Ranking of the best heat shrink tubing for 2022

The most important condition for the efficient operation of electrical wiring is its reliable and safe isolation from the external environment. In order to achieve the proper level of insulation, the wires are covered with special insulating covers, which sometimes (for example, during repair or installation work) need to be removed. Thus, the coatings used should contain two main properties: reliable insulation of current-carrying wires and the ability to quickly remove them without damaging the insulated objects.

When performing any electrical work, for example, installing electrical outlets, installing taps and connections, and other works, the final stage will always be the process of restoring the wire insulation. The traditional means for performing this stage has always been the use of classical insulating tape.However, with all its advantages, the treated surface often did not meet the best aesthetic performance and often came out extremely swollen. However, winding the electrical tape itself in a neat way is not always possible, and indeed it can be inconvenient (especially if the wire being processed is in a hard-to-reach place). The output is heat shrink tubing.

Content [Hide]

- 1 Heat shrink tube: concept and principle of operation

- 2 Scope of application

- 3 Types of heat shrink tubing

- 4 Advantages and disadvantages of heat shrink

- 5 Competent choice of thermocambric

- 6 Features of the configuration and installation

- 7 Ranking of the best heat shrink tubing for 2022

- 8 Instead of an epilogue

Heat shrink tube: concept and principle of operation

In order to avoid the use of electrical tape in the production of electrical work, craftsmen use heat shrink tubing. They can be called differently: heat-shrinkable, and heat-shrinkable, and thermo-cambric, or simply thermo-tubes or heat-shrinks - it's all the same.

Such a tube itself is an excellent alternative to electrical tape and looks like a short (usually no more than a few centimeters) tubular segment made of a thermopolymer.The tube is mounted at the place where the current-carrying wires are fastened, then hot air of a certain temperature is supplied to it from a building hair dryer (or it is simply warmed up with a lighter if the connection is small), due to which it shrinks and insulates the wire connection.

The material for the manufacture of the tube is selected in such a way that it meets several criteria:

- It had excellent properties in the field of electrical insulation;

- Significantly narrowed when heated;

- It had a minimum compression value along the axis (that is, when heated, the compression ratio should be in the range from 2 to 6 units).

Typically, thermotubes are made from the following materials:

- Fluoropolymer;

- Polyester;

- Plastic PVC;

- Rubber elastomer;

- polyolefin polymers.

The introduction of other impurities into the composition of the material is possible to create pipes for special purposes, which will depend on the conditions where they will be used.

Scope of application

Naturally, the main purpose of thermocambrics is the electrical insulation of wiring contacts, but they can also be used in other areas, for example:

- Heat shrinks of especially large diameter are installed on the butt of power transmission towers, which are made of wood or metal and are underground. This operation significantly reduces the risk of metal corrosion or premature decay of wood.

- Thermal tubes with a ribbed outer surface can be installed on the handles of various kinds of objects of sports equipment or construction tools. Due to the enhanced grip of the hand with the surface of the object, confident use of such tools is achieved and increased ergonomics is provided.

- Tubes made using Teflon or PTFE can be used in extreme environmental conditions, as they are able to withstand temperature extremes from +260 to -65 degrees Celsius. With regard to heat resistance, such thermocambrics are even able to withstand the presence of an open source of fire in the immediate vicinity.

- Heat shrinks can also be used to insulate water pipes laid in an aggressive underground environment (for example, often freezing soil).

- With heat shrink tubing, individual cable cores can be sealed, even with external insulation. In this case, together with thermotubes, a special tape is used, which fills the space between the cores.

- In the end, with the help of a heat pipe, you can turn an ordinary tool into a dielectric. For example, to do this, you just need to put the tube on the handle of a screwdriver or hammer.

Types of heat shrink tubing

The easiest way to separate them is by the type of material from which they are made:

- Elastomers are made from synthetic rubber. The main property of such thermocement briks is increased resistance to high positive temperatures (withstand up to +175 degrees Celsius) and to the aggressive effects of fuels and lubricants. However, the demand for such products is low due to their high cost.

- Polyester tubes are considered more popular due to their increased strength and stability, and their price / quality ratio is more acceptable. Therefore, such heat shrinks are most in demand in the electrical industry.

- Silicone heat-shrinkable products have an extremely flexible and non-toxic structure, in addition, they are extremely inert chemically.However, their main disadvantage is their low resistance to organic solvents, which is why they are not used in areas where contact with fuels and lubricants is possible.

- Polyolefin tubes are made of polyethylene and are chemically or radiation-crosslinked. Various dyes and plasticizers, as well as other substances that can suppress combustion, can also be added to this base. Such heat shrinks are used to insulate wires that will be constantly exposed to extremely high or extremely low temperatures - from +125 to -50 degrees Celsius. In addition, they calmly interact with benzene and other strong oxidizing agents, however, they are weakly resistant to the influence of fuels and lubricants.

- Tubes made of polyvinyl chloride (PVC) have increased electrical insulating properties. Their main drawback is that they are sensitive to temperature changes and the range of their application is limited to a temperature range of -20 to +50 degrees Celsius. Among other things, they are poorly resistant to fire and release supertoxic substances when burned.

- Fluoropolymer tubes are the most advanced and modern, they have almost all the positive chemical and physical properties of the above types, but they are not widely used, because the technology for their manufacture is extremely costly and laborious, which makes the price of such tubes very high.

Also, the tubes can differ according to the principle of installation: they come with an internal adhesive base (with sealing) and without it (without sealing). In the first case, after mounting the tube on the wires, the entire inter-core space is filled with a special adhesive included in the kit, which provides additional insulation and tightness.Sealed tubes are the least susceptible to shrinkage.

The tubes themselves may still differ in the shrinkage coefficient, which is indicated by the manufacturer on the packaging - that is, the initial diameter and the diameter after the hair dryer are indicated. For example, "20 mm - shrinkage 2 to 1."

Advantages and disadvantages of heat shrink

The main advantages include:

- The utmost simplicity of working with them - to fix them, it is enough to correctly adjust the temperature of the air flow directed to the treated area so that the heat shrink tightly squeezes the wires;

- Tubes are in demand in a whole range of other fields that are not related to electrical engineering;

- In comparison with electrical tape, heat shrinks are superior in strength and durability (the electrical tape can unwind over time), as well as in ease of installation;

- Thermocambrics can be made in various color variations, which allows the electrician to use them to mark individual conductor connections and wires.

The disadvantages can be identified:

- One-time use of this product (having fixed it once, it will not be possible to reuse it);

- A slightly higher price (compared to the same electrical tape);

- For carrying out operations with a thermotube, it is desirable to have a mounting hair dryer.

Competent choice of thermocambric

Here, the specification of the task for which the product is selected will play an important role. However, the selection algorithm is straightforward:

- Depending on the environment in which the product will be operated, the material of thermocambric is selected;

- It is also necessary to pay attention to the shrinkage coefficient of the product after processing is completed - this is especially important if the tube will be installed in hard-to-reach places;

- The length of the tube is always selected to allow for a 10% reduction after processing;

- Additionally, you need to take into account the temperature at which it is necessary to carry out installation.

Features of the configuration and installation

Thermal tubes can be supplied in coils or in separate sets, in which the tubes can be sorted by diameter and length. Most often, the packaging of the latter is carried out in standard plastic bags of 50-100 pieces.

To work with products, you will need a sharp knife or scissors - for cutting to length and a hot air gun or heat gun - for shrinkage. In extreme cases, the fixing of the product can be carried out using a conventional lighter - the main thing is to observe the temperature regime of installation.

Ranking of the best heat shrink tubing for 2022

sealed samples

3rd place: 3M MDT-A-12/3 medium wall

votes 4

Designed for the production of adhesive-based heat shrink used as a sealant. It has excellent electrical insulating properties and provides excellent protection against premature rusting. Thanks to the adhesive base inside the tube, all voids and irregularities are completely filled. The product has an increased resistance to chemicals and ultraviolet radiation.

| Name | Index | |

|---|---|---|

| Type of | a tube | |

| Length, m | 1 | |

| Operating temperature, °C | -55 to +130 | |

| Shrinkage range, mm | 12/3 | |

| Nominal diameter before/after shrinkage, mm | 12/3 | |

| Wall thickness after shrinkage, mm | 2.5 | |

| Longitudinal shrinkage, % | 5-10% | |

| Shrinkage temperature, °С | 135 | |

| Adhesive layer | Yes | |

| Voltage, V | 1000 | |

| Quantity in a package, pcs | 1 | |

| Color | black | |

| Material | polyolefin | |

| Weight, kg | 0.01 | |

| Dimensions, mm | 12x1000 | |

| Price, rubles | 729 |

- Increased shrinkage coefficient, not typical for a sealed sample;

- Modern manufacturing material - polyolefin;

- Extended range of applications - connecting cables, pipes, couplings.

- Small set.

2nd place: 3M MDT-A-32/7.5 medium wall

votes 0

It is intended for insulation based on adhesive hermetic connection of high-voltage wires, hoses, cables mainly used in industry. Can be used on small water pipes. Possesses the increased insulating properties and the increased resource of operation. Popular model of the advanced American brand "3M".

| Name | Index |

|---|---|

| Type of | A tube |

| Length, m | 1 |

| Operating temperature, °C | -55 to +130 |

| Shrinkage range, mm | 32/7.5 |

| Nominal diameter before/after shrinkage, mm | 32/7.5 |

| Wall thickness after shrinkage, mm | 3.3 |

| Longitudinal shrinkage, % | 5-10% |

| Shrinkage temperature, °С | 135 |

| Adhesive layer | Yes |

| Voltage, V | 1000 |

| Quantity in a package, pcs | 1 |

| Color | black |

| Material | polyolefin |

| Weight, kg | 0.01 |

| Dimensions, mm | 32x1000 |

| Price, rubles | 950 |

- In the fire resistance of the tube, a self-extinguishing mechanism is implemented;

- Made from advanced material;

- UV resistant.

- It is not widely used in the Russian market.

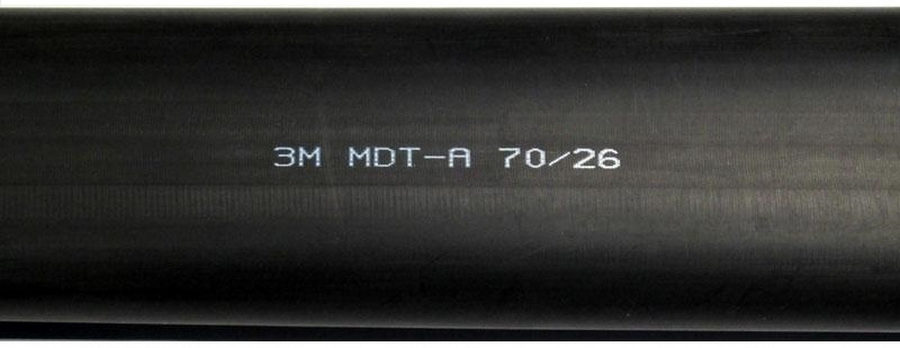

1st place: 3M MDT-A-70/26

votes 1

The tube is excellent for sealing wired components and assemblies of the car, and for isolating various connections on the street. Particularly noted is the resistance to humid environments: thanks to the adhesive base, it reliably seals and absolutely does not let water through. Due to increased shrinkage and high-quality adhesive base, it significantly outperforms Russian counterparts in terms of price / quality ratio.

| Name | Index |

|---|---|

| Type of | A tube |

| Length, m | 1 |

| Operating temperature, °C | -55 to +130 |

| Shrinkage range, mm | 70/26 |

| Nominal diameter before/after shrinkage, mm | 70/26 |

| Wall thickness after shrinkage, mm | 3.3 |

| Longitudinal shrinkage, % | 5-10% |

| Shrinkage temperature, °С | 135 |

| Adhesive layer | Yes |

| Voltage, V | 1000 |

| Quantity in a package, pcs | 1 |

| Color | Black |

| Material | Polyolefin |

| Weight, kg | 0.01 |

| Dimensions, mm | 70x1000 |

| Price, rubles | 2300 |

- Expanded scope;

- Increased moisture resistance;

- Made from advanced material.

- For a Russian buyer, the price may be somewhat overpriced.

Samples without sealing

3rd place: EKF TUT 21 100mm 6275365

votes 1

The most standard set for domestic use. There are several color options for tubes of various diameters. Designed more for marking than for full insulation. Maintains minimum strength and shrinkage requirements. However, all the shortcomings are compensated by an extremely cheap price.

| Name | Index |

|---|---|

| Type of | kit |

| Operating temperature, °C | from 5 to 50 |

| Length, m | 0.1 |

| Shrinkage range, mm | 1.8-1.2 |

| Nominal diameter before/after shrinkage, mm | 2.2 |

| Wall thickness after shrinkage, mm | 0.9 |

| Shrinkage temperature, °С | -90 to 125 |

| Quantity in a package, pcs | 21 |

| Color | multicolored |

| Material | polyethylene |

| Adhesive layer | No |

| Series | HERE |

| Weight, kg | 0.012 |

| Dimensions, mm | length 1000 |

| Price, rubles | 35 |

- Very budget cost;

- The set is excellent for marking individual sets of cores;

- A sufficient number of segments in the package;

- Color variability.

- Limited functionality.

2nd place: Set of heat shrink tubes Vympel TUT-35 5164

votes 0

The kit includes 5 different colors and different tube diameters, which means great versatility.Shrinkage requires standard, not elevated temperature (only + 125 degrees Celsius). The tubes tightly wrap around the parts to be joined, leaving practically no voids. The set is directly focused on work in the field of housing and communal services and electrical engineering, it is very convenient to carry out marking of individual connections with it.

| Name | Index |

|---|---|

| Type of | Kit |

| Operating temperature, °C | -55 to +125 |

| Length, m | 0.1 |

| Shrinkage range, mm | 1,3-0,9; 2,1-1,5; 2,7-1,8; 4,5-3,0; 5,4-3,6; 7,2-4,8; 9,0-6,0 |

| Nominal diameter before/after shrinkage, mm | 5.5 |

| Wall thickness after shrinkage, mm | 0,36; 0,44; 0,44; 0,56; 0,56; 0,56; 0,56 |

| Longitudinal shrinkage, % | 5 |

| Shrinkage temperature, °С | 125 |

| Quantity in a package, pcs | 35 |

| Color | multicolored |

| Material | PVC |

| Adhesive layer | Not |

| Series | HERE |

| Weight, kg | 0.023 |

| Dimensions, mm | 100x185x5 |

| Price, rubles | 150 |

- Democratic price;

- Five-fold variability of choice;

- Great functionality for its scope.

- Small voids may appear after installation.

1st place: mini box JTC-2041

votes 0

This tube is considered a professional consumable and can be used in various industries: radio engineering, electrical engineering, for electrical work. The product is characterized by excellent electrical insulation, very accessible in handling, stored in a convenient cardboard case, from which only as much material is removed as needed. Differs in dense shrinkage.

| Name | Index |

|---|---|

| Type of | A tube |

| Length, m | 10 |

| Operating temperature, °C | -55~125℃ |

| Nominal diameter before/after shrinkage, mm | 10,7±0,4 / 5 |

| Wall thickness after shrinkage, mm | 0.56 |

| Shrinkage temperature, °С | 70℃ |

| Adhesive layer | No |

| Voltage, V | 2500 |

| Quantity in a package, pcs | 1 |

| Color | black |

| Material | polyolefin |

| Weight, kg | 0.28 |

| Dimensions, mm | 180x170x50 |

| Price, rubles | 900 |

- Reduced temperature for shrinkage (only 70 degrees Celsius);

- Advanced material used;

- Significant coil size.

- Possible violation of the integrity of the cover when interacting with fuel and lubricants.

Instead of an epilogue

To date, finding the above products will not be difficult in the Russian market. Popular are not only foreign, but also Russian brands, the latter even to a greater extent, thanks to affordable prices. However, the former are potential leaders in the popularity of their sealed models. In general, this product, due to some simplicity of its manufacture, does not imply any ultra-high cost, so you can buy thermocambrics even in retail stores, even on Internet sites.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131655 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127695 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124522 -

The best men's sneakers in 2022

Views: 124039 -

The Best Complex Vitamins in 2022

Views: 121943 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114982 -

The best paint for gray hair - top rating 2022

Views: 113399 -

Ranking of the best wood paints for interior work in 2022

Views: 110323 -

Rating of the best spinning reels in 2022

Views: 105333 -

Ranking of the best sex dolls for men for 2022

Views: 104370 -

Ranking of the best action cameras from China in 2022

Views: 102220 -

The most effective calcium preparations for adults and children in 2022

Views: 102014