Ranking of the best construction scrapers and scrapers for 2025

A scraper or scraper is an important tool for interior finishing work. Thanks to him, paint and varnish coatings are easily removed, hardened solutions are cleaned off. This construction tool is considered a type of spatula. It is presented in the form of a handle with sharp blades that can be replaced. The rating of high-quality scrapers will help determine the choice of the right tool.

Content [Hide]

Tool Features

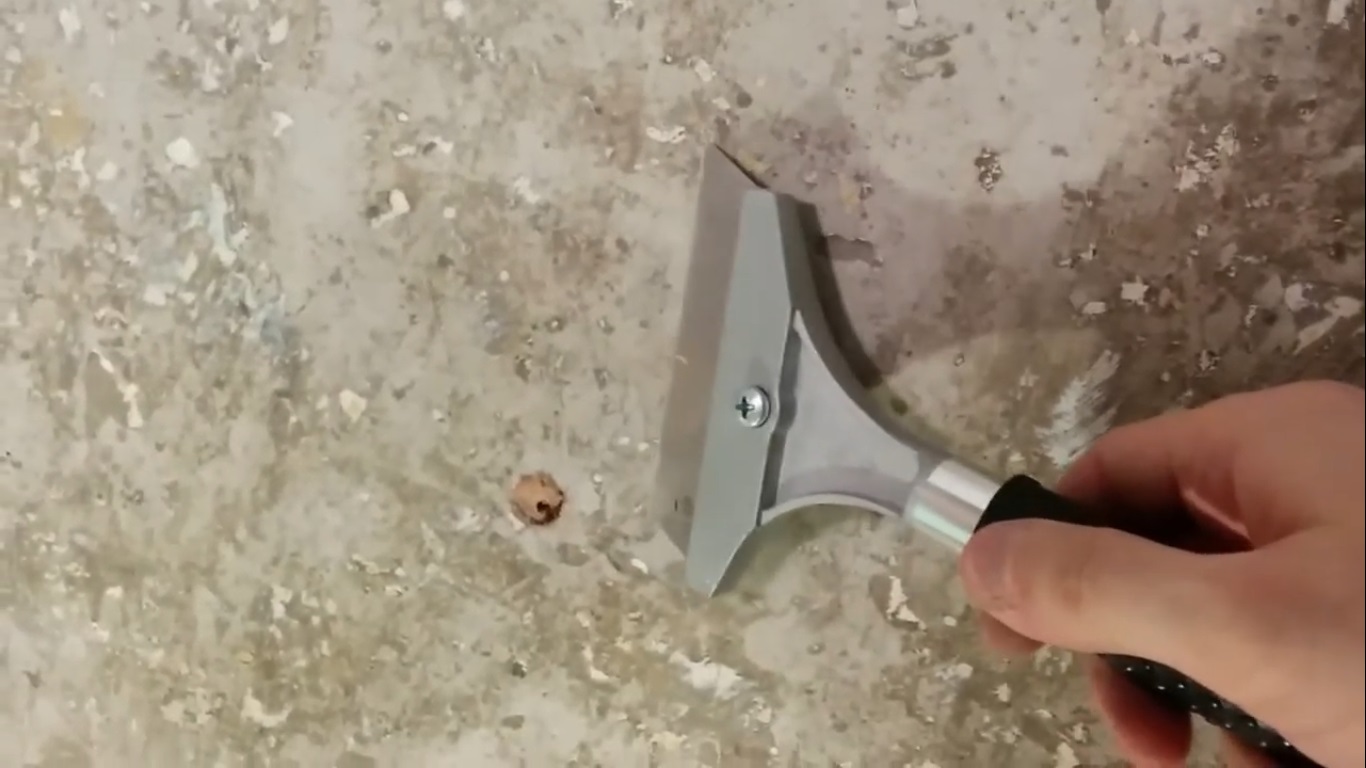

The tool is presented in the form of a device with a handle and a cutting blade. When working, it is placed perpendicular to the surface to be treated.The device fits easily into the hand.

Blades may vary in width and shape. Depending on the characteristics, they can be used to work with flat and three-dimensional surfaces. The most famous are considered tools for parquet flooring. They remove the minimum layer from the wood - the thickness of the chips is not more than 0.04-0.08 mm.

The cycles can be used for different jobs: to prepare skis, snowboards, surfboards. They also create models of ships with them. Devices are carpentry and parquet. There are also options without handles. Modern devices are presented in the form of a mechanized tool that removes the old coating. Work with such a scraper is faster.

Although the characteristics may vary, you need to pay attention to the material. The most reliable option is carbon steel. The usual thickness of the knife is 1.5 mm, and the sharpening angle is 45 degrees. The handle is usually created from natural wood or phenolic pressed mass. The blade is then sharpened at an angle of 25-30 degrees.

Glass varieties are used to clean aquariums, windows. These are conventional scrapers used in the mechanical cleaning of contamination. The shape of the blade is of several types:

- rectangular;

- triangular;

- trapezoid;

- "swan neck";

- ovoid.

When working with wood, scraping is carried out in the direction of the fibers of the material. This will help eliminate the appearance of burrs and other imperfections.

Purpose of the device

Construction tools are designed for scraping the surface of the material. According to the processing method, it is similar to sandpaper, but it performs the functions more intensively. When adjusting small parts, it is the hand-held devices that help to achieve a snug fit.It is best used in a limited area, removing thin layers of wood in the corners - where a special machine cannot be used.

Previously, cycles were used only by carpenters and craftsmen who worked with parquet floors. Now the tool is used for other procedures. Patterned types without handles are needed for small carpentry work.

A figured scraper-trowel is needed in ship modeling during the creation of various complex objects. These devices can be purchased only in specialized stores, they are used only for painstaking work with the material.

The parquet cycle allows you to restore parquet floors. It is indispensable in the case when it is impossible to apply machine procedures. A joiner's knife-scraper is used in woodworking. It can remove glue. After such processing, fine dust does not appear, which can clog in the pores of the material.

Scouring with hand devices is also needed in skiing. This is where their ability to cut through thin layers of material is especially important. Cycling will restore fiberglass skis, make them fast and smooth.

Why is looping required?

Cycles are often used to restore parquet or wooden floors. It is necessary in several cases:

- long operation has caused cracks, cracks, dents;

- the varnish has become dull, therefore unattractive;

- there is damage from flooding;

- the planks were shattered.

With the help of sanding, it will be possible to restore the appearance of the parquet. A certain layer of wood is removed, and then small flaws, roughness, scratches are eliminated. The result will be a flat surface, and the service life is extended for many years.

Features of choice

How to choose a device? It is important to look at the purpose of the device. Parquet and joinery products have different sharpening angles. Don't just look at ads. Electrical products can be presented in the form of a surface grinder, which bears little resemblance to a standard scraper.

The most important thing to pay attention to in the first place is the purpose of the tool. According to experienced craftsmen, the following types are considered the best:

- Rectangular. Designed for carpentry, smooth surfaces. Standard dimensions are 50x100 mm.

- Shaped. They are also called "with a swan neck." Used for working with round parts, woodworking.

- Painting. Allow to make original decorative patterns on plaster. Such cycles allow you to remove the paint layer from vertical and horizontal surfaces.

- Parquet. Tools have a curved handle, rounded front edge. They are fixed in two-handed blocks, allowing you to easily and quickly process large surfaces.

What kind of cycle is better to buy, everyone decides for himself. Do not think that the device will be cheap. Of course, a plastic device costs 1,000 rubles or less. There is also the option to replace the blade.

A high-quality two-handed model costs several times more. Figured views without a handle are sold in sets from 1.5 thousand rubles. And all-metal options cost about 3 thousand rubles.

Hand scrapers are equipped with an oblique fixed blade. This is necessary in order to easily remove a thin layer of wood. There are some other parameters that you need to pay attention to. The best blade width is 5-6 cm. If it is wider, it is difficult to work with it. And the narrow cutting part will require even more movements.

It is important that the handle is of high quality, as well as comfortable for the hands. It should not have nicks, chips or other imperfections. Even small imperfections can lead to blisters.

The cutting part of the tool must be exactly sharpened. It is important that there are no scratches on it. And the steel must be of high quality. Only the right tool guarantees an excellent result.

Restoring a large amount of parquet may require several tools. How many scrapers are required depends on the hardness of the coating. For processing 16 sq. m. you need 3-5 tools.

Please read the description before purchasing the product. It is equally important to read the reviews. Usually this information is of great help in choosing products.

Universal

The popularity of models of this type is related to their functionality. Devices are used in many construction and repair procedures. The following ranking includes practical and reliable scrapers.

REXANT 400mm

votes 0

The device is used to clean surfaces from dirt, including paint. It is chosen for construction and repair: it is used to remove wallpaper, glue from tiles from different materials.

The steel scraper is equipped with a fixed blade. A long handle of 40 cm will help to handle even hard-to-reach places. The cycle has a durable metal handle and a plastic nozzle with an anti-slip coating.

According to buyers, this is an excellent tool for all craftsmen. This is a universal type of cycle with a long handle, which means that it will be very convenient to work with it.

- universality;

- long handle;

- reliable handle;

- anti-slip coating.

- missing.

TUNDRA 2812974

votes 0

The cycle is intended for stripping and removing old paint. Another device is used to remove dirt from glass, tiles, ceramics. The cutting part of the scraper is made of steel, and the handle is made of plastic. When repairing such a product will be indispensable.

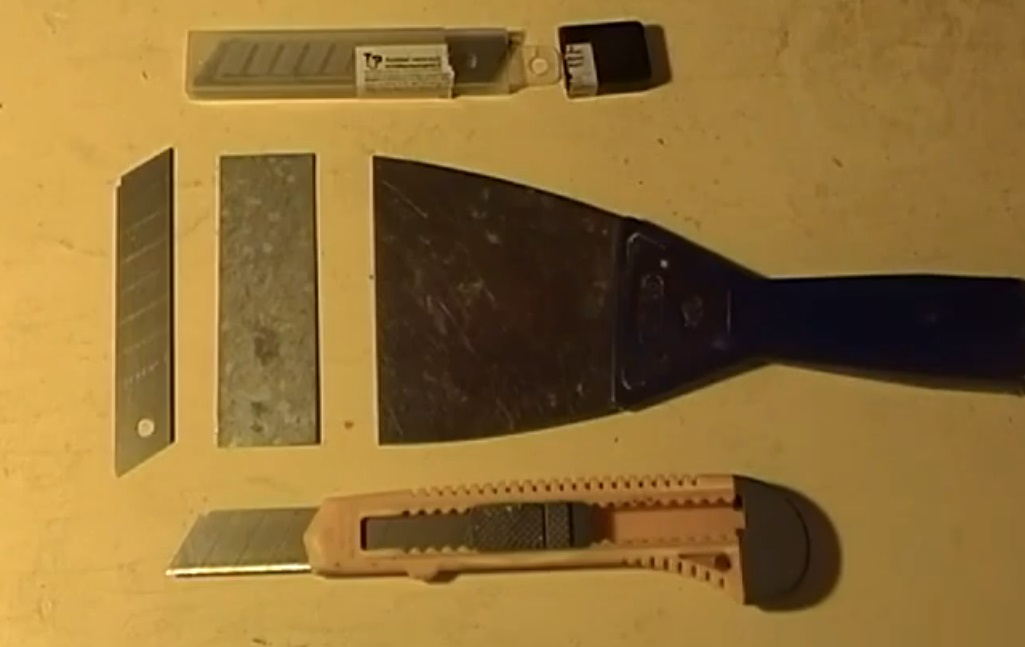

The retractable blade is necessary for safe storage and transportation of the product. The handle has a hanging hole. There are 2 replacement blades included.

- strong steel;

- practical handle;

- the presence of a hole for hanging;

- 2 replaceable blades.

- no.

Stayer Master 100 mm

votes 0

The device is used for cleaning various surfaces. Its cutting part is segmented, steel, and the handle is made of plastic. Although the length of the device is only 21 cm, it is convenient to use.

Spare blades are not available. There is no steel recoil pad, telescopic handle. The weight of the building device is 0.06 kg.

- universal application;

- quality metal;

- light weight;

- durable handle.

- no spare blades.

These are budget types of tools. They can be ordered online from the online store. During construction, they will be indispensable helpers.

Professional

Many popular models have been on the market for a long time. These include professional equipment. They are comfortable, practical and functional, so they do their job perfectly.

Harden 600 mm

votes 0

This construction scraper is made in China and the quality is excellent. Dimensions are 630 x 105 x 34 mm. And the weight in the package is 515 g.

The cycle is easy to use, highly durable and reliable. Although there are no replacement blades in the kit, they can be purchased separately. Then the work will be even easier.

- high quality;

- convenient sizes;

- light weight.

- no replacement blades.

KUBALA 100

votes 0

This scraper easily removes ceramic tiles, making repairs easier. Of course, its weight is quite large (2 kg), but the device does its job perfectly.

The Polish brand made this scraper completely out of metal, so it's heavy. And for other types of work, it is unlikely to be suitable.

- removal of ceramic tiles;

- high quality metal.

- great weight.

Kraftool 085411, 40 mm

votes 0

The scraper can be used for cleaning different surfaces. It contains an H01 blade. The handle is made of 2-component material. The set contains only 1 blade made of hardened steel.

The weight of the product is only 170 g. And the dimensions are 30 x 2 x 10 cm. There is no protective cover in the set. There is also no compartment for spare blades.

- quality metal;

- comfortable handle;

- compactness;

- light weight.

- There is no case for additional blades.

Even among professional devices there are inexpensive cycles. Also, there are new items regularly appearing that have their own characteristics. The best models are those devices that are suitable for performing the necessary work.

How to do it yourself

A home-made device does an excellent job, like a production one. Of course, now manual devices are not so popular.But still, such cycles are needed for piece-by-piece laying of type-setting parquet and other works. Such scrapers allow you to perform even the most difficult work.

To create this device, a simple instruction will help:

- Materials need to be prepared. You need a blade from an old knife, a pallet board. You should also prepare a protective impregnation and sandpaper for grinding. It is important that the piece of wood is wider than the metal part, as well as long.

- A triangular blank should be made of metal. The leading edge is sharpened at an angle of 50 degrees with a cut at 100 degrees. On it you need to make a burr for scraping. It is advisable to choose a diamond tool.

- From a wooden blank, you need to cut out a handle with a wide base. The cutting element is fixed in it. The surface is polished manually or with a tool. Processing is carried out with sandpaper for 100.

- Use a caliper to measure the thickness of the blade. A cut is made at the bottom of a flat edge. It is important that the depth is no more than ½ of the blade height.

- A cycle is inserted into the created hole. If required, you need to fix the cutting part.

- The handle must be treated with a protective and decorative agent.

Here is such a simple procedure will help create a tool for painting. A wood scraper can be made from a triangular metal blank with a welded handle.

How to work with a construction scraper

Previously, furniture is taken out of the room, skirting boards are removed, debris and dust are removed. It is necessary to remove the screws and nails from the floor, and if not, then hammer further so that they do not look out. Restoration of parquet flooring is carried out as follows:

- A special machine is used to remove old varnish, bumps.This equipment allows you to pass the main part. But for hard-to-reach areas, you still need a manual scraper.

- Then, with the help of putty, seams and joints are eliminated.

- Final processing is in progress. With special equipment, the floor is made even.

Modern devices have dust bags, shavings, so there will be little garbage. Then you need to apply varnish in several layers. Thanks to this, the parquet will have a special shade and shine. The updated surface becomes a decoration of the room. In addition, the service life of the coating is extended.

It is quite difficult to do this work, especially without the necessary tools. And when performing construction and repair procedures, it is important to follow basic safety rules.

Features of care

The scraper, like other tools, needs proper care. This will help extend the life and efficiency of the application. Experienced experts advise not to ignore several important procedures:

- After work, rinse and dry the cycle handle. This applies to any material. The cloth also needs to be thoroughly washed.

- It is undesirable to collect a lot of heavy mixtures on the cutting part. This is especially true for those models that are not suitable for heavy loads.

- Do not work with tools and abrasive substances.

- The scraper must be placed vertically for storage. It is best to hang it on a small hook.

If a handy tool is out of order, do not repair it. It is better to make a new fixture or purchase it from a store. This is due to the fact that a broken device will not do its job well.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131660 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127698 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124525 -

The best men's sneakers in 2025

Views: 124042 -

The Best Complex Vitamins in 2025

Views: 121946 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114984 -

The best paint for gray hair - top rating 2025

Views: 113401 -

Ranking of the best wood paints for interior work in 2025

Views: 110326 -

Rating of the best spinning reels in 2025

Views: 105335 -

Ranking of the best sex dolls for men for 2025

Views: 104374 -

Ranking of the best action cameras from China in 2025

Views: 102222 -

The most effective calcium preparations for adults and children in 2025

Views: 102016