Ranking the best thermal pads for 2022

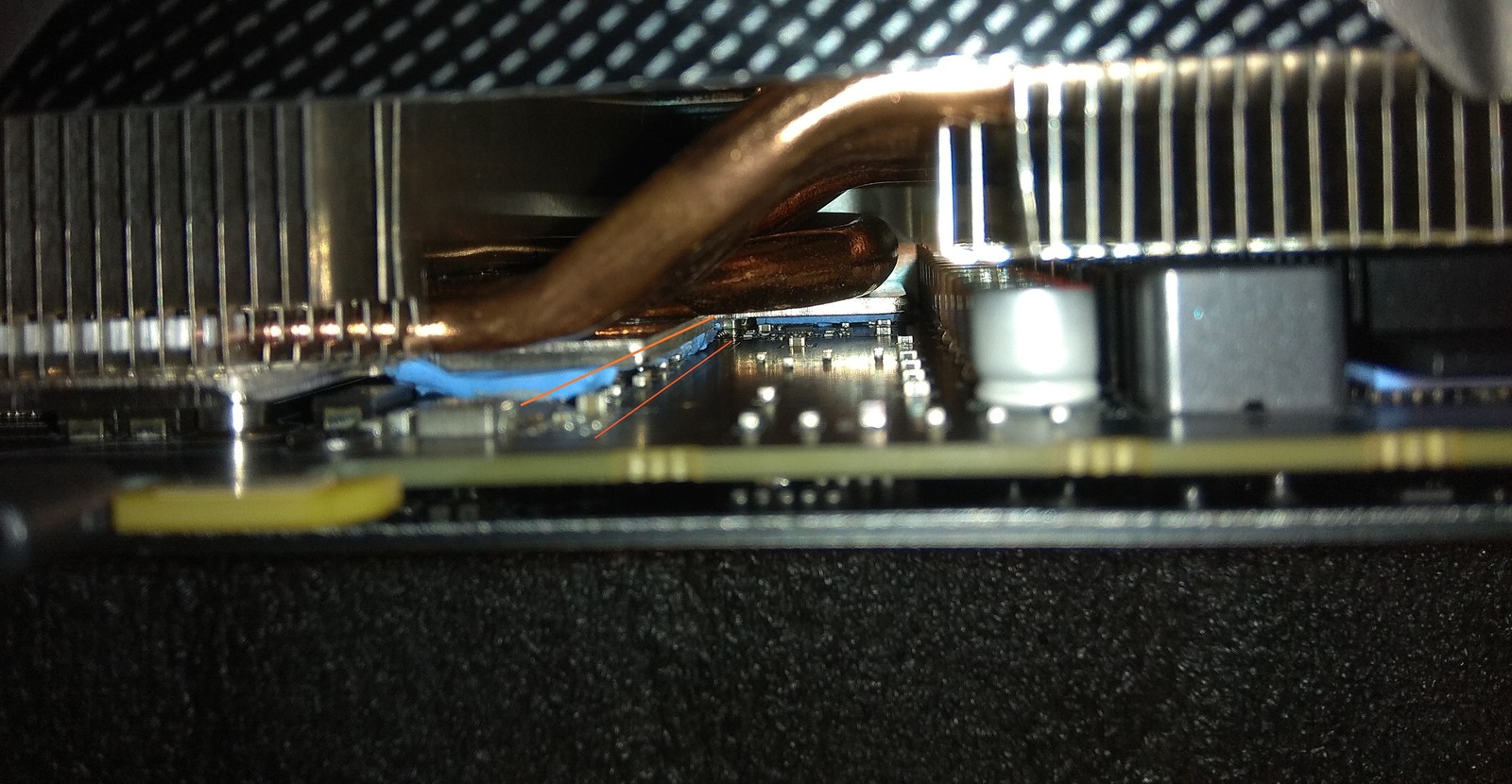

Many consumers who constantly work on computer equipment, over time, experience a decrease in processor or laptop performance, their sudden shutdown or cessation of work. There are several reasons for such problems, but one of them is the deterioration of the thermal pad or layer thermal paste.

Content [Hide]

Rationality of application

So that funds are not wasted, and hopes are in vain, before purchasing heat-conducting pads or paste, you must carefully study the location of their future location. So:

- if the structural parts are in close contact with each other and they have an almost flat surface, then the best option here would be to use a paste;

- if there is an air gap of various thicknesses between the components, and their surfaces are rough and uneven, then it is just right to use a substrate.

Heat transfer pad - what is it?

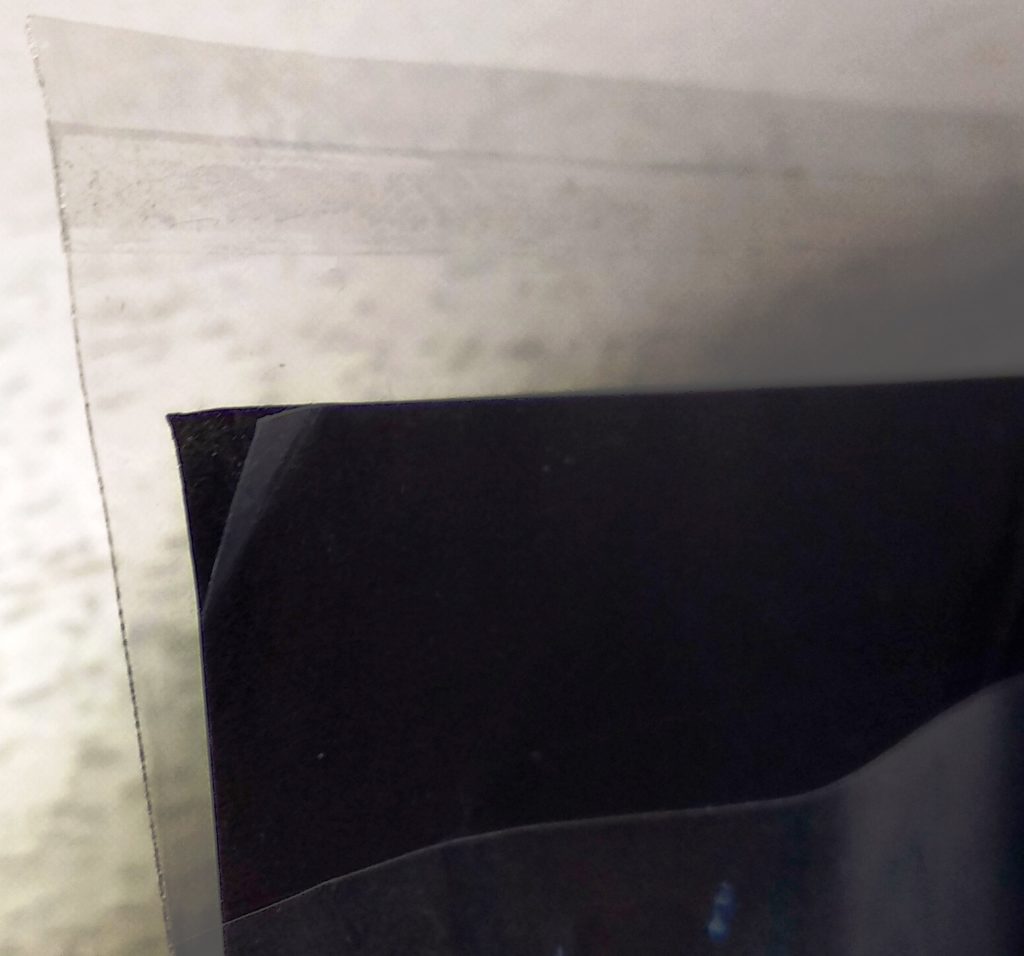

This part means a thin plate (its thickness ranges from 0.5 mm to 5 mm or more), made of a certain material that conducts heat well.

Often used raw materials for the manufacture of thermal pads are:

- silicone,

- ceramics,

- copper,

- mica,

- graphene.

Silicone

Like another type of gasket, the silicone layer accompanies the mitigation of a sharp temperature difference between the components of a processor or laptop. Mostly it is used for cooling:

- video and RAM;

- north and south bridges;

- processor;

- graphics chip.

This thermal pad is recommended for use in situations where there is no guarantee of contact between hot and cold parts of the structure, and also if there is a gap between them that is larger than for the use of thermal paste. The structure of silicone is elastic and easily yields to the necessary deformation when compressing or connecting computer parts.

The convenience and ease of use of silicone thermal pads lies in the fact that before installation, you can not measure the width of the gap between the parts, but use the original material in several layers, applying one after another without additional use of sealant. This is possible due to the large sizes of the sold sheets.

Silicone also copes with mitigating possible impacts of parts against each other with small shocks or mechanical damage to the case.

The only disadvantage of gaskets made from this material is their short service life. Therefore, before using them, it is recommended to determine:

- or often disassemble equipment and change layers;

- or purchase an expensive and durable gasket.

ceramic

Ceramics is considered the most advanced material with high quality indicators for the manufacture of heat-conducting gaskets. It is based on aluminum nitride, which provides a chemically homogeneous microstructure of the raw material. As a result, this affects the excellent heat-conducting qualities of the gaskets, which do not lose their properties during strong heating. They are able to lower temperatures as much as possible during the operation of computer systems. However, they are used for a long period of time. This brings them to the fore among other materials. Also, due to the high thermal conductivity of the feedstock, it is possible to use gaskets of increased thickness. This will not affect their performance in any way.

In addition, substrates from such a composition do not pose a toxic threat to human health.

Aluminum nitride ceramic thermal pads, contrary to the opinion of some consumers, are quite durable. Even the minimum thickness of the interlayer is capable of slight deformation to acquire the shape of a radiator and subsequent tight fit to it.

Copper

Also, a significant place among the heat-conducting substrates is occupied by copper products.They are more effective than silicone ones, but during installation they require additional steps to measure the gap between the parts of a computer or laptop. This is a more time-consuming and costly process, since, in addition to the copper substrate, a sealant must be used to eliminate the distance from the gasket to the heated and cooling components. During operation of the radiator, some amount of substance may be squeezed out of the gaps, but this is quite normal. It is not dangerous and disappears over time.

Graphite

This gasket is made of graphene and is a crystal lattice. Its thickness is only 1 atom, but it has a very high thermal conductivity. In graphite substrates, multiple layers of gratings are generally applicable. These thermal pads exhibit their thermal properties better when placed in a horizontal position than in a vertical position.

Graphite substrates are not applied to the surface like thermal paste, but are cut from the base sheet. Unlike paste, these pads do not dry out and can be reused.

Expert advice

Due to the variety of components and systems of computer equipment, as well as the fragility of some of them, the replacement of thermal pads should be entrusted to a professional. Independent intervention in the "internal organs" of processors and laptops can lead not only to the wrong selection of a suitable material to reduce the heating process of equipment, but also to the breakdown of all equipment.

Rating of the most popular thermal pads for 2022

Numerous heat-conducting substrates for computer equipment are presented on consumer markets, including those of not very high quality and durable.According to experts, the most effective products out of all available are the following.

Silicone

Arctic Cooling Thermal Pad

votes 20

This product is excellent for use between high temperature parts and equipment heatsink. Due to the elasticity and flexibility of the silicone the backing is made of, it is easy to attach and completely fills the existing air gaps. The high thermal conductivity of the material provides a high temperature-lowering effect that protects the components from overheating. In most cases, suitable for use only in laptops. It is not recommended for processors.

The service life of Arctic Cooling Thermal Pads ranges from 12 months.

Can be used at low pressure.

Product dimensions:

- length - 5 cm,

- width - 5 cm,

- thickness - 0.1 cm.

- excellent adaptive ability;

- ease of use;

- does not require preliminary measurements;

- cut well.

- high price;

- short-lived.

Akasa AK-TT300

votes 5

Products of this brand are made of silicone elastomer, which ensures their effective use. Akasa AK-TT300 thermal pads well smooth out possible surface roughness of parts, as well as fill any air gaps between them with high quality. Possessing a sufficiently high thermal conductivity, they ensure the removal of the resulting heat from the heating elements to the radiator with subsequent dissipation. The flexible and elastic structure of the material allows you to completely eliminate the gaps between the component parts of the structures. The temperature range in which these substrates operate is from -40°C to +160°C.The Akasa AK-TT300 kit consists of two gaskets.

Product dimensions:

- length - 3 cm,

- width - 3 cm,

- thickness - 0.15 cm.

- versatility of use;

- good thermal conductivity;

- optimal shelf life;

- ease of use.

- not found.

Arctic Thermal Pad ACTPD00001A

votes 5

These products also belong to the group of silicone thermal pads. Thanks to the additional additives that make up the material, they are endowed with a low dielectric constant and high resistance to electricity. This eliminates possible short circuits in the electrical circuits of the structures. Basically, Arctic Thermal Pad ACTPD00001A substrates are used in blocks of low and medium thermal load. Computer scientists recommend using this product in places where thermal paste leaking out during the heating process and getting on the boards can cause malfunctions.

The manufacturer of the presented brand offers customers several types of thermal pads that differ in size and thickness. The average weight of a sample is about 6 g. This makes it possible to independently cut the substrate of the required parameters. The use of Arctic Thermal Pad ACTPD00001A products is effective with significant air gaps and uneven surfaces of component parts.

Product dimensions:

- length - 5 cm,

- width - 5 cm,

- thickness - 0.05 cm.

- application with large gaps and errors in the surfaces of parts;

- low dielectric constant;

- high resistance to electric current;

- Choice of size and thickness.

- use at low and medium heat load;

- high price.

Alphacool Warmeleitklebepad doppelseitig

votes 0

Products of the presented brand are used to remove heat from heating electronic parts of computer equipment to radiators with subsequent dissipation. Made of silicone components, they have a flexible and elastic texture, which ensures a tight and high-quality fit of the substrates to the contours of surfaces, which often have roughness and irregularities. Also, this composition allows them to be used at low pressure. The product is sold by the piece.

Product dimensions:

- length - 3 cm,

- width - 3 cm,

- thickness - 0.05 cm.

- versatility of application;

- good quality;

- efficiency.

- not detected.

Ceramic

Thermal Grizzly Minus Pad 8 TG-MP8-30-30-05-1R

votes 16

This product belongs to the category of ceramic substrates. They are made of nanoaluminum oxide and ceramic silicon. Due to this composition, they have high thermal conductivity, flexibility and elasticity. They are convenient to use, as these thermal pads perfectly fill the smallest gaps between electronic parts of structures.

Optimum and uniform heat transfer ensures that all parts in contact with the substrate work together. This product is environmentally friendly and does not harm human health.

The temperature range in which the Thermal Grizzly Minus Pad 8 works is from -100°C to +250°C. The product is sold individually, the weight of each of them is 11 g.

Product dimensions:

- length - 3 cm,

- width - 3 cm,

- thickness - 0.05 cm.

- high quality;

- ease of installation;

- efficiency;

- environmental friendliness.

- not detected.

KPTD 2/1-0.20

votes 9

The Russian production, represented by the Nomacon company, releases domestic heat-conducting substrates to the consumer market. Despite their small thickness of 0.2 mm, they have good strength. The structure of KPTD 2/1-0.20 is a smooth surface, resembling thin rubber, which does not stretch and does not stick at all. Such a consistency of these products is provided by the composition, which is based on an organosilicon bond of heat-conducting ceramics. Due to the minimum thickness of sheets, such thermal substrates effectively replace mica and paste. But it should be borne in mind that the thermal conductivity declared by manufacturers is quite low. But such products are excellent dielectrics and provide full protection against possible short circuits in the electrical circuits of systems and structures.

The operating temperature range for this type of product is quite wide and ranges from -40°C to + 250°C.

KPTD 2/1-0.20 thermal pads are sold individually in the form of sheets, the weight of each of them is 15 g.

Item size:

- length - 20 cm,

- width - 15 cm,

- thickness - 0.02 cm.

- high quality;

- long service life;

- excellent dielectric;

- the possibility of replacing mica or paste;

- in multi-layer application can be used to eliminate air gaps.

- low declared thermal conductivity.

Copper

Gelid GP Extreme

votes 9

This product incorporates components used in the manufacture of thermal paste of this brand and which has proven its high efficiency among computer technicians. Gelid GP Extreme Thermal Conductive Pads have good elasticity, allowing them to easily adapt to the details of the application.Due to their good thermal conductivity, they carry out the removal of heat from the heated parts to the radiator, where it is further dissipated. This prevents overheating of computer components and prolongs their life.

Product dimensions:

- length - 8 cm,

- width - 4 cm,

- thickness - 0.2 cm.

- high performance;

- convenience and ease of use;

- optimal settings.

- not identified.

foil

Coollaboratory Liquid MetalPad

votes 6

Products of this brand are thin sheets in the form of foil, made on the basis of liquid metal. Such thermal pads can effectively replace the paste, which is not able to solve the problems with heat removal from heated parts to radiators. Attaching Coollaboratory Liquid MetalPads is a breeze. The material used is safe to use. Due to its high thermal conductivity, the transfer of excess temperature is quite fast and efficient.

The product is sold individually and has the following dimensions:

- length - 2 cm,

- width - 2 cm.

- excellent replacement for thermal paste;

- high level of thermal conductivity;

- ease of use;

- material safety.

- cannot be used in the presence of air gaps.

If you suspect that your computer equipment is not working properly, you should not postpone contacting professionals for advice or help. Perhaps every lost day or hour can exacerbate the problem and lead to irreversible consequences and, as a result, to equipment failure.But timely advice, current inspection and joint replacement of thermal pads (at the request of the customer) from the list presented with you will help keep the equipment in proper order and expand knowledge in the partial repair of a computer or laptop.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131661 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127700 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124527 -

The best men's sneakers in 2022

Views: 124044 -

The Best Complex Vitamins in 2022

Views: 121947 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114985 -

The best paint for gray hair - top rating 2022

Views: 113402 -

Ranking of the best wood paints for interior work in 2022

Views: 110328 -

Rating of the best spinning reels in 2022

Views: 105335 -

Ranking of the best sex dolls for men for 2022

Views: 104375 -

Ranking of the best action cameras from China in 2022

Views: 102224 -

The most effective calcium preparations for adults and children in 2022

Views: 102018