms become sweaty from intense work.

The average price is 5758 rubles.

- durable contour frame;

- universality;

- long service life;

- safety;

- reliability;

- comfortable thick flywheel;

- there is an additional complete set in the form of a spare cutting roller;

- included in the rating of quality products;

- many positive reviews.

- the price is not acceptable for everyone;

- the size is changed by turning the screw;

- packed in a blister, which makes storage problematic.

Rothenberger "Rockat 26 TS"

votes 0

It enjoys well-deserved popularity among both professionals and beginners due to its optimal parameters. A sharp blade stays sharp for a long time. The mechanism is smooth. There are no jerks, the edge does not break. The presence of a special brake in the upper part increases the safety factor of the device. The seat is wide.

The product can be purchased at a price of 2500 rubles.

- safety;

- German quality;

- inexpensive;

- suitable for cutting during construction work;

- an excellent assistant for professional plumbers;

- long service life;

- reliability;

- ease of use.

- missing.

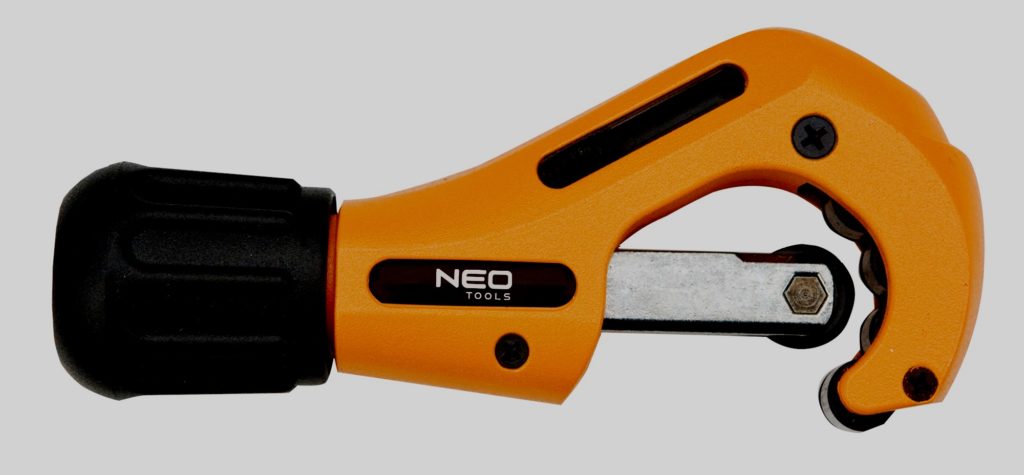

Neo 3 – 35 mm 02 – 010

votes 0

Goods of the Polish production of a roller type. In the manufacture of copper and aluminum were used. Inventory with a massive handle with reliefs for ease of rotation. The frame is durable and does not bend. Product weight - 580 g. The frame is collapsible, in case of breakage it can be quickly brought into proper condition. The cutting roller is qualitatively lubricated at the factory - the manufacturer does not wedge. How do they cut? Simply and easily. Even an amateur will cope with the work. The owners point to the reliability and practicality of the product, the absence of distortion and the high-quality closure of the cut lines in one place.

Sellers offer products at a price of 2358 rubles per unit.

- lasting;

- durable;

- build quality;

- comfortable to use;

- inexpensive;

- there are three thrust rollers;

- the ability to work with small and large diameters;

- moves easily along the guides;

- closing of the cut line at one point;

- thick screw;

- no pipe wedge.

- equipment is expensive;

- the roller can be replaced with special tools.

For copper and brass products

Rothenberger Mini Max 70015

votes 0

The product of a German manufacturer is designed for cutting copper. Made of steel, has two thrust and one cutting roller. The tool is replaced with a shaped screwdriver. The plastic flywheel does not slip in the palms. Works with diameters from 3 to 28 mm. Belongs to the category of professional equipment. Can be used daily.

The average cost is 2499 rubles.

- long resource;

- maintainability;

- quality;

- reliability;

- compactness;

- protruding handles;

- ergonomics;

- easy to hold;

- daily operation;

- light weight;

- high-quality German assembly;

- acceptable cost.

- in the absence of a lathe, the operation process becomes more complicated;

- there is no quick resizing system.

Ridgid 153 32 – 90 mm 36597

votes 0

The product of an American company is designed to work with pipes with a diameter of 32 to 90 mm, made of copper and brass. Do not use it when cutting steel products. The case has a metal C-shaped frame, reinforced in the stop zone. The rollers are equipped with bearings. The movement of the sled is provided by hinges. There is a function of quick replacement of the roller. The action takes place in two touches, without the use of special tools.

The average cost is 12729 rubles.

- lack of backlash;

- quality;

- safety;

- reliability;

- durability;

- increased structural rigidity;

- convenient in operation;

- practical flywheel;

- excellent functionality;

- universality;

- maintainability;

- durable frame.

- overcharge;

- significant weight - 1 kg;

- does not cut steel.

Stayer 23375-42

votes 0

The product is known to many professionals due to the yellow color of the case. It is considered German, but in reality - the Chinese brand filled specialized stores with all kinds of construction equipment and products for plumbing, including pipe cutters. It is considered the most budget model, and this is its main and only advantage. The plastic case cannot boast of durability. One rubber insert allows the device not to slip in hands.It is quite suitable for small household work, but for professional installers you will have to look for another option.

The product is offered at a price of 700 rubles.

- inexpensive;

- compact;

- can be purchased at any specialized outlet.

- the grip is not very comfortable;

- difficult to replace blades;

- not suitable for professional activities;

- plastic base;

- service life is short.

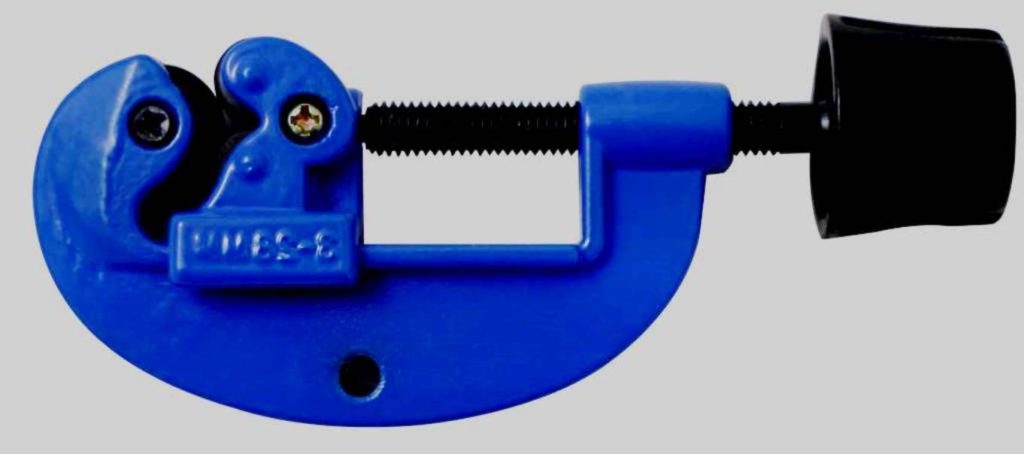

Sibrtech 78710

votes 0

The model has been produced for a long time, but the appearance has changed somewhat. Rotary tool with modern design. Copes with soft pipes, whose diameter does not exceed 60 mm. Structural elements include a large screw and a leading cutting component. The rollers are steel, the structure is completely made of cast iron. Cannot be used to cut small plastic pipes.

The average price is 1350 rubles.

- ease of use;

- safety;

- practicality;

- body strength;

- durability;

- combination of price and quality;

- reliability.

- not installed.

Fiberglass, rubber and plastic cutting equipment

Gross Piranha

votes 0

Gross is the world's leading manufacturer of all kinds of products, including rotary pipe cutters, thanks to which you can quickly and accurately cut plastic products. The presence of a long handle makes the product easy to use. Turning the tool is simple and easy. The dimensions are significant. A diamond disc is tightly fixed on the base, which is used to cut. The rollers press the workpiece, without the participation of the disk.The practicality of the tool is questionable, since it is quite difficult to change the disk due to the non-separable design of the product.

The cost of the product is 2200 rubles.

- long service life;

- reliability;

- safety;

- functionality;

- comfort.

- high price;

- significant sizes.

Jonnesway AN 040019 (AN 040019A)

votes 0

A feature of the model is that the roller is qualitatively attached to a stationary bracket. Support rollers are placed on the retractable screw. For rigidity, the body is equipped with a movable part with additional guides. Works with metal and plastic. Overpowered by a diameter of 28 cm. A find for installers. An exposed screw can be lubricated regularly, but water, dust, and chips can get in.

The average price is 836 rubles.

- the beveler works perfectly;

- clean edge;

- comfortable to hold;

- lack of backlash;

- simplicity of design;

- long service life;

- reliability;

- build quality;

- maintainability;

- excellent value for money;

- does not leave nicks;

- housing made of high-strength aluminum and steel;

- flywheel is comfortable;

- can cut products with a minimum cross section of 3 mm;

- stainless steel rollers.

- chips can get on the thread;

- clamping force must be controlled;

- without a screwdriver, you can not change the tooling.

Zubr Expert 23705 – 42

votes 0

The product differs from its counterparts in the quality of the blade. In its manufacture, high-alloy steel of a special grade is used, which has maximum strength. The blade does not need to be sharpened manually or replaced. Works with plastic pipes up to 42 mm in diameter. Edge bending and flattening does not occur.

The product can be purchased at a price of 1350 rubles.

- practicality;

- reliability;

- quality;

- functionality;

- safety;

- ease of use.

- poor ergonomics;

- working convenient elements and plastic inserts are not provided;

- no latch.

Knipex KN-9020185

votes 0

Scissor model equipped with a lower stop and a clamping upper knife. Produced in Germany. Cuts plastic pipes and rubber hoses reinforced with fiberglass. In this case, the plastic does not crack. The blade is replaced by two fixing screws and a hexagon. In the manufacture of the knife, tool steel is used, hardened in heated oil.

The price of products is 5303 rubles.

- wear resistance;

- blades do not dull;

- convenient to use;

- reliable;

- long service life;

- functionality;

- build quality;

- excellent ergonomics;

- performance;

- equipped with a spring for opening the handle;

- There is a lock for carrying in the pocket.

- too expensive pleasure;

- cuts soft materials and small pipes.

Devices for working with aluminum and metal-plastic

Fit 70987

votes 0

The Canadian brand is produced in China. It is intended for performance of difficult works with metalplastic. In the manufacture of cutters, high-quality chrome-vanadium steel was used. The case is aluminum. Special fastening facilitates the process of transportation. There are rubber inserts on the handle. Weight - 520 grams.

You can buy products at a price of 1700 rubles.

- makes the cut neat and even;

- functionality;

- safety;

- reliability;

- durable case;

- ergonomic handle;

- value for money.

- you need to constantly tighten the screws on the case;

- No replacement blades included.

Kraftool 23385_z 01

votes 0

Products are widely represented in the domestic market. Any specialized store will offer a choice of various models that differ in price, quality of materials used, and functionality. There is an option to purchase a product in an online store by placing an appropriate order online. The model differs from its counterparts in reliability and durability. The pipe turns easily and simply thanks to the rotating rollers.

Made from soft yet durable plastic. Qualitatively cuts aluminum and chrome-plated products, leaving no cut marks on their surface. The diamond disk is brought to the place of cutting by a special threaded mechanism.

Products are sold at a price of 1900 rubles per unit.

- high performance;

- functionality;

- build quality;

- ease of use;

- safety;

- value for money;

- reliability.

- not installed.

Rehau 50-125

votes 0

The German company Rehau is better known as a manufacturer of high-quality and reliable windows, which are preferred not only in Germany, but in other European countries, as well as in Russia. But its production facilities allow it to make various plastic products, including rotary pipe cutters. Convenient and compact products arrive on the shelves of stores. Three rollers act as guides, thanks to which the fixed pipe rotates quickly and smoothly. A large diamond disc is brought in by a special threaded mechanism.

The average price is 8100 rubles.

- durability;

- reliability;

- comfort;

- performance;

- functionality.

- simple tool at an overpriced price.

Conclusion

The work of a pipe cutter is associated with one important point - to choose the right clamping force for the pipe. Excessive force can lead to the formation of a helix, which is almost impossible to correct. You will have to choose another place for cutting. Rapid rotation of the tool can cause the pipe walls to close.

Masters recommend to properly care for the device:

- regularly lubricate the guides and feed screws;

- store the goods in a warm and dry room;

- prevent chips, dents and other mechanical damage;

- check the sharpness of the cutting device, if dull, replace it;

- at the end of the work, clean the surface of the structural elements.

It should be noted that the pipe cutter is an indispensable assistant in the installation and dismantling of plumbing, heating and other types of utility systems. It helps to quickly and accurately cut the pipe, leaving neat edges. The whole process takes a short amount of time. In this case, you do not need to apply excessive efforts. The unit is light enough to operate for 3 to 6 hours, with short breaks for a smoke break.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131650 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127688 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124517 -

The best men's sneakers in 2025

Views: 124031 -

The Best Complex Vitamins in 2025

Views: 121938 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2025

Views: 113393 -

Ranking of the best wood paints for interior work in 2025

Views: 110318 -

Rating of the best spinning reels in 2025

Views: 105327 -

Ranking of the best sex dolls for men for 2025

Views: 104363 -

Ranking of the best action cameras from China in 2025

Views: 102215 -

The most effective calcium preparations for adults and children in 2025

Views: 102010