Rating of the best drills for 2022

For lovers of tinkering and doing men's work around the house, as well as professionals, the tool industry offers a lot of useful devices. Drilling holes and grooves is perhaps the most common operation. For such needs, drills have been created, improved and continue to be modernized. This consumable tool has become a unique element on which the accuracy of the process, the speed of its implementation and reliability depend.

Content

What are the rigs

Drills for metal

Depending on the type of the forthcoming scope of work and material, one or another type of drill is selected.

Design

- spiral type

The tool varies in length in the range of 40 ÷ 400 mm, and in diameter 1 ÷ 50 mm and is considered a classic.

One diameter size is maintained along the entire length, along the circumference there is a cutting edge in the form of a screw with a twisted groove to remove the machined material, that is, chips. The cutting element is duplicated in a pair, which is located strictly at 180 °.

Such equipment is suitable for through holes in metals with great depth and for blind recesses. For a particular hole diameter, a 1 mm smaller drill rod should be selected, as the sides of the material break after drilling.

- stepped type

The drilling element has a conical design. The edge increases towards the base in diameter and has a discontinuous shape. A smooth rise and a sharp edge are present at the beginning of a new step, the drilling process can start from any of the steps. Each tier has a diameter designation in mm, the number of tiers varies from 5 to 10. Such equipment allows you to make holes of various sizes on one sheet without changing cutting elements, which saves time. An existing hole can be drilled to a wider diameter by starting the process with a certain drill tier.Since each tier is part of a single structure, it does not allow for a recess depth of more than 3 mm, which is a significant limitation.

- crown type

Hollow on the inner side of the mold design has a lot of end teeth. The twisted cutting edge continues each tooth and can be in the range of 4÷16. The similarity of the design with the crown determined its name. With the help of such a drill, you can make large holes with a metal depth of 50 mm. In some cases, centering is used with fixed helical elements or pins to ensure accurate work.

- Zenkers

The conical shape has no steps, the cutting edges are continued with grooves. The countersink is used for small recesses up to 5 mm. In addition to round holes, oval drills can be made by increasing the diameter. You can read more about countersinks here.

- Shank

The strength of the attachment affects the undesirable possibility:

- center shift;

- drill breakage;

- damage to the workpiece material.

The type of attachment of the tail section must match the cartridge.

- Cylindrical type

The shape of the cylinder follows the design of the cutting edge, but has a smaller diameter to simplify the rotational movement when plunging into the metal. Three clamping tabs ensure a firm hold when locked. This type is used in electric drills and small machines.

- Hex type

The hexagonal base smoothly transitions into a cylindrical shape and cutting waves. The view does not require additional fixation by twisting the cartridge and is installed in the receiving sleeve of the reciprocal faces. Quick change when creating wells of different diameters saves time.All screwdrivers are compatible with hex shank. Snapping of the tool or reciprocating movements can cause unwanted dropping out of the chuck. This view is not suitable for wells in thick metal.

- conical type

Reducing the diameter of the tail part at the end allows you to fasten the element with muscle effort. The load during operation ensures its firm fit. Extraction is carried out with a wedge driven into the slots of the cartridge. The view is widely used in drilling machines. It is allowed to use an intermediate cone with a large diameter of the cartridge.

Preparation method

The parameter determines the strength; lifetime; types of steel to be processed.

- One piece view

Tooling is obtained by casting and this type is the most common.

Made of high speed steel, these can be countersinks, crowns, spirals and cones.

- welded look

For hole diameters over 20 mm, welded tooling is used; carbon steel was used to make the shanks. The part has a small cost part and a long service life.

- Carbide tips

Grade BK8 is adapted to higher drilling temperatures in tough metals. One-sided sharpening of special technology guarantees an increase in the shelf life. It is allowed to replace the tip while maintaining the body of the element.

Marking

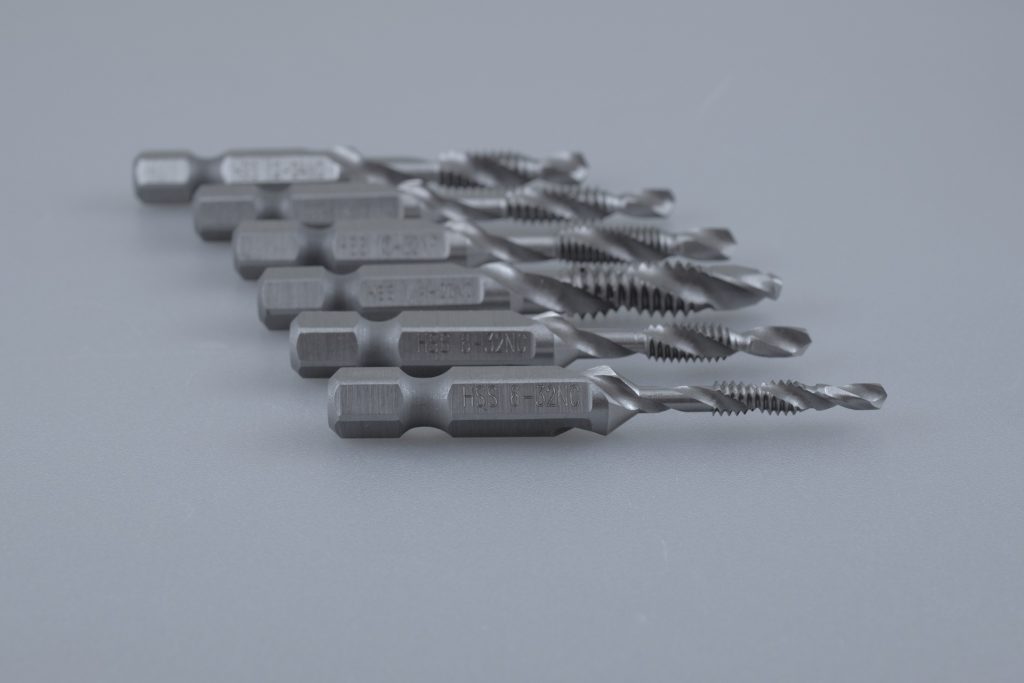

- HSS

General purpose abbreviation for high-hardness and fracture-resistance high-speed steel with impurities.

Impurities determine the type, properties and cost:

P is doping with tungsten;

F is the presence of vanadium;

M is the addition of molybdenum.

- HSS-E

Steel with an addition of cobalt from 5% to 8% makes the tool suitable for stainless steel with a strength of 1200 N/mm². It is often used in drilling processes in difficult materials with an astringent effect when heated. The designation HSS-Co is also allowed.

- HSS TiAIN

The abbreviation for three-layer deposition of titanium, aluminum and nitride marks tooling with a heat resistance of up to 900°. Work on steel of strength 1100 N/mm² is allowed.

HSS-TiAIN elements serve for a long time and exceed other types in terms of service life by 5 times.

- HSS TiN

Sodium nitride is used as a spray on the outer layer. Thermal resistance characteristics are increased to a threshold of 600°.

A drill with this marking is suitable for drilling materials 1100 N / mm² strength:

- in cast iron;

- aluminum;

- alloy steel;

- carbon steel.

- HSS-G

Grinding with cubic boron nitride makes the cutting part resistant to abrasion and resistance to radial runout. The workable steel is only suitable with a strength of 900 N/mm² and is also used when drilling cast iron materials.

- HSS-R

Elements with conventional heat treatment and roller rolling are used in work on cast iron and mild steel grades.

Hard alloys

The material is used for tips and is suitable for high temperature loads. The tooling is highly resistant to wear.

Can be used for drilling:

- in titanium alloys;

- stainless steel;

- heat resistant steels.

Center drill

To obtain holes in cast iron and steel products, metal, cermet alloys, combined centering elements are used. Such equipment is considered professional and provides high quality processing and accuracy.An important characteristic is also the exclusion of errors and inaccuracies in the work. There are several surface roughnesses in relation to the consumable tool used.

Drilling in wood

Construction and repair, manufacturing of parts, many intermediate manipulations in any work require drilling in wood.

Design

The spiral view is common in universal sets that include work on wood, metal, and concrete.

- Forstner type

The twist drill is additionally equipped with cutting elements, while the process produces smooth walls of holes and a flat bottom.

Also, the working part can be of the form:

- centering;

- flat;

- one-sided for deep drilling.

- Shank

All tail parts can be divided into:

- cone type;

- cylindrical;

- 3,4,6 faceted;

- SDS.

Drilling in a wooden material is specific in that it is enough to choose a drill that is harder in structure than wood. A common high-strength steel, from which most drills are made, is suitable.

formwork element

With the help of such a consumable element, a hole is drilled through the inner and outer skin of the boards in one operation. This is due to the length exceeding the usual, average size.

concrete drilling

For such work, a core, screw and twist drill is used.

Ring elements

The type is required for drilling in plastic. You can also use elements of the spiral class.

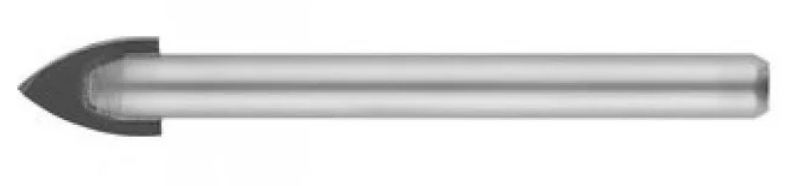

Diamond tooling

Pen diamond elements are used for drilling on glass and ceramic tiles. For larger-scale work - drilling in reinforced concrete for wiring, there is a special tool and diamond crowns for it.

Criteria for the right choice

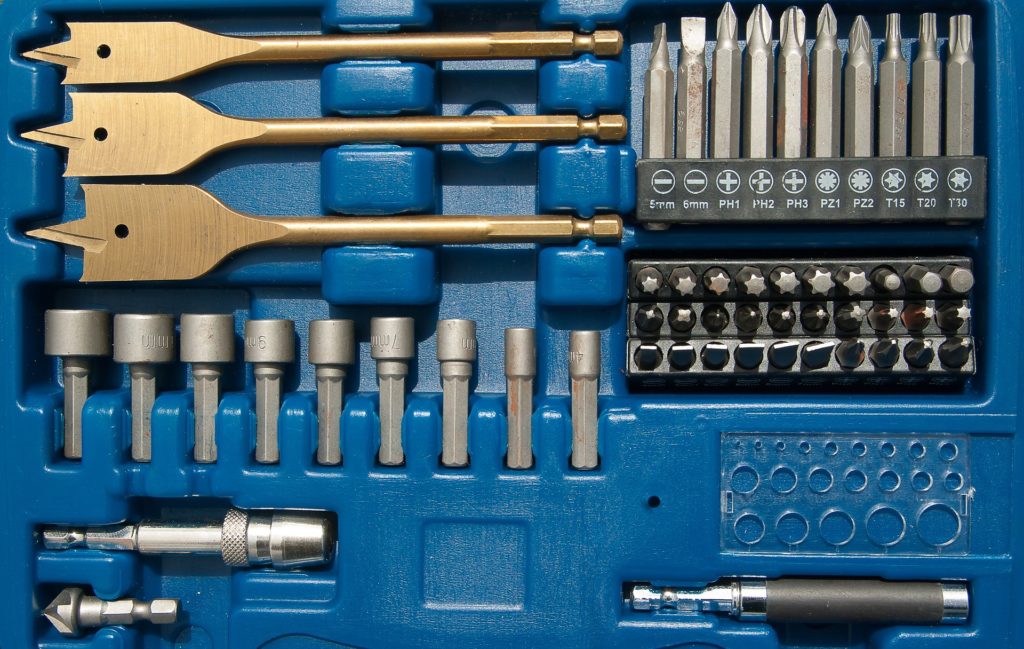

For initial orientation in a wide range of proposals, it is important to determine the forthcoming scope of work. For home or country use, universal sets with blocks of elements for wood, metal and other materials are more suitable. If necessary, you can buy separate drills for specific jobs.

Next, the type of working part is selected, which are described in detail above.

It is important to consider:

- construction;

- material of manufacture;

- alloys;

- diameters.

The shank requires the right approach according to the available tool. You should be guided by:

- on the cartridge;

- capture;

- drill extraction method.

The cost of all equipment ranges from 9 rubles to 18,000 rubles.

Matter:

- professional approach;

- specific work;

- required duration of operation.

Errors when choosing

An amateur or a professional who constantly deals with a tool is sure to face the problem of a shortage of one or another equipment. It is impossible to purchase a set that would once and for all meet all needs. The additional acquisition of piece drills can be called a pattern. A specialized process will require universal provision. However, having several sets and piece equipment in the arsenal, you can cope with any task. You should not strive to buy a set with the maximum number of units when forming a private workshop. Also, it is considered unprofitable to purchase expensive instrumental elements in the hope "someday it will come in handy." It is important to gain experience in drilling work, the ability to distinguish between process features and the ability to make the right choice of consumables.

Rating of the best drills

Overview of the best tooling for metal

DeWALT DT7926-XJ

The American brand is known for its innovative implementations and high manufacturability.

- a set of 29 pieces of different diameters 1÷13 mm;

- intermediate and whole values;

- full coverage of drilling needs;

- with trihedral shanks;

- reliable cartridge mount;

- the presence of three sectional storage case for Midisafe;

- with fast drilling;

- long-term safety of sharpening;

- suitable for professional use;

- with marking above the working area for easy orientation in the required diameter.

- strong heating of a drill with a thin diameter.

AEG 4932352463

The product brand was borrowed from a now defunct German company, but the trust in quality and popularity remained. This allows the Swedish company Electrolux and a group of Chinese companies Techtronic Industries to produce popular devices and widely sell them all over the world.

- set of 18 pieces;

- designed for manipulations with materials made of concrete, metal, wood;

- budget class;

- high resistance to loads of continuous use;

- users note a wide scale of diameters;

- convenient case;

- production material - high-quality steel;

- work on Soviet steel samples;

- long preservation of sharpening;

- an additional compartment in the case.

- there is no diameter of 11/13 mm for metal required for installing locks;

- with a large drill angle of 10 mm, requiring pre-drilling.

Metabo 627098000

The brand of the German company Metabo werk GmbH dates back to 1924 and stands for high-quality power tools, cutting equipment, woodworking equipment of its own production.

- ergonomics;

- comfortable extraction of elements;

- grinding is used in production, which increases edge strength;

- availability of all required diameters;

- there are intermediate values;

- reliability of the iron case;

- an excellent choice for home and country works;

- without edge overheating in operation;

- rotational force without runout.

- average drilling speed;

- there is an additional sharpening with an acceptable breakage of the cutting edge.

Bosch Robust Line2.607.019.925

The brand of German corporations Robert Bosch gmbH, Siemens AG adorns many devices produced in the best traditions of long-term quality and using the latest technologies.

- made of high speed steel with cobalt alloying;

- belong to the class of excellent strength;

- suitable for handling all types of metals;

- manufacturer's exclusive sharpening;

- long service life;

- great wear resistance.

- without intermediate values;

- only for hole up to ø10 mm;

- recommended lubricant, which is not included in the kit.

Irwin Titanium 10503991

A brand from the world famous American manufacturer Irwin Industrial Tools, which specializes in tooling for professional tools, its production is part of the global corporation Newell Rubbermaid.

- coated with titanium nitride;

- increased durability;

- reduced friction during drilling;

- intermediate gradation;

- with a sharpening angle of 135°;

- convenient set of 15 units;

- acceptable price;

- online purchase available;

- contact drilling.

- not found.

The best accessories for wood drilling

Heller TD24646CV

The German company specializes in the production of consumable tools and has worldwide recognition. The experience gained over 160 years of existence, competence, wide selection and unsurpassed quality have made the brand a leader in the drilling and drilling segment.

- spiral type;

- minimum diameter 3 mm;

- a set of 10 items;

- with a strong case;

- characterized by fast penetration;

- great for solving household problems;

- with convenient chip removal.

- the designation of the diameter is not clear enough, requires additional emphasis.

Encore 19131

The trademark of the domestic manufacturer of power tools is recognized by the Russian consumer for price stability and reliability.

- lack of beating in work;

- long-term preservation of factory sharpening;

- good price/quality ratio;

- available in online stores;

- universal selection of diameters for various needs.

- packaging is disposable, storage space is required.

ZUBR Expert 2948-235-N6

The brand of the Russian company Masternet has been known on the market for over 20 years. The products are widely used both by non-professionals and in industrial production.

- good case;

- set of 6 units;

- screw type drill;

- hex shank;

- for quick entry there is a centering tip of a spiral type;

- made of tool steel;

- budget price;

- without beating in active mode;

- excellent sharpening retention.

- additional diameters may be required.

Milwaukee Forstner 4932363704

The American brand is famous for its high technical characteristics, quality assurance and affordable price.

- with a cylindrical shank;

- the working part is 50 mm;

- accurate drilling with perfect processing;

- with a center point.

- for specialized tasks.

D.Bor 840280002D

A universal brand under which the production of tools is carried out in Europe and Asia.

- with a cylindrical tail;

- in a piece;

- with a sharpening angle of 118°;

- affordable price;

- the presence of deep grooves for reliable chip removal;

- made of special steel.

- not detected.

The best diamond and centering elements

Stayer 2986-06 BK6

The German company Kraftool GmBH is known worldwide for the Stayer brand, under which hand-held power tools are produced.

- feather type;

- with a piece complete set;

- affordable price;

- there is an online sale;

- provides for the drilling process in ceramic tiles, glass;

- diamond tip.

- not found.

CNIC D 8x20x80x21 P18 8x80mm

The budget version of the Chinese production of the industrial sector is represented by a high-quality consumable tool. P18 indicates the material of manufacture - high speed steel and 18 percent tungsten.

- presented as a piece;

- with a diameter of 8 mm;

- double-sided type;

- high precision in work;

- wear resistance;

- centering class.

- missing.

| Overview of the best drills | ||||||

|---|---|---|---|---|---|---|

| 1. | The best tooling for metal | |||||

| Model | Shank, shape | Packaging, number of units | Dimensions, mm | Marking | Additional Information | |

| DeWOLT DT7926-XJ | cylinder | 29 | 1÷13 | HSS-G | 3 shank edges | |

| AEG 4932352463 | −”− | 18 | 3÷10 | HSS-R | - | |

| Irwin Titanium | −”− | 15 | 1,5÷10 | HSS-G Tin | with right rotation | |

| Metabo 627098000 | −”− | 25 | 1÷13 | HSS-G | right cutting | |

| Bosch Robust Line | −”− | 10 | 1x12÷10x87 | HSS Co | with a sharpening angle of 135° | |

| 2. | The best accessories for wood drilling | |||||

| Heller TD24646 | cylinder | 10 | 3÷12 | - | with chip removal | |

| D.Bor 840280002D | −”− | 1 | 28*100*400 | - | with a sharpening angle of 118° | |

| Milwaukee Forstner 4932363704 | −”− | 1 | 12*50*90 | - | with 8 Round Shank | |

| Encore 19131 | −”− | 5 | 4÷10 | HSS | - | |

| ZUBR Expert | hexagon | 6 | 6*160*235÷18*160*235 | tool steel | with fast entry | |

| 3. | The best diamond and center drills | |||||

| Stayer 2986-06 BK6 | cylinder | 1 | 6*65 | diamond | used with coolant | |

| CNIC D 8x20x80x21 | - | 1 | 8*25*80 | P18 | holder ø20 mm | |

Conclusion

A wide range of equipment is available for drilling and drilling in various materials. Cutting elements differ in type, design, working part, shank, price, manufacturer and many other parameters. The market offers drills of both Russian and foreign production. For the right choice, it is important to have experience in handling such a tool, adhere to optimal criteria and proceed from the task at hand.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127688 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124517 -

The best men's sneakers in 2022

Views: 124030 -

The Best Complex Vitamins in 2022

Views: 121937 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2022

Views: 113393 -

Ranking of the best wood paints for interior work in 2022

Views: 110318 -

Rating of the best spinning reels in 2022

Views: 105327 -

Ranking of the best sex dolls for men for 2022

Views: 104363 -

Ranking of the best action cameras from China in 2022

Views: 102214 -

The most effective calcium preparations for adults and children in 2022

Views: 102010