Rating of the best thermally insulated pipes for 2025

The formation of a heating system with a long service life (as well as a water supply pipeline) is a very difficult engineering task. Proper organization of such internal highways will allow for decades to receive warmth and comfort of living in a country house. However, in such systems, much will depend on well-chosen conductive communications.

Content [Hide]

- 1 Thermally insulated pipes - general information

- 2 Basic requirements for pipelines based on heat-insulated pipes

- 3 Types of heating mains based on heat-insulated pipes

- 4 Production of heat-insulated pipes

- 5 Features of heat-insulated pipes

- 6 Difficulties of choice

- 7 Rating of the best thermally insulated pipes for 2025

- 8 Conclusion

Thermally insulated pipes - general information

This consumable sanitary material of a modern type is intended for integration in heating networks of cold / hot water supply and transports a coolant (water) with a maximum temperature of about +95 degrees Celsius at an internal pressure of 10 bar. The method of laying them can be both channelless underground and external (on the surface) using pre-built channels. The products in question themselves are polymer objects with polymer foam insulation, which is applied to them in a factory way. Traditionally, they are made on the basis of cross-linked PEX-polyethylene, and high-strength polyethylene is used as an insulating coating. They can be performed in one, two or four-pipe casings. The length of a segment without a joint can be up to 450 meters.Products differ in flexibility, are not subject to manifestations of corrosion, during installation it is not necessary to use special tools.

Basic requirements for pipelines based on heat-insulated pipes

Thermal insulation of cold water and hot water allows you to maintain the calculated performance of the heating system in any season, while minimizing heat costs when transporting the coolant from the entry point to the heating equipment directly. An additional operational factor may be negative temperatures that occur during the cold season and which can lead to freezing of the heating main, especially when it is opened for repair / maintenance. In this case, the water coolant can be replaced with a special antifreeze (which excludes freezing). But at the same time, it is worth remembering that not all boiler equipment is able to use it as a system filler. As a result, the following parameters can be attributed to the main requirements:

- The heat-insulating material should have pronounced hydrophobic qualities in order to exclude the formation of rust in the cavities themselves, which at the same time will prevent a decrease in heat-insulating performance as the carrier passes through them;

- The surface coating of the pipeline must withstand various manifestations of bad weather (rain, wind, excessive ultraviolet radiation), while maintaining the operational properties of the pipeline under moderate mechanical stress;

- When creating a heating main project, special attention should be paid to the durability of the materials used and pipes and insulation in order to ensure that the design indicators are maintained throughout the entire life cycle of the water supply / heating system;

- One of the main parameters for the heating main will be the cost of the pipe itself and its installation materials. Also, it must be taken into account that expensive components and materials can have a higher operational return and will quickly pay for themselves due to their own efficiency and easy installation.

Types of heating mains based on heat-insulated pipes

Their design will directly depend on the location relative to the surface of the earth and the method of arrangement for underground laying. The most common laying method is considered to be placed directly above the ground, fixing on special mounts or supports. Such a method will require some additional investment in the arrangement of supports and may interfere with the movement of cars and people. The only reason justifying the use of this method is the lack of technical feasibility of underground laying. In addition, the outer gasket will once again expose even an insulated product to adverse weather effects.

The underground method involves channelless or channel laying. The first option will require less excavation, which means less financial outlay. However, it will require more reliable insulation (Casaflex, Isoproflex).

Production of heat-insulated pipes

Pipe material

The selective preference for various materials for the production of pipes consists of two main parameters - these are withstand temperatures and pressure. Regulatory documents of the Russian Federation, namely the "Code of Building Regulations" No. 60.13330 of 2012, establish a limit for the temperature that can be allowed in the heating circuit, with a border of +95 degrees Celsius.However, in practice, this limit rarely exceeds +80 degrees, and the pressure is from 1.5 to 2 atmospheres.

For production, the following materials are most often used:

- Galvanized steel - it is able to withstand high pressure, significant temperature, relatively large mechanical loads, but it is characterized by the presence of vulnerabilities at the points of location of the welds. There will be no anti-corrosion protection, which, over time, will necessarily lead to the destruction of the structure. Also, in galvanized steel models, it is advisable not to use a coolant with a temperature of more than +60 degrees Celsius.

- Polypropylene (PEX) - such products can hold a pressure of 9 atmospheres at a temperature of +95 degrees Celsius. However, if such extreme conditions are constantly maintained in a polypropylene line, then its service life will steadily decrease and, approximately, will be from 5 to 9 years. Accordingly, manufacturers recommend using a coolant with a temperature of no more than +75 degrees Celsius in PEX pipes at a pressure of no more than 6 atmospheres. Their main advantage is light weight and easy installation.

- Cross-linked polyethylene - this material is very similar in its basic qualities to the previous one, it has almost the same recommendations regarding constant temperatures and pressures. However, its overall strength will be much higher, which is achieved through the use of a reinforcement order in the structure and a slightly different production technology.

IMPORTANT! It should be noted that a common disadvantage for all synthetic models is their weak resistance to high pressure and temperatures, and this makes their use in central / in-house heating systems with a long length undesirable.However, for arranging a closed system of one country house, they are quite suitable.

Thermal insulation material

For the organization of individual home networks, the following insulating materials are most often used:

- Mineral wool - consists of basalt / glass fibers, is considered a very popular type of thermal insulation due to its low cost and general availability. Its main disadvantage can be called low resistance to exposure to a humid environment. As an example: if mineral wool is impregnated with water at least 5% of the total volume of the layer, then its performance will drop by at least 90%.

- Foamed polyethylene - it is not afraid of water, it is considered one of the highly effective heat insulators. Differs in plasticity and ease, and its cost is quite adequate. Of the shortcomings, one can only mention limited resistance to elevated temperatures, which easily lead to deformation of the coating already from +75 degrees Celsius.

- Expanded polystyrene - has an affordable price, but its mechanical strength leaves much to be desired. Also, one can note low elasticity and resistance to high temperatures (no more than +75 degrees Celsius). Even for limited circuits of heating mains of detached houses, it is undesirable.

- Polyurethane foam is the safest and most effective insulating piping material, but its extremely high price has hindered its growth in popularity. However, the modern market can provide some replacement for it in the form of a polyurethane "shell" (two half-cylinders that are superimposed on the pipe and fixed with a tongue-and-groove lock), its installation is carried out only independently.

Manual installation of thermal insulation is associated with the risks of destroying the tightness of the entire structure, which will be facilitated by various external factors. There is also a high probability of non-compliance with installation rules when connecting fittings. In any case, purchasing models with factory-made insulation will be the preferred solution.

Features of heat-insulated pipes

The type under consideration is a kind of “sandwich”, where a special heat insulator with a special synthetic coating is used as the outer layer. The insulation has a protective sheath over its entire surface, which is designed to prevent mechanical deformations. The resistance of thermally insulated structures to temperature manifestations, the impact of pressure forces should be determined by the production characteristics of the product. For example, the use of cross-linked PEX-polyethylene can guarantee the operability of the line when exposed to pressure up to 6 bar and temperatures up to +95 degrees Celsius. If you use the improved Isoproflex line, then these values \u200b\u200bcan be increased: for pressure - up to 16 Bar, for temperature - up to +115 degrees Celsius.

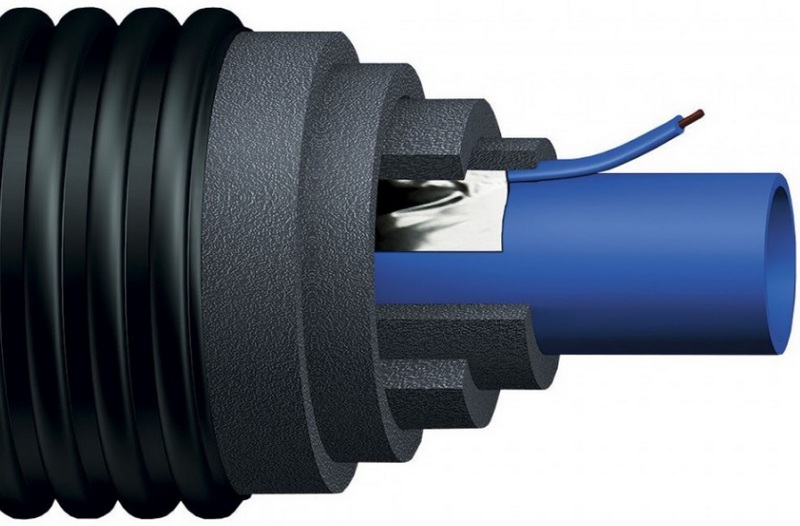

If we talk about the latest improvements in this segment, then the Casaflex line can be an excellent choice. These products use chrome steel along with a twisted surface design. These pipelines are able to operate stably at a temperature of +160 degrees Celsius at a maximum pressure of 16 atmospheres. They also use a signal cable placed under the insulating layer.This feature allows you to quickly monitor the state of the route at a remote distance.

Difficulties of choice

When buying the products in question, you should pay close attention to the following technical parameters:

- Resistance to corrosion manifestations - water or liquid antifreeze passes through the mounted circuits, which can destroy the internal walls of the line. Accordingly, they (the walls) must have a proper protective layer.

- General strength - the usual level of pressure in the heating circuit rarely exceeds 2 atmospheres, however, the purchased product must withstand indicators 2-3 times higher than the standard;

- Temperature - in traditional systems, the coolant is rarely heated by more than +70 degrees Celsius (for "warm floors" this value is +50 degrees). However, the facility must withstand higher rates in case of emergency (for example, malfunction of boiler equipment, malfunctions in automatic control, overheating of the coolant).

- The level of thermal conductivity - the coolant is transported inside the system, while simultaneously giving off thermal energy to the outside. If it concerns the equipment of "warm floors", then the thermal conductivity indicator plays a big role, but if the main acts as a simple conveyor, then increased thermal conductivity is not even desirable.

- Thermal expansion coefficient - this feature must be taken into account without fail, especially for polymer objects and if they are laid under a bulk screed. If the pipeline passes through the surface, then this coefficient will not be of great importance.

- Installation features - different methods can be used to connect individual sections of the route, which will depend on the material of manufacture of the products. It should be noted that in the vast majority of cases, the use of special tools and sufficient installation experience of the master will be required.

- Dimensions - when laying a heat-insulated circuit, the length of one section can reach 100 meters or more, so the overall dimensions of the entire system must be calculated in advance in order to prevent unwanted deviations and joints from occurring under the screed.

- Chemical resistance - a route made of this type of pipe is often placed under a screed or in walls, and aggressive chemical propylene glycol or ethylene glycol is used as a coolant. The internal cavity and external surface of the object must withstand interaction with these substances.

- Operational durability - products must have a long service life, which, according to state standards, is calculated in decades (subject to proper operation).

- Hydraulic parameters - the inner walls must have a low level of hydraulic resistance to the flow of the coolant, while constantly remaining in a completely smooth state. Such a parameter will contribute to increased overall system efficiency and at the same time reduce the energy consumption costs of circular pumping equipment.

- Air permeability - the coolant will always contain oxygen, which is a strong oxidizing agent for metals and is capable of destroying many different materials and surfaces - from heating elements to reinforced layers.Hence, it is important that the insulating sheath let air out as little as possible.

- Price is probably one of the fundamental criteria for any buyer. Professionals advise that when buying the product in question, it is preferable to choose more expensive models made from quality materials, and which, in any case, will quickly pay back the money spent on them.

Rating of the best thermally insulated pipes for 2025

Single pipe

3rd place: "FLEXALEN 600 Standard VS-RH90A25 (25×2.3/90, 8 bar, 95 degrees C)"

votes 0

The model is made of polybutene, a unique material that combines the advantages of PEX polyethylene and PP polypropylene. Polybutene has high strength and temperature characteristics, has a long service life and at the same time allows welding like polypropylene (the cost of fittings is an order of magnitude lower than fittings for cross-linked polyethylene). Outside, the bearing part is covered with an oxygen-impermeable layer. Insulation is a highly energy-efficient thermal insulation made of physically foamed THERMAFLEX polyethylene. The shell is a high-strength, low-pressure corrugated shell with the addition of carbon, which means resistance to ultraviolet (solar) radiation. Thermal insulation and casing are welded to each other. Recommended price for retail chains - 2770 rubles

- Flexible and lightweight design.

- Simplified installation of connections (branches are soldered to the main pipe like polypropylene);

- The increased quality of thermal insulation from the well-known manufacturer Thermaflex.

- Not detected.

2nd place: "Uponor Thermo Single 25×2,3/140 single-pipe for heating, 6 Bar"

votes 1

The product is used when laying underground heating mains for cold and hot water supply. The model is necessary when the boiler house is located at a considerable distance from the heated building. Material - cross-linked polyethylene PE-Xa, thermal insulation made of foamed cross-linked polyethylene PE-X with closed cells (water absorption <1%). The area of use is external heating networks (heating mains) and water supply. Working pressure — 6 Bar (Atm), working temperature +70°С (maximum temperature +95°С). The recommended cost for retail chains is 3350 rubles.

- Protective corrugated casing made of high density polyethylene;

- Service life — 50 years at observance of working parameters of temperature and pressure;

- Oxygen resistant coating.

- Not detected.

1st place: "Ecoflex Supra Plus 25×2,3/68 PN10 with heating cable 10W/m for cold water"

votes 0

It is used in external networks of cold water supply, in pressurized sewerage, in the refrigeration supply of geothermal systems, the freezing of which is prevented by the built-in self-regulating heating cable. The most common use is as an underground pipeline for supplying cold water. The design provides a channel for installing a temperature sensor, located at the coldest point of the surface. When the temperature drops below the set temperature, the thermostat will turn on the heating cable. Laying is allowed in the freezing zone, on the surface of the earth and "by air". The use of underground channelless laying in a trench will greatly simplify and reduce the cost of the installation process. The lengths are connected by means of compression fittings for HDPE, butt welding or electrofusion fittings.Recommended price for retail chains - 3600 rubles

- A complete solution for the cold water supply route;

- The built-in heating cable will prevent freezing of cold water;

- Reliability and preservation of operating parameters for a long period of time (service life of 50 years).

- Not detected.

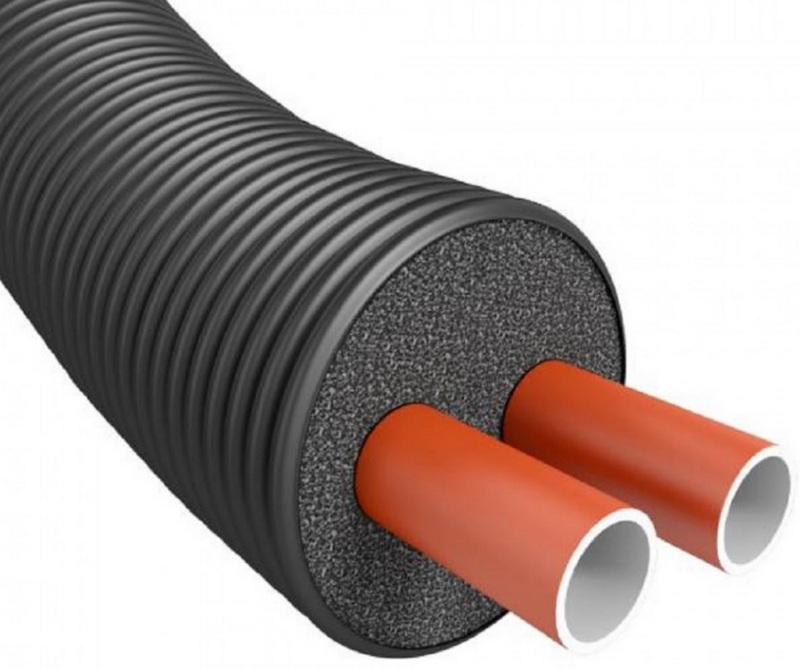

Two-pipe

3rd place: "FLEXALEN 600 Standard VS-RH125A2/25 (2x25x2.3/125, 8 bar, 95 degrees C)"

votes 0

This flexible thermally insulated pipe for heating mains has a high-strength corrugated casing made of polyethylene, produced by low pressure with the addition of carbon, which provides resistance to ultraviolet (solar) radiation. Thermal insulation and casing are welded completely to each other. The recommended cost for retail chains is 3950 rubles.

- Good value for money;

- Corrugated body;

- Impervious to oxygen.

- Not detected.

2nd place: "Uponor Varia Twin 2x25x2,3/140 6 Bar two-pipe for heating"

votes 1

The model is used in private construction for heating a bathhouse (guest house) from a boiler room located in the main house. The material is PE-Xa cross-linked polyethylene (one of the most reliable materials for heating pipes). The thermal insulation is made of closed-cell PE-X cross-linked polyethylene foam (water absorption <1%), whose thermal insulation characteristics do not change with time. The recommended cost for retail chains is 4,000 rubles.

- Protective high-density polyethylene casing - protects against mechanical damage;

- Service life - 50 years;

- Oxygen-tight coating that prolongs the life of the heating system.

1st place: TVEL-ECOPEKS-2 heating main, 2x25x2.3/90, 6 atm, coil 20 m

votes 1

This model is a full-fledged route for the heating and water supply system of a separate building (bath, garage, guest house) when connected to a boiler room. Thus, one boiler room can heat several buildings. Coil length - 20 m, pipe diameter - 25 mm, working pressure - up to 6 atm, liquid temperature - up to +95 °C, permissible short-term temperature up to - +110 °C; resistance to freezing - up to 100 cycles. The material of manufacture is foamed polyurethane foam, the pipe itself is cross-linked polyethylene PEXa. The recommended cost is 39,000 rubles per bay.

- The heating main is coiled at the factory into a compact coil;

- Full laying of the system in a trench is available to one person;

- Easy connection - no specialized tools are required to install clamp fittings.

- Delivery is carried out only in a full-fledged bay.

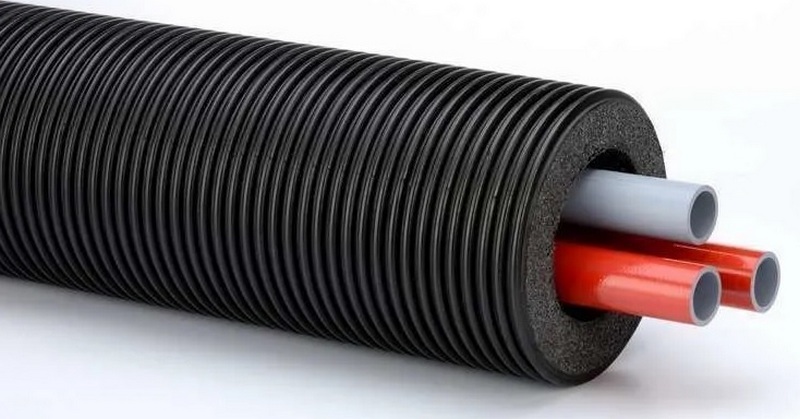

Three- and four-pipe

3rd place: "Thermaflex Flexalen 1000+ for heating and water supply FV+R200A2/25A40"

votes 1

The model is assembled on the basis of an isolated channel for individual FV-ISR solutions. Pipes inside are located freely. The outer diameter of the shell is 160 mm, the two heating pipes have an outer diameter of 32 mm (supply and return pipes). The "H" index indicates that there is an oxygen barrier to better provide heating. The recommended cost for retail chains is 6840 rubles.

- Color differentiation of pipes (convenient for repairs);

- The price corresponds to the quality;

- The presence of an oxygen barrier.

- Not detected.

2nd place: "Thermaflex Flexalen 1000+ for heating and water supply FV+R200A2/25A32A20"

votes 1

This four-pipe model is perfect for arranging hot water and cold water systems in separate buildings. Corrugated housing provides reliable protection against external damage, while preventing the penetration of oxygen. The insulation is made of high quality polyethylene. The recommended cost for retail chains is 9500 rubles.

- Multilevel protection;

- Corrugated body;

- Thickening of the insulation.

- Slightly overpriced.

1st place: "Thermaflex Flexalen 1000+ for heating and water supply FV+R160A4/20A2/25"

votes 1

The model is also four-pipe and is characterized by a special ability to bend, which makes it possible to use the product for arranging contours of various lengths and various shapes. The insulation has a special thickening and can successfully resist the penetration of oxygen. The recommended cost for retail chains is 9750 rubles.

- Good emphasis on the fold;

- Special thickening;

- Ability to create contours of various shapes.

- Somewhat overpriced.

Conclusion

The main advantage of flexible pipes with thermal insulation is their adaptability to almost any difficult operating conditions, even at constant low external temperatures.They have many positive design features, such as the new generation of synthetics, which can successfully withstand mechanical damage and chemical attack. However, in terms of their isolation, traditional materials should not be neglected, as they have not completely lost their relevance. The main thing is that if classical types of heat-insulated routes are used, then the coolant passing through them must correctly comply with the limits of technical capabilities. In general, the modern market for the goods in question is very wide and choosing a specific model for the heating circuit is quite simple, you just need to correctly analyze the specific conditions for future operation.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131656 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127697 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124524 -

The best men's sneakers in 2025

Views: 124041 -

The Best Complex Vitamins in 2025

Views: 121945 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114984 -

The best paint for gray hair - top rating 2025

Views: 113400 -

Ranking of the best wood paints for interior work in 2025

Views: 110326 -

Rating of the best spinning reels in 2025

Views: 105334 -

Ranking of the best sex dolls for men for 2025

Views: 104373 -

Ranking of the best action cameras from China in 2025

Views: 102221 -

The most effective calcium preparations for adults and children in 2025

Views: 102015