Rating of the best pipes for outdoor sewage for 2022

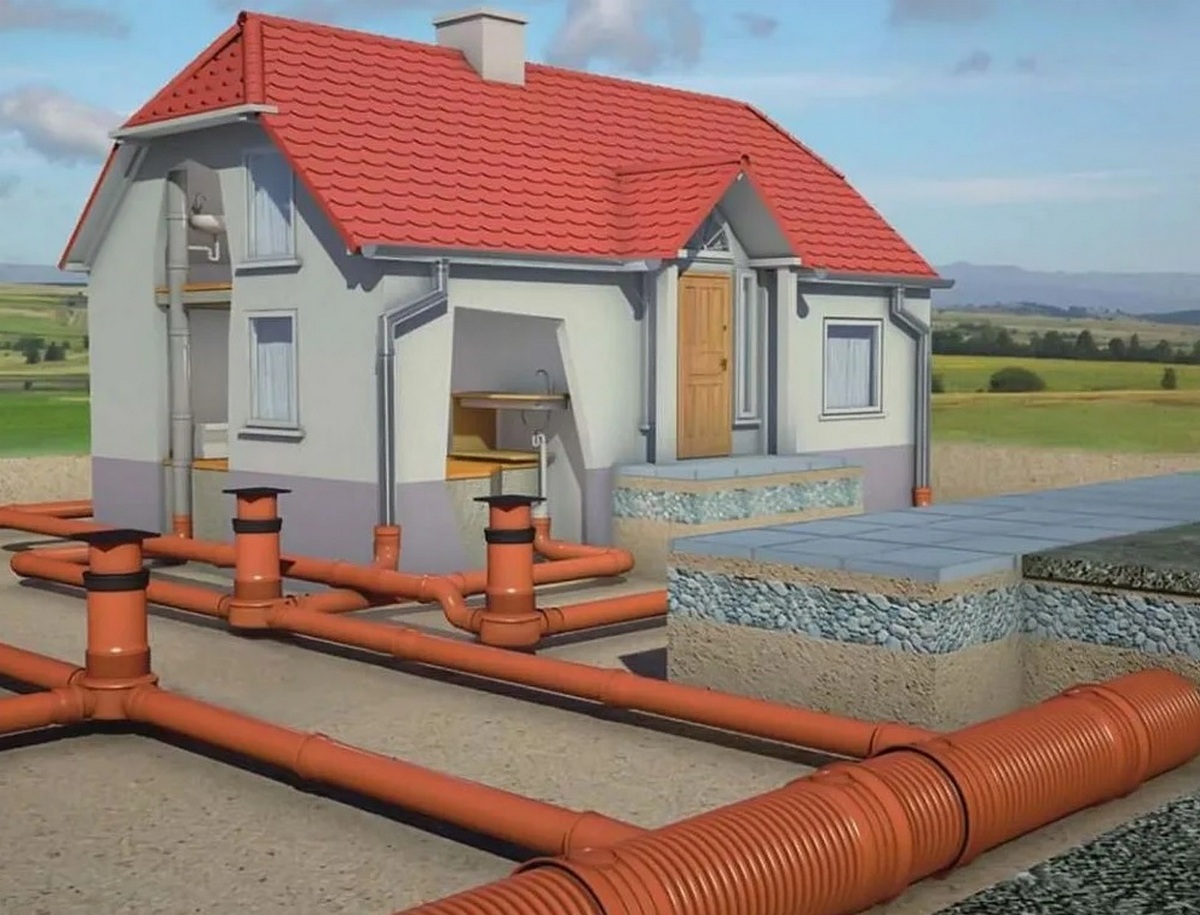

The proper and high-quality operation of the sewerage system will depend not only on internal communications, but also on the pipeline laid outside. These structures are often forced to work in difficult conditions. Accordingly, these pipes must have the properties of resistance to operational wear, be durable and endure any temperature changes. The modern building materials market for creating such networks offers many variations of a wide variety of components. The main thing for the consumer is to carefully study all their characteristics and choose the most suitable option for themselves.

Content [Hide]

- 1 Technical requirements for external sewer lines

- 2 Modern types of pipe material

- 3 PVC pipes as the best material for outdoor sewage

- 4 Self-assembly of external main sewage

- 5 Difficulties of choice

- 6 Rating of the best pipes for outdoor sewage for 2022

- 7 Conclusion

Technical requirements for external sewer lines

Conditionally, only 7 main qualities can be distinguished:

- Proper resistance to static and dynamic loads;

- Stability in interaction with groundwater;

- Increased strength;

- Operational wear resistance;

- Resistance to chemically aggressive agents and substances;

- Resistance to various mechanical influences;

- Ability to withstand temperature extremes.

However, the long-term operation of external sewage will depend not only on the quality of the pipe material used, but also on the well-executed laying of the main, which is not possible without the use of various optional components, such as fittings, corners, plugs, etc. Moreover, additional elements must be compatible with the main segments.

Modern types of pipe material

Cast iron

This material for the manufacture of outdoor communications has been known for a long time and is often used. It is equally good for laying inside buildings and for creating highways outside. Cast iron is characterized by resistance to temperature extremes, is able to withstand various aggressive environments, has increased anti-corrosion qualities, because cast-iron models are necessarily coated with special compounds both inside and out. It is also possible to note their long service life (more than several decades), high strength of the material used, i.e. cast iron (specifically, its ability to withstand significant mechanical loads), which means the overall reliability of the entire assembled structure. In terms of installation, cast iron products do not require the use of any special tools, and a standard cement mortar can be used as a sealant. However, the material under consideration has three significant drawbacks:

- The large weight of the products complicates the installation process, making it rather laborious;

- The inner surface has a certain roughness, which over time allows calcareous growths to form inside them from the constant passage of liquids, and this will necessarily lead to a decrease in throughput and the formation of blockages;

- High price.

IMPORTANT! The practice of the Soviet era shows that cast-iron pipelines can easily withstand up to 80 years of operation.

Ceramics

This material in the field under consideration has been used relatively recently, no more than two decades, but has already managed to become popular. There are several reasons for this:

- Excellent resistance to chemicals, which allows the passage of almost any liquid substance through these samples;

- The inner surface has almost no roughness, so the risk of growths (and, as a result, blockages) is minimal;

- Designs can successfully work with any heated liquid, as well as withstand external elevated temperatures;

- Ease of installation.

Separately, it is worth mentioning the fragility of this material, therefore, you need to choose products from it carefully, carefully examining the product for cracks and chips. The same applies to the accuracy of transportation and the installation process, so that the products do not get damaged. In addition, ceramics will need to use optional elements (joints, adapters), because its length is limited by the properties of physical fragility. This product is supplied with cutting and socket, and the diameter can be from 10 to 60 centimeters.

asbestos cement

Another type of material suitable for making external sewer lines. Portland cement and asbestos fiber products are quite light, so their installation is not particularly difficult. They have a number of important qualities, such as: they successfully resist the formation of internal growths, steadily conduct chemically aggressive substances inside themselves (which implies the possibility of running through the system of any liquid substances), have a long service life, which is at least 50 and maximum 100 years. During installation, if necessary, trim the object, no special tools are needed, it is quite possible to get by with standard helpers.Yet, like the previous type, asbestos-cement variations are quite fragile, which means that careful transportation and installation is necessary. At the same time, at the time of purchase, each part must be carefully inspected for the presence of falcons or cracks.

Corrugated polyethylene

Products from this material are quite popular, because they are suitable for the formation of sewer mains according to various complex schemes, with various dimensions and capacities. Corrugated polyethylene samples can easily endure both high and low temperatures (up to +100 Celsius, but only for a short period), are characterized by a long service life (tens of years), their inner surface does not allow the formation of monolithic deposits due to its own smoothness, and ease of installation does not require the use of special devices and tools for installation. It is also worth noting that it is corrugated polypropylene that has special strength, because it consists of two layers:

- Internal smooth - resists the formation of growths from passing fluid;

- External corrugation - resists high mechanical loads.

The parts of the highway themselves can be laid over very long distances, fastening its individual components using the cold welding method. However, this material is not recommended for placement in an area exposed to direct sunlight.

Polypropylene

This material, due to its fragility, is not often used for the installation of an external sewer system. It is customary to equip private houses and country stormwater with such designs. The advantages of this material include:

- Low weight, thanks to which these models are easily transported and mounted;

- Sufficient durability - proper installation will provide up to 50 years of guaranteed service life of the system;

- The smoothness of the inner surface - this quality will not allow the formation of growths, but only with proper installation;

- Toxic and chemical resistance;

- Ease of assembly and installation - no need to use special equipment or special tools;

- The ability to overcome temperature fluctuations - the maximum upper limit is up to +95 degrees Celsius.

These plastic products, despite their wear resistance, are easily cut with a saw for metal, while not forming cracks and permanent chips in the place of cutting. The market for optional accessories for these sewer samples is very wide, the required additional item (fittings, etc.) is very easy to find in any hardware store.

PVC

This material is probably the best in terms of using it for the production of external sewer pipes. This is due to its technical, physical and operational properties. Today's market can offer three main types of PVC pipes:

- Light variations for installation only outside (or at a shallow depth) - not able to withstand extreme mechanical loads:

- Medium hard variations - they can be installed both outside and underground, can withstand sufficient pressure;

- Heavy variations - they have very thick walls, they are installed mostly underground (up to 8 meters deep) and are used to design industrial sewer networks. It is not economically feasible to use them for suburban private sewage.

PVC pipes are distinguished by easy installation, resistance to many chemically aggressive substances, low weight (availability of manual installation), increased strength and frost resistance, a smooth surface inside that does not retain solid fragments in drains, low cost and long service life.

IMPORTANT! PVC pipes still should not be used on highways where the passing liquid will have temperatures of +60 and above degrees Celsius - this can lead to expansion of the material due to heating. Installation is simple and does not require special skills.

PVC pipes as the best material for outdoor sewage

economic benefit

It will consist of the following indicators:

- Small transportation costs;

- Financial savings on consumables and components;

- Low labor intensity of the assembly process;

- Almost complete absence of waste in the operational process;

- Complete environmental safety.

Specifications and connection features

Outdoor PVC sewerage is considered the next generation main, which will soon replace all other types of pipes from household systems. This is due to the installation features and the ability to work with high pressure up to 10 MegaPascals. Many installation options will allow you to assemble the desired design with ease:

- Socket connection - this type does not require the use of special equipment, you only need to select pipes by diameter. The smooth end of one product is simply inserted into the socket of another, and the sealing is carried out by means of a rubber seal.

- "Cold gluing (welding)" - a special glue is used for this method, the procedure is simple and intuitive, no special equipment is required.

- Flange connection (detachable) - all elements are assembled through fittings that create all kinds of turns and branches and thanks to which the entire structure can be disassembled.

- Coupling - this method is used when a PVC pipe needs to be connected to a model made of a different material (a similar situation is typical for repair work).

Self-assembly of external main sewage

Installation of external sewage in any case will require the availability of project documentation, no matter how simple its design may be - it is necessary to calculate the dimensions of the entire system, select material, count the number of joints and turns. Next, you should purchase all the building materials, acquire the necessary tools and you can begin the installation process. It will include the following steps:

- According to the project, the boundaries of laying the entire structure on the ground are first outlined. Its location will depend on the type of pipes chosen, the height of the passage above the surface and the possible maximum load,

- The place where parts of the highway pass is sprinkled with sand.

- It is allowed to install formwork, which can be sealed or have spacers.

- If there may be a risk of flooding the entire system on the site, then you need to rid it of water as efficiently as possible, for which you can use a drainage system with special pumps. In general, it is absolutely undesirable for the pipes to be in the water.

- Then, the pipes themselves are laid out on a dry base. If plastic products are used, they must first be attached using the socket method, while not forgetting to use rubber seals.

- The laying itself must begin from the house foundation and outward, and all turns are carried out through fittings.It is worth noting that it is highly desirable that both pipes and additional elements be made of the same material, otherwise, when heated / frozen, the articulation systems may disperse.

- All connecting points must be coated with silicone sealant and checked for leaks.

- There must be a moving part at the junction of the pipeline and the septic tank, otherwise the pipes may burst during seasonal ground displacements.

- After completing the main installation, plain water should be passed through the pipeline, checking the structure for leaks.

- If the pipeline is laid on the ground, which is subject to freezing in a certain season, then the pipes must be insulated from the outside with special materials.

- It is allowed to cover the entire finished and tested line with sand or portions of soil, but they are not subject to compaction.

- If the length of the highway exceeds 15 meters, then special signs (or hatches) must be installed at the turns.

Difficulties of choice

When selecting pipes for outdoor sewage in a store, you need to pay attention to the following points:

- Color - it is preferable to choose orange or red colors, because they contribute to easy detection of the laid pipe, at the same time they will not allow unintentionally damaging the line during earthworks.

- Wall thickness - for an external system, this indicator should always be greater than that of an internal one. On the example of PVC samples, it should be 3.4 millimeters against 2.

- Material of manufacture - external pipelines require the use of materials with improved qualities of resistance (as one of the best examples is unplasticized polyvinyl chloride).

- Heat resistance properties – thanks to thicker and more robust walls and the addition of optional components, the heat resistance of outdoor systems should always be greater than that of indoor systems. However, even external pipelines may need separate insulation.

- Operational life - in principle, any material of sewer pipes can easily withstand a couple of decades, but the larger this characteristic, the better the reliability of the entire system;

- Cost - due to its own better technical parameters, the cost of pipes for external sewerage will always be 20% higher than that of similar internal models.

IMPORTANT! Experts strongly do not recommend the use of gray pipes for laying external networks. They are barely visible on the ground, so it's much easier to inadvertently damage them.

Rating of the best pipes for outdoor sewage for 2022

Budget segment

3rd place: "Contour" external bend 45 ° 110 mm "

votes 1

This model has a diameter of 110 mm and a length of 0.185 m. It is intended for guiding the pipeline when laying an external sewage system. Manufactured from polypropylene, equipped with O-rings to seal the joint. Country of production - Russia. Warranty - 10 years, weight - 0.173 kilograms. The recommended cost for retail chains is 110 rubles.

- Small cost;

- The presence of sealing rings;

- Quality material.

- Not found.

2nd place: "Ostendorf KGEM PVC 110×500 mm"

votes 1

This model is made on the basis of unplasticized polyvinyl chloride (PVC-U).Thanks to this, the inner wall of sewer pipes is completely smooth, resistant to abrasive, the outer layer is characterized by endurance, resistance to all substances that are commonly used for backfilling the main, and the flexible core perfectly tolerates pressure and wheel load. Durable marking with the designation of the manufacturer, nominal diameter, standard (DIN EN 1451-1), date of manufacture (the angles of inclination are additionally marked on the fittings), a centimeter ruler is applied to the model. The recommended cost is 210 rubles.

- Super quality material;

- Chemical resistance;

- Additional marking.

- Not detected.

1st place: Leroy-Merlin SN4 110x2000 mm

votes 1

This polypropylene part has a diameter of 110 mm and a length of 2.078 m, designed for laying outdoor underground sewerage. Resistant to drains containing chemically aggressive substances, can withstand the temperature of the drained liquid up to +65 °C, for a short time (up to 300 seconds) - up to +95 °C. A flare joint with an O-ring can ensure complete tightness. The smooth inner surface prevents the formation of deposits. The recommended cost for retail chains is 480 rubles.

- Counteraction to chemically aggressive substances;

- Adaptability to temperature changes;

- Complete tightness.

- Not detected.

Middle price segment

3rd place: PVC-U Chemcore 160 x4.0/L=1000

votes 0

This Russian-made polymer sample is used to create systems that function for decades.It is characterized by excellent drainage of domestic wastewater, high-quality removal of liquid waste generated from human economic and industrial activities, proper drainage arrangement, up to storm sewer equipment. Plastic models are used in private housing construction - as the basis of the main external sewage system. The recommended cost is 750 rubles.

- Excellent technical characteristics;

- Bright color;

- Good value for money.

- Not detected.

2nd place: "RegionTrubKomplekt" corrugated model with socket 250/216 SN8"

votes 0

This two-layer corrugated sample with a monolithic socket is designed for the arrangement of non-pressure drainage systems in the form of external sewer lines. Fully complies with GOST R 54475-2011, has an increased ring stiffness, the maximum service life is 50 years. The recommended cost for retail chains is 810 rubles.

- Rugged housing;

- Compliance with Russian requirements and standards;

- Long service life.

- Slightly overpriced.

1st place: "Polytron ProKan SN10 with 300 L=6 m coupling"

votes 1

This two-layer polypropylene corrugated product is equipped with a coupling and is used in non-pressure drainage systems, which include variations of external sewage. The model guarantees maintaining the maximum temperature at a continuous flow of +60°С and short-term +95°С Celsius. Deliveries are made in lengths of 3 m or 6 m. Corresponds to Russian GOST R 54475-2011, average service life is 50 years.The recommended cost for retail chains is 11,000 rubles.

- Extended temperature mode;

- Operational service life is increased;

- Delivery variability.

- Extremely overpriced.

Premium class

2nd place: "Leroy-Merlin" two-layer corrugated 315 mm, 2 m"

votes 1

Such a two-layer corrugated plastic sample is intended for non-pressure drainage. It can be both household, and storm, and general sewerage. The pipe is made of polymer, in itself it is much lighter and more durable than reinforced concrete counterparts, easy to install and maintain, does not require the use of special equipment, and can withstand high loads. As needed, it can be cleaned using a special hydraulic machine. The advantages include a long service life, easy installation, corresponding to the quality of the cost. Almost any optional elements for the installation of sewer systems on this base are available on the market. Supplied in 6 meter lengths. The recommended cost for retail chains is 12,290 rubles.

- corrugated surface;

- Resistant to high loads;

- Decent value for money.

- Not detected.

1st place: "ARM" D 2585/2400 SN8"

votes 0

A very expensive model, which has a multilayer corrugated structure, is additionally reinforced with reinforced metal. Production material - HDPE and steel sheet. Designed for non-pressure industrial-scale drainage systems. Supplied in lengths of 6 meters and has a very large diameter.The recommended cost for retail chains is 50,000 rubles.

- Large throughput;

- Industrial purpose;

- Multilayer structure.

- Application for private households is not economically feasible.

Conclusion

Every year the choice of pipes for external sewerage is becoming more extensive and rich. Therefore, some private developers often ask themselves the question - “Which pipes are better for these systems?”. At the same time, there is a desire to find out which of the samples on the market will be more durable and cheaper. Everyone wants to get the most reliable and durable product. From this it is clear that this issue should be approached with all care, since the operation of the entire sewer system located outside will depend on the type of product.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131650 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127690 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124518 -

The best men's sneakers in 2022

Views: 124033 -

The Best Complex Vitamins in 2022

Views: 121939 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114979 -

The best paint for gray hair - top rating 2022

Views: 113394 -

Ranking of the best wood paints for interior work in 2022

Views: 110318 -

Rating of the best spinning reels in 2022

Views: 105328 -

Ranking of the best sex dolls for men for 2022

Views: 104365 -

Ranking of the best action cameras from China in 2022

Views: 102215 -

The most effective calcium preparations for adults and children in 2022

Views: 102011