Rating of the best socket wrenches for 2025

Socket wrenches are a very large group of devices related to wrenches, used to tighten or unscrew bolts and nuts of various profiles located in recesses and therefore inaccessible to standard wrenches. As a rule, they are made in the form of a monolithic base and have a T-shaped or L-shaped form, where their respective handles are a lever. Another difference between the devices under consideration is their coverage property, i.e. they can easily interact with fixing elements with an internal spindle, and put on a fastener from the outside.

Content [Hide]

Socket wrench - general description

As a rule, the device in question is put on the nut from the end, i.e. above. Comparing with open-end wrenches, socket wrenches also have a double-sided design. However, the end tool can be produced in much larger variations. It is possible to meet both articulated, and tubular, and angular versions, and they can also be produced in the form of cap heads. Most of all, the key samples under consideration are popular with motorists, because with their help you can easily unscrew the spark plugs or securely fix the wheels. The main advantage of a socket wrench over others is the presence of a larger area of contact with the working element in the process of unscrewing / tightening, which clearly increases the efficiency of the entire operation.

Design features

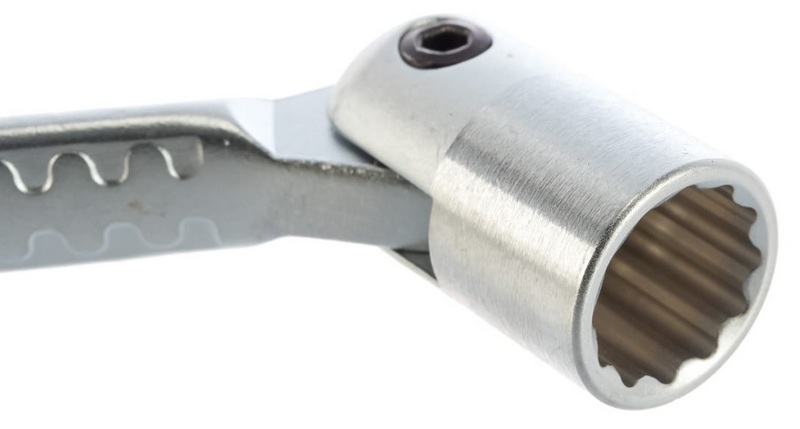

Structurally, the end fixture is a monolithic metal piece of a cylindrical shape, in which a faceted hole is made from one (or more) ends by various methods. There may be six or twelve faces (although there are other options). Others include tools for working with valves, in which the number of faces is from three to four. The size of the hole itself must be suitable in diameter for the desired diameter of the fastener (i.e. bolt or nut).Next, the working cylinder is connected to the lever, when a force is applied to which the device rotates. In the case when removable heads are used, the tool is equipped with a separate rotary rod with a round or square slot (it can be equipped with a ratchet).

The base of the tool itself usually has a different protective coating, as its color will indicate. For example, a black color is given to a key by oxidizing it in oil, and white is obtained by galvanizing zinc compounds on the metal. The shiny finish is created during the chrome plating process. Also, there are modifications with several protective layers included in the main composition, and subject to subsequent polishing.

Existing varieties

The variety of modern modifications of this type of keys is explained by the fact that there are many tasks and different places for their application. To date, the following main types can be distinguished:

- Angular;

- cruciform;

- T-shaped;

- Bilateral;

- Y-shaped;

- articulated;

- With cap head;

- Combined with ratchet;

- tube-key;

- Combined;

- Universal.

Below we will consider only some types of keys that may present difficulties in their operation.

Tubular samples

Made in the form of a conventional tube, on both ends of which there is a profile in the form of a hexagon. The base tube itself is made of special steel with a chromium-molybdenum composition. The protective coating can be done by oxidation in oil or by applying a chrome layer. This design provides for the presence of holes in its body, where the lever responsible for rotation should be inserted.Usually, this is a standard metal collar, made with a diameter suitable for the desired hole.

Articulated samples

This type implies the presence of a hinge, which makes it possible for such an articulation of parts, in which they can move relative to each other in several planes at once. Models with a hinge are used in cases where it is necessary to tighten / unscrew the nut in a confined space (in other words, located in a hard-to-reach place). In this case, the rotational axis of the device is located at an angle to the working element (nut). These models can be double or single (the former have heads with hinges on both sides).

Corner models

If you look at this tool from the side, it clearly resembles the Russian letter "G". The sides of the corner model can be either the same or different lengths. For the latter option, the L-key will have a through hole on the smaller part. It is it that is intended for the turn-turn, which is designed to provide a lever for tightening / unscrewing the nut. An angle tool may also have another purpose, for example, for tightening nuts on long studs, the end of which must pass through the entire fixture. The described modification can have both six and twelve faces, and the diameter is usually created for a nut with a metric size. As a rule, corner models are made of alloyed steel alloys and covered with a protective layer based on chromium and nickel.

T-models

They consist of an axial crossbar-knob and a head with six faces, and the crank is installed perpendicular to the top of the hexagon. Similar end models are created with both a movable and a static lever.Their main convenience lies in the fact that when performing unscrewing / twisting operations, the working force applied to the tool is applied on both sides of the rotational axis. Thanks to this application, the load is distributed more evenly. Another feature is that it is possible to designate the property when the movable knob can be shifted in a certain direction if necessary, thereby increasing the twisting efforts by increasing the lever. Variations of these wrenches for connections with fine threads may have knobs that are coated with non-metallic compounds, such as rubber, for comfortable use. The model under consideration can be produced with removable heads for nuts of various diameters and with swivel joints.

sockets for socket wrenches

One of the most comfortable options for using socket wrenches. If we make a comparison between a full-fledged set of keys and a set of interchangeable heads, then the latter takes a higher place in popularity due to its small size and lighter weight of the entire set. Removable hexagons always come with a wrench, which can additionally be equipped with a ratchet that can be adjusted to move only in one direction. Sets of heads for end tools can be produced in two versions: with an internal square on the head end or with a hole in the side walls. For the second case, the crank is an ordinary metal rod with a certain diameter, and for the first case, it has a square end with a fixing bearing. It is also possible to provide for an extension rod and a swivel joint. A set of interchangeable heads will easily replace the universal end hex tool.In addition, there are modifications with the presence of spring-loaded internal metal pins that can move freely. Deepening, they tightly cover the nut of any diameter and securely fix it for the unscrewing / tightening operation.

Socket wrench extensions

They are used for work in confined spaces as an additional element that transmits torque from the shoulder to the object to be twisted / twisted. Usually, end tools are equipped with such extensions, which are intended for plumbing work (for example, when working with mixers). A cap with a square hole is installed on one end of the metal rod, and a square with fasteners is placed on the other. As a standard, the whole structure looks like a regular tube, can be equipped with hinges and can be produced in various lengths.

Extension cords can also be produced in a flexible version. Such models are a bar bending in all planes, which has traditional tetrahedral slots at the ends. Their shell can also vary - they can have either a polymer or rubber coating. Inside such a tool there is a spring, which is responsible for transmitting the torque of the device to the rotating nut.

Basic rules of use

A few practical tips on using a face tool will help maintain its integrity, extend its service life and effectively carry out the process of tightening / unscrewing any nut:

- It is preferable to use end fixtures with interchangeable heads, accurately selecting the size for the object to be unscrewed.If the diameter of the fixture is larger than the element to be unscrewed, then there is a risk of rounding of the bolt or nut edges. In the future, the fastener will cause difficulties during rotation, and in especially severe cases, it will simply become unusable;

- Nevertheless, if the situation described in the previous paragraph arose, then you can try using a file to remove part of the metal layer from the side nut edges, thus artificially fitting the nut to a smaller key size. However, the size of each face must be equal to each other, which is quite difficult to implement. It is important to note that the tighter the connection with the head, the greater the effect of the entire operation;

- Before starting the unscrewing process, it is worth making sure that the fastener does not “stick” or “stick” to the base over time. The check is carried out by trying to turn the nut with a slightly greater effort, otherwise the thread or fastener may be damaged;

- If the rotation with little effort still does not reach the desired goals, then the fastener should be lubricated with kerosene or penetrating lubricant, leaving it alone for a while. After a few minutes, you need to lightly tap on the nut so that it moves away from the base;

- In order to increase the unscrewing force, a lever with a longer length should be used. The farther the axis of rotation is from the point of application of the force, the greater the torque will become;

- When using removable heads or extensions, you should make sure that these devices are tightly fixed in their respective sockets. A tight connection is indicated by a clearly audible click of the latch;

- In the case when a socket wrench is used together with a ratchet, the shoulder must be set in a strictly defined position.Otherwise, when unscrewing, the entire mechanism will perform the reverse operation, and vice versa.

Difficulties of choice

Before you start using a certain type of socket wrench, you need to decide on the intended tasks. And for a competent selection, you need to pay attention to the following three parameters:

- The key size is a decisive property when choosing, since it will depend on it with which fastener it is possible to work. For open-end, end and cap tools, the working part is unregulated. Thus, initially you need to inquire about the size of the nut and, accordingly, select a device for unscrewing / tightening. In Russia, the standard sizes are 13x17 and 8x10 millimeters. Professionals still recommend having in their arsenal a sufficient set of keys or heads to work with fasteners of any diameter;

- Material of manufacture - due to the fact that during operation the tool is subjected to excessive mechanical impact both from the side of the operator and on the working base (especially when working with tightly tightened nuts), it is necessary that the body of the device is durable and does not succumb to deformation with ease. Thus, for the manufacture of the devices in question, chromium-vanadium alloys or tool steel are often used. These materials belong to the category of high-strength and are able to withstand high mechanical loads. At the same time, to protect against the manifestation of traces of corrosion, products can be coated with zinc or oxidized layers of substances. You should pay attention to the above properties directly at the time of purchase, finding information about this in the product description.For example, if it is supposed to work in difficult climatic conditions or in conditions of high humidity, then corrosion protection for the tool will be very useful, which will significantly extend its service life;

- Handle - you should always pay attention not only to the material of the working part, but also to the handle. The convenience of work (comfort of grip, efficiency of rotation, lack of slip, etc.) will completely depend on it. As a rule, for all-metal models, the handle is also made of metal, but for some models of socket and socket wrenches, a rubber pad can be installed on the handle to ensure proper grip. The two-component handles with anti-slip coating are considered the most comfortable. At the same time, the coating can be made on the basis of dielectrics, which will ensure safe work with objects under voltage.

Rating of the best socket wrenches for 2025

Budget segment

3rd place: ZUBR 27185-19

votes 1

This sample is made of high quality tool steel, which means the ability to successfully withstand intense mechanical stress. In order to increase reliability and extend the service life, the main working parts are hardened in a special way. A protective anti-corrosion coating based on chromium is applied to the surface. The length of the fixture is 198 centimeters, the profile is 19 millimeters. The small size makes storage and transportation easy. The increased lever allows you to work with a difficult fastener. The recommended cost is 360 rubles.

- Sufficient leverage;

- Chrome plated;

- Excellent durability.

- A little heavy.

2nd place: "King Tony 1084-13"

votes 0

This specimen has a tapered profile with thin walls, which makes working with deep-seated fasteners quite easy. The production material is durable tool steel, which can easily withstand intense mechanical loads. The chrome covering reliably protects from emergence of the centers of corrosion. The length of the sample is 254 mm with a profile size of 13. The increased lever allows the operator to apply a minimum of necessary effort. Has a low weight. The recommended retail price is 530 rubles.

- Deep profile;

- Adaptability for intensive work;

- Small mass.

- Fairly high price for little functionality.

1st place: "Airline AT-FHS-08"

votes 0

This model is made using innovative technology of hot forging from chrome-vanadium steel. Its distinctive qualities are high reliability and durability. The chrome coating of the tool prevents the harmful effects of the external environment. Working dimensions of the profile mounted on hinges = 19 and 18 millimeters with a total length of 262 millimeters. The swivel joint reduces the risk of damage to bolts and nuts, and also reduces the possibility of injury to the operator himself. The recommended cost for shops is 600 rubles.

- Durable manufacturing material;

- Resistance to corrosion manifestations;

- Comfort and ergonomics of use.

- Somewhat large mass.

Middle price segment

3rd place: "Jonnesway S41H0812"

votes 0

This tool is good for working with the same types of joints both in production and at home.It has a simple and reliable design, is not afraid of complications during storage, as well as intense work loads. Chrome vanadium steel is used to make the case. The dimensions of the profiles used are 12, 10, and 8 millimeters, the total weight of the object is 190 grams. Carefully selected design and shape minimize the risk of damage to working parts, even when handling old fasteners. The light weight makes it comfortable to use. The entire surface is chrome-plated and polished (good protection against scratches and corrosion). The recommended cost for retail chains is 690 rubles.

- The presence of a double protective coating;

- Three working sides;

- Light weight;

- Increased strength.

- Due to polishing, the handle may slip.

2nd place: "Jonnesway W43A1213"

votes 0

This model is the best suited for use in automotive workshops. It is made of high-strength chrome-vanadium steel and covered with a special protective layer, which guarantees anti-corrosion protection and protection from minor mechanical scratches. The weight of the tool itself is relatively small - only 200 grams, which makes it extremely convenient to use and transport. The total length is 222 mm with profile dimensions of 12 and 13 mm. A comfortable grip is ensured by the grooved handle. The recommended retail price is 780 rubles.

- Durable metal, coupled with a protective coating;

- Small mass;

- Comfortable and secure grip.

- Not detected.

1st place: "JTC Auto Tools JTC-3943"

votes 0

Another sample, directly oriented for use in the field of car mechanic works.Heavy-duty chrome-vanadium steel is used to create the case, which means high resistance to heavy loads. Due to the location of special notches on the handle, a reliable grip of the operator's hand is provided, even with wet hands or fabric gloves. The total length of the key is 242 mm and weighs 235 grams. Working profiles have dimensions of 14 and 12 millimeters. The matte finish protects the case from minor scratches. The recommended retail price is 810 rubles.

- professional orientation;

- Reliable working grip;

- Protective matte layer;

- Not detected.

Premium class

3rd place: Felo 30410480

votes 0

This sample wrench is directly positioned by the manufacturer as a tool designed for intensive, professional and daily work. Its handle is made using two-component plastic, which means a comfortable grip and a reliable and comfortable working environment. The working rod is made of a steel alloy based on chromium-vanadium with molybdenum and is characterized by increased strength and stability. The total length of the tool is 175 millimeters with a profile size of 10. The weight is only 124 grams, which does not burden the hands during operation. The recommended cost for retail stores is 950 rubles.

- Increased safety margin;

- Comfortable and ergonomic work;

- Small mass.

- Not detected.

2nd place: "Unior 3838909190976"

votes 0

Powerful and multifunctional tool manufactured according to the international standard ISO 1456-2009.Absolutely applicable in all areas - from professional industrial use to domestic use. All parts of the tool are working and at the same time can serve as handles. Production material - chrome-vanadium steel. The size of the profiles varies from 13 to 17 millimeters. The total weight is 450 grams. Handles are covered with dielectric material. The recommended retail price is 3000 rubles.

- All four blades are functional;

- Dielectric coating;

- Production according to European standard.

- Extremely high price;

- Big mass.

1st place: "Knipex 980413"

votes 0

An excellent model, directly oriented to use at a car service station. The handle on the outside is equipped with a dielectric coating, and the metal base itself has a chrome layer. Protection against external mechanical impact is guaranteed, it is possible to work with fasteners energized up to 1000 volts. The key itself has a length of 200 millimeters with a profile size of 13. Relatively small dimensions make work more comfortable even in tight spaces. The material of manufacture is oil-hardened tool steel. The key is unpretentious to storage conditions. Recommended price for retail chains - 3300 rubles

- Compact dimensions;

- Dielectric and anti-corrosion coating;

- Extended service life.

- Very high cost.

Instead of an epilogue

The analysis of the market of the instruments under consideration found that it is quite extensive and it is not difficult to choose the right model for quality and price.At the same time, all devices that have at least some protection against external damage or are protected by a dielectric coating cost ten times more than their simpler counterparts. Regarding the national composition among manufacturers, one can note the fact that Russia is almost not represented: the price of domestic tools is much higher compared to similar indicators for the same Asian manufacturer. The premium class, with its high-quality performance and maximum security, belongs entirely to Europeans.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131651 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127691 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124519 -

The best men's sneakers in 2025

Views: 124033 -

The Best Complex Vitamins in 2025

Views: 121940 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114980 -

The best paint for gray hair - top rating 2025

Views: 113395 -

Ranking of the best wood paints for interior work in 2025

Views: 110319 -

Rating of the best spinning reels in 2025

Views: 105330 -

Ranking of the best sex dolls for men for 2025

Views: 104366 -

Ranking of the best action cameras from China in 2025

Views: 102216 -

The most effective calcium preparations for adults and children in 2025

Views: 102011