Rating of the best heat presses for 2022

Every self-respecting company must have all the necessary equipment in order to receive a truly high-quality product. In the advertising business, you simply cannot do without high-quality units. Not only wide format printers can be used for printing. With their help, you can apply really high-quality images that will not deteriorate over time. Other fields of activity also need such assistants, in which the exact transfer of the fruits of many years of work to paper is required. However, before choosing a quality product, it will not be superfluous to figure out what plotters are and what functionality they have.

Content [Hide]

What is it and why is it needed

A heat press is an electromechanical device that is used to transfer an image onto a selected material. The process of transferring an image is called thermal transfer. As a working surface can be used:

| Metal | Glass | Leather |

|---|---|---|

| Wood | Paper | Textile |

| Cardboard | Plastic | Ceramics |

Sublimation on fabric is a process in which the substance used (special paint) passes from a solid state to a gaseous state by means of strong heating. From a temporary carrier, the coloring composition passes to textiles, penetrating deep into the fibers of the fabric. Thus, a stable image is created on any object.

With a more detailed examination of the printing equipment, we can come to the conclusion that the picture lies more evenly under the horizontally rotary thermal press. Folding models do not have such characteristics. It is not so convenient to work with vertically folding structures, since during use the heating element is above the hands of the worker, which is considered unsafe.

It should also be noted that the rotary mechanisms are bulky, which can be a decisive factor when choosing a popular model. Among the selection criteria, attention should also be paid to the ease of closing and opening the machine. Extra effort will entail both time and physical costs. If we take into account the fact that the press will have to be closed and opened dozens of times during the day, then by the end of the shift, the worker will not be happy. According to buyers, semi-automatic and automatic models from the best manufacturers deserve more attention.

What should you pay attention to when choosing

Among the many new products, flatbed or flat units deserve special attention. They will be used for sublimation printing of images on T-shirts, souvenirs, tiles (ceramic) and other flat structures. Heat presses are divided into several categories, depending on the method of moving the heating element:

- Swivel. Massive fixtures. To use them, you will need a lot of free space due to the fact that the heating element does not rise, but moves to the side. Only in this way will the worker be able to get close to the bed. They belong to the category of equipment of a professional type.

- Folding. Multifunctional models that do not take up much space due to the mechanism used. Characterized by ease of use. Can be used for both small and large runs.

In order not to make one of the many mistakes when choosing an apparatus for applying images, you should first designate the scope of the unit. An example is the situation in which it is necessary to put an image on a T-shirt.In this case, it is recommended to give preference to designs with a flat thermoelement. For mugs, you need a model with a cylindrical element. Special attention deserves universal fixtures, which are equipped with interchangeable linings for different types of workpieces used.

| Manipulation Objects | Scope of use |

|---|---|

| For caps | The devices are equipped with a lower convex and upper concave plate, which has a cylindrical shape. Thus, the print is easily transferred to uneven fabric, which is extremely convenient for printing on caps or hats. |

| for cymbals | The picture is printed on dishes, metal, ceramic and glass plates. It is also possible to use for flat blanks (for example, puzzles). |

| Universal | Multifunctional devices that combine the functions of different types of heat presses. In the kit, you can find several additional attachments that will allow you to perform different tasks without the need to purchase additional devices. |

| For cups, mugs and handles | Designs are used to print on cylindrical objects such as glasses, shot glasses, mugs or cups. A feature of the devices is the presence of a cylindrical thermoelement. There are vertical and horizontal models. The latter type belongs to the category of universal ones, and they have no height restrictions. |

Rating of quality mug heat presses

A.Adkins Studio Mug Press

votes 0

The model belongs to the popular category. Designed for convenient and fast creation of medium runs. Made from high strength aluminum alloy. It is characterized by high operational life and degree of reliability. It is based on a round heating element. The microprocessor responsible for adjusting the time and temperature is easy to operate.Equipped with a convenient system for loading cups and the ability to adjust the clamping force. The corresponding marking is placed on the case.

The average price is 56,000 rubles.

- suitable for standard shaped mugs;

- durable case;

- operational period;

- reliability;

- manual adjustment;

- automatic shutdown function in the event of an emergency;

- warranty from the service center;

- the model is equipped with an LCD display and a sound timer.

- price;

- average circulation.

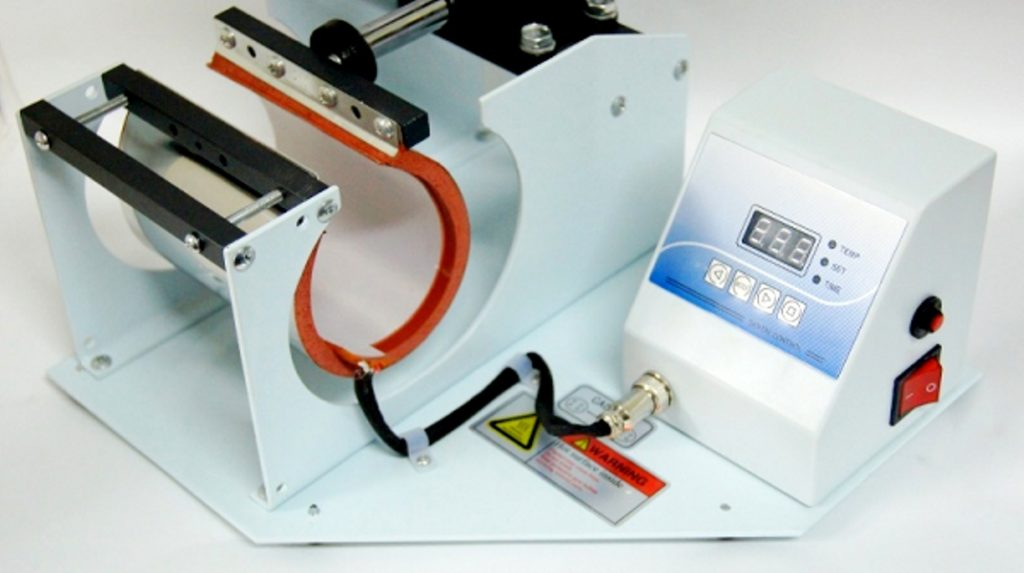

LOPO Mug Cuter 4 in 1

votes 0

Professional equipment that is used in large enterprises. The buyer is guaranteed to receive equipment of excellent quality and a large margin of safety. During operation, the temperature is distributed evenly, and the pressure allows you to achieve a high result. Such equipment guarantees the high quality of the services provided. Thermal transfer is carried out at a professional level, which is unusual for this price segment. Allows you to transfer the image to coffee mugs, lattes and standard ones. Included is a nozzle for standard products.

Price - 25,000 rubles.

- the price corresponds to the quality;

- small dimensions;

- compatibility with raw materials of popular formats;

- the presence of an indicator of time and temperature;

- LCD display;

- strength;

- practicality;

- build quality.

- not identified.

HM-M11

votes 0

A high-quality model, which is rightfully included in the TOP budget ones. To transfer sublimation, it is possible to use special (good result) or office paper (acceptable result), as well as appropriate inks. Every hour, the manufacturer recommends taking a break for 10-15 minutes.The height is adjusted manually, which will improve the accuracy of transferring the pattern. After heating the element to 180°C, a beep will sound. After 15 seconds, the mug is ready. However, you should not rush to remove it from the device, because it is very hot.

Price - 6500 rubles.

- power of 350 W;

- temperature control 0°-210°С;

- the presence of a timer;

- mugs of standard diameter;

- build quality;

- rapid heating of the element.

- mug diameter 85-95 mm;

- The heating element is not designed for continuous operation.

START (d=7.5-9.5cm)

votes 0

Another inexpensive model of a heat press, which, through sublimation, will transfer images to cylindrical structures (thermoses, flasks, mugs, cups). The main thing is that their diameter is 75-95 mm. High quality steel is used as the main material. The device, which can be purchased at any online store, is extremely easy to use. In addition, numerous online sites allow you to put your favorite designs in a comparison table, with which you can make the final choice. It is characterized by the presence of electronic type control. The pressure level is adjusted manually. After a while, the heating element can be replaced. You can buy it in any store or order online if necessary.

Cost - 5700 rubles.

- temperature range up to 250°С;

- power of 350 W;

- weight 8 kg;

- the presence of a timer;

- electronic control;

- independent clamp;

- the heating element can be replaced separately.

- manual opening;

- the quality matches the cost.

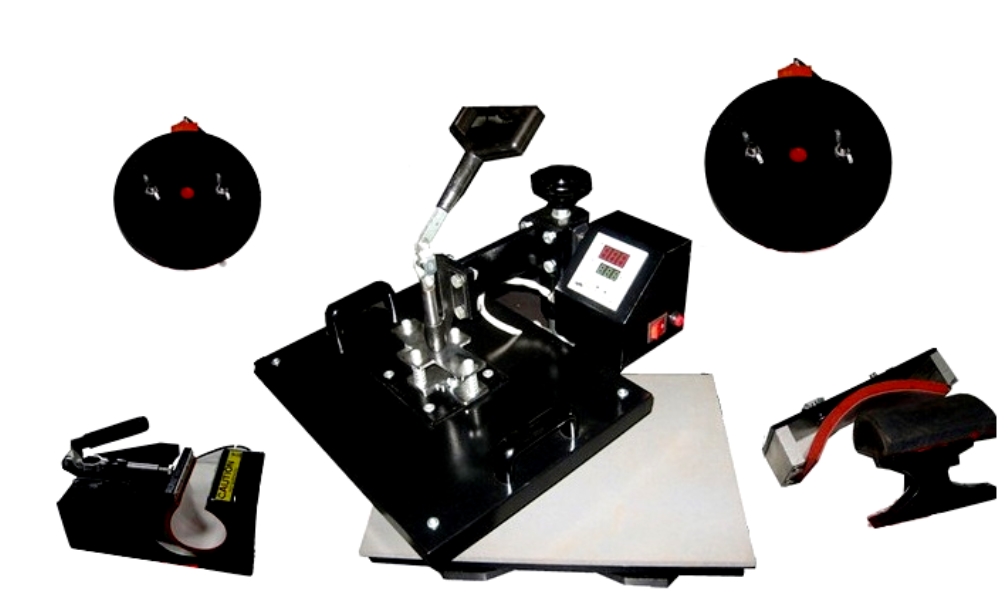

Thermopress universal 5 in 1

votes 0

A universal device of a horizontally rotary type of the "5 in 1" series, which will allow you to transfer an image to an object of any type. Initial review found images to be easily portable to:

- sleeves;

- ceramics;

- plastic;

- plates;

- textile;

- cardboard;

- baseball caps;

- metal;

- mugs;

- skin.

Based on numerous reviews, in the set you can find several auxiliary nozzles for sleeves and baseball caps, plates and mugs. If necessary, the unit can be easily converted from a heat press for mugs, into a device for printing on caps or other objects. According to buyers, this aspect is key when choosing such equipment. The flawless result over the years has increased the demand for this popular model in many countries.

Price - 20,000 rubles.

- ease of use;

- build quality;

- versatility (wide scope of use);

- the presence of auxiliary nozzles in the set;

- manufacturer's warranty;

- speed and accuracy of settings;

- CE certificate;

- uniform heating;

- ease of replacement of individual elements;

- digital indicator;

- electronic control system.

- not identified.

Rating of the best plate heat presses

Vektor YH-100 TR

votes 0

It is this product from one of the best European companies that is recommended to be purchased for applying pictures to plates. Experts advise using only Teflon sheets, which will protect not only the lower, but also the upper heating element. Other materials can be used if necessary. Also, the layer will become a kind of protection against scratches, soot and toner residues.

What is the price? The purchase will cost 29,000 rubles.

- operational period;

- the ability to adjust the working pressure;

- work stability;

- ergonomics;

- the quality of the finished product;

- reliability;

- the presence of a sound signal;

- high-quality silicone substrate;

- protective (Teflon) coating;

- ease of use.

- missing.

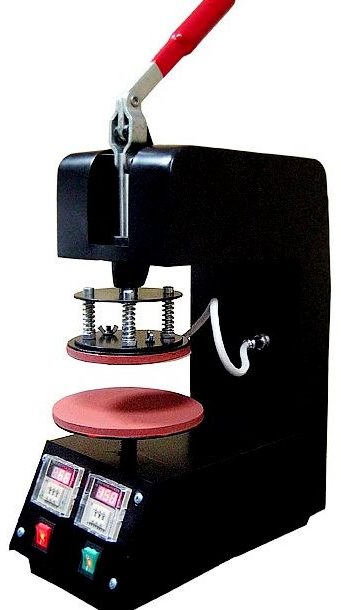

START, 12.5cm

votes 1

This model is used to create souvenirs. The installation will allow you to apply images to the plates. High quality images are obtained largely due to the use of a special technology that is configured for sublimation transfer of images. Before you start printing, it will not be superfluous to read the instructions provided by the manufacturer. It is also highly recommended to follow the safety rules. Installation is carried out on a flat surface. Before starting, check the device for damage.

Price - 8700 rubles.

- strength;

- image quality;

- modern design;

- digital panel;

- compactness;

- digital control;

- electronic timer;

- power 250 W;

- temperature range 0°-220°C.

- you should not touch the plates themselves, as this is fraught with burns;

- lack of additional nozzles in the set;

- warranty - six months;

- only sublimation paper is used.

Grafalex 2 in 1

votes 0

The design allows you to transfer pictures to products with a diameter of 19-25 cm. There are two nozzles in the kit: 15 cm and 12 cm in diameter. As a blank, it is better to buy a Teflon sheet in advance. It is applied as additional protection of the bottom and top heating plates. It also reduces the risk of scratches, sludge and toner residue. The model is equipped with a unique time and temperature control system.This allowed us to improve both the speed of settings and the accuracy of drawing. The temperature regime is under the control of the employee. The pressure is also manually adjustable. The set is equipped with several auxiliary nozzles.

You can buy for 14500 rubles.

- reliability;

- ease of use;

- build quality;

- work stability;

- ergonomics;

- operational period;

- LED display;

- power 350 W;

- indicator;

- temperature range 0°-240°C.

- weight 12 kg;

- lack of safety shutdown function.

Bulros TT-15

votes 0

Such a device will easily transfer the selected image to a plate and any other product of a flat shape and the same diameter. An excellent solution for the manufacture of souvenirs and the individualization of existing dishes. The design is reliable and durable. There is a proprietary time and temperature control system. Equipped with a reliable microchip, which favorably affects the speed of settings. The model is available in several colors. The working surface is made of Teflon, which is the best solution for sublimation. The absence of backlash indicates a high build quality.

You can buy a set for 12500 rubles.

- strength;

- reliability;

- ergonomics;

- modern design;

- manual settings;

- LED display;

- data update rate;

- checking the performance of work at any time;

- mechanical pressure adjustment;

- power 380 watts.

- significant weight of 10 kg;

- significant price.

Vector SP02

votes 0

A quality product from a trusted manufacturer.With it, you can transfer pictures from thermal applications, thermal transfer paper or other working material onto plates. The heating plate is covered with a protective Teflon coating. Among the components you can find a time and temperature controller. Device control type – electronic.

Price - 11500 rubles.

- protective coating of the main element;

- time and temperature controller;

- vertical way of lifting;

- additional nozzles included;

- power 300 W;

- preheat for 7 minutes.

- weight - 15 kg.

Rating of the best baseball heat presses

Bulros TC-11

votes 0

The equipment allows you to transfer the image to sleeves, baseball caps and other fabric structures. It should be noted that there is a modern time and operating temperature control system. A proprietary microchip is responsible for the accuracy of the settings and the application process. Teflon is used as the main material and coating of the working surface. The current data and settings are displayed on the LED display. The frequency of updates is optimal, which allows you to monitor the process, control it and make adjustments if necessary.

Cost - 19500 rubles.

- practicality;

- strength;

- print quality;

- processing speed;

- temperature regime;

- protective covering;

- operational period;

- manual settings;

- convenient display.

- weight - 15 kg.

Bulros TC-10

votes 0

Used to print bright and clear prints on fabric surfaces such as sleeves and baseball caps. It is characterized by a high degree of reliability and ease of operation.A special microchip is responsible for controlling the temperature regime and time, which favorably affects the response speed at the time of changing the settings and the accuracy of applying the ornament. It should also be noted the possibility of adjusting the pressure. Teflon acts as the base of the work surface, which is considered the best solution for sublimation. All the necessary information is displayed on a convenient display. The update speed is excellent. The product is made in China. The weight of the model is 12.5 kg.

Price - 19100 rubles.

- durable case;

- modern design;

- intuitive settings;

- possibility of manual control;

- ergonomics;

- the presence of a protective coating;

- the quality of the final product.

- not identified.

Bulros TC-12

votes 1

The thermopress belongs to the category of horizontal folding. It is used for printing images on sleeves, baseball caps and other products. The model is equipped with electronic control. The design is reliable and at the same time easy to use. Equipped with electronic controller and timer. Temperature range 90°-220°C. The quality of printing is under full control, regardless of the time of the request. If necessary, you can use manual settings, using a special regulator. The working surface has a protective coating based on Teflon.

Price - 24800 rubles.

- a microchip responsible for the speed and accuracy of the settings;

- convenient display;

- power 500 W;

- frequency of updating information;

- allowable dimensions 8x15 cm;

- reliability;

- protective covering;

- operational period;

- unusual appearance.

- price.

START, 14×8cm, swivel

votes 0

A rotary type model specialized in transferring images to the surface of baseball caps. The design belongs to the category of digital, so any manipulations are programmed electronically. The product is used for both sublimation printing and film transfer. In addition, the device can be used by individuals (at home) in cases where it is a hobby. Before starting the equipment for the first time, it is necessary to take care of high-quality grounding, as the manufacturer advises. After switching off, the device is switched off from the socket.

Cost - 15200 rubles.

- build quality;

- image clarity;

- practicality;

- ergonomics;

- economical consumption of related materials;

- operational period.

- cleaning surfaces with special compounds.

Adkins Studio Cap

votes 1

The robust unit is made of high quality aluminium. Belongs to the category of professional tools that are in demand among large enterprises. It is preferable to print on branded caps and baseball caps from famous brands. The microprocessor controller is responsible for setting and tracking time and temperature conditions. It is possible to customize the image for products of any size. The switch is equipped with a status indicator. The timer has an audible alert.

Cost - 82400 rubles.

- automatic shutdown function is provided;

- detailed instructions from the manufacturer;

- follow-up service in the corporate center;

- warranty - year;

- has appropriate markings;

- the degree of pressing is changed manually;

- heat-resistant rubber is used as the base;

- vertically folding design;

- working field - 170x80 mm.

- missing.

Rating of the best flat heat presses

Schulze E-PowerPress, 2x38x45 cm

votes 0

Horizontal-swivel model from a well-known manufacturer. It should be noted that the coefficient of the working surface (the size of the picture on the product) is 380x450 mm. Temperature is regulated in the range of 0 ° -220 °C. The power indicator reaches the mark of 2000 watts. Device dimensions 80x95x155 cm. The timer is set in the range of 1-5999 seconds. The weight of the professional design is 205 kg, so the product does not differ in mobility. The element heats up to 180°C in 10 minutes. Innovative automatic press equipped with a bed and a rotary heating plate. There are two working surfaces. The only thing that is required from a person is to place the product on the table.

Price - 657,000 rubles.

- fully automated model;

- two desktops;

- versatility of the unit;

- build quality;

- operational period;

- the size of the transferred image.

- price.

Schulze AirPressX, 2x40x50 cm, on base

votes 0

A flat professional press designed to apply an image of any complexity to the selected product. The method of lifting and opening is rotary-horizontal. Working surface dimensions 400x500 mm. Temperature regime - 0 ° -220 ° С. The power indicator is 2400 W, which should be considered when choosing equipment. Press dimensions - 167x74x98 cm with a weight of 175 kg. In 12 minutes the surface will warm up to 180°C. There are two working surfaces, which will significantly reduce the time allotted for printing.With proper use and timely adjustment of pressure indicators, the device will work for a long time and reliably.

Price - 570,000 rubles.

- per cycle, the device will consume 3.3 liters of air;

- pressure - 6 bar;

- maximum pressure 2490 kg;

- interchangeable tables;

- ease of use;

- automated control;

- print quality;

- work continuity.

- price.

Vector SQ04

votes 0

The device is used for the manufacture of various products, including souvenirs, through thermal transfer and sublimation. With the help of such equipment, you can easily transfer the selected print to any flat surface. Often we are talking about leather, plastic, cardboard, metals, ceramics and textiles. However, other materials may also be used. The control system is completely electronic. Time and temperature can be set manually. The upper part of the heating element is made of Teflon coating, which indicates a high coefficient of practicality of the device and its long service life. The manufacturer recommends using a material whose thickness is at least 40 mm.

Price - 166,000 rubles.

- dimensions of the printed field - 30x30 cm;

- independent temperature control up to 400°С;

- lifting and opening method vertical;

- body strength;

- ease of use;

- guarantee period;

- the possibility of using manual settings.

- not identified.

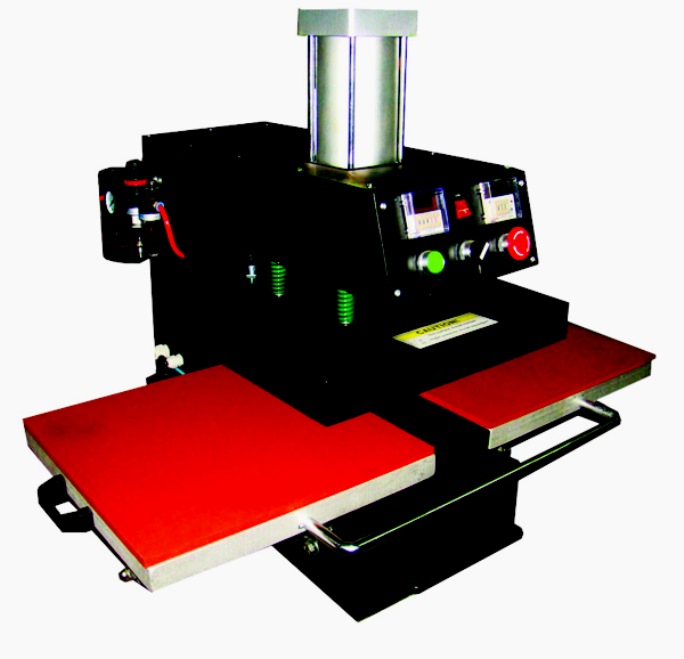

Schulze AirPress 4 X

votes 0

Flat-type heat press, which is widely used for thermal transfer of images on:

- banners;

- advertising products;

- natural leather goods;

- nameplates;

- signboards;

- plates;

- computer technology;

- mouse pads;

- flags;

- overalls;

- military uniform;

- tracksuits.

The product is most in demand in the advertising business, for the manufacture of souvenirs, labeling of goods, copy shops, as well as companies that manufacture their own products. Firms that are equipped with silk-screen printing equipment deserve special attention. Working area 400x500 mm. The device allows for manual adjustment of the temperature regime in the range of 0°-220°C. The declared power is 2400 watts. The total weight of the structure is 220 kg with dimensions of 160x160x200 cm.

Cost - 1050762 rubles.

- programmable economy module;

- economical consumption of electricity;

- electronic control panel;

- four working surfaces (tables);

- own cooling station;

- pneumatic drive;

- 180° rotation.

- price.

Bulros T-330

votes 0

A flat-type heat press that allows you to transfer pictures to various types of surfaces. Examples are surfaces from:

- skin;

- plastic;

- ceramics;

- textiles;

- metal.

The design is reliable and at the same time easy to use. Allows you to roll out the picture evenly on the work surface. The press opens automatically, in addition, the model is equipped with a platform (lower) of a retractable type. There are eight heating elements. The design is equipped with a unique system that allows you to control the time and temperature. This becomes possible due to the presence of a proprietary microchip, which guarantees a high response speed and accuracy of the manipulations performed. Manual settings are provided.All the information of interest to a person will be on a convenient LED display.

Price - 52100 rubles.

- weight 31 kg;

- power of 2800 W;

- temperature regime 90°-400°С;

- working surface 400x500 mm;

- vertically folding model.

- missing.

Conclusion

Every person throughout his life is faced with products that have passed through a heat press. The most sought-after items include cups, T-shirts, caps and dinnerware, which seek to decorate in the most unusual ways. The heat press is responsible for applying the selected print from special paper to the work surface by applying high temperatures and pressure to the surface. In addition to alignment, the pre-drawing is placed at the required angle. After turning on the equipment, a chemical reaction occurs, in which the graphic element peels off the media and remains on another surface.

Between themselves, the models differ in the way of use, purpose, forms and cost.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131652 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127693 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124520 -

The best men's sneakers in 2022

Views: 124034 -

The Best Complex Vitamins in 2022

Views: 121941 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2022

Views: 113396 -

Ranking of the best wood paints for interior work in 2022

Views: 110320 -

Rating of the best spinning reels in 2022

Views: 105330 -

Ranking of the best sex dolls for men for 2022

Views: 104368 -

Ranking of the best action cameras from China in 2022

Views: 102217 -

The most effective calcium preparations for adults and children in 2022

Views: 102012