Rating of the best heat accumulators for heating for 2022

A heat accumulator can be called a fairly common device that saves energy costs for space heating and hot water supply. The device is suitable for use both in residential buildings and apartments, and in enterprises of various sizes. So, in the article we will consider in more detail why this device is needed, what it happens and what models, according to users, can be called the best among those on the market.

Content

What is a heat accumulator and why is it needed

The device is a large reservoir of water, which in this case acts as a coolant. Due to the high heat capacity of water, when the entire volume in the tank is fully heated, a large supply of heat is accumulated, which is then used as needed. The heated water is often used in the heating system to maintain a comfortable room temperature.

The main task of the heat accumulator is to accumulate thermal energy in case there is excess in the heating system, and its subsequent transfer at times when there is not enough heat, for example, when the main heat source is turned off. From this it follows that it is best to use heat accumulators with heat sources with a pronounced period of operation. When combined with thermal storage and electric heating boilers, users save a lot on electricity costs, as in most communities there is a difference between night and day tariffs. As a rule, the difference in price at night is almost half, so if you use the boilers at night and consume the heat that the battery accumulates during the day, you can notice a significant difference in costs. And given the regular increase in electricity prices, many are beginning to consider such designs as an ideal solution to save money. Also, a heat accumulator can be used as a connecting element between several heat sources, by switching between us, which minimizes energy costs.Of course, not all devices are endowed with such capabilities, and therefore, before buying, you should familiarize yourself with the functionality in advance.

Pros and cons

Before installing the device indoors, experts recommend that you familiarize yourself with the advantages and disadvantages of heat accumulators.

- the cost of electricity and fuel is significantly reduced;

- increases the performance of heating systems;

- devices do not overheat;

- the consumption of solid fuel in boilers is reduced;

- users can select and set the desired temperature;

- due to the presence of a redistributing function, the service life of the boiler is extended;

- there is the possibility of combining with several heating systems;

- increases the convenience and safety of using heating boilers.

Users also note that due to the joint operation of the boiler and the heat accumulator, the fuel in the furnace does not burn out completely, the product is saved and, in addition, there is no need for regular cleaning of the combustion products from either the boiler itself or the chimney.

- it takes quite a long time to start up in normal operating mode, from a cold state;

- transportation of the device is inconvenient, since it has a large number of components, this also affects its installation;

- requires considerable financial investments, which do not quickly pay off by saving on electricity and fuel;

- there is still a need for a fuel storage near the boiler house.

Quite often, craftsmen independently equip boilers with heat accumulators, which reduces the cost of their installation and maintenance.

Unit types

Manufacturers produce several types of devices, and buyers, already focusing on the functionality and complexity of the heating system, choose the appropriate model.So, there are devices:

- With circuits connected directly: they are considered the simplest and are used in cases where the same heat carrier is used for the circuit and the boiler, or the pressure in them is the same regardless of the fact that the sources themselves are different, and also if the temperature at the pipe outlet is higher than in the contour. There are times when a direct connection is the only solution, even if the above conditions are not present. This is possible when connecting with additional heat exchangers, in this case, in addition to installing a buffer tank, three-way valves and mixing units are also used.

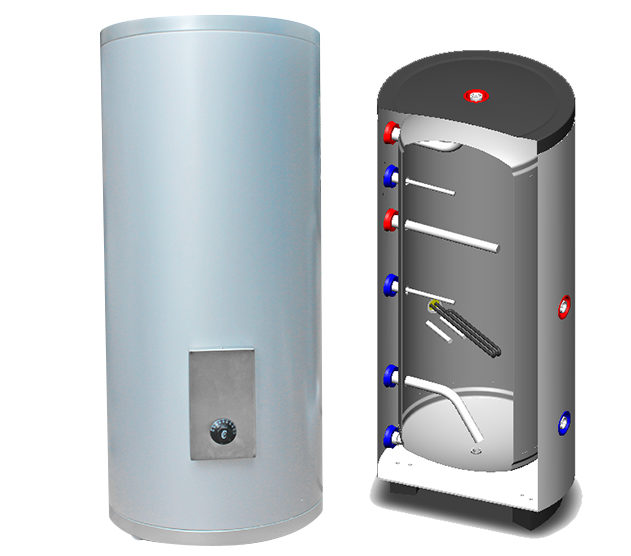

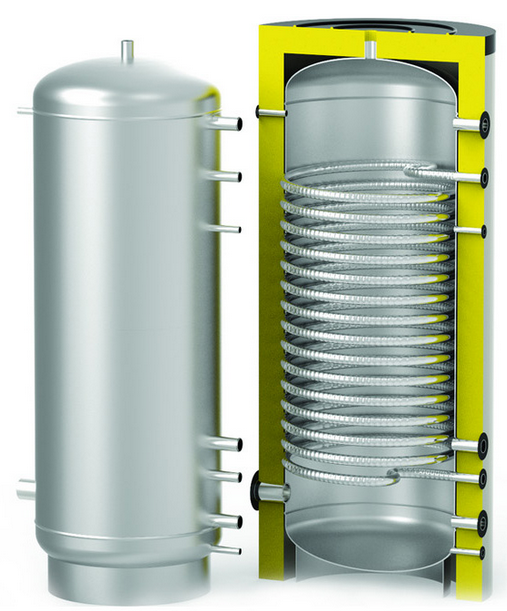

- With a built-in heat exchanger, which is a spiral, corrugated or plain, made of stainless steel and placed inside the tank on its lower part. This design is used in cases where the source temperature and pressure in the circuit are much higher than at the outlet of the heating system, and also if several different types of heat sources are used. Such devices differ in that the water heats up more from below, that is, where the spiral is located, which allows you to quickly heat water and heat rooms.

- With built-in heat exchangers that have a flow supply of heated water in such models, they are located in the upper part of the tank, and water is supplied from below. The place of hot water intake is a limiter, such schemes are suitable for tanks in which the volume of hot water is stable and practically never changes.

- With a built-in tank, this type of heat accumulator in operation resembles a conventional boiler, heating occurs indirectly. Such devices are installed if the boiler is unstable in generating heat and incoming energy and there is not enough energy to heat and heat water.Also suitable when the boiler is used rarely and for a short time.

All types of construction are suitable for use both in domestic and commercial settings, but it is necessary to take into account the type of heating system, what volumes it consumes and the way it works.

Installation Features

Before installing such a design, a project is first approved, which takes into account all the recommendations of the manufacturer and the features of installation work:

- the surface of the storage tank must be insulated; this will protect against heat loss;

- thermometers must be installed on all pipelines, both outlet and inlet;

- containers with a volume of more than 500 liters, as a rule, do not pass through doorways;

- it is recommended to install a drainage channel at the bottom of the tank, it will be required to drain the water completely if necessary;

- in the pipes through which the liquid will flow, strainers should be installed, thanks to them large debris will not get inside;

- at the top point of the branch pipe, a valve must be installed, it is either provided for by the design, or is installed additionally during installation;

- it is also necessary to mount a pressure gauge and a safety valve, which are located next to the battery.

Having a solid fuel boiler in your use, the purchase and installation of a heat accumulator will be an excellent solution that will not only save fuel and electricity costs, but also extend the life of the heating equipment.

The principle and functionality of heat accumulators

The basic principle of operation of the device is that while the boiler is operating, part of the heat received is directed to heating the coolant in an additional tank.Due to the fact that the battery tank is well insulated, it perfectly retains the heat received for a long time. After turning off the boiler, the water in the heating system begins to cool down, and the devices that control this moment turn on the pump, and the liquid from the additional tank begins to circulate. The process continues until the temperature of the coolant in the additional structure remains quite high, the period varies from two hours to several days, it all depends on the volume of the additional tank.

As for the function of the heat accumulator, among them are:

- accumulation of heat from the main source and its distribution as needed in the premises;

- prevention of possible overheating of the boiler, due to the fact that it takes away the excess heat received;

- allows you to easily combine various heating devices into one common system;

- improves the operation of heating equipment, reduces the consumption of fuel materials and increases efficiency;

- delivers hot water suitable for domestic needs;

- reduces the need for constant monitoring of heating system equipment, and also eliminates the need for constant fuel loading into the boiler.

The functionality of the instruments should be examined before purchase and taken into account during installation.

How to choose the right heat accumulator

When choosing which heat accumulator to purchase, you should familiarize yourself with its characteristics, take into account the dimensions of the heating system and the requirements for it. When selecting a device, the features of heating devices should be taken into account:

- the power of which the boiler is endowed;

- maximum pressure volume;

- temperature for warming up;

- the presence of other sources of heat;

- the size of the area to be heated;

- degree of thermal insulation.

When choosing a heat accumulator, attention should be paid to such details:

- on the dimensions of the device;

- on volume;

- the material from which the unit is made;

- protection located inside;

- Is there a removable cover?

- efficiency;

- simplicity and ease of use;

- period of operation;

- work automation;

- the presence of additional functions, for example, is there a built-in heat exchanger, is there protection against possible overheating, is there a temperature control sensor, and others.

When choosing and installing heat accumulators, many buyers have difficulties, and in order to resolve them and secure the operation of heating systems, it is worth resorting to the help of specialists.

When choosing a heat accumulator model, you should not save and dwell on unfamiliar brands, the fact is that cheap devices have the appropriate quality, which will affect not only the efficiency, but also the quality of the operation of all heating equipment. Recommendations for selection should also be taken into account, since in the absence of a heat exchanger it will not allow heat to linger for a long time, and poor coverage will lead to rapid wear. All this will lead to the fact that the unit will not perform its intended functions and will not be able to ensure the safe operation of the main parts that provide heat.

Rating of the best heat accumulators for heating for 2022

To choose the right model of the unit, you should carefully study all its characteristics and take into account the features of the heating system itself, and use the services of specialists for installation. The Internet provides a list of devices that, according to users, can be called the best among them, devices that have both a high and more affordable cost.

Expensive units

The section of expensive units includes those whose cost exceeds 100,000 rubles, as a rule, they have all the additional functions that ensure the necessary operation of heating systems.

Electric boiler Heat Tank

This model belongs to the industrial, contains about 1500 liters of water and allows you to maintain a temperature of +35 to +85 degrees. Suitable for use with gas and solid fuel boilers. A 30 kW heating element allows you to use electrical energy as a backup power source. The container is made of stainless steel and has a thermal insulation of 25 mm, as well as additional protection in the form of a nylon cover that prevents corrosion. Small dimensions (diameter 1 m, height 2 m) make it easy to place the device in the right place, and the location of the nozzles makes it easy to connect the model. Optionally, you can install a tubular heat exchanger, thereby increasing the power of the heater up to 150 kW.

- has precise thermostat settings;

- smoothly adjustable;

- there is an automatic switch TEN;

- warms up in less than 3 hours;

- there is a safety valve;

- pressure of 0.6 atmospheres.

- price;

- not suitable for industrial water use.

Oso Accu AS

The rather compact Oso Accu AS model has a volume of 100 liters and is suitable for working with solar collectors or small heat pumps. The inside of the container is made of stainless steel, and the design itself can withstand a pressure of 9 atmospheres. The small dimensions of 45 by 45 cm allow you to install the device anywhere in the room and easily make a simple docking with the harness.The model is sold without thermal insulation and allows you to independently choose and install the appropriate level of protection that prevents heat loss. Maximum safety in the event of a source failure is ensured by a full load on the tip.

- the device is made in a modern design;

- has high resistance to corrosion;

- eyeliner is located on the side;

- efficiency;

- TEN is built in;

- double connections are provided.

- high price;

- no heat exchangers.

S-Tank Hfwt DUO-1000

The thermal accumulator S-Tank Hfwt DUO-1000 is suitable for use both in a residential area and in a small industrial one. The volume of the tank reaches 1000 liters and is equipped with two stainless steel spiral heat exchangers. The model is completed with solar collectors, natural gas or solid fuel boilers, as well as heat pumps. The coil located at the bottom of the tank is connected to a heating source, the water passing through the coil from above is heated to a temperature 2 degrees lower than the liquid accumulated in the tank itself. The owners regularly use about 1000 liters of hot water. The unit comes with a heat-insulating casing made of flexible polyurethane foam and polyester. The working pressure in the heat exchanger can reach 6 atmospheres.

- the highest heating temperature reaches 95 degrees;

- increased resistance to corrosion;

- in this model, water glycol solutions can be used as a heat carrier;

- the warranty period from the manufacturer is 5 years;

- stable construction.

- price.

Drazice Nado 300/20 v6

An excellent unit that has two heat exchangers, one of which is designed to heat 20 liters of technical fluid, and the second is for docking with a solar collector. Drazice Nado 300/20 v6 with a volume of 300 liters is covered with enamel inside, the maximum heating temperature reaches 110 degrees. The kit includes two connections for screw-in fluid heaters powered by the mains. The required level of heat is maintained by the installed thermal insulation in the form of a layer of polyurethane and a removable casing. The vessel is painted with a special heat-resistant paint, thanks to which a high level of protection against rust is provided.

- the coil is located along the entire length of the tank, which increases heat transfer;

- the dimensions are so compact that they allow you to mount it even in a small room;

- insulating material is presented in a separate package;

- pipes are well placed.

- price.

Inexpensive models

The inexpensive section contains models whose cost does not exceed 100,000 rubles.

Hajdu AQ PT6 500

The Hajdu AQ PT6 500 device is designed to provide heating systems with a heat carrier, suitable for connection to a boiler running on solid fuel, oil or natural gas. The tank also functions in conjunction with solar panels and fuel pumps. The design tank is designed for 500 liters of liquid. Due to the fact that the device does not have an anti-corrosion coating on the inner walls, it is only suitable for heating systems. The package does not include heat-insulating material, it is purchased separately, which makes it possible to choose a heater of the thickness that is needed, taking into account the needs of the room.

- price;

- ease of connection;

- dimensions;

- versatility in connection;

- heating element can be connected.

- due to the lack of an anti-corrosion coating, it is only suitable for heating systems.

Nibe BU-500.8

This model allows it to be used in conjunction with various heating boilers and heat sources, and is also suitable for use as an alternative supplier of heat energy in case of its central shutdown. Collaboration with boilers that use solid fuel eliminates their overheating, increases efficiency and extends the period of operation of the boiler room equipment. The floor structure holds up to 500 liters of liquid, which warms up to 95 degrees and has a pressure limit of 6 bar. Thermal insulation reaches 14 cm and is easily removed, which allows you to reduce its thickness if necessary. Nibe BU - 500.8 is suitable for heating equipment of high complexity, including those with high thermal loads.

- construction design;

- polystyrene foam insulation up to 14 cm;

- it is possible to connect several electric heaters;

- is like an alternative source for heating when the central one is turned off;

- there is a night tariff for electricity consumption, in the presence of two-tariff meters;

- some designs provide additional coils that allow you to connect additional heat sources.

- no.

Sunsystem P 1000

Universal model of the heat accumulator for 1000 liters, allows you to connect it to any type of boilers.The vertical design is suitable for placement in small rooms (boiler rooms), as it will take up a minimum amount of space. The tank is made of low-alloy steel, coated on the outside with a primer and soft polyurethane 10 cm thick as thermal insulation. The material is protected from rust by a PVC-based polymer coating. The good location of the nozzles makes it easy to connect to the system, and the internal thread makes the connection as reliable as possible. The presence of a heater allows you to use them as an additional power source. The liquid in the accumulator can reach a temperature of 95 degrees, and the operating pressure should not exceed 3 atmospheres.

- simplicity and clarity of settings;

- convenient location of communications;

- the warranty period from the manufacturer is 3 years;

- Allows simultaneous use of up to three heat sources.

- no DHW coil.

S-TANK SERIES HFWT 300

The S-TANK model of the HFWT 300 SERIES has a feature that allows you to use any number of heat sources at the same time, this feature is very important when creating a multi-valent heating system. In the tank there is a high quality stainless steel spiral, the temperature during heating varies from 39 to 110 degrees. The total volume of the container is 300 liters, it reaches a height of about 1.5 m, and a diameter of 63 cm. The warranty period provided by the manufacturer is 5 years.

- price;

- quality;

- long service life;

- small dimensions;

- At the same time, any number of heat sources can be connected.

- no.

De Dietrich PSB

The De Dietrich PSB unit with a volume of 1500 liters is produced by a French brand, the tank walls are made of thick steel and can withstand a pressure of 7 atmospheres. From the inside, the walls are coated with a primer, and from the outside with a decorative, PVC-based polymer coating, which provides powerful protection against corrosion. De Dietrich PSB can be connected to several sources at once. The container comes with a flexible lining made of mineral wool 10 cm thick, or a casing made of rigid polystyrene.

- convenient location of the eyeliner;

- design;

- excellent build quality;

- good rust protection.

- TENY are not built in.

The installation of heat accumulators has a beneficial effect on the entire heating system, allowing it to extend its service life and protect the boilers from overheating, and also saves the owner's budget, saving on fuel and electricity costs. When choosing a model, you should take into account the installed heating system and the functions of the battery itself.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127688 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124516 -

The best men's sneakers in 2022

Views: 124030 -

The Best Complex Vitamins in 2022

Views: 121937 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2022

Views: 113393 -

Ranking of the best wood paints for interior work in 2022

Views: 110317 -

Rating of the best spinning reels in 2022

Views: 105326 -

Ranking of the best sex dolls for men for 2022

Views: 104363 -

Ranking of the best action cameras from China in 2022

Views: 102214 -

The most effective calcium preparations for adults and children in 2022

Views: 102010