Rating of the best rigging for 2022

Modern equipment for rigging is a set of various equipment that must be placed in the design position and then used to move oversized and heavy objects. These operations may be needed in the field of reconstruction and construction, technical re-equipment of the building, when moving production facilities. Such actions are associated not only with lifting loads, but also with their mandatory movement, so the rigging kit will always include slings and traverses.

Content [Hide]

General information

In the general sense, rigging refers to all devices that help to carry out unloading and loading procedures when interacting with large-sized objects. The narrow meaning of this concept implies their designation as special tools for lifting / transporting / unloading commercial or household goods. Unlike cranes and reach trucks, rigging is not a single mechanism, so the operator is not completely relieved of work - it only becomes as light as possible. As a result, the tools under consideration are not only certain devices, but also some design solutions that can be combined with each other. For the first time, rigging began to be used in the navy, but far from being used to secure the goods being transported. This was the name of the complex of gear, through which the spars were fixed and the sails were controlled.

Principle of operation

Initially, the tackle was simply attached at one end to the object, and with the help of the thrust of the other end, the load moved.If it was required to provide some flexible connection during transportation, then the rope was thrown over the block, i.e. support having a rotary pulley. So it was easier to manage the load when lifting, regardless of the difference in the level of the operator and the luggage. If you combine several blocks, you can get a chain hoist, which will greatly increase the applied draft force. As a result, a whole system of devices was developed, in which individual elements were responsible for lifting / lowering the object, the second - for its uniform retention, and the third - for moving.

Pinning principles

For reliable fastening of the load, special small elements have been developed - these are eyebolts, brackets or loops. They were screwed into special fixtures on the object in threaded holes. In cases where it was required to throw the cable over the support without sliding, thimbles were used instead of blocks. In any case, when handling fasteners, it is required to ensure their maximum clamping to the load. At the same time, it is necessary to provide increased cable tension, for which special rigging components - turnbuckles are used. It is worth noting that most fasteners are reusable items.

Modern types of rigging equipment

Today's sets of the tools under consideration include several dozen elements for lifting, fixing and transporting objects in different planes, as well as for increasing the applied efforts. Currently, the following types of equipment are considered the most common:

- Tali are classic devices for lifting objects. They consist of cables and blocks, and the principle of their operation is based on winding a lifting rope onto a drum. Manual and electric models are available for sale.

- Winches - this device has some similarities with the above, however, it is intended only for moving objects in a horizontal plane.

- Ropes / cables - they are produced on the basis of synthetic nylon, ordinary hemp and even steel fibers. They are the main components of the classic rigging set.

- Jacks are special devices used to raise or raise certain objects to a small height in order to further fix their final position. Can be used separately from the entire rigging system.

- Slings - these devices have the only function - it is fixing the load in a fixed position when carrying out operations with it. Supplied with mounting brackets, rings or hooks.

- Chain hoists - equipment for increasing the traction effort of the entire system. They are several blocks entwined with ropes or chains. They can also increase the speed of work;

- Nets, belts and dopelstocks are devices for stabilizing the load during its direct transportation (they visually resemble scaffolds or floorings).

Advantages of rigging systems

These primarily include:

- Adequate cost - a set consisting of a jack with a platform will cost much less than a hydraulic trolley or stacker, which perform essentially the same functions;

- Ease of operation - no knowledge of complex safety rules is required during operation, and the principle of handling the equipment is intuitive.

- Reliability - all components are made of very durable materials, such as dense synthetics or high-quality steel.

- Compactness - the equipment can be used in such cramped spaces where it is simply impossible to use a similar automated device.

- Load capacity - for a rigging system it is easy to move a load of 24 tons.

- Reduced injury risk - although during operation some physical efforts from the operator will be required, but the need for them will be much less. Accordingly, by controlling only the system of blocks and levers (and even then at a decent distance), a person endangers himself to a minimum.

- Increased productivity - even large-scale operations for the transportation of oversized cargo can be solved with a minimum set of rigging in a short time.

Jacks as a special element of rigging equipment

These devices will allow you to quickly and easily lift oversized cargo to a small height. Their peculiarity lies in the location of the working location - they are installed directly under the object. It is this location that allows work in the absence of various load-supporting devices. There are enough models of jacks on the market today, but most often they are classified according to the mechanism of action and therefore there are 4 main devices.

- Hydraulic.

They get their mechanical motion by converting the pressure in the working fluid. The whole operation is carried out by raising the lever of the pump plunger, after which the special fluid fills the chamber below it, and when the plunger is lowered, the pressure will increase, which unlocks the check valve, from which the working fluid moves into the piston tank, and the piston itself rises. Thus, lowering and raising the lever extends the stem and raises the load. Hydraulic models have the following advantages:

- Increased performance;

- Smooth lifting of cargo;

- The operator makes almost no physical effort;

- The whole structure is stable and compact.

Hydraulic models are more often used as an independent tool, less often - in groups of several devices at once.

- Pneumatic.

These models are ordinary inflatable pillows, whose base is made on the basis of rubber-cord or elastomeric materials. Capable of lifting up to 20,000 kilograms. Their advantages include:

- Light weight and small dimensions in the transported position;

- Increased resistance to abrasion and possible punctures of the base;

- Ease of positioning and simple operation;

- Unpretentiousness in service.

The principle of their operation is to inject air into the pillow, which is carried out by an automatic compressor. Air is supplied from a special cylinder, where it is stored in a compressed state. Due to the accumulation of air inside, the pillow increases its volume and lifts the object. In general rigging systems, they are used in the same way as hydraulic ones, that is, in groups of several pieces.

- Rack.

They are supposed to be used in confined spaces. Their design includes a steel case, inside of which there is a gear rack. At its upper end there is a support platform for the load, and at its lower end there is a bent “paw”. When moving the rack up and down (by rotating the handle), the working force is transmitted to the gear. On the same roller with a handle there is also a ratchet wheel, against the teeth of which the “dog” rests, fixing the current position of the rack. Among their advantages can be noted:

- Easy operation and overall reliability;

- Comfortable work in confined spaces;

- Smooth and high-quality lifting of the load.

Rack jacks are more often used separately, but as part of a rigging set, they are more used for lifting bulky, but not too heavy loads. Their load limit is 14,000 kilograms.

- Screw.

In such samples, the main component is a screw having a trapezoid-shaped thread. It rotates inside a static nut that is welded into the body. At the top, the screw has a special square section, where a functional handle is mounted, and there is also a cup for fixing the load. The handle is equipped with a ratchet wheel with a double-sided pawl. Screw models are directly designed for single use, they are rarely found in rigging systems, they are preferable to use for tasks in a limited space. The maximum load capacity is 20,000 kilograms.

Features of operation and maintenance of rigging

To work safely with rigging systems, follow these simple rules:

- Mandatory periodic inspection of all components for defects, chips, cracks, etc.;

- Checking the control of the strength reserve of individual leading components and the reliability of fasteners;

- Carrying out general tests for the performance of the entire complex as a whole;

- Testing mechanisms for compliance with expected loads and regulatory standards;

- Mandatory access to operations with rigging only by such personnel who have the appropriate permission.

When handling this type of equipment, the condition for regular maintenance is mandatory. The same applies to periodic checks and inspections.It is always worth remembering that the negative results of the checks will not allow the complex to be operated in the practical sphere. Separately, it is worth mentioning unscheduled checks - they are mandatory in the case when the equipment was used at the limit of its capabilities or in excess of them. And in this situation, fasteners and cables should be subjected to increased attention.

Any worker who handles rigging must have received a safety briefing and be in possession of the appropriate regulatory clearance. In addition, the operator must use special safety equipment in his work.

Each rigging set (or its individual elements) must be accompanied by a certificate of laboratory testing for compliance with state standards. If the certificate is missing, lost, or the tackle is produced outside the Russian Federation, then laboratory tests must be carried out before the start of operations with it. Chains and ropes of foreign production must confirm their reliability in laboratory conditions every six months.

The storage of hemp-based ropes requires a special environment, namely, they must be kept in boxes made of roofing sheet steel. There they are placed after use and after the passage of the drying cycle. If the rope is reinforced with steel fibers, then it must be lubricated before starting the storage mode.

When testing jacking elements, it is necessary to carefully check all their working mechanisms. The thread should be intact and show no signs of wear, and the teeth should be of the correct shape and easily hold the pawl. Storage of mechanical jacks is allowed in dry and warm places.

Difficulties of choice

The complex of loading devices must fully comply with safety standards.Only a system of high-quality and reliable elements can ensure the safety of the object being moved, as well as protect its operator from injury. First things first, before purchasing, you should decide on the scope of future frequently performed work. If non-intensive work on small loads is expected, then you can purchase a set of a minimum of components (jack, slings, winch). In all other cases, it would be better to stock up on a full-fledged kit, which will include many auxiliary elements - from threaded clamps to ramps and dopelshtok. It is also necessary to take into account the following parameters for the future use of equipment:

- The amount of travel distances;

- Average weight and dimensions of the cargo;

- The order and methods of securing objects during transportation;

- The most frequently recurring environmental conditions.

Rating of the best rigging for 2022

Slings

3rd place: "Loop textile sling 1t 1.5m, TORGSNAB"

votes 0

This textile product is characterized by softness and increased strength, it is able to provide good fixation of the object and at the same time not deform it. A model of this type is indispensable when working with large objects that are afraid of scratches and subject to various types of deformations. It features light structure, can perfectly maintain the safety of the cargo, has great deformation resistance, and is compact. The recommended cost for retail chains is 250 rubles.

- budget cost;

- Reliable execution;

- Simple operation.

- Not detected.

2nd place: "OMR VP" textile sling, color - khaki. 50mm width, 10m. length"

votes 0

This belt is produced by weaving on the basis of high-tenacity dyed polypropylene threads, which provide increased strength and resistance to working abrasion. Resistant to oils, solvents and other aggressive chemicals. Successfully resists ultraviolet and extreme weather conditions. It is used for use as cargo slings, various cargo fastening devices, as well as for reinforcing various textile products. Operating temperature from -45 to +90 degrees Celsius. Breaking load 1800 kg/cm (until full break). The recommended cost for retail chains is 510 rubles.

- Wide working area;

- Can be used as a safety device for personnel;

- Excellent moisture resistance.

- Not detected.

1st place: "Textile loopback sling (STP) 2 t 3 m, 2 pcs"

votes 0

This is a convenient and modern rigging element designed for loading and unloading operations. With ease maintains rather big weight, thanks to the strong polyester basis. The production technology of the product provides it with the proper degree of elasticity and flexibility, which makes work fast and comfortable. The length of the sling is 3 meters, the maximum load capacity is 2 tons. The recommended cost for retail chains is 1400 rubles.

- Two items included;

- Easy straightening at the object of transportation;

- Wide base.

- Not detected.

Jacks

3rd place: "Hydraulic bottle jack Skyway S01804001, 10 t."

votes 0

This design uses innovative valves that provide maximum fail-safety and safety. Thanks to the use of hydraulic technology, the load capacity of the model has been increased several times. Group use is allowed. Load capacity - 10,000 kilograms, minimum lifting height - 20 centimeters, maximum lifting height - 40 centimeters. The piston rises by 12.5 centimeters, the additional stop rises by 6 centimeters. The total weight of the device is 5.3 kilograms. The recommended cost for retail chains is 3200 rubles.

- Democratic price tag;

- Easy stroke of the stem;

- The overall compactness of the device.

- Somewhat inconvenient location of the working handle.

2nd place: Rolling Jack Hydraulic Whirlwind 73/5/4/1, 2 t.

votes 0

Such a rolling model is intended for lifting loads and for automotive repairs. For safety reasons, all Whirlwind lifting tools are equipped with overload protection, which will not allow you to lift a mass that has exceeded the allowable value. Supplied in a convenient carrying case. The maximum allowable lifting weight is 2 tons, the lifting height is not higher than 135 mm, the lifting height is not higher than 385 mm. The recommended cost for retail chains is 3460 rubles.

- Good protective system;

- Comfortable handle grip;

- Average dimensions.

- Somewhat heavy weight of the device itself.

1st place: “Mechanical rack and pinion jack DOMK121, 3 t.”

votes 0

The model can be used in the construction and automotive sectors, as well as in any other when performing repair, installation and dismantling work.It is designed to lift the car in off-road conditions by the power elements of the body or the wheel, and, if necessary, the rack jack can be used as a manual winch. It is allowed to use in combination with other rigging systems and group operation of several devices. As a result, this is a necessary and practical thing for both a car enthusiast and a warehouse worker or loader. The recommended cost for retail chains is 5500 rubles.

- Comfortable use;

- Sufficient traction force;

- High lift.

- The pins are a bit weak.

Winches

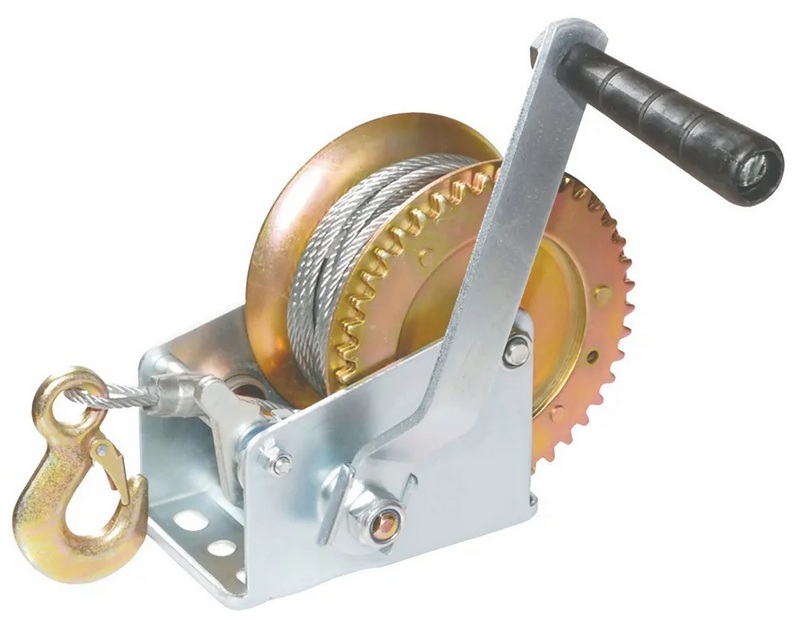

3rd place "Gear winch with a steel cable 0.6 t. AVTODELO (43675)"

votes 0

This gear model is designed to move goods or pull cars. The drum mechanism allows wide application for pulling wires, rope or steel ropes. The model is equipped with two forged hooks. The rope diameter is 4.5 mm, the rope length is 10 m, the gear ratio of the ratchet mechanism is 4.1 to 1, the maximum permitted load is 675 kg. The recommended cost for retail chains is 1800 rubles.

- Focus on horizontal movement;

- Ease of use;

- Durable manufacturing material.

- No locking mechanism.

2nd place: Lever cable winch TOR МТМ 1600 kg, 20 meters

votes 0

This sample is a mechanized tool that is adapted for lifting and moving loads weighing up to 1.6 tons. The dimensions of the product allow it to be used in confined spaces. The body material is aluminum alloy.A rope with a diameter of 11 mm is included by default, its length is 20 m, it is equipped with a hook. The recommended cost for retail chains is 15,110 rubles.

- Large rope length;

- Durable manufacturing material;

- Ability to work in tight spaces.

- Overcharge.

1st place: "Electric Winch" portable electric winch"

votes 0

The model is perfect for both car evacuation and industrial tasks as part of a rigging complex. Installation of the winch is easy and does not cause any difficulties. All planetary gears and the gearbox itself are made of hardened steel. The brake on the winch is friction. The traction force is just over 4 tons, which is enough to complete most of the tasks. 20 meters of steel cable is enough for any working situation. It is excellent for operation in difficult weather conditions due to its extended strength. The recommended cost for retail chains is 20,300 rubles.

- Powerful automatic equipment;

- Ability to work in extreme weather;

- The price matches the quality.

- Not detected.

Conclusion

Without rigging equipment today it is unlikely to be easy to carry out dismantling / installation and transportation of oversized cargo. Today's market offers many options for acquiring such elements both individually and as part of assembled sets. And here the main thing is to calculate future work in such a way as not to purchase equipment, the functionality of which will then simply not be fully used.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127687 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124516 -

The best men's sneakers in 2022

Views: 124030 -

The Best Complex Vitamins in 2022

Views: 121937 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2022

Views: 113393 -

Ranking of the best wood paints for interior work in 2022

Views: 110317 -

Rating of the best spinning reels in 2022

Views: 105326 -

Ranking of the best sex dolls for men for 2022

Views: 104362 -

Ranking of the best action cameras from China in 2022

Views: 102214 -

The most effective calcium preparations for adults and children in 2022

Views: 102010