Rating of the best transporters and furniture moving kits for 2022

By itself, the process of rearranging furniture can change the interior of the room radically and at minimal cost. However, it often becomes necessary to move a rack or cabinet in such a way as not to damage the flooring, and to do this procedure with minimal labor. Naturally, all this can be done only at the expense of one's own muscular strength, but then such a movement may be fraught with the risk of injury or damage to a piece of furniture or the environment.Therefore, today there are many ways to perform this operation - from purely folk (lining various items used as sliders, for example, plastic tires) to quite technological (for example, furniture conveyors).

It is worth noting that some transportation kits are direct successors of folk methods, and it is possible to include special slider stands made of a special material and produced in the factory. But a more productive tool for carrying out operations for the transportation of large furniture are furniture conveyors. With their help, it is possible to lift the edge of the object, place the fastening legs on it, and then securely fix the object on a special moving platform. Using such a device will allow you to move the object without much effort.

Content [Hide]

- 1 Modern technological ways to move furniture

- 2 "Folk" ways

- 3 Features of the use of furniture conveyors

- 4 Features of using sets of furniture sliders

- 5 Features of the movement of furniture on different types of surfaces

- 6 Creation of an air cushion for the relocation of very heavy objects

- 7 Safety regulations

- 8 Rating of the best transporters and furniture moving kits for 2022

- 9 Premium class

- 10 Instead of an epilogue

Modern technological ways to move furniture

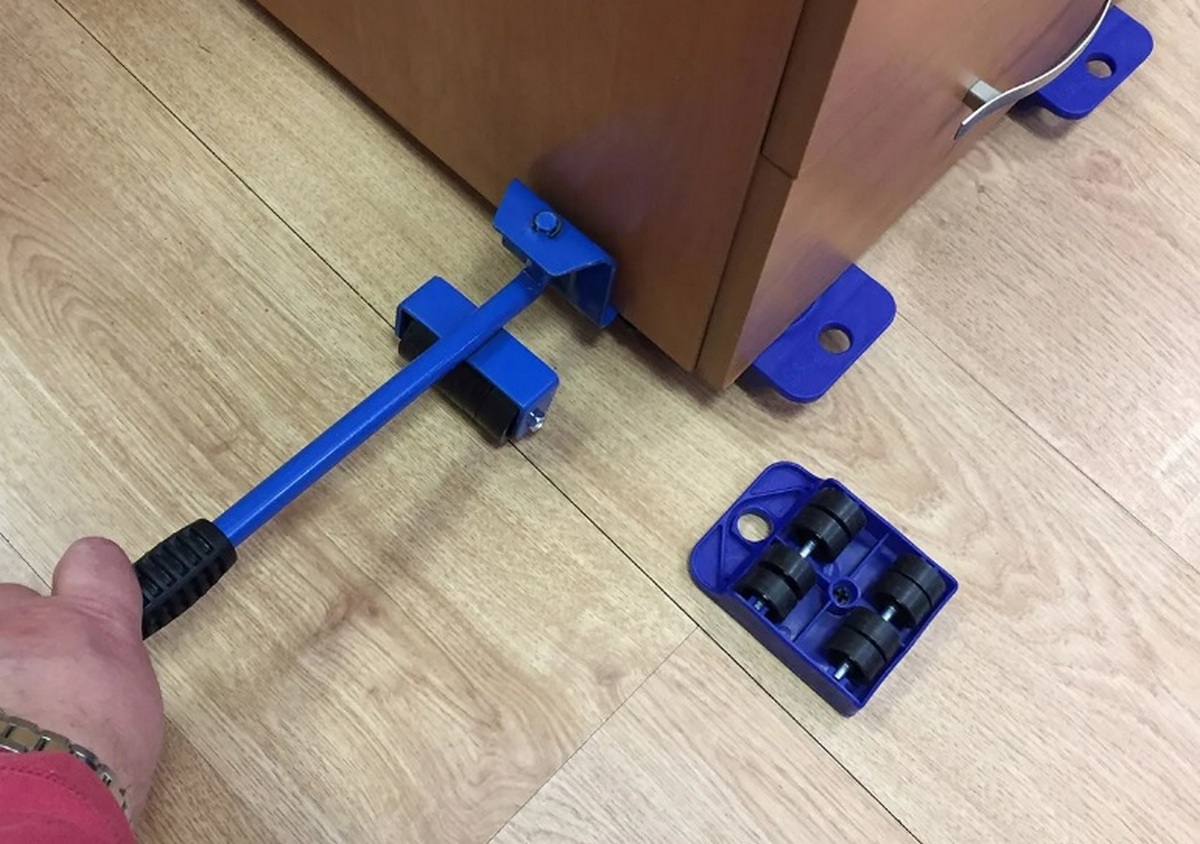

- Furniture conveyors

This is a set of items that includes a small lever that has the function of a jack, responsible for lifting one of the corners of a piece of furniture, and it also includes four coasters with wheels that can be directed in any direction. Substituting mechanisms for movement under each side of the object, it will be easy to move around the entire perimeter of the room.

IMPORTANT! In cases where it is required to move a heavy object precisely on a decorated coating (carpet or carpet), then a conveyor with wheels of a large diameter should be selected so that they cannot “drown” in the pile of the coating.

- Special furniture stands

They are squares or circles of various diameters and thicknesses. To move around the carpet, plastic ones with a smooth base are suitable. They are fixed on an adhesive base, either on built-in nails or on screws. The option with built-in nails is perfect for massive furniture, because it can be very difficult to put such an object on its side.

IMPORTANT! It should be remembered that the fixation of adhesive-based coasters is not always able to withstand the weight of massive objects, so it must be reinforced with super-glue with high adhesion!

- Hand ("garden") carts

To carry out the operation of moving furniture, it is also possible to use ordinary metal carts on two wheels. A similar option is used in cases where it is necessary to move a relatively small object (bedside table or chest of drawers) from one room to another. However, even if the object is light, but has large dimensions in width, it is preferable to work together so that the second person can hold the opposite edge. However, you can also secure the object for stability with a flat and wide belt.

- Durable foil

This simple way of moving is most suitable for furniture, in which the supports are made in the form of legs. This includes tables, couches, massive chairs. The foil is simply folded in several layers, then placed under the leg, and the free edges are wrapped around. Such wrapping will not allow the material to peel off the leg during movement. It should be noted that this method is not suitable for very massive objects - the foil can easily tear under their weight.

- Carry straps

Special belts (it is also possible to use a regular strong rope) for carrying are the most popular way to move any piece of furniture that is not small in size. However, such carrying should be carried out by at least two people. The essence of the method lies in the fact that a belt (or rope) is stretched under each pair of legs, and its ends are held by people. This method is very effective when it is required to carry out an operation, which is called “on weight”, avoiding contact when moving furniture with a sensitive floor surface. The method will 100% save the floor covering from dents, scratches and other mechanical damage.

- Hardboard fragments (hardboard)

This method is best used when you want to move a small cabinet or cabinet on a fleecy surface. To do this, the hardboard with a smooth side is placed on the carpet, and the rough side is placed under the leg of the object. Further, to evenly move all sides, it is preferable to use belts.

"Folk" ways

- Using Lubricants, Glycerin, Detergents or WD 40

These tools are perfect for moving furniture on flat and even surfaces. But first you need to check if the product leaves unnecessary marks on the floor covering. To do this, it is applied to an area that is not visually conspicuous in the interior of the room. Next, you need to wait a few minutes and wash off the applied composition with a degreasing solution. If there are no traces left on the floor, then the composition can be safely applied.

To move, it is necessary to distribute the sliding composition on the floor along the future trajectory of the object, in proportion to its width. Then you need to set the object on the created "path" and move it with light efforts. The friction force in this case will be extinguished by the sliding properties of the composition. It should be mentioned that this method is preferable to use when moving furniture over short distances.

- Use of mats

This method is suitable for moving furniture pieces on carpet or carpet. To do this, I turn the rug upside down, and an object of movement is installed on its rough surface. The fleecy side will perfectly slide over both the pile and the parquet, and the wide base of the rug will be able to capture the bottom of the furniture across the entire width.

- Use of felt coasters

They are made by hand, similar to plastic coasters, but are considered less dangerous for smooth floors.With their help, it is possible to move large-sized structures without parsing them in parts. To speed up all processes, it is worth using at least four gaskets.

- Use of a bedspread

To move furniture, it is also possible to use an ordinary blanket, which can also be used to cover things when transporting them by road. The essence of the action is very simple - a cover is simply laid under the lower base of the object and then it is simply dragged to the right place. Also, with the help of several bedspreads, it is possible to move the load up, for which they (the bedspreads) need to be laid out on a flight of stairs, creating a kind of ramp. However, this method will require the participation of at least two people.

Features of the use of furniture conveyors

Traditional sets for moving furniture are a lever with a comfortable handle, combined with a wheeled platform. By means of the lever, the platform is installed in the right place. For proper use of the conveyor, several parameters should be taken into account:

- The material of its manufacture and all parts (may be different);

- Dimensions of a piece of furniture;

- The design of the legs of this item.

The wheels for the device must be selected depending on the surface on which the movement will take place - whether it will be parquet or laminate, or soft flooring. At the same time, you should make sure that the device as a whole is comfortable to use. Professionals say that a high-quality conveyor will allow even a person who does not shine in physical form to cope with the movement of a large-sized object alone.However, the help of an assistant in complex operations should not be neglected, because extra control and safety net of the entire process will never become superfluous.

Thus, when choosing a conveyor for transporting furniture, you need to pay attention to the following points:

- The material of manufacture - the platform itself with the lever must be made of durable metal that can withstand a significant load. Steel is excellent for these purposes, as a material that is strong, durable and resistant to deformation. It is from a material of similar quality that a lever must be made without fail.

- Platform - it must be suitable in size, shape, be provided with sides and a relief surface. The best option would be the presence of a universal base, which has a rounded recess for the legs and corresponding sides on both sides. Such limiters will not allow the load to slip during movement.

- Wheelbase - the material of the wheels must be as strong as the arm and platform. The minimum standard for conveyors is to maintain a load of 100 kilograms. It would be ideal to have wheels with a swivel function. Sometimes, instead of a wheelbase, moving plates are used - they work best on a decorative fleecy coating.

- The shape of the handle - the thinner the part that needs to be pushed under the furniture, the smaller the gap will be needed for it. A metal cylinder or a wheel is usually used as a support. Wheeled models are best used for sensitive types of flooring - they will scratch the floor less.

IMPORTANT! It should be noted that for large-sized furniture it is possible to use several conveyors at once - this is a common practice.

Features of using sets of furniture sliders

Special furniture sliders are a set of technological and simple devices, thanks to which the process of moving furniture is greatly simplified. As a rule, several pieces of sliders are included in the set, which makes it possible to move furniture of various dimensions and with a different number of supports. Depending on the type of surface on which the object is supposed to be moved, the appropriate type of sliders should be selected (with a plastic or fleecy base).

The process itself is quite simple: the slider is individually placed at the desired angles or furniture legs. To do this, the object is slightly raised and a slider is placed under it in the appropriate place, turned with its working side to the floor surface. The working side will reduce the friction force, which will greatly facilitate the movement procedure.

Next, the trace object is simply pushed in the desired direction along the surface. The movement should be smooth and in small jerks, with the help of a second person will be useful in order to exercise proper control over the stability of the object. Upon completion of the movement, the sliders are simply removed from under the furniture.

Features of the movement of furniture on different types of surfaces

Methods for fleecy coating

In order to prevent a breakthrough of the soft cover when moving large-sized furniture, it is preferable to use devices on rollers or sliding devices. However, the key to a successful move will be the observance of the following features:

- Large-sized furniture must be freed from the things in it;

- Its internal elements, for example, removable heavy shelves or drawers, are also preferable to be removed for a while;

- Any locking elements, such as sashes or doors, must be immobilized by securing them with tape.

Smooth Coating Methods

When moving massive furniture structures on an unprepared surface, there are many risks - the surface may be damaged or even the person himself will be injured. To prepare a smooth coating for the movement of furniture, you should start by washing the floors. Heavy objects will move more easily if there is no dirt on the surface that can create excessive friction. Depending on the chosen method, the movement can be carried out either with the help of special devices. Or simply lubricating the path of movement with a sliding composition. It is worth remembering that movement on a freshly painted surface is not allowed in order to prevent damage to the paint layer. It is required to wait the required period in the amount of 8 to 10 days.

Creation of an air cushion for the relocation of very heavy objects

In cases where you need to move an extremely heavy object, even regardless of its dimensions, the best option would be to use an air cushion, which you can make yourself. It will lift the load above the surface and simply slide on it, which means a decrease in the applied muscular effort on the part of the person at times.

To manufacture and manage such a pillow, you will need:

- Small pump (for example, for inflating an inflatable boat);

- A sheet of plywood of the required area with a thickness of at least 8 millimeters;

- Fabric rubberized on one side;

- Polyethylene foam pad.

The manufacturing process includes the following steps:

- First, a cushion platform is made from a sheet of plywood, the size of which should be slightly larger in area than the base of the furniture to be moved (i.e. the edges of the plywood should extend beyond the base of the object);

- Closer to the edge, a hole is made in plywood for inserting a pump nozzle for pumping the pillow with air;

- Linings are cut to fit the size of polyethylene foam plywood, the total length of which must be at least 20 millimeters;

- Then a piece of rubberized fabric is prepared that does not allow air to pass through, its dimensions must be larger than the dimensions of the plywood base by at least 10 centimeters on each side;

- The prepared piece of fabric is tucked up and attached to the plywood base in such a way as to prevent involuntary release of the pumped-up air under the pressure of the object being transported. Fixation is carried out using a reliable super-glue with a high level of adhesion.

Upon completion of the glue hardening process (the period is indicated in its instructions), the pillow is ready for use. It should simply be placed under the object, air is pumped into it, and then moved. The smooth surface of the pillow will easily slide on a flat base, and its rough part, inflated with air, will hold the object being moved. However, if the object itself is dimensional, then stability control by another person will be required.

Safety regulations

Moving furniture is always a pretty hard job that carries the risk of injury. From this it is clear that people involved in this process must comply with the minimum safety requirements:

- It is necessary in a calm environment and technically competently to plan the entire procedure, while at the same time making sure that the transport devices are securely fixed.

- Do not apply excessive force to heavy and dimensional objects if they do not give in the first time. It is better to use special means of transportation.

- The path of movement must be freed as much as possible from all sorts of obstacles, so as not to complicate the process of movement bypassing them.

- During the movement of the object, constantly maintain a stable position, do not make sudden maneuvers.

- Always remember that it is better to disassemble a large object in parts and reassemble it in a new place. This simple method will help to avoid traumatic situations.

- You should not neglect the help of other people - together it is easier to control the position of the furniture and its stability during its rearrangement.

Rating of the best transporters and furniture moving kits for 2022

Budget segment

3rd place: "EURO-LIFT CRA6 00012451 load capacity 6 t"

votes 0

This platform is characterized by small dimensions and is intended both for moving pieces of furniture and for various heavy loads. The model has small polyurethane wheels, which greatly facilitates transportation. Such a wheelbase ensures comfortable movement under pressure even of heavy objects. The device itself is reliably welded from durable parts, has stiffening ribs under the platform, which ensures greater strength and quality. Country of origin - Russia. The established cost for shops is 5300 rubles.

- 4-wheel strong base;

- Simple control;

- Small size.

- No swivel mechanism.

2nd place: "EURO-LIFT CRA8 00012452 capacity 8 t"

votes 0

This example of a roller transport platform is designed to transport small pieces of furniture, despite the fact that they can have quite a significant mass. There is a swivel mechanism that allows you to rotate all 360 degrees. The model is characterized by increased reliability, which is ensured by the thick metal of the entire structure. The elements are connected by welding seams. There are stiffening ribs under the base providing maximum lifting force. The weight is evenly distributed on all 6 wheels. Country of origin - Russia, Set price for store chains - 8,500 rubles.

- The presence of a rotary mechanism;

- 6-wheel base;

- Reliable construction.

- Calculation for work together.

1st place: "EURO-LIFT SF-20 00001345"

votes 0

This conveyor is specialized in moving very heavy furniture objects. The wheels are made of durable material, which allows you to evenly distribute the total pressure over the surface. It also (wheelbase) ensures that there is no risk of surface damage during transportation. Strong welding seams perfectly connect all structural elements. The country of manufacture is Russia, the established cost for retail chains is 8900 rubles.

- The presence of a special handle for ease of installation of the object;

- The use of thick sheet steel in the structure;

- Warranty - 1 year.

- Not detected.

Middle price segment

3rd place: "Stella SF60 6t"

votes 0

This conveyor is equipped with 6 castors with nylon protection, which allows you to carefully handle the floor covering when moving. The design itself is made of elastic and durable material. The tubular handle, located on the side, will allow you to attach the conveyor to vehicles, which is realistic with it most of the load from the operator. The whole system is simple and safe to operate. The country of manufacture is Russia, the established cost for stores is 10,600 rubles.

- Stable construction;

- Overall system stiffness;

- Wide range of application.

- Not detected.

2nd place: "EURO-LIFT CRA 12 00012453 load capacity 12 t"

votes 0

This platform is used to move heavy pieces of furniture and is provided with the ability to rotate in a horizontal plane by 360 degrees. The sample itself is not large, so it is convenient to use it in confined spaces. A significant area of contact with the surface is provided by 8 roller wheels. Even at maximum load, such a design feature is not capable of damaging the floor covering. The country of origin is Russia, the recommended cost for stores is 11,500 rubles.

- Small dimensions of the device;

- The presence of a rotary mechanism;

- Ability to transport heavy loads.

- Not detected.

1st place: "Lifting heel with a capacity of 1.5 tons EURO-LIFT RC-15 00000664"

votes 0

This type of conveyor is made in a minimalist style and is the simplest device used to transport small furniture objects over short distances.The sample is equipped with two metal rollers and an ergonomic T-shaped handle. The whole structure is made of durable and high-quality materials, which guarantees a long service life. The country of manufacture is Russia, the established cost for the store chain is 11,600 rubles.

- Housing protection against corrosion;

- Maximum lifting level;

- Long service life.

- Not detected.

Premium class

3rd place: "EURO-LIFT ST30 controlled platform for moving heavy loads"

votes 0

This sample is a controlled version of the lifting heel and has 4 movable rollers. The rollers themselves are made entirely of nylon, which maximally protects the surface of movement from mechanical scratches. The handle has a length of 1.05 meters, which provides high leverage when setting the load. Permissible weight for transportation - 3 tons. Suitable for moving various types of cargo, not just furniture. The country of manufacture is Russia, the established retail price is 16,200 rubles.

- Long control rod;

- One year warranty;

- Extended range of use.

- Not detected.

2nd place: "Stella ST60 g / p 6t"

votes 1

This type of conveyor can rightly be called universal: it has a swivel mechanism, is able to transport objects of various sizes and weights, and its roller motion system provides reliable support. Maneuvers are very convenient to perform even in confined spaces. Durable metal construction will last a long time. The country of manufacture is Russia, the established cost for the retail network is 28,000 rubles.

- Rigid system as a whole;

- Does not require additional maintenance;

- Comfort during operation.

- Not detected.

1st place: "Stella SK30 transport and roller set"

votes 0

This shipping kit contains an extended set of adjustable and steerable platforms, which are stored in a special case. The whole set is very easy to assemble and disassemble, which makes it possible to fine-tune the conveyor for a specific piece of furniture. The roller system is responsible for the uniform distribution of the load, which indicates the lowest possible wear of all structures. The kit is supplemented with a crowbar and a grab, making it convenient to remove the platform from under the load. The country of manufacture is Russia, the established retail price is 45,000 rubles.

- Stable construction;

- Rigid system;

- Reliability.

- Extremely high price.

Instead of an epilogue

It is gratifying to note that the majority of conveyors and sets in this market segment are represented by Russian manufacturers, which does not diminish their positive qualities. At the same time, the price of high-quality and complete sets can sometimes seem overpriced. However, this will be more than offset by the speed of payback of devices.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131652 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127692 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124520 -

The best men's sneakers in 2022

Views: 124034 -

The Best Complex Vitamins in 2022

Views: 121941 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2022

Views: 113396 -

Ranking of the best wood paints for interior work in 2022

Views: 110320 -

Rating of the best spinning reels in 2022

Views: 105330 -

Ranking of the best sex dolls for men for 2022

Views: 104367 -

Ranking of the best action cameras from China in 2022

Views: 102217 -

The most effective calcium preparations for adults and children in 2022

Views: 102012