Rating of the best pipes for underfloor heating for 2025

The "warm floor" system is a variant of panel heating and is an excellent addition to the classic radiator heating grid. With the help of panels, it is possible to provide relatively uniform heating of the floor covering to acceptable temperature indicators. Radiators will provide similar heating, but not quickly, because they are designed to heat only the air. For example, for a living room, the calculated air heating is only +20 degrees, while building codes provide for an indicator of +26 degrees Celsius, and this can only be achieved through a “warm floor”. Nowadays, panel heating powered by electricity is popular, however, this variation is associated with high financial costs for paying for electricity. An alternative in this case can be a “warm floor” with glycol or water heating, where pipes act as a conductor of heat.Such models are cheap to maintain, but will require certain conditions to be met, which is provided for by their design features.

Content [Hide]

- 1 Requirements for pipes of a water "warm floor"

- 2 Tools for installing the pipeline in the "warm floor"

- 3 Installation and connection of the pipeline in "warm floor" systems

- 4 Difficulties of choice

- 5 Rating of the best pipes for underfloor heating for 2025

- 6 Instead of an epilogue

Requirements for pipes of a water "warm floor"

The warm floor itself is a structure that is mounted on a reinforced concrete screed. Being in such "aggressive" conditions, pipes must withstand temperature and pressure drops without losing their own efficiency. Therefore, the materials of their manufacture must comply with some special requirements that guarantee long periods of their work. These include:

- Increased strength along with wear resistance (for example, polyethylene models have a durability guarantee of 50 years);

- Excellent thermal conductivity;

- Reduced hydraulic resistance;

- High resistance to corrosion;

- Sufficient flexibility for different types of laying, i.e. bending should not interfere with the proper performance of functions;

- Sufficient insulation and complete tightness.

It should be noted that the quality of durability will play a dominant role, because the pipeline must withstand various loads, while avoiding critical deformation. PVC products are considered the most durable, since this material is more stable in contact with aggressive substances and environments, and is also not subject to corrosion.

Classification of pipes according to the material of manufacture

The characteristic of the material from which the pipeline is made in the heating systems under consideration has a significant impact on the duration of operation and the overall service life.

- Polypropylene (polyethylene)

These models are extremely in demand for laying a heating main. They are characterized by excellent thermal conductivity, market availability and special durability. Of their shortcomings, only low plasticity can be distinguished. Polypropylene is extremely difficult to coil, and therefore, when arranging the floor, you will have to use additional corners / tees, connecting them together using a special soldering iron. With proper execution of installation work, it is possible to create a reliable design in the proper size.

- Stainless steel

These corrugated variations show the perfect combination of strength and ductility.They are characterized by an extended service life, which can only be limited by the wear of the replaced rubber seals, and on average this period is 20-30 years. If you make a complementary braid on them, then it will improve the mechanical strength of the pipeline.

- Polyethylene cross-linked

In the manufacture of polyethylene, it is subjected to a special high-pressure treatment process with the addition of peroxides, placing the future product under an x-ray beam or treating it with a silane. As a result, PEX products are obtained, which have increased strength and are resistant to high temperatures. These qualities are facilitated by the molecular carbon bonds of the three-dimensional level created in the structure.

If we talk about the most popular type of this material, then we can mention the combined REHAU brand polyethylene, the price of which will depend only on the size. This material is popular due to:

- Light weight, which makes the process of installation and transportation easy;

- The ability to dampen small pressure fluctuations in the overall design;

- The ability to restore shape when the stress factor is removed;

- Absence of tendency to manifestations of corrosion;

- Special strength;

- Frost resistance properties;

- Price availability.

Among the shortcomings, one can note the weak resistance to ultraviolet radiation, as well as some special requirements for installation work in terms of the use of special tools. Also, for this material, the anti-diffusion shell must be permanently intact.

- Copper

Products from this material occupy a special place among all other pipes intended for "warm floor".They can demonstrate an increased degree of thermal conductivity, are characterized by an extended service life (more than 50 years), and have corrosion and biological resistance. However, they are very sensitive to the coolant passing through them, namely to its hardness and acidity. Nevertheless, copper is not afraid of excessive temperature and mechanical influences, and with significant heating of the coolant water, it is not prone to melting and cracking. Copper can easily be given the desired type of bend, which makes it possible to form a highway from such products with any configuration and length. You will need special tools for installation. In addition, copper components can be connected to steel.

- metal-plastic

Such pipelines are considered the most popular, as they allow you to form a heating main of increased efficiency with better efficiency. Their aluminum layer, which is included in the structure of the material, is able to provide proper thermal conductivity. And thanks to the structural multilayer, it is possible to prevent the formation of harmful deposits inside the heat-conducting main. It is worth remembering that it is preferable to use a solid pipeline for a water floor, because the presence of many connections made using various turn signals and adapters increases the risk of coolant leaks.

Tools for installing the pipeline in the "warm floor"

When all calculations on paper along the heating circuit are completed, you can begin to select the necessary tools. As a result, before starting work, the master should have:

- Construction tape (for measuring various distances);

- Laser level (for more accurate construction of planes on horizontal lines);

- Construction knife (for accurate cutting of edge insulation, insulation and waterproofing);

- Calibrator (for work on pipes), chamfer, pipe cutter;

- Wrench / adjustable wrench (for connecting compression fittings to the distribution comb);

- Crimping equipment (for production and control of tightness).

Also, you need to take care of the following consumables:

- Thermal insulation (polystyrene or EPS, placed under the pipes);

- Polyethylene or multifoil waterproofing film (it is an air-bubble material with a foil coating);

- Edge insulation (foamed polyethylene in the form of a tape, designed for mounting on the surface of walls and between independent heating circuits, in order to compensate for the expansion of the screed when exposed to elevated temperatures);

- Reinforcing mesh (necessary for the protection of the concrete screed and strengthening the highway);

- Anchor brackets (for fixing the pipeline as a base element);

- Collector (aka comb), used to distribute the coolant evenly throughout the circuit;

- Mixing pump unit (required to maintain nominal temperatures for panel heating).

Installation and connection of the pipeline in "warm floor" systems

The main stages of laying the coolant line in the "warm floor" include:

- Laying damper tape indoors around the entire perimeter;

- Flooring of heat-insulating material;

- Laying of reinforcing metal mesh (variable);

- Installation of a distribution manifold assembly ("comb");

- Layout of the pipeline subject to the required bend radii;

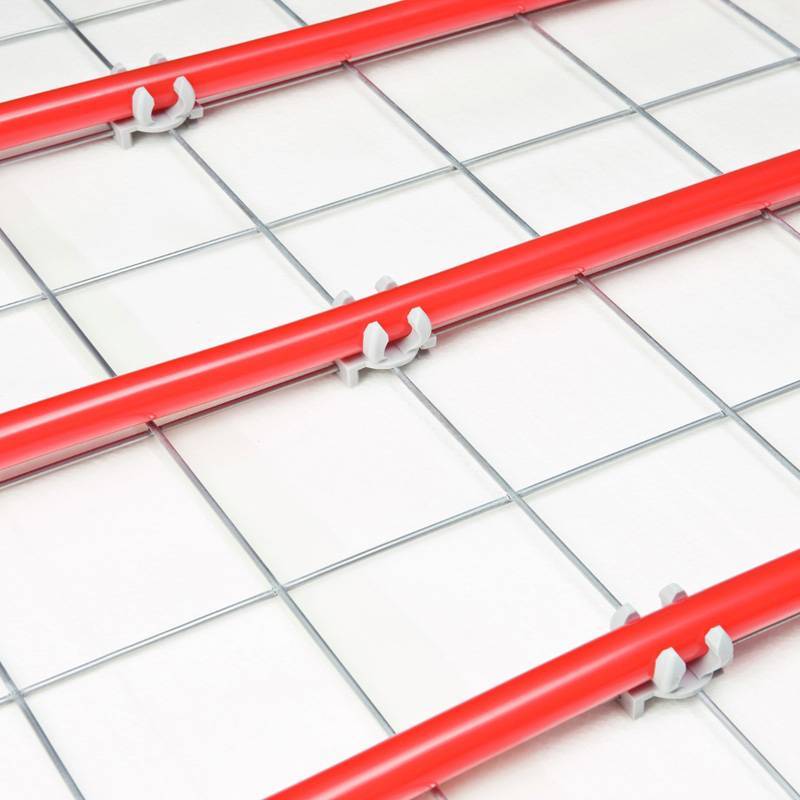

- Installation of pipes by means of plastic clamps / brackets-anchors on smooth mats or their installation in mounting mats with bosses;

- Laying a mesh of reinforcement over the pipeline to give the system special strength (variable);

- Full circuit pressure test to test overall tightness and strength.

Pipes are laid starting from the collector, and at the intersection of the damper seam, they must be protected by a special damper tire in order to avoid possible mechanical deformation. If the product is not particularly flexible, then the clamps are placed in increments of 1 meter. If work is carried out with a well-flexible material, then staples / clamps are installed more often - based on a distance of no more than 0.7 meters.

If a positive result is obtained during the test start-up of heating, then you can proceed to the formation of the screed. As a rule, a cement solution is used for this operation, where a special plasticizer is added (in a ratio of 3: 1). The composition must be thoroughly mixed, it must reach a uniform consistency, and only then they are allowed to fill the floor (until it has completely hardened). The average thickness for such a layer is 5 centimeters, starting from the upper tier of thermal insulation. The whole process can be facilitated by using ready-made mixtures specially produced for pouring water-type "warm floors" (however, such a solution is associated with inevitable additional costs).

An alternative way to arrange a water floor

All additional methods of constructing a "warm floor" based on water mains are extremely costly. The reason for this was the high cost of the materials used. However, some owners wish to take advantage of them. The most common of these is the so-called "dry screed method". It uses a solid prefabricated polystyrene board with slots for pipes.This option is thin-layer and is suitable for rooms with low ceilings, where an increase in loads on load-bearing floors is highly undesirable. To create such systems, smooth plates with special recesses intended for the heating pipeline are also used. Accordingly, the alternative method will be the best solution for laying out old wooden floors, which have significant load restrictions or are suitable for rooms with a fully completed renovation. Uniform heating in the “dry screed method” is provided by additionally superimposed straight and reversal plates made of galvanized steel.

Difficulties of choice

Before buying, it is necessary to clearly assess the conditions in which the pipes will be operated. This should include the rigidity of the winter period, the total heat loss of the building, the area of \u200b\u200bfurnished rooms, the design of the existing heating system, and the type of flooring. These parameters will directly affect some specific installation nuances - the permissible maximum temperature of the coolant, the pressure in the system, the length of the circuits to be laid, etc.

If, instead of a screed, frame equipment is planned, then external influences on the highway will be less. From this it is clear that it is possible not to use a protective tubular sheath. However, its absence will call into question the thermal conductivity indicator, because the heat will go outside, not restrained by anything. Experts believe that a stainless steel corrugated pipe will become the “golden mean” in this matter.

If a screed is planned to be applied over a warm coating, then metal-plastic products will be an ideal option.

Directly at the time of purchase, you need to pay attention to the following technical characteristics of the product:

- Strength - it is expressed in the nominal and maximum pressure allowed in the equipped system;

- Heating - there are also nominal and maximum values;

- Service life - is determined by the manufacturer, subject to the recommended mode of operation;

- Indicators of thermal conductivity and electrical conductivity;

- Ability to resist acid diffusion - this characteristic applies exclusively to synthetic materials and is expressed in the presence of an "anti-oxygen" layer;

- The ability to resist corrosion and various chemical activities - a list of substances with which contact is prohibited for the pipe;

- Mounting features;

- Brand reputation.

It should be noted that the last point often becomes the most significant, because any calculations made are easily offset by poor-quality production or material. Moreover, at first glance it is simply impossible to establish the degree of quality of the goods. In this case, the “name” of the manufacturer is the moment that can confirm the overall quality of the product, the degree of reliability of data on technical characteristics, which justify the validity of the ratio of quality and price.

Rating of the best pipes for underfloor heating for 2025

Polyethylene

3rd place: "PE-RT type II RTP 16 mm x 2 mm 100 meters heat-resistant polyethylene gray"

votes 1

Designed to create systems of cold / hot water supply, heating in residential, public, administrative and industrial buildings, as well as use as technological pipelines. The product complies with GOST 32415-2013 and is used for 1, 2, 4, XB pipe operation classes. Installation is carried out using press and compression (crimp) fittings.It is allowed to make connections by means of polyfusion welding using special fittings. These products are distinguished by special quality, reliability, ease of installation and packaging, durability and proven safety. The technical characteristics of the product are optimal for underfloor heating equipment in residential buildings and any commercial facilities. Different color schemes, variability of wall thickness and winding coils allow the implementation of the most unusual projects in the field of construction. The recommended cost is 4040 rubles per 100 meters.

- Sufficient length in the bay;

- Availability of various colors;

- Connection variability.

- Not detected.

2nd place: "SINIKON PE-RT 16×2.0 200m heat-resistant polyethylene"

votes 1

The product is made from high temperature resistant polyethylene. The use of this type is an economically viable option for utility systems. Such pipelines, as a rule, work with pressure from 2 to 10 bar at temperatures up to +80°C with limiting temperatures of +95+100°C.

With good long-term hydrostatic strength at elevated temperatures, along with excellent flexibility, the product is the best solution for high temperature underfloor heating, hot and cold water applications. The recommended cost is 8000 rubles per 200 meters.

- Ability to work at elevated temperatures;

- Wide area of use;

- hydrostatic strength.

- Not detected

1st place: "PE-RT type II EVOH RTP 16 mm x 2 mm x 200 meters 5 layers"

votes 1

This product has an EVOH type anti-diffusion layer. The EVOH anti-oxygen layer effectively prevents the penetration of oxygen into the pipeline, protects metal fittings from corrosion and ensures high quality of the coolant. The connection is made using compression fittings or press fittings. Products are distinguished by competitive price, quality, reliability, ease of installation, packaging, durability and proven safety. Technical characteristics are optimal for the formation of underfloor heating systems in residential buildings and any public facilities. Various color schemes, wall thicknesses and winding coils allow the implementation of the most original projects in the field of construction. The recommended cost is 13,048 rubles per 200 meters.

- Compound variability;

- 5 layers of security;

- Maintaining the proper quality of the coolant.

- Somewhat overpriced.

Cross-linked polyethylene

3rd place: "LerDepo PE-RT, 16x2.0 mm, coil 100m"

votes 1

Made of high temperature resistant polyethylene, intended for use in heating systems. Able to work at high temperatures and pressures of the working medium, has a low roughness of the inner surface and low energy costs for moving the heat transfer medium and insignificant noise generation, can return to its original shape after expansion or bending, which allows the use of connecting fittings without sealing rings, has flexibility, strength and abrasion resistance.It has a low weight compared to metal pipes, does not emit toxic substances into the environment and does not have a harmful effect on the human body in direct contact. The recommended cost is 4577 rubles per 100 meters.

- Easy and simple installation;

- Inertness to stray currents;

- Resistance to tearing when the medium freezes;

- The possibility of embedding in building structures and floor screed.

- Not detected.

2nd place: "PE-RT 200m CONTOUR"

votes 1

The product is used in all systems of heat and water supply and underfloor heating, due to improved mechanical properties when operating at elevated temperatures. The manufacturer has implemented and applies the international quality standard ISO 9001. At all stages of production, the quality of products is controlled by its own certified laboratory. The recommended cost is 8590 rubles per 200 meters.

- Maximum operating temperature: +70 °С;

- Maximum emergency temperature: +200 °С;

- Service life - 50 years;

- Warranty - 10 years.

- Not detected.

1st place: "PEX-b-EVOH DTRD cross-linked polyethylene with anti-diffusion layer"

votes 1

This product is intended for cold/hot water systems, hot water heating, including surface heating and snow protection. The connection is made by means of press and compression (crimp) fittings. The recommended cost is 13,710 rubles per 200 meters.

- Increased strength, flexibility;

- Resistant to pressure and temperature changes;

- Low coefficient of linear expansion;

- Complete absence of corrosion, deposits;

- High chemical resistance, including antifreeze in any concentration.

- Not detected.

metal-plastic

3rd place: "PEX-AL-PEX 26x3.0 coil 100m (without seam) TST"

votes 1

In addition to transporting water and non-freezing glycol coolants, it is allowed to use this product as part of pipelines of other media that are non-aggressive to the materials used. The advantage is the absence of corrosion, strength, smooth inner surface, technological and economical installation. Operating temperature at a pressure of 10 bar - from 0 to +95, operating temperature at a pressure of 25 bar - from 0 to +25. The recommended cost is 17341 rubles per 100 meters.

- Excellent strength;

- Smooth inner surface;

- Ability to work with different coolants.

- Not detected.

2nd place: "FV MULTI PERT-AL 16 (2.0) bay 200m"

votes 1

The product can be used both for transporting water and non-freezing glycol coolants in underfloor heating, as well as for other media that are non-aggressive to the materials used. The sale is carried out in bays in protective packaging. Size indicators - outer diameter and wall thickness of the metal-plastic pipe. Possesses memory on a bend and the increased durability. The five-layer construction has a longitudinally welded aluminum layer, the maximum operating temperature is +95°C. The recommended cost is 21,835 rubles per 200 meters.

- Delivery in protective packaging;

- Five layer construction;

- Wide scope.

- Somewhat overpriced.

1st place: "VALTEC 16 (2.0) bay 200m"

votes 1

Extremely durable and reliable pipe model for arranging a warm floor.Easily laid and equipped with a cement screed. It has a long service life and a five-layer base structure, which indicates increased strength. During operation, it does not emit foreign unpleasant odors and toxic substances into the surrounding space. The recommended cost is 23,059 rubles per 200 meters.

- Environmental friendliness;

- High strength;

- Possibility of work with different heat carriers.

- Somewhat overpriced.

Instead of an epilogue

The range of pipe products for a water floor in the current market is huge. However, for underfloor heating systems, most of them are suitable with only a few caveats. The underfloor heating pipes from the inside are under increased pressure from the hot coolant under pressure, and the installed screed presses on them from the outside. Operating conditions are quite specific. Making a choice for such a consumable, looking only at prices, is unacceptable. Therefore, it is worth learning how to compare the technical characteristics of a particular product with the conditions for its future use.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131651 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127691 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124519 -

The best men's sneakers in 2025

Views: 124033 -

The Best Complex Vitamins in 2025

Views: 121940 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114980 -

The best paint for gray hair - top rating 2025

Views: 113395 -

Ranking of the best wood paints for interior work in 2025

Views: 110319 -

Rating of the best spinning reels in 2025

Views: 105329 -

Ranking of the best sex dolls for men for 2025

Views: 104366 -

Ranking of the best action cameras from China in 2025

Views: 102216 -

The most effective calcium preparations for adults and children in 2025

Views: 102011