Rating of the best tie down straps for 2025

Belts for cargo tie (they are also tie-down) are the most common means for fixing transported objects on vehicles. They allow you to securely secure and properly transport cargo from point to point. By themselves, they are an elastic textile tape, with which the cargo is securely fastened, which eliminates the possibility of damage during transportation. The main consumers of such products are various freight forwarding companies on any type of transport. The production of these devices is based on weaving technology, which uses a durable polyester textile tape. The width of the tape fabric for weaving can be 25, 35, 50 millimeters, which will depend on the intended load and scope of use. There are also options where a tape with a width of 75 to 100 millimeters is used for weaving - such devices are needed for extremely massive and dimensional transportation.Usually, the maximum possible load for each product is indicated on the label attached to it. This information must be taken into account under any circumstances, otherwise there may be a break during reloading and damage to the cargo (cargo) itself.

Content [Hide]

Design features

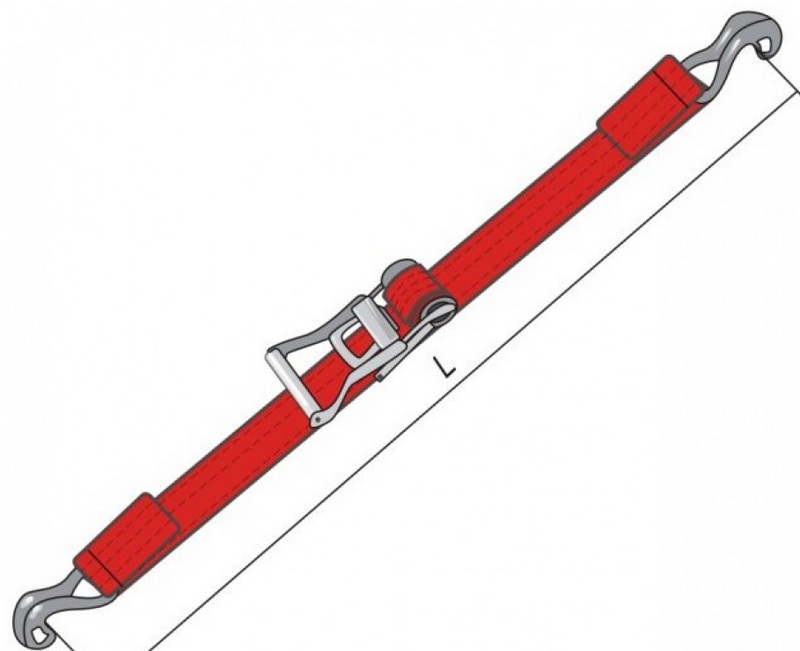

The classic tie-down strap (regardless of load capacity) consists of:

- Ratchet;

- Directly to the tape itself;

- End fitting.

- For the production of a reliable belt fixture, it is necessary to use a special textile material that would meet the following requirements:

- It has reliable resistance to climate change and sudden changes in temperature - it must function normally in the temperature range from -40 to +100 degrees Celsius;

- Wetting should not cause extreme deformation;

- It is resistant to long-term tension and mechanical abrasion.

Usually, the textile base of the tape fabric is made up of polypropylene, polyester, polyamide. The width of her canvas varies from 25 to 100 millimeters, and the length - from 6 to 12 meters. In cases where the device is equipped with a ratchet mechanism, it consists of two tapes, at the end of one of them there is a fastening device. The end fitting, which may be a double hook, single hook or carabiner, may also not be present in all samples. An example is the ring screed. Typically, the fitting is located at the end of the web and with its help the device is fixed to the trunk, body or trailer.

A ratchet is a fixing device that is used to stretch the tapes and fix them in the proper position. Its design includes several metal elements:

- Springs/bolts;

- Asterisk providing tension / rotation of the material;

- Handle for rewinding the tape and its subsequent fasteners.

The principle of operation of the ratchet mechanism is simple: at the beginning, the tape is installed in the gap in the middle of the ratchet, then it is stretched by shifting the position of the handle. When the ratchet opens 180 degrees, it simply pops out. Thus, the device ensures proper fastening of the web.

In turn, ratchet mechanisms can differ according to two criteria:

- According to the material of manufacture - steel is usually used and the stronger its indicator, the greater the mass of the cargo can be secured without the risk of deformation of the object being transported;

- By dimensions - the ratchet is selected based on the size of the object being transported.For example, a ratchet that is too small will not be able to hold a large object, because it deforms under its weight, therefore it will not be able to realize its holding functionality.

Belt buckles - traditional and long

Depending on the features of their own design, belt ties for fixing loads can be hook or ring. The ring consists of a ratchet and a ratchet lock, which represent a tension element, and a tape web with free ends. The working length of such a product should be selected based on the task being performed. The hook consists only of a cargo tape equipped with hooks and the ratchet itself.

The ratchet mechanism (it is also a ratchet) is required to maintain the tape in a permanently taut state, which is designed to ensure the integrity of the fixed object and contribute to the safety of the surrounding workers involved in transportation. By means of ring fixation, it is possible to move small volume loads or several objects at once compactly, while the risk of breakage is eliminated. The hook-and-loop tape maintains tension by attaching it at several points at once. In this case, care must be taken that it does not come into contact with the sharp edges of the vehicle or the object being moved. Otherwise, it may cause a cut and damage to the cargo.

In our time, samples equipped with a reverse thrust mechanism that stretches the tape as it moves down have become extremely popular. The main feature of such a product is the handle, the length of which is twice as long as the handle of traditional mechanisms. With its help, the belt is given maximum tension, which, of course, gives reliability when transporting cargo.In addition, such a mechanism has a guiding auxiliary axis, which protects the tape from mechanical friction. All this makes it safe to transport goods over significant distances.

Ratchet design

Coupling belt device with a ratchet is structurally divided into two elements: a short one - in addition to fasteners, there is a retainer for the inner surface in it, and a long one - a ratchet is mounted at its end. The very structure of the mechanism consists of the following parts:

- Steel base needed to attach the ratchet to the tensioning belt device;

- Lock designed to grip the ratchet;

- Swivel bar with a spring, necessary for length adjustment;

- Toothed ratchet with a pawl that protects the entire device from unauthorized unfastening.

The mechanism itself is fixed by means of brackets or rivets equipped with monolithic locks. The mount itself is rigid, and length adjustment is carried out using a movable loop located on the short part. To fix cargo with a ratchet, you should correctly select the product, while paying attention to its technical capabilities and dimensions. But such mounting options as winches are no longer used in the modern world.

Performance parameters of ratchet straps

The selection of such devices will depend on the following conditions:

- Dimensions and weight of cargo;

- Cargo parameters - long containers, pallets, furniture, bags, piece packages;

- Transfer conditions - closed trailer or van or open platform;

- Established cargo attachment plan.

Traditionally, the following fixation variations are used:

- From below, if the bottom of the trailer is flat and even, and the objects themselves are packed on one pallet;

- Diagonally, if the cargo has an uneven configuration and is not in the package;

- "Cross-cross" (mixed) - the edges of the cargo itself or pallets are located too close to the edge of the platform, which makes it impossible to secure them overboard;

- Combined - used for cargo with significant heights, which is why it is not possible to secure it to the side edges of the platform or the surface of the truck.

Coupling fasteners must be selected in the following sequence. First, the maximum width for one product is determined, which should not be greater than the width of the adjacent horizontal platform, over which the screed will be located. Next, you should choose the number and length of fixtures. These parameters will depend on the maximum circumference of the load to be moved. Its length also necessarily takes into account the distance to the ring or hook, and should be able to adjust the entire device in such a way that the ratchet securely fastens the cargo.

The total belt length is determined based on the following conditions:

- The length of the distance between adjacent devices should not exceed the largest size of the load. This requirement applies to flat surfaces. If the load is in a protective polymer film, then the distance should be reduced by a factor of two or more. The same is true for situations where fixation is carried out on complex surfaces (round, oval, etc.).

- In the case of a combined cargo attachment, the upper girth of the ratchet necessarily runs along the short side, and not along the long side.

- The length of the free end must be twice its width, which will create the necessary comfort when using the ratchet.

A belt length of 3-6 meters is considered classic, but this option is more suitable for private haulers. For heavy, heavy and large-sized objects, they are used in belt bays with a length of 50 to 200 meters.

The final stage (however, the most important point) will be the selection of the device according to its maximum load. The limiting condition here may be a textile tape, the technical characteristics of which may not withstand the applied load or stretch. Modern clamping products are produced with the following tightening force values (in kilograms): 1000-2000-3500-5000-7500-10000. If we take into account the safety factor, then the minimum safety factor should be at least 2 units (and for used devices, it is twice as high).

Rules for working with clamping devices

There are three fundamental rules when working with clamping devices (the rest can be called optional):

- It is forbidden to give out a load more than that indicated in its technical characteristics on the label;

- Towing or lifting any load is also not allowed, because the device is not intended for these operations;

- The secured load must not have any play and must be permanently in a fixed position (it is possible to use special blocking bars or spacer bars with mats, which will increase the stability of the cargo).

Also, when choosing belt devices, you need to consider:

- Dimensions and weights, shape and type of the transported cargo, plus the method of fixing the object itself and the angles of the screed, an indicator of the degree of friction between the cargo and the surface;

- Type and design of fasteners;

- The presence of a label with data on the manufacturer, the maximum load allowed on the tape and the working length.

IMPORTANT! If there are more than 2 parts in the belt, then each part must have its own tag with information about its technical characteristics.

Fundamentals of safe operation of the screed when securing loads

Before using the belt, it must be carefully examined for any damage. A damaged unit must not be used under any circumstances!! Common injuries include:

- Rust or deformation of the metal parts of the belt (ratchets or hooks);

- Various cuts on the tape;

- All kinds of tears in the stitching on the connecting seam.

When transporting cargo with an uneven surface or sharp parts, you should use special pads, additional corners and other means to protect the fabric. Belt devices, on the other hand, must be attached to special clamps so that the main part of the load from the stretched tape can be distributed over the necks of the hooks.

During the use of clamping devices, it is strictly prohibited:

- Warp/twist the tape;

- To hook one hook after another or to cling to the side of the vehicle if the latter does not have special lugs;

- Cleaning with chemically aggressive substances;

- Use a device with obvious signs of corrosion / deformation of a metal lock or hooks;

- Use tape damaged by high temperatures;

- Use tape damaged in length by more than 10% of its width;

- Use a ribbon tied in a knot;

- Use a tape that does not have an information label, or the information on which is not readable.

Questions of the right choice in the buying process

The main criterion for a potential buyer should be the following condition.In cases where the cost of a tightening device from one of the manufacturers is significantly lower, with equivalent declared technical parameters (working / breaking load, length of the belt itself, width of its web), then most likely the belt device is not a complete analogue in terms of its performance. This circumstance is justified by the fact that at modern manufacturing enterprises, the production technology and the cost of manufactured products do not differ much.

When choosing to buy a tie-down belt, first of all, you should pay close attention to the following points:

- The tape is the most sensitive element of the belt, and, as a rule, it is the first to be damaged during operation. It follows that before buying it must be checked for strength by first feeling it. The main sign of a low-quality tape is its friability and softness, which means that the production process took place with technological violations and of poor quality. Due to the fact that this element must be made from many individual threads, it must withstand a safety factor exceeding a triple degree, and the thinness of the web will directly affect its breaking load. At the same time, if longitudinal black stripes are found on the basis of the tape, which is clearly not regulated by the production standards, then this fact will also indicate the low strength of the tape.

- Hook - on this element, its maximum possible load is indicated without fail, which is indicated in Latin as LC. This marking means that it is able to withstand 5 tons (alternative marking looks like 2500 DAN or 25 KN).Before buying, it is recommended to check the thickness of the hook itself - it should be at least 12 millimeters, which just corresponds to the ability to hold 5 tons.

- Ratchet - its design should be considered more closely, because manufacturers often, in order to reduce costs, use thinner metal in the process of stamping ratchets than is necessary according to standard technology. Similarly to the hook, the ratchet should also have a marking indicating its maximum load during the tensioning process - for example, the LC marking means that it can withstand 5 tons (alternative marking looks like 2500 DAN or 25 KN). At the same time, the thickness of the metal for such a mechanism should be from 2.6 millimeters to 3.6 millimeters, because different thicknesses are required for different components of the ratchet). If the thickness is less than necessary, then the negative effect of the load will be directly on the mechanism, because it bears the main load in tension. You should also pay attention to the spring located on the fixation device, for which you need to lift the device up and lower it sharply a couple of times. Thus, it will become clear whether any efforts will have to be made to raise it, or whether the lifting will be easy. In the latter case, such a circumstance will indicate a short service life of the mechanism as a whole.

- Tag (etiquette) - it is necessarily located on each part of the belt, and is, in essence, its technical passport.According to accepted standards, its color should be blue (on a polyester belt), it indicates the full technical parameters of the belt: length, nominal working force, expected tension force, working and breaking load. The manufacturer and his data must also be indicated.

Additionally, before purchasing, it is necessary to weigh the belt device - the lighter it is, the less material was spent on its production, which means less possible loads that are subject to such a belt. Accordingly, its useful life will also be short.

Rating of the best tie down straps for 2025

Budget options

3rd place: "ROMEK 25.025.1.k 2000000005706"

votes 1

A worthy sample from a Russian manufacturer provides proper convenience and safety during transportation. The tape is endowed with hardened characteristics and exhibits special resistance to interaction with moisture and aggressive chemicals. The locking mechanism is able to securely tighten the tape, which indicates the maximum fixation of the load. The clamping force is 250 kilograms, the total length of the belt is 2.5 meters, and the weight is 120 grams. The country of manufacture is Russia, the recommended retail price is 160 rubles.

- It is used for securing cargo on road transport;

- The tape is resistant to moisture and chemicals;

- Inexpensive cost.

- Not detected.

2nd place: Hitchhiking AB-2.5-2 4.0

votes 0

This model is designed for the transportation of goods by road. Designed for relatively small objects that have regular geometric shapes. The strap is made from durable synthetic fibre.Double clamps are designed to provide maximum security of fastening. With its low weight (only 100 grams), it is able to easily hold a 500-kilogram load. The total length is 2.5 meters, the country of manufacture is Russia. The recommended retail price is 220 rubles.

- Sufficient load capacity with a small belt width;

- Reliable clamps at the ends;

- Absolutely light weight.

- Short enough for professional transportation, more suitable for household.

1st place: "Zipower PM4019"

votes 0

We can say about this sample that it is the best among all budget options. The manufacturer positions this tie-down strap as a device specifically designed for transporting various types of cargo in an open trunk. The quality of the woven fabric is on the level, the fixing fasteners can easily withstand a journey of 4000 kilometers at an average speed. The maximum clamping force is determined at 250 kilograms, with a length of 4 meters. Own weight - 400 grams. The brand is from the USA. Produced in Russia under license. The recommended retail price is 280 rubles.

- Narrow specialization;

- Inexpensive cost;

- Reliability on a long journey.

- The fasteners may look flimsy.

Middle price segment

3rd place: "Gigant SR 1/3"

votes 0

A good model with adjustable length. It is quite suitable for both domestic transportation and professional activities. Thanks to the ratchet mechanism, the possibilities of the model are significantly expanded. The fabric is based on textile threads made using innovative technologies, which ensures a long service life.The maximum load is 1 ton, with a length of 3 meters and a dead weight of 200 grams. The country of manufacture is Russia, the recommended market price is 310 rubles.

- The ability to independently adjust the length;

- New textile technologies;

- Sufficient quality.

- Slightly uncomfortable handle to adjust the length.

2nd place: "TOPEX 97X183"

votes 0

Despite its Asian origin and rather low cost, this sample has proven itself in practice. Fixing objects inside the trunk occurs properly and with the required degree of reliability. Although metal buckles are not made of extremely durable steel, they fulfill the task assigned to them in full - during installation, the load does not stagger, and there are no problems during transportation either. The maximum load is 2.5 tons, with a length of 2.5 meters and a weight of 160 grams. The brand is from China. May be made in Poland. The recommended price for the market is 350 rubles.

- Slings have excellent firmware;

- Reliability of fastening;

- Decent combination of price and quality.

- Not detected.

1st place: "MEGAPOWER 3500kg, tape 8m x 40mm M-73358"

votes 0

An almost universal screed option that can be used on almost all types of transport (wagon, van, river boat). With this belt, it is possible to tighten not only objects that have a solid shape, but also those that have a certain amount of softness. For example, a belt can be effectively used to transport hay bales. The product itself is extremely light weight. Withstands a clamping force of 3.5 tons, with a dead weight of 1 kilogram and a length of 8 meters. Produced exclusively in Germany.The recommended price for the market is 400 rubles.

- Can be applied to any cargo;

- Can be used on any type of transport;

- It has an increased length and a reliable ratchet mechanism.

- Not detected.

Premium class

3rd place: "KantaPlus Ratchet 35mm/5.0m"

votes 0

An extremely high-quality sample, in which, in addition to the intended purpose, other aspects associated with cargo transportation are implemented. The manufacturing material itself can be easily cleaned from almost any contamination, and reliable fixation locks will provide real safety for the staff. At the same time, the belt has a sufficiently strong clamping force of 2.5 tons, with its own length of 5 meters and a weight of 1 kilogram. The manufacturer (Russia) claims an extended service life. The recommended market price is 750 rubles.

- The load is held firmly and does not slip;

- The product has an extended service life;

- Reliable latches ensure the safety of workers

- Not detected.

2nd place: Argos UPY-5000-4.0m UT000007420

votes 0

The most durable and reliable belt from a domestic manufacturer. The fasteners have a new alloy composition, which means they can withstand increased loads, while providing maximum fixation reliability. The most important quality is versatility - the belt can be used not only for transportation, but also for slinging heavy objects on construction sites. The recommended price is 870 rubles.

- Versatility;

- New alloy composition in locks;

- Maximum reliability.

- Not found.

1st place: "SKYWAY S03601005"

votes 3

An excellent option, equipped with a ratchet mechanism and a convenient length adjustment handle. Suitable for any work, the fabric is sewn securely and firmly. Manufacturer - Russia, recommended price - 1000 rubles.

- Versatility;

- Affordable price;

- Good firmware.

- Reverse order of pulling the tape web.

Conclusion

Unfortunately, in the Russian Federation, it is the production (and not operation!!!) of tie-down belts that is poorly regulated. This circumstance has led to the fact that the market is overflowing with low-quality and cheap goods. It is worth noting that brands that care about their image apply the European standard 12195-2 “Fixing straps made of chemical fibers - fastening and safety” in the production of belts. However, this standard in the Russian Federation is not mandatory, and the current standards for the product in question are very liberal.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131650 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127690 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124518 -

The best men's sneakers in 2025

Views: 124032 -

The Best Complex Vitamins in 2025

Views: 121939 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114979 -

The best paint for gray hair - top rating 2025

Views: 113394 -

Ranking of the best wood paints for interior work in 2025

Views: 110318 -

Rating of the best spinning reels in 2025

Views: 105328 -

Ranking of the best sex dolls for men for 2025

Views: 104365 -

Ranking of the best action cameras from China in 2025

Views: 102215 -

The most effective calcium preparations for adults and children in 2025

Views: 102011