Rating of the best scaffolding and tower tours for 2025

If you have to do facade work at a height of more than one and a half meters, then you can’t do without special devices called scaffolding. The name "forest" appeared spontaneously. The first versions were made exclusively from wood cut down in the forest. Currently, structures are produced both wooden and metal. Installed permanently. They are assembled for a long time, as well as disassembled, so it is difficult to rearrange them from one place to another. As a rule, they are mounted wherever work is to be done.

Content [Hide]

Types of fixtures

The best manufacturers produce many popular models of scaffolding. In order to avoid mistakes when choosing, you need to figure out what settings are. All of them can be divided according to the following features:

- connection method (there are frame and modular structures);

- the principle of installation (there are suspended and attached);

- material of manufacture (metal or wood).

Let's look at each option in more detail.

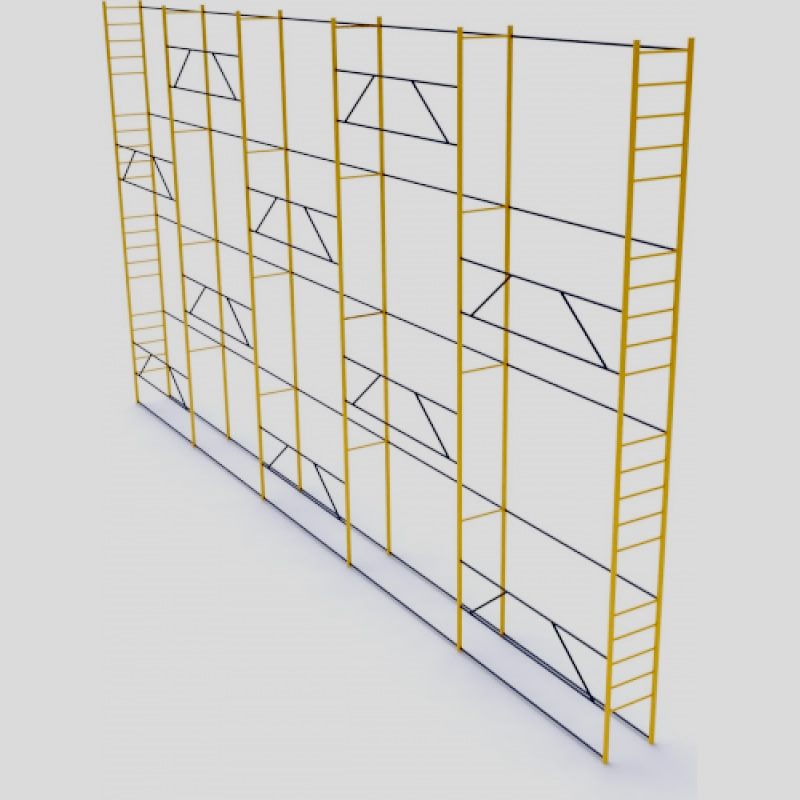

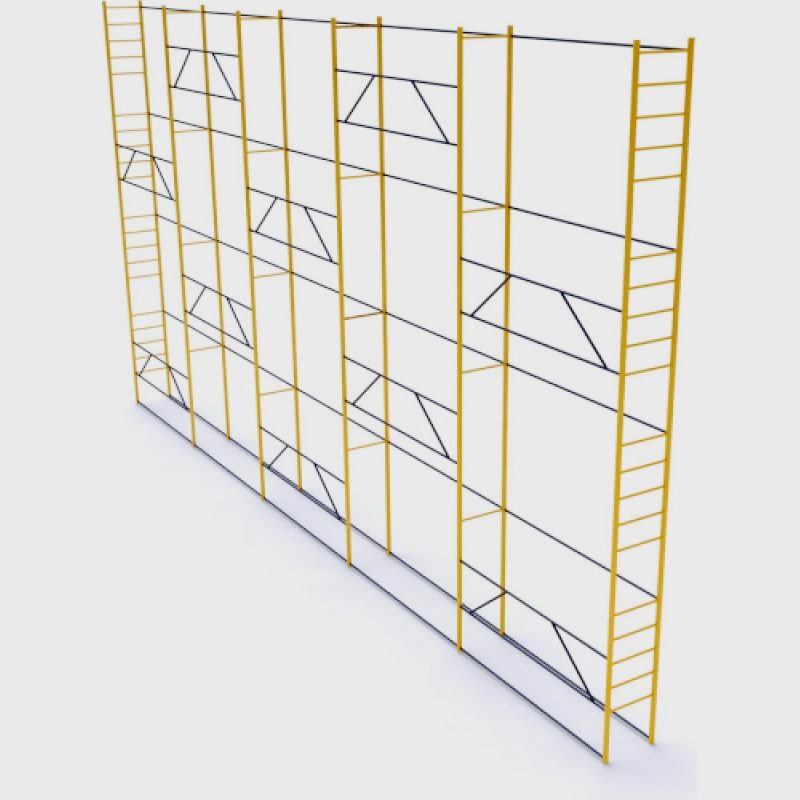

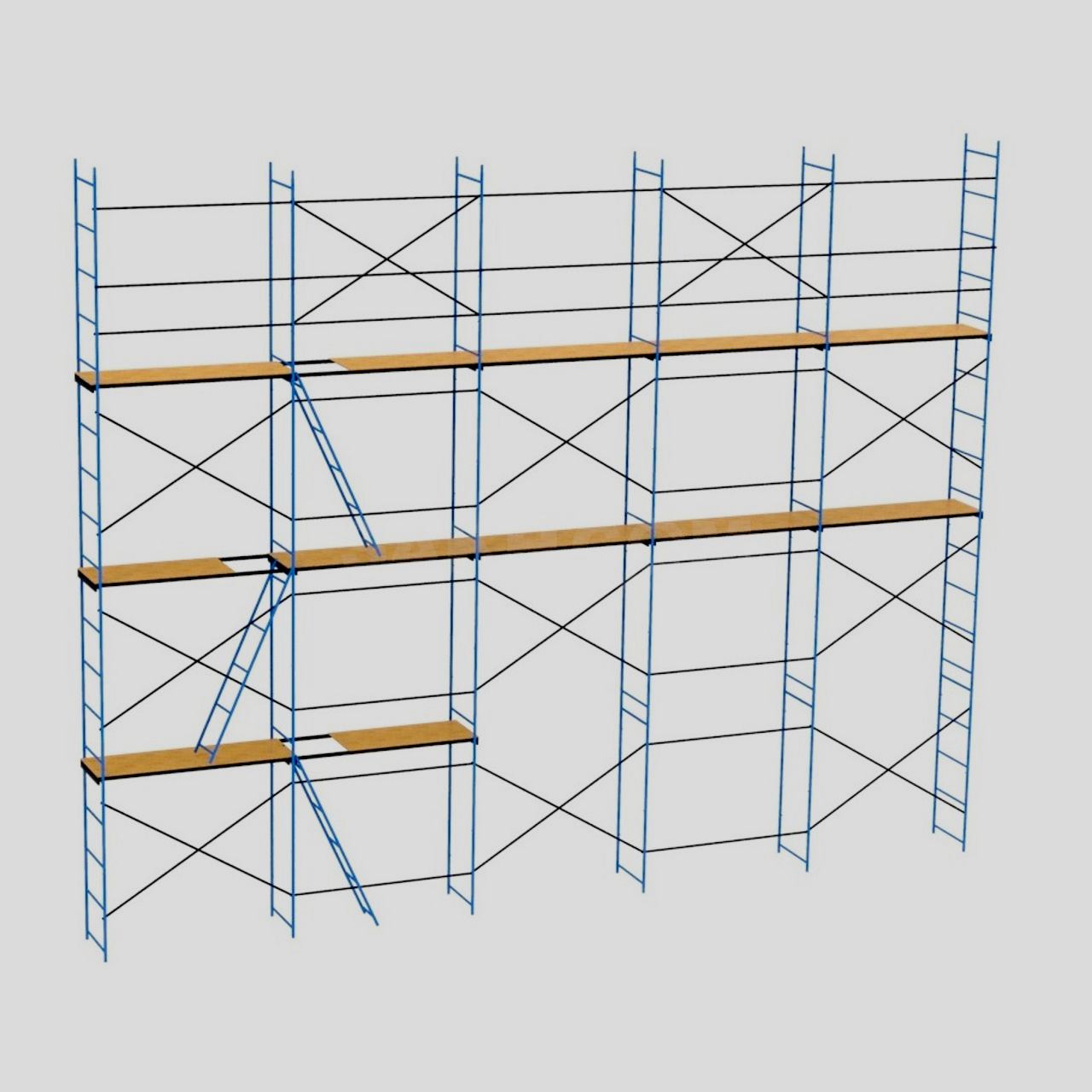

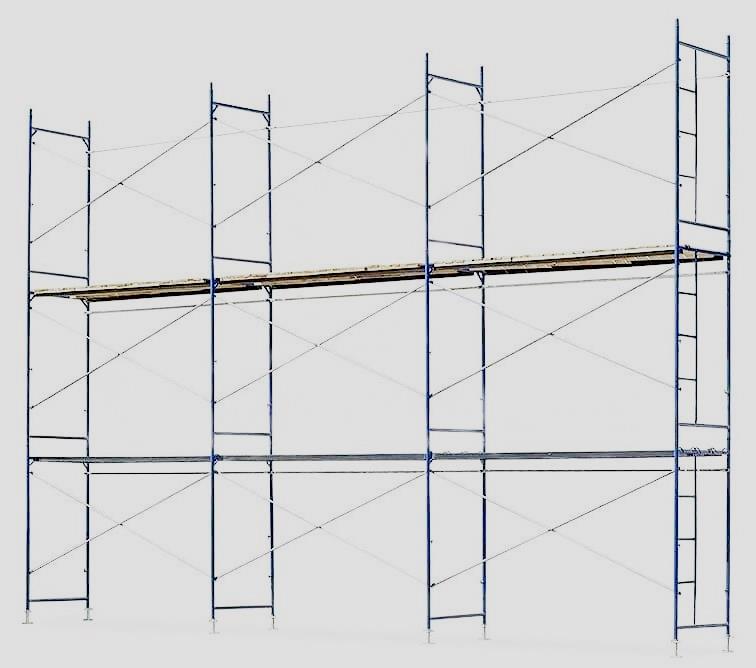

frame

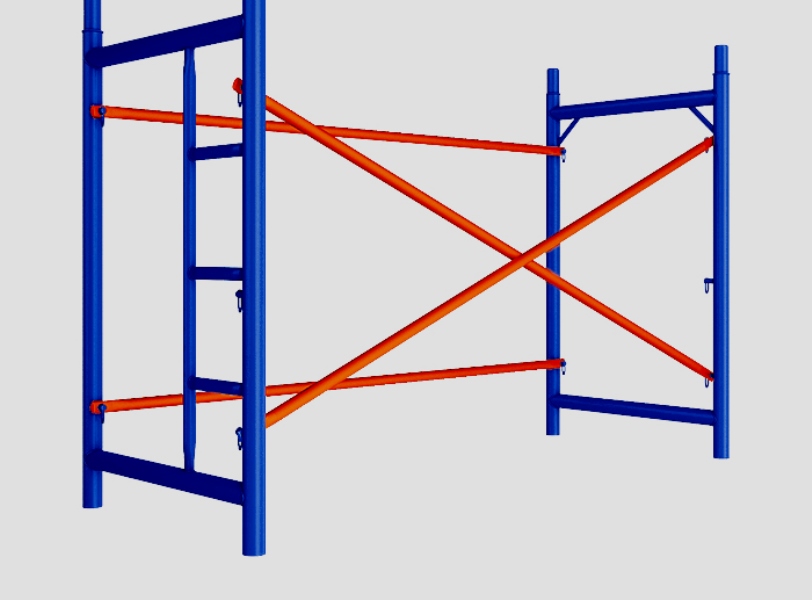

Consist of horizontal and diagonal beams. When assembling, the threadless method is used. To prevent folding, the devices are fastened with locks (flag ties). There are no serious fasteners, so there is no need to have special tools or equipment with you to mount the product. Assembly and disassembly is fast. The efforts of three to four workers are enough. The main disadvantage is considered to be the limitation of the maximum height - up to 6000 cm.

Frame structures are divided into the following subspecies:

| Type of | Description |

|---|---|

| Cherry forests | A distinctive feature is that the vertical elements are connected by horizontal beams. Diagonal struts are not provided or are quite rare. The flooring is laid directly on the frame. Often used for work at heights up to 2000 cm. Able to withstand a maximum load of 250 kg per 1 sq.m. |

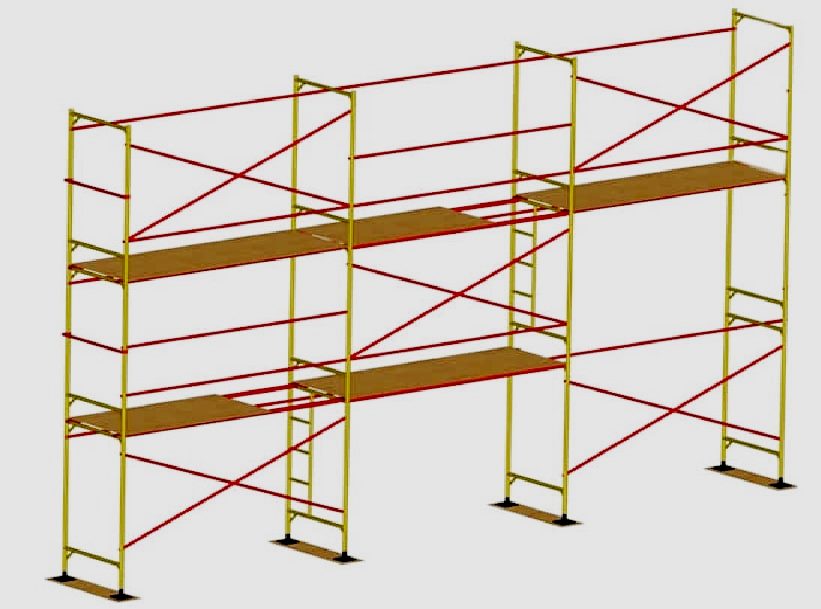

| Flag | The composition includes transverse and diagonal elements, support shoes and special ladders that allow you to move around the structure. Withstand a maximum load of 200 kg per 1 sq.m. Assemble quickly. They have significant strength. |

| Pin | Pipes are only horizontal. They are assembled very simply: just insert the narrow end of the pipe into the wide one. The lower end of the rack rests on special shoes, which gives the structure stability. Diagonal struts ensure stability. They can work at a height of no more than 4000 cm. |

In a separate category, it is worth highlighting towers - tours. When assembled, the product reaches from 200 to 2100 cm. It belongs to the class of mobile. Moves from place to place by means of small wheels. It is very popular for short-term work at low heights. It can be mounted both inside the building and outside.

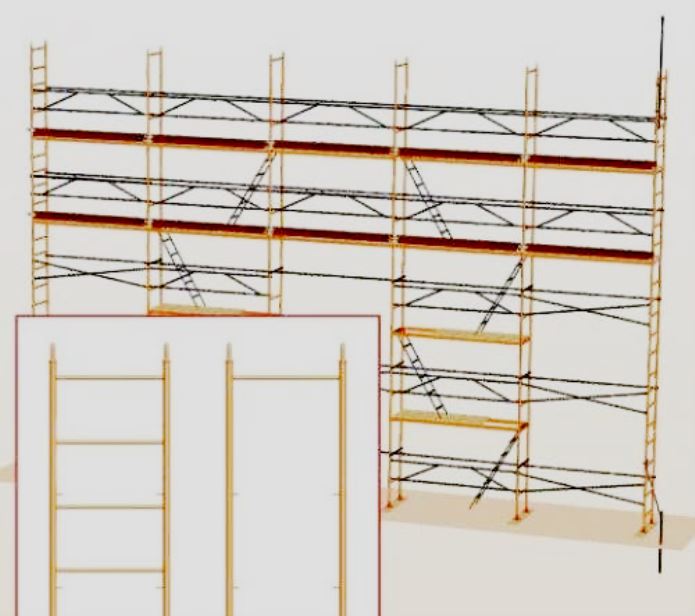

Frame scaffolding is built as follows:

- A site is selected, the soil is leveled and planned, stones and debris are cleared, and dried.

- Before mounting the structure, it is necessary to make sure that there is a certificate of conformity for the purchased product, and check its completeness.

- Scaffolding can only be installed by specialists with permission to carry out such work.

- The initial installation point is one of the corners of the building. Wooden shoes are installed first. Their length is about 40 cm. Supports will subsequently be mounted on them. The pitch of the supports is set by the manufacturer, indicated in the attached documents for the products. This value should never be increased independently.

- The first row of adjacent vertical frames is installed using thrust bearings and screw supports.Connection occurs through connections. The parallelism and horizontality of the elements is controlled by the level.

- The rest of the horizontal modules are installed in the same way.

- The structure is attached to the wall with dowels or anchors. The installation step is clearly defined by the manufacturer.

- After that, the installation of crossbars and decking on the first tier is carried out. Work must be carried out so that there are no gaps, loose fit or shifts.

- Side railings are being installed.

- Using the same technology, each subsequent tier is installed. It should be borne in mind that the stiffeners must be placed in a checkerboard pattern.

- The last step is to test the scaffolding for strength. The recommendations of experts boil down to the following: everything is subject to testing - fences, decking, flag connections.

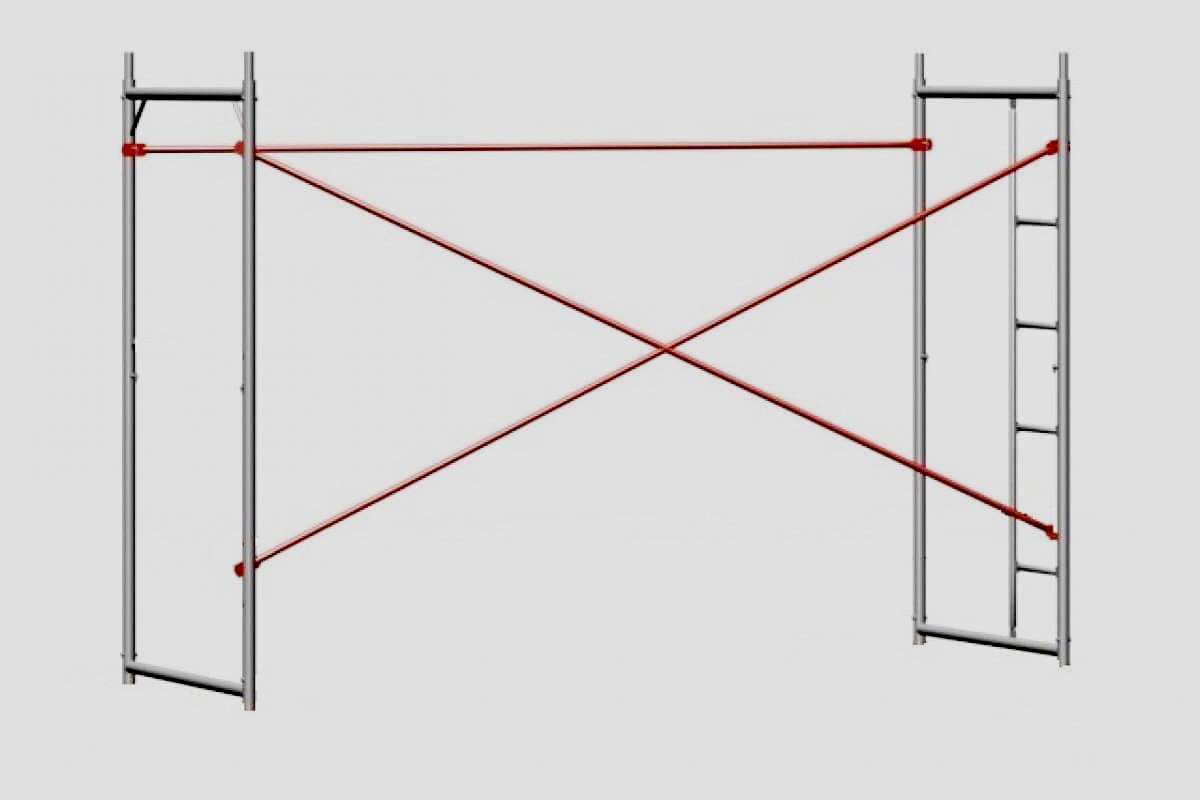

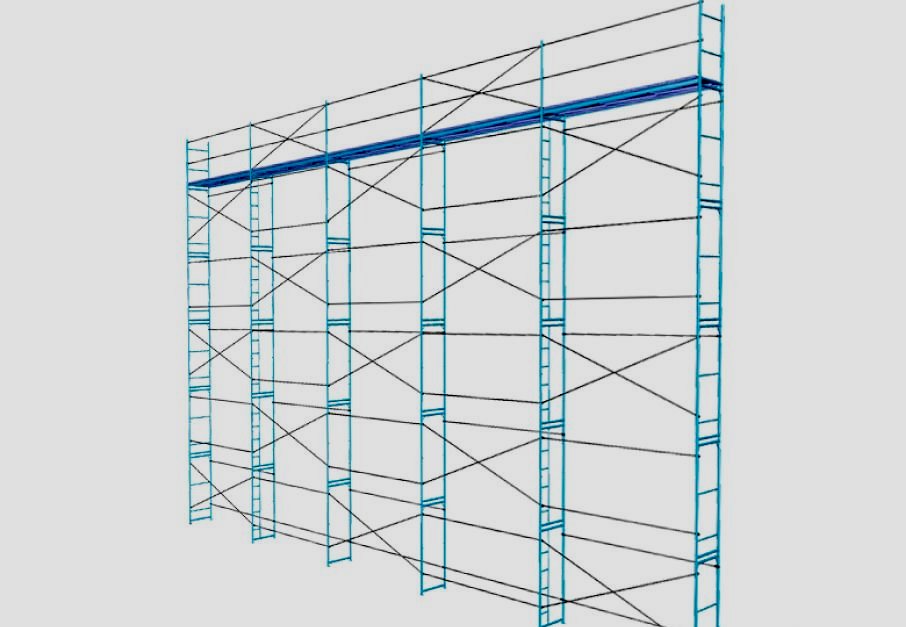

Modular (system)

They differ from previous devices in the possibility of connecting vertical blocks at different angles. This helps to establish forests with different configurations. It is used in cases where there is a need to carry out work on objects with an unusual architectural solution. There are such types:

- wedge-shaped. The name was given due to the appearance of structural elements - wedges. Designed to expand the frame. In order for the design to have a holistic view, they are equipped with personal latches. Belong to the category of universal. They allow you to configure the frame scheme as you wish.

- Khomutov. The name was given due to special fasteners - clamps. They fasten the longitudinal and transverse beams. Are issued rotary and deaf. Helps to give the device any direction. Working height - 8000 cm.

- Suspended.It is used in the case when it is strictly forbidden to use other equipment to perform manipulations at a significant height. Mounting method - facade walls. In this case, beams inserted into the ceiling are used.

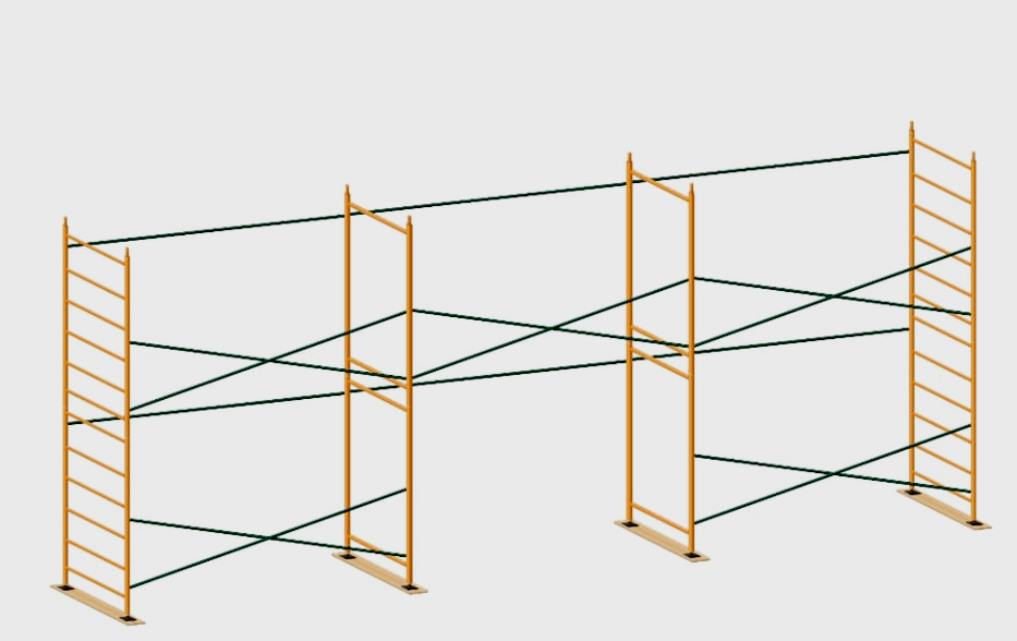

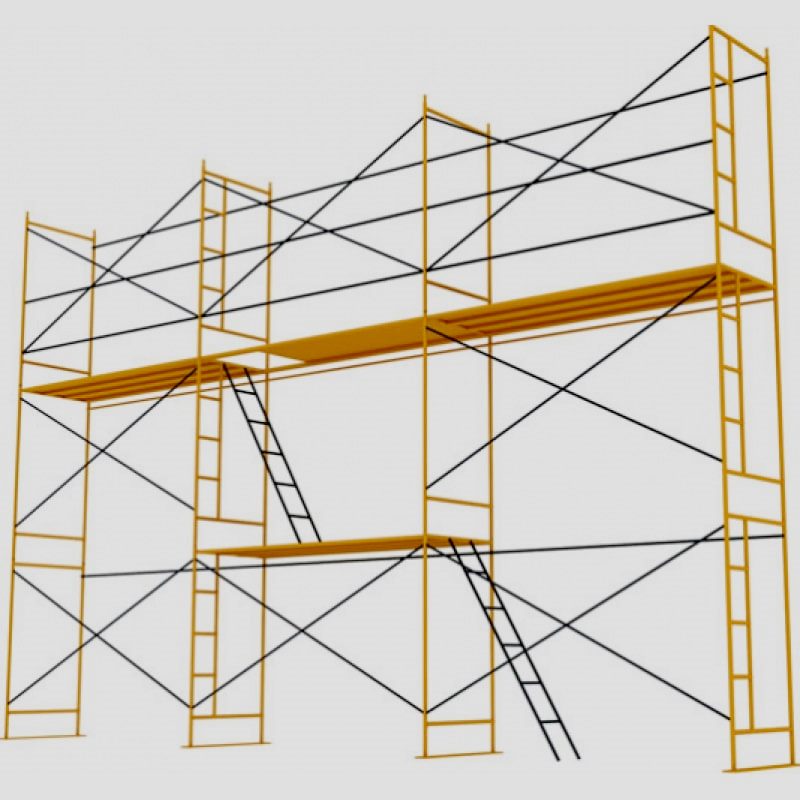

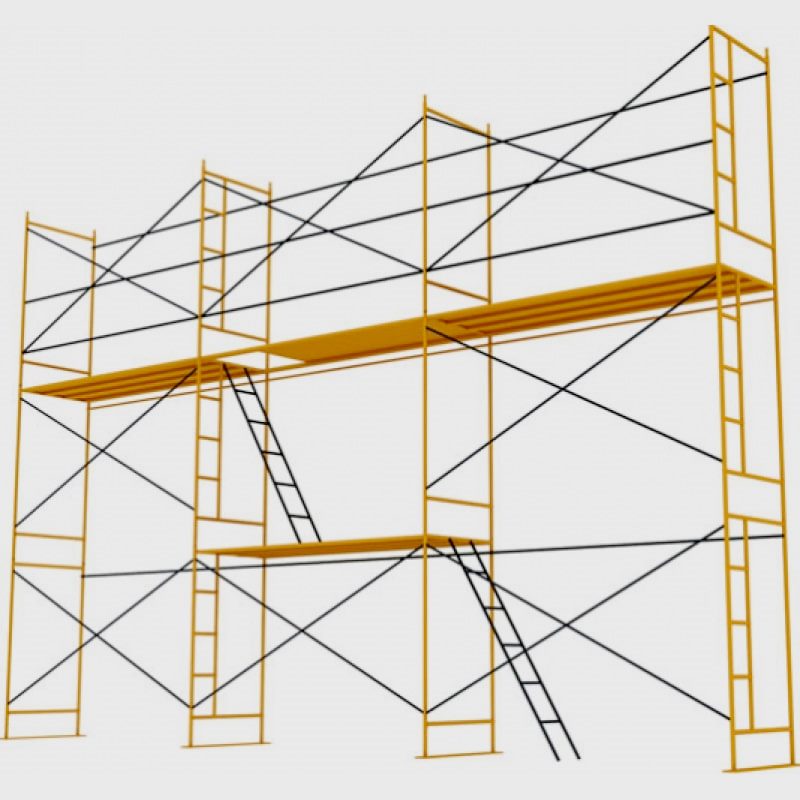

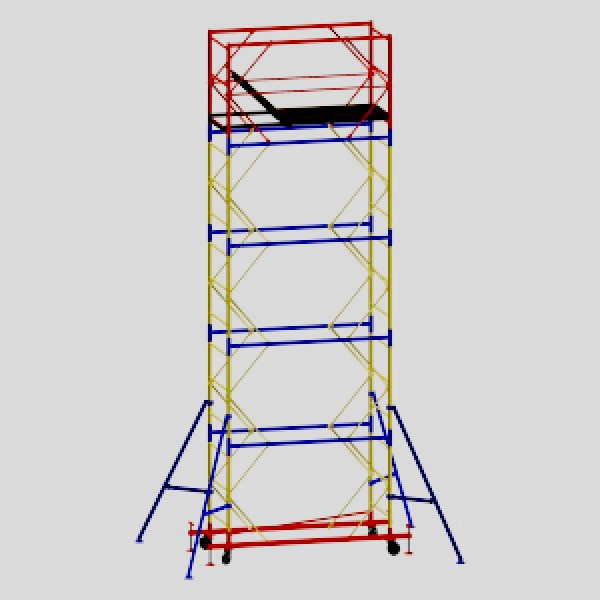

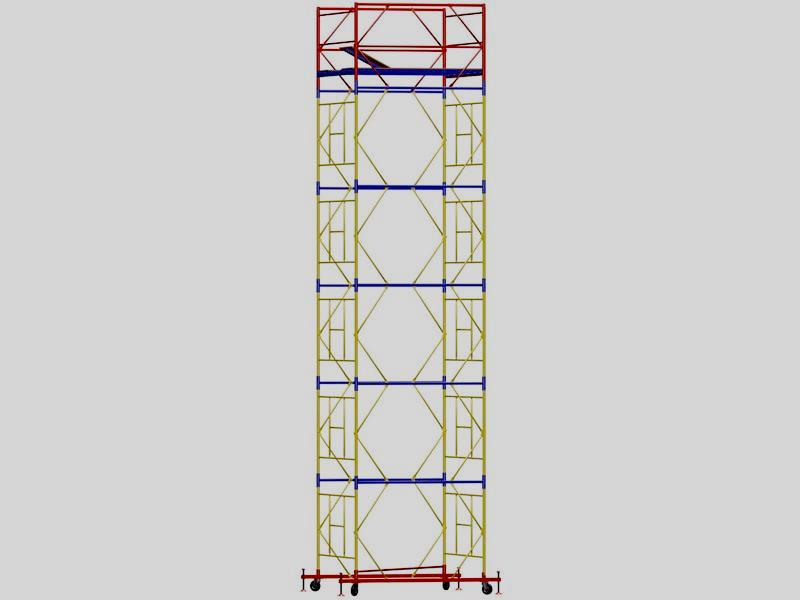

Towers - tours

Irreplaceable assistants during construction and installation manipulations. They are tower structures with stairs for movement. Sections are formed by means of a pair of parallel stairs. To increase the degree of rigidity of products, locks and beams are used. For installation, a special frame is provided, equipped with wheels and jacks. The device is characterized by a high level of reliability, mobility, ease of installation, compactness. There is no need for its installation to make the surface perfectly flat. Thanks to the presence of jacks, the structure can be easily and simply leveled.

The main structural elements are:

- frame;

- special mounts;

- ladder rungs;

- diagonal connections;

- horizontal frame;

- special flooring.

Some popular models are additionally equipped with a sunroof. The base is made of durable metal. Towers differ in the mechanisms of movement. Designs are produced that move with the help of special support paws. They rise, after which the device is installed in a new place, after the paws are lowered and fixed.

The advantages of towers include:

- They can accommodate all the necessary tools, materials and equipment.

- Transportation to the destination is carried out in a small truck.

- For installation, you do not need to make the site perfectly flat.

- Speed and ease of installation and dismantling.

- No need to involve specialists in the construction.This can be done on your own, without helpers.

- Assembly tools and equipment are not required.

- Versatility. Designed for use during any manipulation.

- Practicality.

- Reliability.

- Safety.

- Strength.

- Compactness.

- Mobility.

- Acceptable price.

- You can buy both at a specialized outlet and order online in an online store.

- Best for short term jobs.

As disadvantages, it is possible to note the performance of work at a height of no more than 20 meters, a small carrying capacity, and a limited working area.

Scope of use of towers - tours:

- carrying out finishing manipulations on any object;

- restoration of facades;

- erection of buildings;

- participation in the maintenance of logistics complexes;

- when carrying out repairs on large high-rise buildings and structures;

- installation and dismantling of scenery, exhibition equipment.

How to choose

The range of forests is so large that you can get lost in the diversity. Specialized outlets will offer a choice of goods of domestic and foreign production, household and industrial, made of steel and wood, with a folding mechanism and without a folding mechanism. Everyone has different selection criteria. Which product is better to buy depends primarily on its scope of use. What should you pay special attention to during the buying process?

Experts advise not to lose sight of such characteristics:

- Fixture options.

- Load capacity.

- The maximum allowable application height.

- Distance between adjacent tiers.

- Flooring width.

- What is the pitch of the vertical support posts.

Of no small importance is the material of manufacture and the type of fasteners. If you have to work at a low height, then you can purchase frame structures or towers - tours.What is the best product to buy for work at high altitudes? Definitely, pin, hanging or wedge-shaped scaffolding. When it becomes necessary to repair domes or arches, to carry out repairs on buildings with complex architectural forms, it is better not to find collar scaffolding.

Which company is better to buy depends on personal preferences. According to users, it is not worth overpaying for a promoted foreign brand. A review of the presented novelties shows that Russian enterprises produce reliable and safe structures at an affordable price.

Rating of high-quality inexpensive forests

LRSP-250, d-32 mm

votes 1

Goods from a domestic manufacturer. Lightweight option. Flooring is not provided. The manufacturer provides a six-month warranty for its products. Belongs to the frame category. In the manufacture of strictly observed TU. Elements with a diameter of 32 mm. Length - 24 m, width of the tier - 0.7 m, length - 400 cm. Maximum allowable load - 250 kgf / sq.m. Between the frames, a step of 300 cm. Purchased to perform plastering and finishing manipulations at a height of no more than 20 meters. Assembly rules and operation features are defined in the attached passport.

How much does the product cost? You can buy it at a price of 26,900 rubles.

- strength;

- safety;

- stability;

- practicality;

- functionality.

- missing.

LRSP/250, 16*3

votes 1

Scaffolding is produced by a Russian company. In their manufacture, TUs are taken into account. Belong to the category of frame, attached. The overall weight is small. Consists of elements with a diameter of 32 mm. An ideal assistant when carrying out finishing and plastering manipulations on buildings whose height does not exceed 20 meters. Dimensions - 16 * 3 meters. The distance between the tiers is 200 cm.The platform will withstand a load of 250 kgf / sq.m. There are no floorings. Where can you buy products? Any specialized outlet.

The purchase price is 23,120 rubles.

- positive user reviews;

- convenient in operation;

- easily and simply assembled and developed;

- can be transported to the destination in a small truck;

- manufacturer's warranty - 6 months;

- acceptable cost.

- not identified.

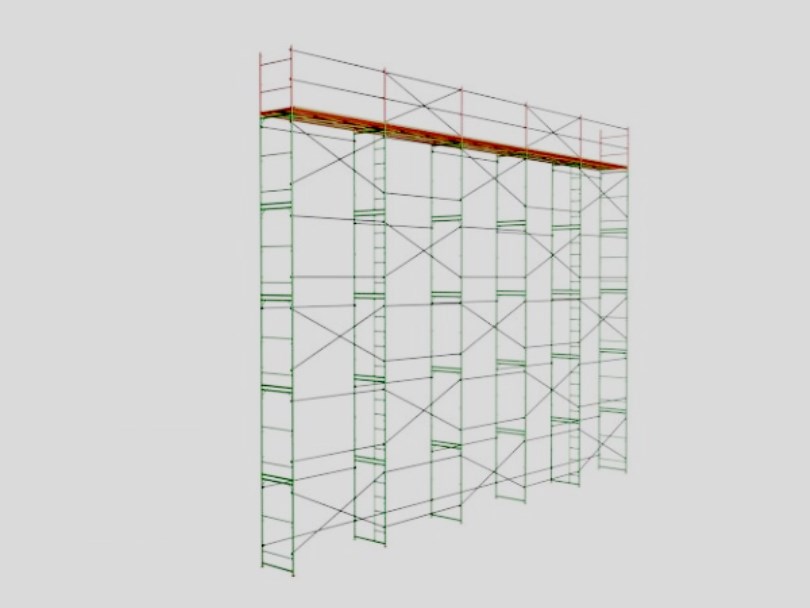

LRSP/250, 8*12

votes 1

Convenient lightweight design from a domestic manufacturer. There is no flooring included. Parameters - 8 * 12 meters. Consists of elements with a diameter of 32 mm. The frame attachment is manufactured in accordance with the specifications. The manufacturer guarantees the reliability and good quality of products. Installation and operation is carried out in strict accordance with the product passport. It will help to carry out plastering of buildings and finishing manipulations at a height of no more than 20 meters.

The average price is 29480 rubles.

- not expensive;

- universality;

- practicality;

- ease of assembly;

- ease of use;

- reliability;

- durability;

- guarantee of the quality of the materials used.

- not installed.

LRSP/300, 2*3 m

votes 1

Can't decide which company is better to buy products? Pay attention to this model. The device can be safely attributed to the budget category. The functionality is minimal, however, it will become an indispensable assistant in carrying out construction and repair manipulations, such as laying bricks, installing facade systems, painting walls, ceilings, finishing, and so on. The frame is strong and reliable.

Made from quality steel. The weight is small. Install fairly quickly. There is no need to attract a specialized team for these purposes.Elements are reliably protected from corrosion by powder coating. The frame is connected pipe to pipe. Fastening is carried out by means of flag locks.

A distinctive feature is that they are simply combined with clamp models for performing manipulations on atypical buildings. The number of components is minimal. Assembly requires no tools or equipment. It is implemented with several flooring options: for facade work (withstand a load of 200 kg / sq.m.) and for brickwork (maximum allowable load - 400 kg / sq.m.). The width of the tier is 1 meter, the step is 2 meters. Pipe diameter - 42 mm.

The average price is 4310 rubles.

- the strength of the crossbars;

- stability;

- reliability;

- long service life;

- practicality;

- safety;

- functionality;

- universality;

- value for money.

- missing.

LRSP/250, 6*24

votes 0

The design consists of pipes with a diameter of 32 mm. Flooring is not provided. When purchasing a product, the buyer is issued a product passport, which specifies the rules for assembling and operating the device. Differs in universality. With its help, you can quickly and efficiently finish and paint ceilings and walls, lay bricks and repair the facade. Made from durable steel. On top there is a powder anti-corrosion coating.

Flag locks act as latches. The principle of connection is pipe to pipe. There are not many components, you can cope with the assembly yourself, without the involvement of assistants. Additionally, you can purchase flooring for laying bricks or carrying out facade work. They differ in the maximum allowable load. Ideally combined with clamp scaffolding.

The purchase price is 8470 rubles.

- quality assurance from the manufacturer;

- anti-corrosion coating;

- ease of use;

- functionality;

- safety;

- reliability;

- ease of assembly;

- acceptable price.

- not installed.

LRSP/300, 6*3

votes 1

The total weight of the structure is small. Assembles quickly. If you have any difficulties, you can use the attached product passport. Differs in reliability and durability. The device is made of durable steel. An anti-corrosion powder layer is applied on top. The scope of use is extensive - facade, finishing, construction work on any objects, whose length does not exceed 20 meters. It can be installed both outside buildings and inside. To connect pipes, flag locks are used. Are operated with two types of floorings: front and for a bricklaying.

The purchase price is 12,300 rubles.

- practicality;

- universality;

- light weight;

- compactness;

- wear resistance;

- long service life;

- ease of transportation and installation.

- not installed.

Rating of scaffolding in the middle price segment

LRSP/250, 6*24

votes 0

Lightweight construction consisting of metal pipes with a diameter of 32 mm. Belongs to the frame category. In the manufacture of strictly observed technical conditions. It is used when carrying out plastering and finishing works. The maximum allowable length is 2000 cm. Withstands a load of 250 kgf / sq.m.

The average cost is 39270 rubles.

- positive user reviews;

- functionality;

- reliability;

- safety;

- stability;

- durability;

- value for money.

- work at a height of more than 20 meters is not recommended with their participation.

LRSP/250, 18*6

votes 0

Lightweight product.The manufacturer guarantees the quality of the products. In the manufacture of high-quality metal is used. Consists of pipes with a diameter of 32 mm. Flooring is not included. Easy to assemble and disassemble. There is no need to resort to the help of specialized teams. It is applied to performance of finishing works and plastering of a surface. The maximum allowable height is 20 meters.

The average price is 40,500 rubles.

- practicality;

- universality;

- long service life;

- manufacturer's warranty - six months;

- positive user reviews;

- sustainability.

- not identified.

LRSP/250, 6*27

votes 0

Metal structure made of pipes with a diameter of 32 mm. Parameters - 6 * 27 m. High-strength metal is used in the manufacture. The own weight is small. Easily installed on site. It is purchased for the construction of structures or for repair work at an object whose height does not exceed 20 meters.

You will have to pay 43,220 rubles for the goods.

- value for money;

- practicality;

- functionality;

- universality;

- durability;

- wear resistance.

- missing.

LRSP/300, 6*27

votes 0

Reliable and durable scaffolding is sold without flooring. They are assembled from metal pipes with a diameter of 42 mm. They allow you to quickly paint walls and ceilings, install facade systems, make brickwork. They weigh a little. The frames are joined pipe to pipe. Connecting elements - flag locks. Few accessories. No tools or equipment are required for installation.

The purchase price is 75,420 rubles.

- wide scope of application;

- safety;

- the quality of the materials used;

- strength of locks;

- manufacturer's warranty - 6 months;

- there are no problems with the acquisition;

- long operating life.

- not identified.

Expensive scaffolding

LRSP/300, 16*15

votes 0

The length and height of the structure is 16 x 15 meters. Made from high quality steel pipes. The total weight is negligible. An indispensable assistant when painting walls and ceilings, laying bricks and other building materials, equipping the building with facade systems, and so on. The metal is coated with a powder anti-corrosion coating. Perfectly combined with clamp fixtures. No tools are needed for installation.

The average price is 111,810 rubles.

- convenient to use;

- easy to assemble;

- serve for a long time;

- high level security.

- not installed.

LRSP/300, 20*12

votes 0

For the manufacture of this model, metal pipes with a diameter of 42 mm are used. The fixture parameters are 20 * 12 meters, which is quite enough for work on a medium-sized object, whose height will not exceed 20 meters. Differs in reliability, durability and small weight. No tools are needed for installation. There are not many parts in the kit. For fastening flag locks are used.

The average cost is 114,020 rubles.

- practicality;

- functionality;

- reliability;

- safety;

- durability.

- missing.

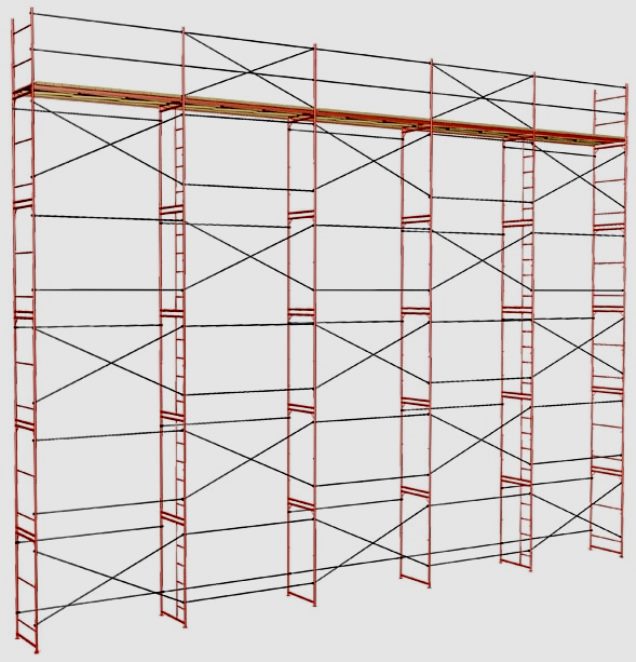

LRSP/300, 18*27

votes 0

Walk-through construction model with dimensions of 18*27 meters, light in weight, but very reliable and durable. In the manufacture of pipes, high-quality metal is used. Flooring is not included.The manufacturer's warranty is valid for 6 months from the date of purchase of the product. It is advisable to entrust the installation to professionals. The metal is coated with an anti-corrosion compound. Flag type locks. It is purchased for bricklaying, installation of facade systems, painting and finishing ceilings and walls. Frame step - 3 m, tier step - 2 m.

The average price is 163,500 rubles.

- excellent combination with clamp forests;

- suitable for finishing buildings with an atypical configuration;

- strong locks;

- durability;

- wear resistance;

- not afraid of chemical influences;

- ease of use.

- not identified.

LRSP/300, 10*27

votes 0

If finishing or facade work is coming, then you won’t find a better assistant. It weighs a little, there are no problems with transportation. They are installed quickly, however, it is advisable to use the services of professionals in this matter. Differ in reliability and long service life. Powder coating of pipes reliably protects them from corrosion. Safety of operation is guaranteed by flag locks. Mounting tools are not required.

The average cost is 122,120 rubles.

- element diameter - 42 mm;

- structural strength;

- durability;

- ease of use;

- positive reviews;

- value for money;

- suitable for work with clamp scaffolding.

- not installed.

Rating of the best towers - tours

BC/250-0.7

votes 0

The model is compact and easy to use. Working height is only 7.5 meters. It is purchased for both indoor and outdoor work. 1 section 1.2 meters high. Moreover, the parameters can be adjusted. The minimum height of the goods is 3 meters.Suitable for both finishing work and installation of ventilation systems. The working platform includes one deck of steel elements. A strong plywood sheet is placed on top.

Pipes are thick, solid, not afraid of chemical influences. Covered with polymer paint. One person can install the tower. There are strong wheels, thanks to which the product can be moved from place to place. Fixing in a new place is carried out by means of special brakes. The maximum allowable load is 250 kg.

The purchase price is 11,500 rubles.

- reliability;

- mobility;

- small sizes;

- light weight;

- quickly installed;

- does not require a perfectly flat area;

- anti-corrosion coating.

- missing.

BC/250-2.0

votes 0

A distinctive feature of the model is a large and wide square working platform with sides of 2 * 2 m. The set includes screw supports. The maximum height is 20.7 meters, the minimum is 2.7 meters. The standard section spacing is 1.2 meters. Supplied with four solid plywood decks. Steel frame. The manufacturer equipped his offspring with a convenient hatch. The product has a certificate of conformity.

The purchase price is 9200 rubles.

- reliability;

- stability;

- designed for 2, 3 or 4 sections;

- durability;

- mobility;

- the quality of the materials used;

- acceptable price;

- speed of installation;

- versatility.

- not identified.

Conclusion

If you have to carry out construction or finishing work, then you can’t do without a tower - a tour or scaffolding. The choice is large enough.On sale you can find designs for one, two, three or four sections, with different load capacities, made of aluminum and steel, with or without additional functions, with a different number of steps, and so on. Everyone chooses a product based on personal preferences. But it is worth paying attention to the reliability, strength, safety and durability of any design. Not only the quality and speed of the work, but also the health of the master depends on this.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131661 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127699 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124526 -

The best men's sneakers in 2025

Views: 124043 -

The Best Complex Vitamins in 2025

Views: 121947 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114985 -

The best paint for gray hair - top rating 2025

Views: 113402 -

Ranking of the best wood paints for interior work in 2025

Views: 110327 -

Rating of the best spinning reels in 2025

Views: 105335 -

Ranking of the best sex dolls for men for 2025

Views: 104375 -

Ranking of the best action cameras from China in 2025

Views: 102223 -

The most effective calcium preparations for adults and children in 2025

Views: 102018