Rating of the best grinders for 2025

Mechanical wear is such a serious problem that even the strongest metal alloys are subject to it. Over time and during operation, the pointed edges of any cutting tool will definitely become dull. To restore their sharpness, special grinding machines will help.

Content [Hide]

General information

Electric grinders or grinding machines are special devices that allow you to restore the sharpness of the edges on the cutting tool, as well as on similar fixtures and accessories. The "heart" of such a device is a motor (mechanical/electrical) that rotates a special shaft with a grinding wheel attached to it. When this circle is touched by a machined tool, the latter is sharpened as a result of the friction process. The properties of sharpness are returned to the tool due to the action of the abrasive force of the grinding wheel.

The type of equipment under consideration is most often used for sharpening:

- Reamers, drills and countersinks;

- cutters and various types of knives;

- Drummers, peak and chisels;

- Trowels and spatulas;

- Saw chains, saw bands and hacksaw blades.

If you look more broadly, then the scope of grinding installations is generally not limited to one function. If the device is modern enough, it has the ability to replace the working circle, reduce / increase the rotation speed, then it is quite possible to use it as a stationary grinder. And this is just one of the impressive set of optional features.

Basic Specifications

The type of equipment under consideration has a number of basic parameters, on which its working specialization, functionality and cost will depend.

Power

It can be called the main indicator that indicates the overall performance of the device.Professional models, the use of which will be of a daily nature, must have a power of at least 300 watts. They can easily withstand long-term operation without overheating the electric motor. It is convenient to sharpen not only specialized tools on them, but also, for example, shovels, scythes and axes.

For household needs, when it is periodically necessary to sharpen small objects (thin drills, knives, chisels, etc.), high power will definitely not be needed, therefore, an electric grinder for these purposes can have a power ranging from 150 to 250 W, which will be quite enough .

The number of maximum revolutions of the working disk

Usually, this parameter is from 2700 to 3000 rpm. If you lower the speed on a powerful device, then the electric motor will idle by a third. If you deliberately increase the speed even on a professional device, while processing a simple knife blade on it, the knife material will gradually heat up, which will reduce the quality of the result and in general can lead to deformation of the workpiece. Higher speeds are only suitable for strong alloys and large (not thin!) Items. The solution to the "golden mean" can be called the use of diamond (finely abrasive) grinding wheels. Their fine grain works so neatly that even at high speeds (up to 15,000 rpm), it is quite possible to sharpen even a very delicate tool with them. In general, these discs are ideal for the accurate processing of drilling perforation heads or soldering on circular saws.

Landing diameter of the working disk

This parameter will determine which objects on it (i.e., the disk) can be sharpened. For domestic needs, a small shaft diameter will do.However, it will no longer be possible to install a professional, heavy abrasive wheel on such a shaft. Any such attempt will easily cause the shaft to bend, and the disk itself will certainly break (if it does not fly out). For professional tasks, it is preferable to use a sharpener with a large diameter. However, low-power models can also have an increased diameter, which prevents beats during operation, and any sharpening, even small objects, is of extremely high quality.

Disc diameter

This parameter is directly dependent on what size objects will have to be sharpened. For household knives and scissors, a small circle will do, but for wide and large blades, such as elements of a scythe or an ax, the diameter should be much larger. When choosing a circle, it should be remembered that their large variations will certainly give out high inertia during rotation. Although, it is she who will provide uniform grinding and an even load on the mechanism of the electric motor, and this will positively affect the life of the latter.

In addition, one should always take into account such a moment: the larger the diameter of the working disk, the greater the power of the machine should be, and all together this increases its price.

Disc thickness

Another parameter that will directly affect the dimensions of the processed products. Knives with chisels can be completely renewed on a circle with a small thickness, in other cases - its thickness should be much wider. However, there is the following nuance for this parameter - this is the wear rate factor. Thicker wheels grind at an accelerated pace, while losing the correct shape, which together leads to their imbalance. Conclusion: thick circles will have to be changed much more often.At the same time, they have a large weight, respectively, for their proper rotation, a more powerful engine is required.

Additional options

Optional accessories that can be installed on an electric grinder can greatly facilitate the entire workflow, while at the same time extending the life of the device as a whole. Most often they include:

- Protective shielding (protective casing) - is an element of physical protection for the user, which increases the safety of work. If a worn wheel is used, then in the process of work it can break, and separate flying pieces will be shielded (“beaten off and reflected”) by the casing, thereby protecting the master.

- Backlight - usually it is made in the form of a lamp with a flexible and thin leg. It is convenient to highlight the processed part on the subject. Also, it can play the role of a general light source.

- The platform for work is an ordinary flat surface made of durable material, which can be set at different angles to the disk, which makes it convenient to sharpen drills, chisels and chisels;

Support surface - with its help, the machine is firmly fixed on the base (for example, a workbench), which allows you to dampen production vibrations, which create problems when working with large objects.

Types of machines by tasks and functionality

- For sharpening chains

These devices are used to update the equipment of gasoline and electric saws. With their help, it is easy to resharpen the chain if the latter is worn or damaged. Most often, such equipment is used in repair shops and in the procurement industry. Less common in home users.Visually, they resemble a cut-off saw in their design, but instead of a standard special disc, a grinding disc is installed. The use is intuitive: the chain is fixed in the proper position, the wheel is manually brought to each saw tooth separately and the sharpening takes place. Despite the need for repetitive operations of the same type, the whole process is quite fast. If such a device is chosen solely for the stated purpose (i.e., the renewal of chain teeth), then when choosing it, special attention must be paid to the shaft speed indicator, which will determine the quality of future operations. For continuous and intensive work, it is better to choose a device capable of operating at high speeds. An additional option will also become important, which includes the ability to rotate the grinding head before work - with this possibility, you will have to spend less time setting up equipment for sharpening various types of chains.

- For sharpening drills

Sharpening drills will significantly save on the purchase of new equipment and always have a sharp tool “at hand”. For this operation, the units in question are directly divided into two types - household and professional:

- The former are small appliances suitable for installation at home or in small locksmith/carpentry shops;

- The latter have greater productivity, are capable of processing drills with a diameter of more than 20 millimeters (which are made of high-strength tool or high-speed steel), and can also sharpen milling cutters for metal. This technique already has a clearly industrial level of application.

For a competent choice of such a machine, first of all, you should pay attention to the maximum diameter of the drill that it can process (information about this is indicated in the accompanying documents without fail). Household models can process drills with a diameter of 2 to 13 millimeters, and industrial ones - over 20 millimeters. Also, such a unit should be able to adjust the shaft speed - this function will allow you to most accurately select the desired speed value for a specific drill diameter.

- For sharpening various tools

Such equipment will be useful in plumbing, carpentry, and for domestic needs. It is equally possible to sharpen a knife, and an ax, and a scythe, and cutters, as well as a drill, and a milling cutter, and a chisel, and other cutting tools on it. The design of this type includes an electric motor with an extended shaft, on which grinding consumables are installed on both sides. Such a constructive solution is convenient because it is so possible to immediately use a pair of discs with different grain sizes and use one for roughing, and the second for finishing. At the same time, the type of equipment being updated will not play a big role.

As a rule, these machines are divided into standard and specialized:

- Angular (standard) - they are used for grinding in a "wet" way. Inside them is a gearbox, due to which the circle rotates at different speeds. Usually they use samples with a large diameter, one part of which is constantly immersed in a special bath with water or oil during operation.In this way, it is possible to carry out better dressing of planer knives, different cutters, because the lubricating fluid will lower the coefficient of friction, while preventing the working surface from overheating and causing damage to the tool being processed.

- Specialized variable (they can use both a sanding belt and an abrasive disc) - they can process not only metal objects, but also wooden blanks. Specialized models are rightly called universal - the grinding disc works on iron, and the tape works on wood.

For both variations, it is required to correctly select the maximum allowable size of the grinding disk. For example, professionals consider samples with a thickness of 20 millimeters to be the standard universal option. It is also necessary that the motor power and the permissible shaft speed are properly related to each other. The gap between these parameters should not be too large, as this may affect the accuracy of the edit.

- For engraving and sharpening

Such electric sharpening engravers are a highly specialized tool that combines an engraver working on a flexible shaft and a sharpening device with a pair of abrasive discs. The main purpose is the editing of the cutting tool, the performance of cleaning, grinding, sharpening and engraving (using burrs) of various objects. Such equipment is most popular with individualist craftsmen in small workshops or at home. They have low power and the maximum duration of their work should not be more than half an hour. Engraving machines are probably that very special category of highly specialized devices that constantly need a break, because. their engine overheats very quickly.Nevertheless, the type in question is equipped (in the vast majority of cases) with additional functionality, which includes a very smooth frequency rotation adjustment mechanism, which is necessary for very accurate engraving operations. It is this option that helps to overcome the risk of overheating of the electric motor.

Difficulties of choice

Before buying an electric grinder, you should decide on the specific area of \u200b\u200bits future use, i.e. what objects will be processed most often on it. At the same time, the intensity of the intended use should be taken into account. Professionals recommend when buying to adhere to the following rules:

- If very frequent use is not expected (for example, no more than two or three times a year), then a low-power model from the budget segment will be an ideal choice. For a job lasting a few minutes, more is not required.

- If the upcoming scope of work implies some kind of versatility of application (different objects, different intensities and volumes), then it is better to choose a model with a medium power gearbox and the presence of a “wet” cleaning option.

- If there are a few operations with complex objects that require the highest quality processing (for example, such production tools as drills), then it makes sense to stop at compact but powerful specialized equipment from the middle price segment;

- To ensure the work of a small engraving workshop, it is better to choose a multifunctional machine with an expanded set of options. These are present in the lower level of the premium segment.

IMPORTANT! It should always be remembered that the electric grinder is technical equipment for special purposes and poor-quality results of its work can lead to irreparable consequences. Therefore, when buying, preference should be given to the best and proven brands-manufacturers.

Rating of the best grinders for 2025

For engraving and sharpening

3rd place: "PROMA BKL-750 25450075"

votes 0

The device provides high-quality grinding, polishing and turning of small objects. The design includes an engraver, which expands the scope of the device. The model is actively used in the domestic sphere and does not require the user to have special skills in working with the tool. The compact device does not create problems during storage. The robust housing contributes to a long service life. The recommended cost for retail chains is 4757 rubles.

- For safe operation, the unit is equipped with a protective screen that prevents sparks and dust from flying towards the operator;

- Transparent stop allows you to carefully grind parts at the same angle and does not interfere with the view;

- Engine speed is easily and simply regulated using a rotary toggle switch;

- Has resistance to vibration.

- Somewhat insufficient power for sharpening.

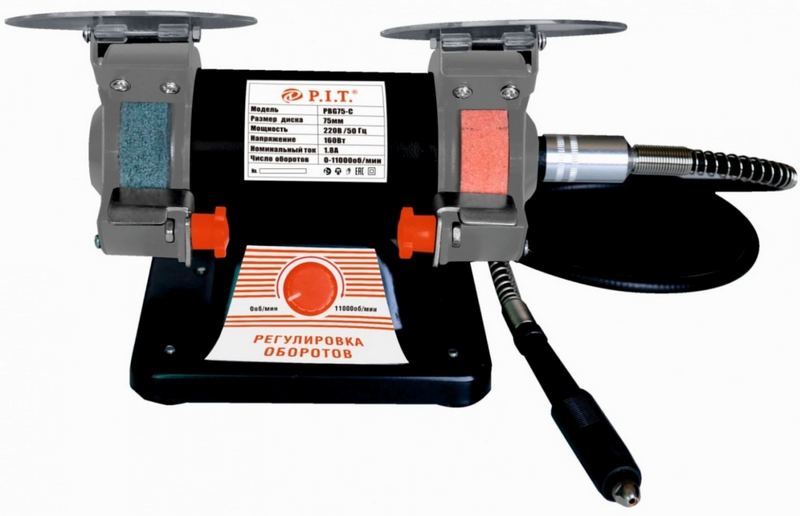

2nd place: P.I.T. MASTER PBG 75-C"

votes 0

This device is used for cleaning and grinding. The kit comes with two discs. Transparent protective shields protect the operator from sparks and dust. With the help of the speed controller, it can be increased to 11,000 rpm. It is recommended to fix the machine on the workbench with bolts. The asynchronous motor has a long service life. The recommended cost for retail chains is 4939 rubles.

- Asynchronous motor;

- Transparent shield;

- Anti-slip feet;

- Two circles included.

- The high cost of abrasive discs.

1st place: "Einhell TC-XG 75 Kit 4412559"

votes 0

This universal model can process various tools. The flexible shaft on ball bearings allows precise machining without any gaps. It is also possible to adjust the speed depending on the purpose of the application. Thanks to the large number of accessories included with Einhell, it can be used for cutting, cleaning, polishing and sanding. Four rubber feet provide reliable stability and dampen vibrations. Adjustable work feet make the unit easy to handle. Spark shields are adjustable without tools. Robust metal compact design ensures long service life. The recommended cost for retail chains is 10,400 rubles.

- Adjustable work feet expand the range of applications;

- Spark shields can be adjusted without tools;

- Long service life is possible due to the robust metal construction.

- Not detected.

For tools and knives

3rd place: ZUBR d200 mm, 400 W, ST-200

votes 0

The device is designed for grinding and sharpening cutting tools and metal blanks. The machine is used for operation in the workshop and in small-scale production. This model has a compact body. There is a dust switch. The recommended cost for retail chains is 3893 rubles.

- Asynchronous motor that does not require serious maintenance for almost the entire service life;

- There are transparent screens to protect the operator from the processed products;

- Dust-proof switch for trouble-free operation - available;

- Possibility of fastening to a supporting surface;

- Adjustable stop for the tool.

- When using low-quality discs, excessive vibration may occur.

2nd place: "PULSAR ST 150/200 791-370"

votes 0

The equipment is used for sharpening and grinding tools, chamfering parts and removing burrs. Cast base and housing provide a rigid and reliable construction. Light weight and dimensions allow compact storage and transportation of equipment. The model is equipped with grinding wheels for dry and wet grinding. The recommended cost for retail chains is 5290 rubles.

- Small weight and dimensions;

- Stable construction;

- Cast housing;

- Simple control;

- Protection of the control button from dust and moisture;

- Possibility of dry and wet polishing.

- Requires periodic lubrication of moving parts of the mechanism.

1st place: "Einhell TC-WG 200 4418008"

votes 0

This device allows you to sharpen the tool as accurately as possible due to the low speed of rotation of the disk. This reduces the generation of sparks and the risk of operation. Installed by default two disks (included). The tool can be placed on a workbench or any stable, level surface. The recommended price for retail chains is 17,900 rubles.

- Can be used for wet grinding;

- 4 rubber feet provide stable support and dampen vibrations;

- Long service life due to durable metal construction;

- Large, corrosion-resistant water tank;

- Grinding fine-grained wheel for wet grinding;

- The second circle is leather, polishing;

- There is a grindstone;

- Honing compound;

- An angle gauge is provided for adjusting the angle of sharpening and grinding.

- Too high price.

For sharpening drills

3rd place: "DIOLD MZS 0.2 10162020"

votes 0

This is a modern and compact model for restoring the cutting ability of drills and other products. The device effectively copes with sharpening consumables with a diameter of 3 to 13 mm. The machine is easy to use and does not require special maintenance. The unit is widely used in carpentry and furniture workshops, as well as in the private sector. Stone circles made on the basis of a fine fraction of glued sand. The recommended cost for retail chains is 4049 rubles.

- Safe operation;

- Efficiency at work;

- Collector engine;

- High build quality;

- Suitable circles with dimensions 45*8*10 mm, 59.5*8*10 mm, 45*11.5*10 mm;

- Stable construction;

- Forced cooling.

- Not detected.

2nd place: "DOCTOR DRILL DD500ХI 33052"

votes 0

The model is used for fast and high-quality processing of twist drills with a diameter of 2.5 to 13 mm. The device sharpens at an angle of 118 and 135 degrees, and also has the function of cross-shaped sharpening of all types of drills with a high level of accuracy. The model has compact dimensions and does not take up much space on the desktop. The recommended cost for retail chains is 24,090 rubles.

- The ability to adjust the angle of sharpening;

- System for creating a self-centering cruciform undercut;

- Fast cleaning;

- Easy replacement of the diamond blade;

- Improved cartridge design;

- Accurate drill alignment;

- Powerful engine;

- Compact body.

- There is no instruction in Russian.

1st place: "REALREZ Z13 (230V) REZ-Z13(230V)"

votes 0

This professional model consists of a body and drill holes. It has an electric motor and a working element - an elbor disk. In the kit there is a set of collets (or one, but adjustable for different diameters, which will depend on the selected configuration), which allow you to feed the drills at the right angles. In addition, the machine is equipped with a tray for abrasive and chips. Appart will easily help to extend the cutting ability of drills. Powerful and reliable motor provides fast cleaning at the selected angle. The machine is easy to carry and use at any workplace, it is compact and lightweight. A simple device allows you to work even without special skills. The model is suitable for both private craftsmen and production needs. The Realrez brand is characterized by high precision sharpening of the edge of the drill and other tools, reducing the time spent on work and simplifying it. The recommended cost for retail chains is 40,000 rubles.

- Works with almost any alloys;

- professional specialization;

- Improved accuracy.

- High price.

Conclusion

Naturally, a grinder can hardly be called a necessity for an ordinary locksmith or carpenter. Most Russian craftsmen do without it, when the need is only one-time.If there is a need to sharpen kitchen knives, then it is much easier to use conventional manual sharpeners, since today's manufacturers offer a lot of options for such products for every taste. However, the presence of a special machine with an electric motor speeds up the process, which is sometimes vital for quick and high-quality sharpening. This is especially true if it is necessary to systematically restore the functionality of a frequently used cutting tool (chisels, drills, chisels, planer blades), where a manual sharpener helps little with a similar task, and the whole operation takes a lot of time. And here, an electric-driven grindstone will cope with such work just perfectly.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131650 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127689 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124518 -

The best men's sneakers in 2025

Views: 124031 -

The Best Complex Vitamins in 2025

Views: 121938 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114979 -

The best paint for gray hair - top rating 2025

Views: 113394 -

Ranking of the best wood paints for interior work in 2025

Views: 110318 -

Rating of the best spinning reels in 2025

Views: 105328 -

Ranking of the best sex dolls for men for 2025

Views: 104365 -

Ranking of the best action cameras from China in 2025

Views: 102215 -

The most effective calcium preparations for adults and children in 2025

Views: 102011