Rating of the best welding tractors and carriages for 2022

A welding carriage (or a welding tractor) is a special type of self-propelled equipment that is used to continuously and accurately move the welding torch (or several) along the required trajectory during the welding process. The small size of this mechanism allows it to be used in the most inaccessible positions. This type of mechanized device is able to weld seams of increased length, while eliminating the factor of human error and maintaining a high degree of quality of the work performed.

Content [Hide]

Basic design details

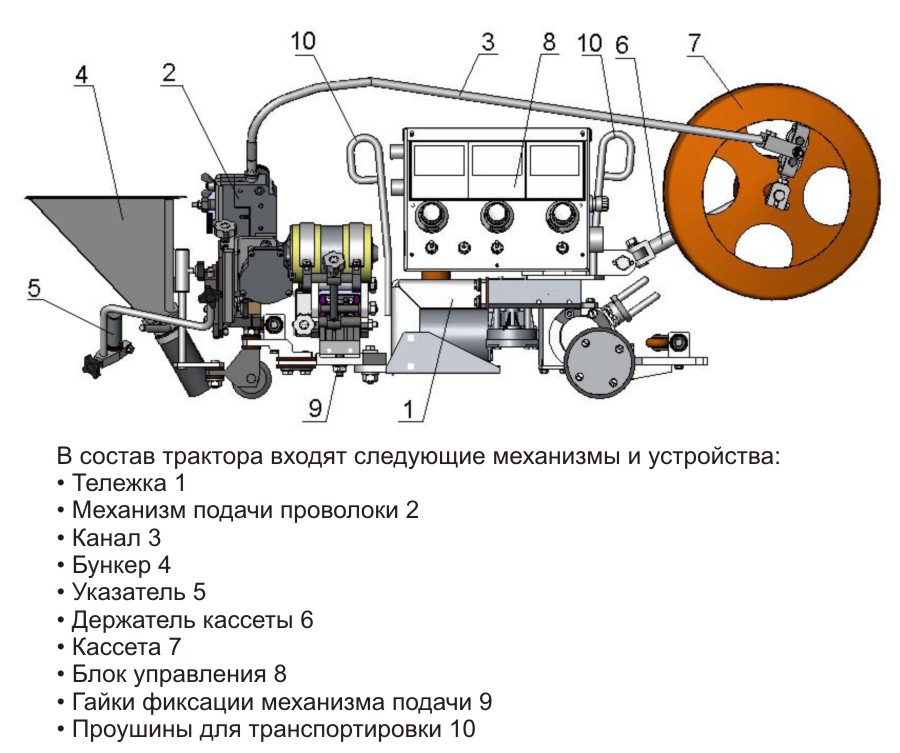

By means of the welding carriage, electric arc welding is performed. Like any automatic machine, it works according to a certain program, has special wheels with which it moves. The main feature of this apparatus can be called its self-propelledness - movement is carried out along rails (laid along the axis of the seam) independently or the motion vector is determined by a person. The carriages are quite compact, and it is very easy to transport them between adjacent rooms due to the fact that the rails for movement are lightweight, and they can be carried along with the device. The main working element is the welding head, through which liquefied gas is supplied. Consumable wire and protective flux also play a huge role. In general, the design of the device is like a trolley with a control panel, on which the tractor itself and additional mechanisms are located. Most of the details can be either built into the mechanism or taken out of its design. By themselves, the described devices are most often used in industrial enterprises and in mid-level workshops. They can be used both separately and as part of a large conveyor.The amount of possible functionality will directly affect the price of the carriage (for example, more expensive models have the ability to automatically control the correctness of the geometry of the applied seam or can independently regulate the amount of protective flux issued).

Existing classification

To date, several types of equipment under consideration have been developed, which can be grouped according to certain criteria. If we talk about the number of engines that are installed in the welding carriage / tractor, then they can be divided into:

- Single-engine - all movement is carried out using a single engine (they have simpler technical characteristics, however, they are light in weight);

- Dual-motor - the movement of the carriage is controlled by two motors along different axes (such a device is more massive, but has a higher degree of reliability, and its parameters can be adjusted at a finer level).

Classification according to the methods of protection used can occur according to the following types:

- "Open arc welding" - with this method, no protection is used at all, therefore, the seam can be subjected to various negative influences, however, the production process itself becomes cheaper;

- "With gas protection" - with this method, by creating a protective environment from active / inert gases, oxygen is not allowed to enter the seam and it is not subjected to other negative influences;

- "Submerged arc" - in this method, an additional flux is used, which improves the quality of the seam on the metal being welded and at the same time protects production from negative influences;

- “Use of a non-consumable electrode” - the filler material is simply not used in the welding process.

Classification according to the method of simultaneously supported welding arcs:

- Single arc - leads one arc, adapted for most traditional operations, is the simplest method and is used in single-motor carriages;

- Two-arc - is able to conduct a pair of arcs in parallel, while welding occurs simultaneously, which significantly speeds up most complex operations, for example, in mass production;

- Three-arc - capable of introducing three arcs at once and is intended for professional welding work of high complexity (can only be used in two-motor systems).

Welding tractor with PU for all positions

This type of tractor runs on flexible steel/aluminum rails, which are fixed to the machined structure with magnetic clamps. The flexibility of the rail allows you to repeat the contours of the welded object, while the seam will be applied strictly according to the specified pattern. This automation method is extremely productive in creating continuous and long seams. Also, one of the most important features of this type of tractor is their innovative control function, thanks to which the speed of the carriage is maintained regardless of the load received (within 45 kilograms). This fact means that the tractor can, during operation, pull up the welding wire feeders, as well as the cables required for the operation of the device.

In order to increase the flexibility of the automated process, several program templates have been developed.There are tractors that work according to the program for the execution of welding seams in a chain of simple operations (“Instant start”, “Stop”, “Start of the welding arc”, “Welding”, “Stop”, “Repeat”). As a result, the purpose of using algorithm templates is to increase the speed and accuracy of welding, which significantly speeds up the production process compared to classical manual welding. Thus, PU (software control) is an ideal option for the implementation of large-scale projects where it is necessary to automate the same type of processes.

Detailed functional advantages of using welding tractors

The use of self-propelled welding tractors for semi-automatic welding in shielding gases plays an important role in the field of full automation of complex production processes. They qualitatively change the conditions, speed and accuracy of work in comparison with conventional manual welding, and among their immediate advantages are:

- Application of standard welding equipment - in case of permanent use in the industry of welding tractors, there is no longer a need to purchase any other options for special devices - most tractors are easily compatible with traditional semi-automatic welding machines and a wide range of welding torches.

- There is no need for financial costs for additional training of operators - the operation of the welding carriage itself is intuitive, and it can be used by any welder familiar with the operation of semi-automatic machines. The only thing is that you still have to go through the initial briefing, but it can take a maximum of 2 days.In addition, carriage welding is allowed to be entrusted even to those specialists who have lower qualifications even in relation to the manual process. This is due to the fact that the main welding parameters (wire feed speed, voltage and current) are pre-set by more experienced specialists directly on the control panel, and the welding control speed (carriage speed) and the inclination of the welding torch in relation to the surface to be treated are also outside control of the current operator and determined ahead of time. Thus, the operating operator only has to put the carriage in the proper position over the object to be welded, select the required welding mode and press the "Start" button. After that, it remains only to visually control the entire procedure.

- Improving the overall quality - when welding using a tractor, the distance from the angle of the torch (both across and along the joints) to the exit of the welding torch nozzle, which sets the arc size, will be permanent and controlled by the welding torch installed in the holder. The speed will remain unchanged for the entire arc distance along the joint. The trajectory of moving the arc is also subject to control. All this contributes to controlled penetration, the creation of a finely flaky and uniform weld structure, the prevention of undercuts, an increase in the geometric quality of the applied weld, and the creation of a smooth flow to the base metal of the deposited bead. When using the oscillating block of the burner, the welding quality of the facing and filling beads of the seams with many passes is improved.Even if the weld joint is not properly assembled, good work quality can be obtained by the fact that most carriages have stop rollers that can track the joint line while correcting the path of the welding torch.

- Increasing the intensity of the welding process - it is natural that any automation of any process makes it possible to increase the intensity of labor. Regarding the topic of carriage welding, according to statistics, the intensity of labor will increase by 40-45% of the total working time, which equals a saving of about three or three and a half hours per shift, compared to manual welding. In cases where expensive and multifunctional welding tractors are used, this figure can approach savings of five or six hours of working time per shift. As a simple example, the following situation can be cited: even an experienced welder with a certain amount of perseverance will rarely be able to make a seam longer than one meter without changing his position. In any case, he will either have to move himself along the seam being made or change the position of the workpiece. Naturally, carrying out these operations, the welder is forced to extinguish the arc. When resuming work and before the mandatory welding of the overlap of the seam by 15-25 millimeters, he must first clean the end of the seam from films and splashes. The welding tractor, on the other hand, moves without interruption, simultaneously welding a seam along any length, so it does not need to change its position (like a welder), while interrupting operations. Thus, periodic interruption of welding work does not occur.In addition, the absence of the need for periodic rest of the welder will also play a significant role, because it is not necessary to permanently control the progress of the welding speed and at the same time maintain the proper electrode reach in order to obtain a better weld. This shows that the operator can monitor not only his own small section of the arc, but he is also able to control the situation in general, including watching the actions of other operators who process the same object in order to timely coordinate their actions with them. The same can be said about the control over the behavior of the structure itself in the process of work. A big plus can be the use of a device with two welding torches, which makes it possible to simultaneously carry out two seams in parallel or make two passes along the same seam when separating the edges. At the same time, one operator is able to serve several carriages at once, which will further increase productivity by several times.

- Reducing the percentage in the field of deformation welding - control over heat input allows you to reduce the overall percentage of deformation of the machined structure after completion of work. This circumstance is a direct consequence of the fact that during processing very accurate welding parameters are maintained - arc voltage and welding speed, which cannot be achieved within the framework of manual production. In addition, the constant extinguishing / ignition of the arc when the welder moves along the length of the seam, as well as the need to perform the procedure for closing the seam - all this affects the risk of subsequent deformations. It should be noted that suturing with two carriages at the same time will reduce the risk of possible negative consequences by half.

- Savings on welding consumables - this circumstance arises due to the implementation of finer adjustments of welding parameters and their maintenance throughout the entire work. As the main factor, one can single out the decrease in losses in the volume of welding wire during spatter. It also affects the absence of interruptions during work, when moving along the joint of the welder, and, in fact, the very resumption of work (the absence of the need to overlap the seams significantly saves welding materials). The number of passes can be reduced due to the possibility of welding with transverse vibrations. In addition, with the uniformity and homogeneity of all operations, the consumption of protective gas is reduced, which will be a significant article in terms of savings when expensive argon-based gas mixtures are used for protection.

- Auxiliary processes will require less cost - the cost of additional operations, such as cleaning the heat-affected zone and seam deburring, as well as removing the seam reinforcement, will be significantly reduced due to the fact that smooth and neat seams will be obtained already in the first pass. Reducing the level of spatter will also affect the costs associated with grouting.

- Increasing the environmental level of production - environmentally friendly working conditions will be achieved due to the fact that the welder will be in the operator's place, and not sit in close proximity to the smoke and heat that are generated during arc welding.

As a result, with the use of tractor welding, it is possible to automate any, even a small, enterprise and bring it to a “plus”.This is especially true for those companies where the staff of specialists has sufficient experience in working with semi-automatic welding in shielding gases - then the result will be achieved in the shortest possible time and will be more pronounced. In addition, the introduction of carriages / tractors will not require extremely large investments and will pay off pretty quickly (unless a super-large and complex project is planned) and there is time for installation:

- Some carriage models cost even less than their submerged tractor counterparts;

- Despite the fact that the purchase volumes of consumables (shielding gases and consumable wire) will remain at the same level, however, their costs will drop significantly;

- There is no need to purchase additional equipment for calcining the flux, as well as re-equip a special room for this;

- There is no need for a radical change in the technology of the processes being performed (for example, there is no need to introduce new types of edge cutting);

- There is no need to train personnel in new welding methods, respectively, there will be no need for additional certification and attestation of workers.

Existing deficiencies

Unfortunately, with all the significant positive aspects, the devices under consideration also have significant drawbacks:

- Before starting work, you will need to make all the settings very accurately;

- Precision equipment is subject to complex breakdowns, so quick repairs and resumption of work are extremely doubtful;

- There are specific restrictions on the maximum/minimum diameter of looped seams;

- The technique itself most often has a small mass, but an accidental excessive load on it can quickly disable it;

- Operation requires certain skills, which makes this technique poorly accessible for small businesses;

- High price.

Problems of competent choice

Each welding task has its own specific parameters that need to be carefully checked when purchasing a carriage/tractor. For tasks of small volumes that do not involve particular complexity and require only the constant execution of the same type of operations, single-engine machines without program control are quite suitable. They are easy to operate, do not present any particular difficulty in the event of repair situations. In the event that a large-scale project is required, and even more so its implementation in a short time, it is better to purchase multi-arc and multi-motor samples. The same will apply to the implementation of serial production.

IMPORTANT! When buying, the main selection criterion should be the indicator of maximum and minimum current, as well as the size of the consumable wires used!

Rating of the best welding tractors and carriages for 2022

Budget price segment

2nd place: "EvoSAW 1250-II"

votes 0

This self-propelled apparatus is adapted to independently perform welding work using flux; structurally divided into two blocks (actually automated device and inverter power supply). It is characterized by an increased speed of work - within sixty seconds it will easily complete a seam with a length of 10 to 15 centimeters. However, the speed of tasks will be affected by the thickness of the metal being processed. Among other things, the inverter can be used as a stand-alone equipment for cutting to a given depth (air-arc gouging) or as a manual welding machine. The package includes a system of protection against short circuits and overheating.The country of origin is Russia, the recommended retail price is 250,000 rubles.

- The presence of protection;

- Possibility of separate use of elements;

- Quality build.

- It has limitations on the thickness of the welded metal.

1st place: ADF-1000

votes 0

This sample from a Russian manufacturer can carry out multi-layer and single-layer welding with surfacing of consumable wire under flux protection. However, it will require a three-phase electrical connection. The software supplied in the kit solves the issue of synchronizing the speed of movement and the feed of the electrode wire. The unit is able to move both along pre-installed rails and directly on the surface of the object being processed. A remote control is available, through which it is also possible to adjust the welding voltage. The working element - the head - is movable, can be installed at a certain angle to the working surface. For the convenience of visual control, a laser designator is provided in the design. Seams can be applied both in annular and in a straight line technique. The device is capable of welding without cutting edges or with them (butt), joining in "taurus" (at an angle), and overlapping seams. The recommended price is 260,000 rubles.

- Movement on the surface of the working object is available;

- The presence of a laser marker;

- Has a remote control.

- A three-phase mains connection is required.

Middle price segment

2nd place: Promotech LIZARD

votes 0

This sample has a stable moving speed, which remains unchanged throughout the entire workflow.This fact makes it possible to achieve extreme precision in the application of the weld, as well as to ensure its improved quality. At the same time, the filler material will be used extremely economically. The machine can be programmed to sew a long or special seam with stitches. Only by pressing two buttons it is possible to determine the type of the desired seam, while the parameters of length, line spacing, seam filling, crater filling time can already be preset. A very important option is the presence of an oscillatory unit, with the help of which the necessary criteria for the welding operation are automatically selected. This block significantly expands the capabilities of the device, which is especially important for vertical seams and seams with cutting along the edge. The recommended price is 312,000 rubles.

- Rigid and lightweight one-piece body;

- The presence of a magnetic positioning system;

- Capable of recording up to 40 program templates.

- Not detected:

1st place: "Riland-Aurora PRO MZ 1250"

votes 0

A good sample from a Chinese manufacturer, which has a modular architecture with a separate inverter. The unit is capable of performing submerged arc welding operations in an automated mode. This mode will have a positive effect on the effective acceleration of production in general, while the quality of the applied seams will not be lost. Able to weld at an angle, as well as overlap and even butt. It can move both along the processed object and along a given vector with the help of installed rails. The position of the weld is quite adjustable - it can be located both outside the track and inside it.The device itself is structurally very simple, which means increased reliability. Protection against power surges and heating - present. High-quality forced cooling is provided, which affects the increase in service life. The recommended price is 338,000 rubles.

- Forced cooling system available;

- Can perform welding in non-standard ways;

- Separate modular architecture.

- Not found.

Premium class

2nd place: "Svarog MZ1000"

votes 0

Another Russian sample designed to work with metal objects with a thickness of 4 to 30 millimeters. Shows high productivity when using the device in almost continuous production operations. The evenness of the arc is ensured by fine adjustment of the settable current parameters, which means better suturing. The unit has an insider stabilization circuit that controls input voltage fluctuations, but it will require a three-phase network to connect it. Comfortable management and operation is provided by bright and contrast information displays and the control panel. Up to 100 algorithm templates can be loaded into memory, which will allow you not to set up the equipment again every time. The recommended price is 350,000 rubles.

- Up to 100 programmable patterns;

- There is an internal stabilization circuit;

- Quality stitching.

- A three-phase network is required.

1st place: ESAB A2 Multitrac

votes 0

Excellent, but very expensive model from a European manufacturer. In the production process, it is able to work with two arcs, splitting the consumable wire.Access of air to the area of application of the seam is prevented by the supply of inert gases. By installing a special adapter, it is possible to produce air gouging with a carbon electrode. The thyristor inverter can provide a stable arc even at low voltage. The recommended price is 1,100,000 rubles.

- Arc stability at low voltage;

- Parallel operation with two arcs;

- thyristor inverter.

- High price.

Instead of an epilogue

Welding tractors/carriages are a simple yet functional solution for automatic arc welding. They are able to move along a pre-selected path or along special rails, which leaves a person with only the obligation to visually control the work being done. The main task of the operator is to correctly and appropriately set the necessary settings in accordance with the task being performed. The machine can do all the work on its own. The type of work can be completely different, so the devices themselves can be light and inexpensive or bulky and expensive. Nevertheless, it is more correct to say that a welding tractor or carriage is primarily focused on industrial production volumes.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131667 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127704 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124530 -

The best men's sneakers in 2022

Views: 124049 -

The Best Complex Vitamins in 2022

Views: 121953 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114988 -

The best paint for gray hair - top rating 2022

Views: 113406 -

Ranking of the best wood paints for interior work in 2022

Views: 110335 -

Rating of the best spinning reels in 2022

Views: 105340 -

Ranking of the best sex dolls for men for 2022

Views: 104380 -

Ranking of the best action cameras from China in 2022

Views: 102228 -

The most effective calcium preparations for adults and children in 2022

Views: 102022