Rating of the best glass cutters for 2025

Professional glaziers perform work quickly and efficiently, skillfully handling a glass cutter, through which glass products acquire neat and even contours. This work requires not only skills, but also the presence of a special device - glass cutters, of which there are a great many varieties.

Content [Hide]

Purpose

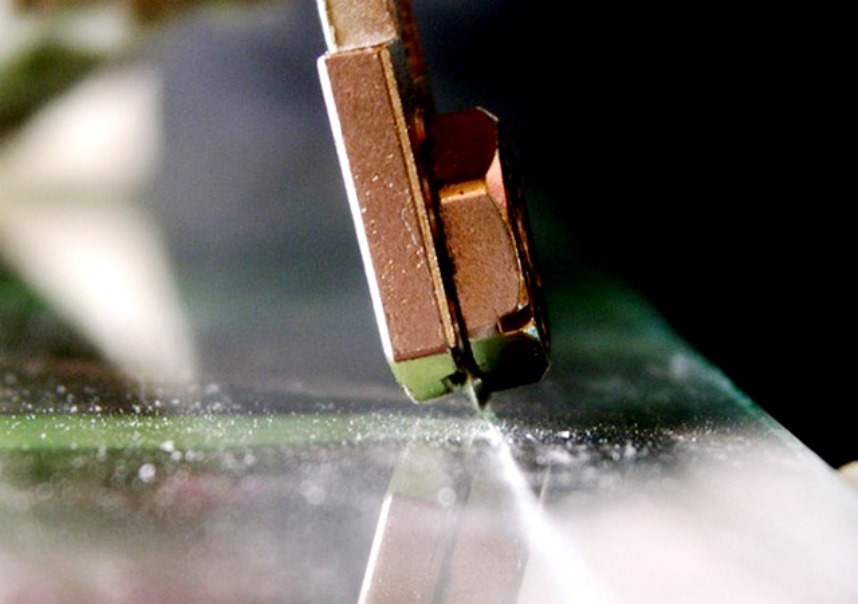

Whatever the object is used: a semi-automatic table for cutting glass or a manual device, the essence of their functioning is the same - applying a direct scratch to the surface, along which a fracture occurs in manual mode. In addition to glass, popular models successfully cope with tiles, ceramics, corrugated glass base.

When working with corrugated glass, the cut is made from the smooth side. It is not recommended to cut tempered glass. The slightest damage leads to their crumbling into tiny particles.

Description and characteristics

The simplest devices have the following structural elements:

- handle with a tube (connecting rod);

- head, visually resembling a hammer;

- mandrel with a cutting working element.

Based on the type of head attachment, there are such types:

- Rotating mandrel capable of drawing curved lines.

- Fixed plan tool.

An artificial diamond crystal acts as a cutting element. There are two versions of the crystal, differing in shape:

- Cutter with curved surface.

- A cutter resembling a four-sided regular pyramid in shape.

Models with such cutting elements are usually called diamond. If the device is equipped with rollers for cutting, then they belong to the roller category.

The classic version - on the head there are one or more grooves of various widths. There are popular models with grooves on a small bar attached to the handle shaft. Thanks to such recesses, the glass edge breaks off. The grooves help remove excess material if the break did not occur at the markup.You can also use special tongs or pliers.

Manufacturing materials

In the manufacture of the handle is used:

- phenoplast;

- polystyrene;

- dense tree species;

- other materials with similar mechanical properties.

The remaining structural elements (with the exception of the diamond cutter) are made of alloys and metals:

- Hammer and stem - steel or brass.

- The holder is high quality steel.

- The base is aluminium.

The working elements are made of synthetic or natural diamond, and the first option is almost as good as its natural counterpart in terms of its characteristics. The carbide cutter is made from Pobedit, the carbide rollers are made from cobalt-tungsten alloys.

Options

The standard dimensions of the product are as follows:

- length - 120 mm;

- thickness - 88 mm;

- width - 30 mm;

- weight ranges from 20 to 100 g.

Cutter in the form of a pyramid 22 mm long, curvilinear - 16 mm, in accordance with GOST.

The maximum glass thickness for natural diamond to function is 10 mm. The rollers in the models of the same name have different diameters, however, 6.6 mm are considered the most common and in demand.

Other options:

- cutting depth (max) - 5 mm;

- sharpening angle - 100 degrees.

There are models with the function of oil cooling of the rollers, a sharpening angle of 150 degrees (used for cutting thick material of 20 mm) and 135 degrees (works with a maximum thickness of 10 mm).

Resource and marking

Manufacturers even for the best models provide a guarantee of one year from the date of sale. However, there are other indicators as well. So, a diamond device is able to cut up to 12000 m. material. As for roller species, the maximum resource is 350 m.

The marking of diamond tools shows the orientation of the working edge. Products intended for import have applied diamond chips, the mass of which is indicated in carats. The hammer is engraved with the manufacturer's own trademark. The best manufacturers participating in the rating of quality goods apply the appropriate marking to the product.

What are

Tools differ in design features, and therefore they are divided into the following types, the differences between which are indicated in the comparative table:

| Varieties | Description |

|---|---|

| Diamond | A diamond crystal of a natural or synthetic type acts as a working element. During operation, it gradually wears out. It comes in two types: the curved cutting edge is more suitable for beginners, while the pyramidal shape is preferred by professional glaziers. With slight wear, it is possible to lap on a bar using mastic with diamond dust. The maximum resource is 10000 running meters. The average price is 1500 rubles. |

| victorious | Roller models, the cutter is made of Pobedit. Visually does not differ from the previous version, but at a lower price. The functionality is not so extensive. It is used for domestic needs, and then rarely. The main disadvantage is the rapid blunting of the carbide cutter, the result is a poor-quality groove. Product reviews are negative. |

| Roller | Popular with both beginners and professionals. The cut is made by means of a rotating roller. Specialty stores offer a choice of six, three and one roller options. Rarely, but there are two-roller with a plastic case. They are budget options.Tools with a steel wheel are sold at a price of 700 rubles, the most inexpensive ones with a minimum resource can be purchased for 90 rubles. |

| Oily | Roller model, equipped with a small reservoir for filling oil that falls on the cutting element during operation of the device. A hollow handle is often used as a reservoir. Differs in the high operational term and smoothness of movements. Resource - 5000 linear meters with a maximum material width of 20 mm. The product is sold at a minimum price of 160 rubles. |

| Glass cutter - compasses | Used for cutting round shapes. Based on a circular mechanism. A suction cup acts as a support, thanks to which the tool is attached to the surface. Other structural elements: cutter and scale. |

| Circular | Designed for cutting ovals. Thanks to the two centers, it is possible to move along a complex trajectory. The cost exceeds 1000 rubles per unit. |

| Special | It is used to obtain glass circles with a minimum diameter in industrial volumes. The appearance is original - a flat design with a bar and a cutter equipped with locking elements to avoid shifts. There is a convenient "G" - shaped handle. |

How to choose

Specialized retail outlets offer a wide range of glass cutting products. On the shelves you can find novelties from the world's leading manufacturers, leading the TOP of modern products and inexpensive Chinese-made options with a minimum resource. Where to buy and which company is better depends on the preferences of the master. However, there are basic selection criteria that must be taken into account in order to avoid mistakes when making a final decision:

- Thickness and type of material to be cut.

- Volume of work.

- Master's professionalism.

- How much does the tool cost.

What to look for when choosing a tool for the home? The expert advice is:

- If you have to assemble a furniture set, you should not look for expensive industrial goods that top the list of high-end tools used in large-scale real estate construction.

- There is a large amount of work with high requirements, and there is no experience, it is better to seek help from professionals. They work with their tools and you can make a claim if a marriage is found.

- When carrying out repairs, the main thing is to use convenient devices. Pay attention to the ergonomics of the handle. According to buyers, the most convenient are wooden options that do not slip and lie comfortably in the hand. A device with a metal case may have roughness and bumps.

- Experience with various devices. If you preferred to use roller models, then you should not switch to diamond ones.

- Pay special attention to the quality of the videos. They shouldn't hang out.

- Which one is better to buy? Only a high-quality and reliable product. Before paying for the goods, you should ask the sales manager to demonstrate the device in action. Pay attention to the notch parameters of oil and diamond tools. It should be very thin, almost invisible. Roller models should function quietly, without creaking, crackling a little.

Before visiting construction markets, review the products offered, select the best option. You can order goods from China using the Ali Express delivery service. Those who prefer to purchase devices in the online store can place an order online.So you can save a little on the price of the goods.

Rules for working with the tool

The efficiency of the glass cutter and the receipt of a minimum amount of waste directly depends on the correctness of the actions. Let's dwell on the main nuances:

- The glass is pre-cleaned and dried, laid on a flat horizontal surface, covered with a piece of thick fabric for softness.

- A cutting plan is prepared and depicted on a piece of paper.

- A ruler or template is taken and pressed tightly against the sheet.

- The glass cutter is held by the base of the handle.

- A line is drawn without pressure, starting from the far edge. Using a diamond model, you get an almost invisible feature. Roller will make a deeper groove. The action is done once. If a mistake is made, the sheet is turned over and a line is drawn on the other side.

- The final stage is the fracture of the surface. Produced with gloves. To simplify the process, it is worth gently tapping the mandrel on the back of the sheet. The sheet is laid on the table so that the cut line coincides with the edge of the table top. A sharp movement should lead to a qualitative breaking off.

- The smoothness of the edge is provided by a special drill with a grinding nozzle clamped in the chuck. Work is carried out exclusively in protective glasses.

Rating of the best glass cutters for 2025

Diamond

FIT 16932

votes 0

Found application in the professional sphere and in everyday life. Designed for cutting glass surfaces. Suitable for stained glass. It has a significant resource of use - 4500 m. The diamond component is subject to sharpening, which improves quality and accuracy. In the manufacture of the holder, high-quality tool steel was used. The handle is made of wood.

The average price is 306 rubles.

- great resource;

- quality;

- ease of use;

- reliability;

- high speed;

- build quality.

- significant have not been established.

Kraftool Silberschnitt 33677

votes 1

Oil device. The cutting part is made of tungsten carbide. The main difference is noteworthy strength and reliability. In the manufacture of the head, nickel-plated steel was used, the handle is brass, there is an abrasive coating. Works with material 12 mm thick.

The average cost is 3129 rubles.

- resource 50000 m;

- effective;

- professional;

- convenience of the handle;

- oil is supplied automatically;

- cutting accuracy;

- complete with case;

- strength of the manufacturing material.

- significant cost;

- no grooves for breaking glass;

- it is difficult to determine the amount of oil in the container.

Russia 87225

votes 1

The product of a Russian manufacturer has good characteristics and an affordable price. The head is steel, chrome-plated, the handle is made of plastic. Weight - 0.3 kg. Cutting depth - 5 mm maximum. Works great on window glass.

Sellers offer products at a cost of 217 rubles.

- high strength;

- comfortable to hold;

- long service life;

- convenient to use.

- large head size closes the full view;

- the cut is only straight, figured quality does not work.

Brigadier Extreme

votes 0

Enjoys well-deserved popularity among professional glass cutters. Heads the TOP of diamond models. In the production of the head, hardened steel was used, a wooden handle, varnished. The cut is made with synthetic diamond. Product length - 180 mm. The case is equipped with special grooves that allow you to break off the edges with high quality.

The average price is 524 rubles.

- reliable fixation of the cutting element;

- excellent functionality;

- easy to use;

- cut evenness;

- functions in any direction;

- long service life;

- safety.

- the handle slides;

- storage is provided exclusively in a case;

- significant price;

- The handle may break if pressed too hard.

FIT 16930

votes 0

Canadian development, produced in China. A distinctive feature is the presence of industrial diamond at a certain angle. It is used for cutting material with a thickness of 5 mm. The manufacturer provides 5 grooves for high-quality breakage of the surface with different sections. The wooden handle fits comfortably in the hand.

The price of products is 421 rubles.

- quality of work;

- significant strength;

- long resource - 50000 m;

- comfortable to hold;

- can be used both for domestic needs and in production;

- quality grooves;

- durability;

- excellent combination of price and quality.

- insignificant depth of cut;

- weak fixation of the diamond;

- the possibility of grinding a wooden handle.

Roller

FIT 16921

votes 0

The Canadian company has launched the production of high-quality glass cutters with noteworthy features. A strong steel head and a special screw make it possible to make high-quality fixation of the axis position. The plastic handle is equipped with special recesses for comfortable holding by fingers. Brass inserts minimize the possibility of device slipping. The maximum cutting depth is 8 mm.

The average price is 451 rubles.

- excellent cutting ability;

- the flask for oil is transparent, which allows you to control its volume;

- convenient to use;

- used for professional purposes;

- anti-corrosion properties of the material;

- long service life;

- reliability.

- equipped with one roller;

- the possibility of breaking the plastic handle;

- the head is fixed poorly;

- needs a special storage case;

- overpriced.

Bohle Silberschnitt

votes 0

Excellent German model for professional work. Single-roller device with a resource of up to 5000 m. The maximum cutting thickness is 6 mm. He enjoys authority among experienced glass cutters.

The average cost is 375 rubles.

- comfortable handle;

- comfortable to use;

- excellent cutting qualities;

- reliable;

- quality assembly;

- made from quality material.

- one roller;

- lack of grooves for breakage;

- the worn disc is not changed, the tool is thrown away.

Sparta 872235

votes 0

Budget version of the Chinese glass cutter. There is a drum with spare rollers in the amount of six pieces. A small margin involves cutting only 300 m of glass. Metal head, wooden handle. Cutting depth - up to 5 mm.

The average cost is 214 rubles.

- combination of price and quality;

- the handle is comfortable to hold with the palm of your hand;

- ease of operation.

- the head may loosen;

- margin of safety is insignificant;

- only direct movements;

- low quality model.

Truper CV-5, 12953

votes 0

The Mexican all-metal tool differs from similar products in its significant strength, reliability and long service life. It is almost impossible to break or damage it. The maximum cut is 8 mm. The handle has a special ball for tapping on the surface.The head is equipped with three grooves for breaking off small glass pieces.

The manufacturer offers goods at a price of 557 rubles.

- reliability;

- durability;

- strength;

- small dimensions;

- inexpensive.

- long incisions are excluded;

- too light weight;

- the handle can slip and is uncomfortable to hold;

- not used for industrial purposes;

- poor quality of work.

Stanley 0-14-040

votes 0

High-quality American device for cutting glass at home. Differs from analogues in the presence of six tungsten rollers. After blunting one of them, you can use the other, after turning the drum over. Nickel plated to prevent rust. The lacquered handle is made of durable wood.

The average cost is 689 rubles.

- fits comfortably in the hand;

- does not slip;

- comfortable;

- light;

- durable;

- reliable;

- can be used as a tile cutter - pencil;

- excellent cutting characteristics;

- insignificant price.

- large volumes are not able to master;

- shallow incision depth - up to 4 mm.

Biber 55531

votes 0

The tool is easy to use and efficient. There is a dispenser for filling with kerosene or spindle oil, which allows you to quickly and easily carry out this work. Equipped with a carbide cutting element, giving it strength and durability. Weight - 0.05 kg, plastic handle, one cutting element, no circular function.

The average price is 178 rubles.

- easy to operate;

- comfortable;

- qualitative;

- effective.

- significant ones are missing.

Matrix 87264

votes 0

A small tool is able to master different surface thicknesses, working at different angles. The hollow handle is designed for filling with oil or kerosene. The cutting element is made of VK-8 (hard alloy). Makes only straight lines, there is no possibility to draw circles.

The average cost is 292 rubles.

- strength;

- durability;

- reliability;

- ease of use;

- light weight;

- effective;

- significant working resource;

- head of a special shape that allows you to work at any angle;

- two-year warranty;

- optimal dimensions.

- significant have not been established.

Stayer Profi 33692

votes 0

The oil roller model of the German brand, however, is made in China. It is used for cutting glass surfaces with a thickness of 2 to 10 mm. Differs in a practicality and convenience. Due to the all-metal construction, it has a long service life.

The price of the goods is 489 rubles.

- the presence in the kit of a special dosed flask;

- durability;

- strength;

- convenient dimensions;

- spring-loaded head;

- roller version;

- used in industry and at home;

- reliability;

- significant resource.

- significant ones are missing.

Sturm 1077-OL-01

votes 2

Roller oil device with integrated oil reservoir in the handle. In the manufacture of the handle, high-quality impact-resistant material was used. Parameters: 235 x 62 x 14 mm, weight 0.06 kg. The brand comes from Germany, production is located on the territory of the Celestial Empire.

The average cost is 166 rubles.

- durable construction;

- 25 months warranty;

- reliability;

- convenient length of the product;

- durable plastic case;

- efficiency;

- performance.

- significant have not been identified.

Circular

Circular Glass Cutter

votes 0

For quality work, experienced glass cutters prefer to deal with professional devices, because mistakes cannot be made. There is only one attempt to cut a circle in thin glass or ceramic tile. Otherwise, you will have to purchase another sheet. Ordinary glass cutters are suitable for straight cutting. To draw a circle, you need to purchase a special device - a circular glass cutter.

Despite the simplicity, the design is very well thought out. The metal ruler is equipped with a rubber suction cup, which is necessary for fixing in one place. A glass cutter is mounted on the ruler, which moves freely along the entire length. Using the provided handle, the tool is fixed at a certain division of the ruler, the maximum length of which is 20 cm.

The product is sold at a price of 731 rubles.

- used in both horizontal and vertical position;

- works with surfaces of different thicknesses;

- easy to use;

- reliable;

- allows you to cut any configuration;

- optimal scale;

- used both at home and in industrial enterprises;

- light weight;

- convenient dimensions;

- safety.

- missing.

Hasal 308.25/308.50

votes 0

Professional compass - glass cutter with adjustable cutting angle. Cutting diameter - 95 - 500 mm. Widely used for cutting double-glazed windows. The product is manufactured by a Turkish company with a worldwide reputation. Differs in reliability, durability, convenience in use.

The average cost is 9758 rubles.

- applied on an industrial scale;

- long service life;

- safe;

- quality;

- efficiency;

- good combination of price and quality;

- essential resource.

- significant have not been established.

KD, art. BLD(R)

votes 0

A professional hand tool is used for cutting substantial circles of 10 - 200 cm. Produced by a Chinese company. Equipped with suction cup, square profile measuring rod, large capacity for cutting fluid. Works with glass thickness from 6 to 12 mm.

The average price is 4047 rubles.

- reliability;

- efficiency;

- long service life;

- safety;

- quality;

- significant resource;

- durable material of manufacture;

- convenient to operate.

- significant were not found.

Conclusion

Before becoming a happy owner of a new tool, it is worth deciding what characteristics it should have, how durable and reliable it should be. If the device is used quite rarely and exclusively for domestic needs, then you can opt for inexpensive roller models. They are convenient, comfortable, easy to use, suitable for both beginners and experienced glass cutters.

On an industrial scale, it is best to cut glass surfaces with a professional product that allows you to maintain maximum accuracy and quality of work. For these purposes, the most suitable option would be expensive diamond glass cutters. Oil models can be used as an addition to professional equipment for drawing small lines.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131654 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127694 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124522 -

The best men's sneakers in 2025

Views: 124039 -

The Best Complex Vitamins in 2025

Views: 121943 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114982 -

The best paint for gray hair - top rating 2025

Views: 113398 -

Ranking of the best wood paints for interior work in 2025

Views: 110321 -

Rating of the best spinning reels in 2025

Views: 105332 -

Ranking of the best sex dolls for men for 2025

Views: 104370 -

Ranking of the best action cameras from China in 2025

Views: 102220 -

The most effective calcium preparations for adults and children in 2025

Views: 102014