Rating of the best hoists for 2022

Hoists are lifting devices specially used to lift heavy objects, whose weight ranges from hundreds of kilograms to tens of tons. This device allows you to qualitatively reduce the labor costs and time required to perform such procedures. The hoists can be used for domestic purposes, in small workshops, and are also widely used in industrial enterprises and large construction projects. Modern types of such devices differ in the principles of operation, design and price limits.

Content [Hide]

general information

Hoist is a relatively small device for lifting heavy loads in the framework of rigging, assembly / dismantling operations, as well as unloading / loading procedures. Their carrying capacity limits can vary from 100 kilograms to 7 tons, and the lifting height of an object can be up to 10 meters. The principle of operation of the device is based on the difference in the diameter of the gears, through which the force is transmitted. The built-in gearbox makes it possible to increase the tractive force several times, which will be quite enough to move multi-ton objects from scrolling the lever manually or through an electric drive. The modern market will easily provide the buyer with about 200 different models of the devices in question. However, this figure does not completely limit the product range, because for some models there may be up to a dozen of the smallest modifications, each of which will have its own rigging nomenclature.

Tali manual

This type of rigging tool is driven by the muscular efforts of a person. But with the development of technology, they stopped using ropes and ropes in their construction, and began to use metal chains, which are considered more durable and reliable and can withstand heavy weight loads.The "heart" of the whole structure is a special drum, on which the chain is typed. Next comes the transmission mechanism connected to the drive, as well as a hook for fixing the hoist to the beam. The very same cargo chain can have a length of 3 to 10 meters and one end is equipped with a steel hook and a carabiner that serves to hook the load. The very same action of the device can be carried out by a lever or chain. Accordingly, manual models can have two basic modifications:

- Lever - for these devices, the lever is fixed directly on the body and therefore they need to be mounted at a height where the user would be comfortable managing it (traditionally, this is about 2 meters from the ground). To perform the lift, the user oscillates with a lever, and the chain begins to pick up on the drum. With the help of a lever modification, it is quite convenient to lift heavy objects to small heights in order to place them on a workbench or on the working surface of the machine. The device will perfectly cope with the majority of household tasks and will perfectly serve for performance of production tasks in the conditions of a small workshop.

- Chain - these devices are equipped with two chains at once - cargo with small links (for hanging objects) and power with enlarged links (acts as a drive). Lifting is done while the power chain is being tensioned by the user. The device can be suspended at greater heights than described above, while the height will depend on the size of the chain (its length can reach from 10 to 25 meters). Models are widely used in repair shops and construction sites.

Summing up a little, it can be argued that manual hoists are unpretentious and easy to maintain, they do not need a separate source of energy.All this reduces the cost of their operation. They are able to work both outdoors and indoors. Their main disadvantage is the low lifting speed, which directly depends on the strength of the operator-user. From this it is clear that if the task is precisely in the rapid lifting / lowering of loads, then the use of such models will not be rational, because a larger productivity factor will be required.

Electric hoists

For this equipment, the design includes a drum, which is installed on a steel platform, a metal cable, dialed on it, and a control panel. The movement of the entire mechanism is carried out using an electric motor that transmits rotational feed to the drum, where the cable is wound / unwound, depending on the command given by the operator. The fixture of the device is located on a special crane-beam or a steel profile with a rectangular cross-section. The main advantages of such devices are:

- The operator does not make any special muscular effort during operation - he is only required to press the buttons;

- The lifting of the load is carried out quickly, due to the winding of the cable on the drum at a speed of 4 to 10 meters per minute;

- Climbing to a great height became available through the use of a cable, and not a chain, because it is more compact when folded, and this does not make the overall weight of the device heavier, even if the cable itself exceeds a couple of tens of meters;

- Special automatic protective systems, such as automatic stop brakes and limit switches, are responsible for the safe use of the device. It is they who keep the entire system from the risk of failure or structural failure.

However, the possession of an electric motor imposes certain restrictions on this type of hoist.So, there are special requirements for the position of the device - it must be in a dust-free room, protected from moisture, the surrounding space must have room temperature, and the power supply must meet certain voltage indicators. Moreover, electric models cannot work continuously and they need a short “rest” interval every 10-15 minutes.

Nevertheless, these "minuses" should not be counted among the shortcomings of the device - you just need to take a more responsible approach to working with it. Any operator must know and follow the order of work, keep a log with marks of prevention and maintenance. Due to the fact that the electric hoist is characterized by increased productivity, it is advisable to use it in the field of industrial production and for complex repair tasks, for example, when repairing special equipment.

Expanding the functionality of hoists

Any type of hoist, both manual and electric, has basic factory performance regarding lifting height and load capacity. Based on these parameters, it is convenient to determine the scope of tasks for which the device is designed. For example, the limit for some model is set to the ability to lift 1 ton to a height of 6 meters. But what if you need to lift a slightly larger load to the same height? Does this require the purchase of a new device? It turns out that doing this is completely optional. In principle, any hoist can be equipped with a special polyplastic block, which will help increase the pulling force. In this case, the cable will fold in half. In addition, in some cases it is required not only to lift the object, but also to move it horizontally (which is often necessary for the tasks of repair shops).Accordingly, the apparatus can be equipped with a special moving carriage. As a result, there are many additional devices, through which it is possible to expand the working functionality of the lifting apparatus:

- Drive and idle wheels;

- Trolleys for remote transportation of the device;

- Hanging hooks;

- Additional slings;

- Ceiling / wall brackets;

- Various consoles and beams;

- Crane collapsible tracks;

- Remote control.

Telfer as a special type of electric hoists

Telphers are the most powerful types of electric hoists and provide the fastest lifting of massive loads to a great height, while they are often equipped with a horizontal movement carriage. However, for their full operation, special conditions are required, which are established in the State Standard No. 15150 of 1969. These may include the temperature regime, which should not go beyond the boundaries from -20 to +40 degrees Celsius. Telphers differ in high cost, but it is compensated by their greater reliability. So, there are special models, whose body and internal mechanisms have undergone special anti-corrosion treatment, which allows them to function even in conditions of high humidity. At the same time, they can be reinforced with strong and dense insulating layers, which is important for their mobile use within the equipment installed on marine cargo ships. The same models are standardly reinforced with inactive parts, which perfectly counteract third-party vibrations that occur in sea rolling conditions.

Features of hoist service

Being quite complex equipment, hoists need preventive maintenance, periodic maintenance, urgent / scheduled repairs.These works are subject to mandatory documentation and records of such works must be kept by the assigned operator. Practice shows that most often in this type of device components of the control panel and limit switches fail. Therefore, the responsible operator must carry out the following activities on an ongoing basis:

- Editing the crane beam;

- Repair of the lifting mechanism;

- Correction of the brake system;

- Lubrication of working channels.

For smooth and efficient operation, the implementation of the above activities must be carried out in a timely manner and without delay. The schedule for their implementation should be established with an annual margin. The main thing is not to bring the equipment to a state of overhaul, when a complete replacement of the main parts and mechanisms is required.

Difference between hoist and hoist

The difference between standard models and reinforced ones lies in their dimensions and the ability to perform a certain set of operations. Telphers are large, they are more adapted to the addition of all kinds of equipment, they can perform large-scale traction work. The largest variations of them can even be equipped with a special cabin for the operator, which will make his working conditions more comfortable. Summing up, two main conclusions can be drawn:

- Simple hoists are preferable to use in a cramped working space and it is better to lift small loads to medium heights with them;

- Telphers will become indispensable devices in loading and unloading terminals, in the operation of warehouses, on construction sites - in general, wherever it is necessary to move massive objects.

Difficulties of choice

During the purchase of the equipment in question, it is necessary to pay attention to the following important nuances and technical parameters:

- Load capacity - when solving this issue, it is advisable not to select the most accurate indicators, but it is better to purchase a device that will be slightly stronger than planned. So you do not have to operate the device on the verge of its capabilities, and this will positively affect its service life.

- Type of mechanism - the choice in favor of lever or gear models will directly depend on future tasks, working conditions and the location of the operator (for industrial purposes, it is better to choose a remote-controlled model).

- The weight of the device itself - it depends on the platform on which the hoist will be placed. In addition, if work mobility is assumed, i.e. equipment will need to be moved frequently, then a light weight model will be preferred.

- Purpose - for light loads and low-intensity work, it is better to choose compact manual control models equipped with gear wire. Their cost is much more affordable than that of expensive samples, whose potential may not even have to be fully used.

Rating of the best hoists for 2022

Manual models

4th place: ZITREK HS-Z 1t 3m

votes 0

This hand gear type is used for lifting and holding a variety of medium weight loads. With its help, it is convenient to raise and lower relatively heavy objects in the production of construction, installation and repair work. The country of origin is China. The maximum lifting height is 3 meters, and the maximum load limit should not exceed one ton. The recommended cost for retail chains is 3600 rubles.

- Excellent combination of price and quality;

- Reliable fastenings;

- There is a 2 year warranty.

- Not detected.

3rd place: "Izhsnabtorg" chain 1t 3m "

votes 0

The model is a simple, comfortable and inexpensive tool for lifting loads. It can be used in any specialized area - small-scale construction, storage facilities, repair and installation operations, household work in household plots and summer cottages. The sample allows you to develop a sufficiently powerful draft force, while the operator will not apply too much physical effort. This device is perfect for use in cramped conditions, for example, in sewers or wells. It has sufficient load capacity and lifting height. Does not require power supply. The recommended cost for retail chains is 4100 rubles.

- Unpretentiousness to operational conditions (humidity and temperature);

- Easy maintenance and preventive maintenance;

- Easy replacement and repair of major components;

- Versatility and breadth of use.

- Not detected.

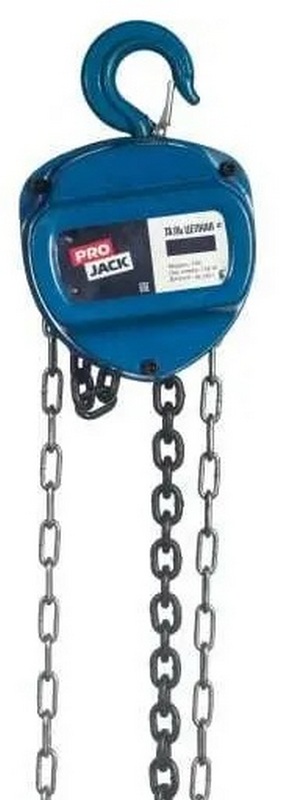

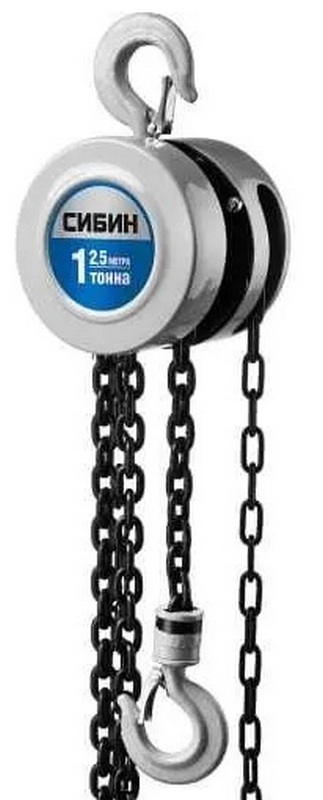

2nd place: "SIBIN" gear, 1t / 2.5m 43085-1_z01 "

votes 0

This not particularly complex device is controlled by a draft chain. It does not require a connection to a power source. All functional components and mechanisms are made of high-strength steel, and the chain itself has been hardened for maximum wear resistance. The sample ease will cope with the lifting / removal of goods in car services, garages, warehouses, as well as in industrial workshops. The total weight is 7.6 kilograms, the chain length is two and a half meters (this also means the maximum lifting height), the maximum load capacity is 1000 kilograms. The recommended cost for retail chains is 4510 rubles.

- Rugged construction;

- Special hardening of the working chain;

- Long service life.

- Not detected.

1st place: "NOMINALTRADE" lever 1 t 3 m"

votes 0

This model is designed for lifting / moving loads in the implementation of construction, repair and other work. Powerful and reliable, it is portable enough to be used without a fixed fixation in one place. It works by means of lever movement, the length of the cable is 3 meters, the maximum lifting weight is 1000 kilograms. The recommended cost for retail chains is 7880 rubles.

- Light weight;

- Compact dimensions;

- Easy use.

- Not detected.

Electrical Models

4th place: "QUATTRO ELEMENTI TL-250"

votes 0

The equipment is designed for lifting / lowering loads weighing up to 250 kg to a height of up to 6 m (at 125 kg - up to 12 m). This sample can be used in work areas, garages, utility and industrial premises, construction and repair sites, warehouses, service stations. The kit includes special fasteners for fixing the device on the beam and a pulley block. Required supply voltage, V - 220, required power, W - 550. Rope / chain length, m - 12, winding speed, meters / min - 10. Warranty 1 year, country of origin - China. The recommended cost for retail chains is 7200 rubles.

- Household orientation;

- Good value for money;

- Easy installation.

- Small load capacity.

3rd place: Caliber ETF-500

votes 0

The model can be used as a separate and independent load hoist, or as a component of composite cranes. Maximum load weight - 500 kg, lifting height - 12 m, cable diameter - 4.2 mm, winding speed with load - 10 meters / min. The control panel is included in the package. The recommended cost for retail chains is 10,800 rubles.

- Simple control;

- High speed rope winding;

- Sufficient load capacity.

- Not detected.

2nd place: "TOR PA 250/500 kg 12/6 m"

votes 0

The sample is designed for lifting / holding in a raised position and lowering a load weighing up to 500 kg (using the block that comes with the kit) during repair, installation and construction work. The height of the lift reaches 12 meters. The motor of the device has overheat/overload protection and is automatically able to switch the temperature, which ensures a long service life. Load capacity is achieved through a block of 500 kg. There is a limit switch for lifting with a frequency of 50 Hz. Total speeds - one, protection class - IP54, insulation class - "B", lifting motor power, kW - 1.02. The recommended cost for retail chains is 11,300 rubles.

- Increased power;

- Adequate price tag;

- Advanced security options.

- Not detected.

1st place: "DENZEL 52014, TF-800, 0.8t, 1300W, height 12m, 8m/min"

votes 0

The product lifts loads up to 800 kg with a rope winding speed of 8 meters / min to a height of 12 m. It will be useful on a construction site, in a car service, in a garage or in warehouses. The motor with copper winding is resistant to intense loads and overheating.In case of overload and exceeding the permissible lifting height, the hoist is switched off automatically, which prevents its breakage. For the safety of the load, a brake mechanism is provided that prevents spontaneous lowering and unwinding of the cable. For effective cooling of the hoist, special ribs and a grille on the body are provided. The hook is equipped with a protective bracket, which provides reliable fixation of the load. A special canopy allows you to always keep the hook in a vertical position for easy work. The cable with a thickness of 5.1 mm is made of steel, so it is durable and has a high resource. The recommended cost for retail chains is 13,300 rubles.

- Remote control;

- Quick installation (fasteners are included);

- 3 year warranty.

- Not detected.

Conclusion

The need to lift heavy and large objects requires 100% use of lifting equipment. Among these devices, a special place is occupied by hoists with a manual or mechanical drive, which can lift a considerable weight to a considerable height. This equipment is extremely in demand both for the industrial and domestic sectors, where it has proven itself in the best way.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127687 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124516 -

The best men's sneakers in 2022

Views: 124030 -

The Best Complex Vitamins in 2022

Views: 121937 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2022

Views: 113393 -

Ranking of the best wood paints for interior work in 2022

Views: 110317 -

Rating of the best spinning reels in 2022

Views: 105326 -

Ranking of the best sex dolls for men for 2022

Views: 104362 -

Ranking of the best action cameras from China in 2022

Views: 102214 -

The most effective calcium preparations for adults and children in 2022

Views: 102010