Rating of the best fuel filters for 2025

In any car there are several elements that are not very noticeable at first glance, but their work is very important. One of these elements is the fuel filter. Its functionality is particularly imperceptible: for example, after replacing it, the car will not react more sharply to pressing the gas pedal, the car will not produce less noise, its speed will not increase. At the same time, the timely replacement of this cleaning device is guaranteed to extend the life of the engine, despite the fact that the filter is not so expensive. Automotive fuel filters are designed to clean the incoming fuel from solid fragments that are in the fuel mass or can get there during transportation or storage. Water and foreign particles can permanently enter the fuel through the tank vent.Thus, the cleaning process of this mixture must take place on an ongoing basis so that the power supply and injection system is not damaged or corroded.

Content [Hide]

Existing species

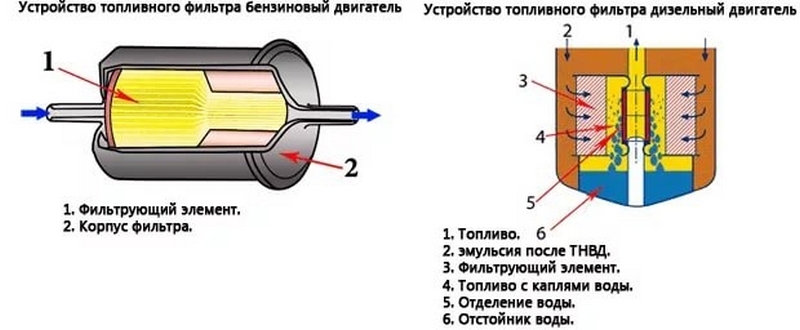

Modern filtering devices may seem the same type, differing only in form, however, they differ significantly in design and functionality. Today there are two popular types of filters.

The first is used when working with gasoline engines and its purpose is to protect the elements of the injection system, as well as cylinder liners, pistons and prevent their premature wear. All operations are carried out by cleaning the fuel from foreign impurities (which are equal to or greater than 10 micrometers).Filters of another type work on diesel engines and are designed to prevent not only contaminants from entering the fuel, but also ordinary moisture, which is nominally contained in small volumes in the fuel itself. This type of filtering device can capture fine particles as small as 3 micrometers. In addition, today's filters operating on diesel vehicles are equipped with various protective systems that simplify their maintenance and allow the same filter to be used invariably for more than a year (which, after all, will be directly dependent on the quality of the fuel). Among these filters, the following gradation can be distinguished:

- Equipped with heaters - they are able to prevent the formation of deposits on the paraffin layer and prevent water from freezing;

- Equipped with water sensors - report the presence of water accumulation in the sump, which must be drained;

- Equipped with a magnet - able to catch small metal fragments;

- Equipped with a plug for draining water - such a filter does not require annual replacement - you only need to drain the accumulated water in time every 20,000 kilometers.

IMPORTANT! When using a filter with a drain plug for the first time, the accumulated moisture should be checked on a periodic basis, approximately every 8,000 kilometers.

Fuel filters - classification

They can be conditionally divided into four categories:

- Carburetor - installed on cars with the same fuel supply system. Capable of retaining small fragments with a diameter of at least 20 micrometers. This indicator is sufficient to prevent the possibility of clogging the internal combustion engine of a machine in which a fuel supply system through a carburetor is installed.

- Injection - used on machines with an injection power system and are capable of filtering particles with a diameter of 10 micrometers or more. Such high-quality cleaning is required due to the high sensitivity of injector devices to blockages.

- Diesel - can provide the highest level of purification, blocking the penetration of particles with sizes from 5 micrometers.

- Gas - installed on machines with gas cylinder equipment. By their design and principle of operation, they are little different from filtering equipment for fuel based on petroleum products. The difference lies only in the filter element, which is a thick paper of low permeability.

Location of the fuel cleaning device

This equipment is necessarily present in any car and can be installed in various places:

- In the engine compartment;

- Under the floor of the car;

- In the immediate vicinity of the fuel tank (should have an additional cover for protection);

- And right in the fuel tank itself (in this case it will be a direct part of the injection pump).

Design and principle of operation

Depending on the degree of purification quality, filtering equipment can be conditionally divided into two types:

- Preliminary - for rough cleaning of the combustible mixture;

- Finishing (final) - for fine cleaning of the combustible mixture.

On machines equipped with a diesel engine, in addition to the cleaning parts used, and due to the increased content of water in diesel fuel, in order to separate it and clean it from mechanical fragments, a combined type modular device is additionally mounted - the so-called "separator" (separator), which consists of a special water separator and fuel filter.

For cars with a gasoline engine, the use of such separator devices is not relevant, because the filter for coarse cleaning can be carried out by both the fuel intake and the cleaning part of the submersible pump. Usually, they are made in the form of synthetic or metal meshes.

The fine filter is designed for final cleaning of the fuel mixture. It can be made as a pumping element or be directly integrated into the pipeline. For gasoline engines, filters are usually produced in a monolithic, non-separable version - a cleaning element is simply mounted in their housing. Combustible liquid is supplied to the filter / leaves it through fittings - inlet and outlet, respectively. On fittings, manufacturers can sometimes mount plastic spigots with removable fittings.

The principle of operation of the filter is as follows: after passing through the element for coarse cleaning, the fuel from the tank through the pipeline enters through the inlet fitting directly into the body of the device. Then, moving through the “curtain” of the cleaning paper part, the mixture is cleaned of large mechanical fragments and is sent through the outlet fitting to the fuel pipeline to the engine.

It should be noted that the cleaning part of the filter for fine cleaning of the fuel mixture is made of the same paper that is installed in the oil filter. However, there are devices with a more complicated design. For example, some models of cleaning equipment may have as many as three fittings, one of which is considered additional, and the other two are considered basic. The additional one is designed to transfer the mixture back to the tank, in cases where there is an increase in pressure in the fuel system.Most often, the multifunctional devices described above are installed in cars of Western European production.

Fuel filter maintenance

Need for replacement

The cleaning device in question is only one of the parts of a large injection pump system in the car, and despite the fact that its functionality itself is carried out automatically, however, its role is important and without this component the entire system can quickly fall into decay. Simply put, the filter works as a cleaning barrier, through which foreign particles (sedimentary fragments, dust and dirt) are removed. After some time, it will invariably become clogged, which will affect the functioning of the entire system, and above all, the high-pressure pump and nozzles will suffer. This shows that it is absolutely not worth delaying the issue of timely replacement of this filter. Checking its purity should be carried out within the period specified by the manufacturer, and the purity of the fuel used should be taken into account.

Symptoms of a Clogged Fuel Filter

These include:

- The volume of fuel consumed by the car has increased significantly;

- When entering a hill, the car may twitch sharply;

- Significantly reduced engine power;

- In the operation of the motor, “triple” is clearly visible;

- The machine may stall at "idle";

- Braking can be carried out without the driver pressing the corresponding pedal;

- Dips may occur when the engine speed is increased.

It is also worth noting some signs of clogging that are typical for certain types of motors. So, the impossibility to start the car from the first start, as well as the occurrence of jerks while driving, can be attributed to a sign of contamination of a diesel engine.

In injection models, signs of clogging are directly related to a decrease in motor power. This is due to the fact that the engine has a cleaning level in the range of 5 to 10 micrometers, respectively, fragments of smaller sizes can seep into the fuel injection system. In fact, they are not capable of seriously harming the system, but they can significantly reduce engine performance.

In carburetor machines, the filter device clogs imperceptibly and gradually, which is hardly noticeable to the driver. This circumstance is associated with an increased level of gasoline purity, which ranges from 15 to 20 micrometers. This shows that large fragments almost do not penetrate the fuel line and do not damage the injection system.

Violations in the functioning of the filtering equipment cannot happen suddenly. At first, many of the symptoms may seem insignificant, however, ignoring them is unacceptable. Otherwise, the car may soon fail. Thus, any changes in the operation of the motor must be responded to in a timely manner and paid due attention to them. Filter replacement should be carried out on a periodic basis.

Among other things, it must be taken into account that the above signs may also indicate other problems, namely:

- Violations in the operation of the crankshaft position sensors;

- Malfunctions of the control unit;

- Excessive air consumption;

- Incorrect throttle position;

- Candle malfunctions;

- Damage to the electrical wiring of the machine;

- Malfunctions of the idle speed controller.

Troubleshooting Fuel Filters

In cases where the cleaning device has become clogged on a diesel model, it is preferable to contact a service center to properly replace the equipment, however, with experience, this can be done independently. Nevertheless, it is worth remembering that the lack of experience, skills and knowledge in this operation will most likely lead to incorrect operation of the engine and its final failure. For the procedure for changing the filtering device, you will need a set of screwdrivers and wrenches, rubber gloves and a container for draining the waste fluid from the used filter. In order to correctly dismantle this element, it is better to study the car instructions.

In other cases, when the filter element on carburetor or injection cars has been clogged, you should only use the help of service center professionals, because this procedure will definitely require special skills and abilities.

The effect of blockages in the filter element on fuel consumption

If the vehicle is used with a clogged fuel filter, this circumstance will invariably increase fuel consumption. This situation arises due to the fact that the fuel enters the engine in insufficient volume, in addition, the structure of the mixture itself will change due to the presence of dust and dirt on the cleaning unit. From here, the speed and power of the vehicle will be reduced, and the driver will have to make additional efforts when pressing the gas pedal.

Pollution indication

In most machines, there are contamination sensors - this is the name of the devices, thanks to which the process of filling the cleaning device with foreign particles is controlled.When a certain level is exceeded, the corresponding indicator signals the driver about a problem. The indication directly indicates the need to replace the cleaning filter. Timely indication will reduce the wear of the fuel supply system, as well as help save on the costs of its various replacement parts. However, not all vehicle manufacturers integrate these indicators into their vehicles.

Determination of filter clogging in the absence of an indicator

If the design of the car does not provide a clogging indicator, then you can determine the clogging of the filter yourself. To do this, you need to find it in the car - as a rule, it is located near the fuel tank. Then loosen the clamp on the fuel line hose. After that, the end of the fuel hose is placed in a transparent container, and the car is set to the brake position and switches to neutral. The ignition key is placed in the initial position, in order to prevent the engine from stalling. If the fuel begins to flow into the tank very slowly, which empties the tank, then this is a sure sign of contamination.

Choosing a filter device for cleaning

Qualitative indicators

Even world-famous firms can sometimes produce defective goods, which for some reason skip technical control. To avoid the risk of acquiring a low-quality cleaning agent, before buying, you need to pay attention to the following points:

- Uniformity of density and quality of filter paper - if the thickness of this element is uniform along the entire length, then the quality of filtering out foreign elements and the level of general cleaning will be much higher, because the chance for them to bypass the filter element is minimal;

- The density of the winding of the filter material - high-quality cleaning will be achieved only with a high value of this density;

- Uniform filling - if foreign elements are unevenly located on the cleaner, the filling is uneven (which can be seen after removing the device), then such an element can be safely considered defective and subject to high-quality replacement.

IMPORTANT! For passenger cars, the fuel cleaning element must be replaced every 8,000 to 10,000 kilometers.

Difficulties of choice

When choosing a filter element, first of all, it is worthwhile to realize the importance of the quality of this product, correctly correlating the concept of "price - quality". Inexpensive models may contain a small amount of cleaning material, or this material will be of poor quality. If such an element is put into operation, then fuel cleaning will become ineffective, and metal fragments, dirt, rust particles, as well as excessive moisture (for diesel engines) will certainly get into the system. All this will generally affect the functioning of the motor and lead to many of the problems already mentioned. The fuel filter market is oversaturated with fakes and very expensive and well-known brands are most often faked. Thus, a well-known brand product at a low price is more than a likely fake.

In addition, existing injection systems are characterized by increased accuracy, which is typical for both diesel and gasoline engines. Therefore, the best option would be to purchase a device with a capacity of 65-95% and which is capable of stopping fragments larger than 10 micrometers. These indicators are extremely important for the life of the injection system, as well as for the motor itself. At the same time, do not forget about the purity of the fuel used.

In addition, you need to consider the type of motor, driving conditions and the installed injection system. The cleaning accuracy will mainly depend on the engine size and the injection system used. Their mutual mismatch (which must be established by both the vehicle manufacturer and the filter equipment manufacturer) can lead to serious problems. Most modern car dealerships today have their own official website, where, by indicating the model and make of the car, you can accurately select the necessary commercially available filter.

Rating of the best fuel filters for 2025

For diesel vehicles

3rd place: "Diesel Technic 2.12232"

votes 0

A good example from a company that specializes in the production of components for used vehicles. The presented model is a universal element for serviced cars. This consumable is perfect for special equipment of Asian, European and American production. A distinctive feature is a set of improved properties that allow you to deal with intense loads during operation. Has excellent case protection that means additional resistance to vibrations and mechanical influences. The seals are made of elastic material and reliably ensure tightness. The recommended retail price is 850 rubles.

- Improved quality;

- Universality of sizes;

- Ease of replacement;

- International certification.

- High popularity among counterfeit manufacturers.

2nd place: "Knecht KL 581"

votes 0

This brand is consistently among the leading brands. The product is characterized by excellent operation of all valves, good density of the retaining paper layer.This consumable has a long service life - it can be changed after 20,000 - 25,000 kilometers. It is focused on cars of the European and East Asian segment. The applied Micro-STAR technology is responsible for the excellent quality of fuel cleaning. The filtration element is securely housed in a dense housing, which has an anti-corrosion coating and is protected from the destructive influence of a humid environment. Good for stopping metal impurities. Estimated price for retail chains - 3100 rubles.

- Universal compliance with the most popular dimensions;

- High level of cleaning;

- Good throughput of a clean combustible mixture.

- Somewhat overpriced.

1st place: "Volkswagen 7H0127401B"

votes 0

This model can be integrated into cars of its own production, as well as into other Western European brands (Porsche, Seat, Audi). The sample under consideration is preferable to be installed on powerful crossovers and conveyors operating in heavy loads. The body is made of durable opaque material and equipped with 4 outlets. Straight-through element, high-density paper with synthetic inclusions is used in the cleaning component. The service life has been extended to 25,000 kilometers. The product is positioned as a consumable for vehicles under extended warranty service. The recommended retail price is 4200 rubles.

- High-quality location of taps;

- Dimensional accuracy;

- Rugged housing.

- High price;

- Popular with counterfeiters.

For petrol vehicles

3rd place: "Sct ST 336"

votes 0

This product is produced under a German license in Asian countries. As a cleaning component, high-density paper is used, which has no factory defects and is uniform in density along the entire length. The whole mechanism is enclosed in a durable plastic transparent case, which greatly simplifies the control of the state of this consumable. Focused mainly on integration into cars of Asian brands (relevant for Japanese). It can also be used as a post-warranty repair component for the Ford brand. With its help, the engine will be reliably protected from the penetration of rust particles into the fuel, water will accumulate in a special sump. The recommended retail price is 180 rubles.

- budget cost;

- Ease of replacement;

- Durability.

- The plastic case is afraid of frost.

2nd place: "Filtron PP 839"

votes 0

A product from a world famous Eastern European manufacturer whose products are characterized by a high level of quality control. The model is intended for both European and American vehicles. By itself, it is the closest analogue of many popular filtering devices. The case is made of dense material, without the presence of manufacturing defects. Its strength allows the device to be used in high pressure conditions. The end parts are securely fixed on the metal base. The recommended cost for retail chains is 870 rubles.

- Universality of dimensions;

- Good ratio of indicators "price-quality";

- Ease of installation;

- The resource is set at 15,000 - 20,000 kilometers.

- There is no water drain.

1st place: "Mannfilter WK 69/2"

votes 0

This product is manufactured by a brand that specializes in the production of consumable components for conveyors of all famous automotive brands in the world. Can be installed on both Asian and European cars. Internal pressure can reach 4 bar. The cleaning paper base has a multi-layer structure that is able to provide reliable protection against rust, dirt and fine solids, while maintaining normal flow. The housing is sealed, resistant to mechanical stress and temperature fluctuations of the environment. The inlet/outlet diameter is 8 mm, which makes installation as easy and comfortable as possible. Such a device reliably guarantees a reduction in the degree of wear of the internal combustion engine. The recommended store price is 1250 rubles.

- Long service life;

- Complete cleansing of the stream;

- Democratic cost (for its segment).

- Not identified.

Instead of an epilogue

The conducted research of the market has established that it is extremely suffering from an overabundance of counterfeit and counterfeit goods. Most often there is a fake, i.e. when products are sold under world-famous brands that do not comply with the original manufacturing technology and have extremely low performance. At the same time, counterfeit products are present in no less volume - although such goods are made according to the technology of the original, they are made from low-quality materials, which means their short service life. From this, the only correct conclusion suggests itself - products should be purchased only at positively proven sales outlets.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131650 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127688 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124517 -

The best men's sneakers in 2025

Views: 124031 -

The Best Complex Vitamins in 2025

Views: 121938 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2025

Views: 113393 -

Ranking of the best wood paints for interior work in 2025

Views: 110318 -

Rating of the best spinning reels in 2025

Views: 105327 -

Ranking of the best sex dolls for men for 2025

Views: 104363 -

Ranking of the best action cameras from China in 2025

Views: 102215 -

The most effective calcium preparations for adults and children in 2025

Views: 102010