Rating of the best cold forging machines for 2022

Blacksmithing is a complex physical labor that requires the use of special equipment, and the master must have specialized skills and knowledge. However, for the manufacture of some finished metal products, it is enough just to bend the workpiece at the required angle. Any deformation of the metal can be applied without heating the latter, i.e. in a simple mechanical way, which is called cold forging (it is also “gentle processing”).

Content

Cold forging technology

Its main difference from traditional metal processing is that the latter does not require heating, although heating of small areas in which it is planned to bend is allowed. The principle of this technology is based on the ductile qualities of the metal, so calling this operation “forging” is not entirely correct (during forging, both the shape of the workpiece and its cross section change at the same time).

Any material has tensile, tear and bending strengths. One category of metals is able to resist bending, while the other can twist and stretch without loss of quality. It is these properties of metals that are used in cold forging technology, i.e. when processing workpieces by pressure without heating. All work is carried out by means of a system of levers, which significantly optimizes the applied muscular efforts of the operator.

As a result of pressure testing, in places of impact, the structure of metals becomes very strong, compacted.Due to the fact that high temperature treatment is not used, there is no change in the quality characteristics of the materials. Accordingly, there is no need for finishing firing or final hardening of the products. For cold forging, metals with proper ductility and toughness are perfect, which include:

- Low-carbon rolled steel;

- Aluminum;

- Bronze;

- Copper.

After bending, there is no residual stress in these metals, which can contribute to their rapid destruction. Cold forging technology is used to produce:

- Lampposts;

- garden furniture;

- Balcony and window grilles;

- Decorative decorations for the facade;

- Openwork fences.

IMPORTANT! Separate elements created using cold forging can be assembled into a single artistic composition, but this operation already involves the use of a welding machine.

Artistic and cold forging is the essence of technology

By and large, cold forging is one of the methods of artistic forging, i.e. is a decorative item. Its main difference is the absence of the need to heat the processed material. For example, for the manufacture of a forged gate, neither a burner, nor a heater, nor a forge, nor a muffle furnace will be needed. However, practice shows that in order to create works of art, one has to combine hot and cold methods. For the same gate, it is possible to produce several separate parts in a cold way, but for the manufacture of a “goose foot” (locking device), hot plastic deformation of the element will already be required, which can be done in a stamped form or on a rolling machine.In everyday blacksmithing, it is the combined technology that is most often used, although up to 90% of all artistic forging operations can be performed in a cold way.

Areas of use for cold forging

The considered blacksmithing method has been and will be in demand at all times. It can be used to decorate fences for country residences, for the manufacture of window grilles in prefabricated houses, for the production of artistic elements of street design. Most often, cold forging machines are used in:

- furniture industry;

- Engineering industry;

- Production of construction equipment.

For any of the above industries, the presence of a couple of such machines is typical. For a small business or home workshop, it is quite possible to get by with one manual type machine with universal functionality.

Advantages and disadvantages of "gentle processing"

The popularity of this technology can be explained by several reasons, which include:

- Cheaper production process, because there is no need to purchase and use equipment for heating;

- After processing, the product almost immediately acquires its final presentation and does not require final hardening;

- The ability to obtain the most identical elements - they can be very easily adjusted to a single template;

- The resulting metal structures have increased strength.

The disadvantages include:

- The need to apply sufficient muscle effort during work, because. unheated metal is more difficult to bend;

- Large objects will require the use of powerful machines in order to ensure proper pressing efficiency;

- The impossibility of processing durable sheet metal (the so-called "blanks");

- The need for complete cleaning of the object before processing.

The cold forging process has clear economic advantages, as there is no need to create a real forge with a furnace, which is an expensive and troublesome business. But the shortcomings of the cold method can hardly be called insurmountable.

Modern cold forging machines

This equipment is of several types and it is almost impossible to find one universal unit. Therefore, before acquiring it is better to decide on future tasks.

- "GNUTIK"

This is the basic machine for artistic forging, it is on it that most amateurs begin to master blacksmithing. The device is as simple as possible to operate, however, it has a significant drawback - there are very few options for creating products. It is suitable for forming an arc or ring, bending the workpiece at the required angle, but it is impossible to perform a curly fold on it.

- "WAVE"

The name of this machine speaks for itself and it is designed to give a metal workpiece a wave-like shape. Not a very inventive device, consisting of rollers and rollers, on which the workpiece is pulled manually.

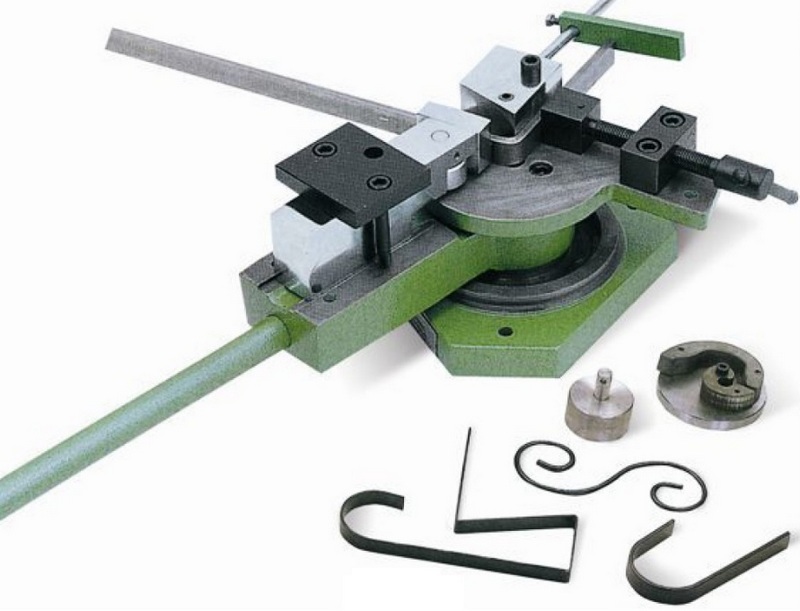

- "SNAIL"

Such a device is most often used in blacksmithing and its device has an average level of complexity. Due to its twisted design, it allows you to create spirals, curls and other complex elements from iron rods. Such forms are very difficult to make by hand, because you have to make a lot of physical effort. There are two versions of the machine - mechanical and electric.

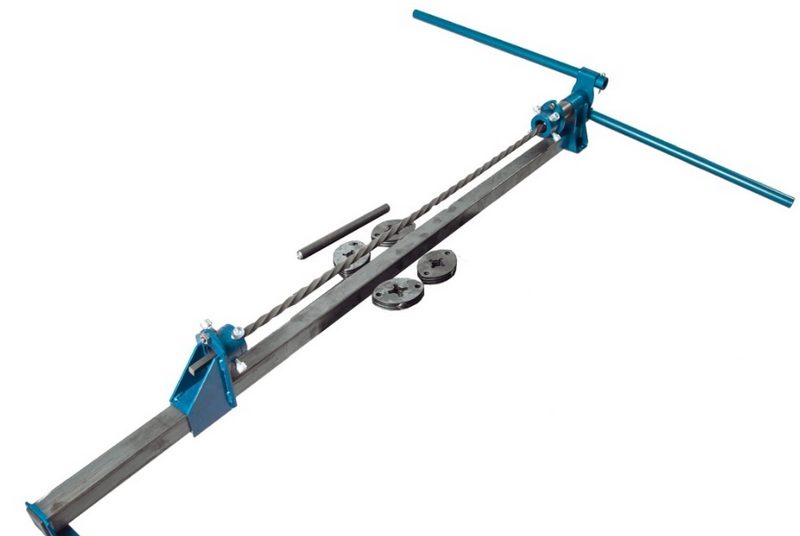

- "TWISTER" (Flashlight)

These nicknames denote a torsion bar with a simple design. It assumes the presence of two clamps that are opposite each other.On one side there is a mechanism for turning, which performs the main function of bending. An iron rod is inserted between the clamps, after which the mechanism is scrolled by the user. The result will be a twisted workpiece.

- "THE GLOBE"

This machine is very similar in its functionality to the "Snail", but the action is performed in a different way. A metal bar is fixed on one side of the machine, and then manually rotated and ends up on the other side. Thus, the workpiece acquires the same bent shape.

IMPORTANT! When choosing a machine for certain operations, you should take into account its power and correlate its size with the dimensions of the workpiece to be processed. Some models simply will not be able to bend a rod that is too long or too thick.

Basic operations of "gentle processing"

These may include the following processes:

Twisting (torsion, torsion) - this operation is a longitudinal twisting of the workpiece (both in separate sections and along the entire length), while the workpiece is subject to rotation along the axis relative to each other;

- A snail (spiral, volute, curl) is the basic and most popular element in forging, which consists in the rotation of a bar (square, other type of material) around a special mandrel template, through which the desired shape of the object is formed.

- Lanterns (cones, blacksmith's baskets) - during this operation, by means of longitudinal twisting of four blanks of uniform length (squares or rods), it is possible to obtain a three-dimensional artistic and decorative element.

- Bending - with the help of this action it is possible to give an object or its part a special angular shape.The execution mode can be both hot and cold, which will depend on the thickness of the workpiece and the grade of the profile. Bending can be carried out in special equipment, on different dies and mandrels, in special fixtures, and even in a standard vice. The result of the action will be the bending of the workpiece at different angles, the execution of arcs and rings, irregular hooks, as well as the production of blacksmith waves and snakes.

- Baluster - this operation involves the implementation of a complex decorative element, which can also be made on a forging press using special stamps. With the cold method, it is performed on several machines at the same time. The final object is used to design railings, balconies, window bars.

- Goose foot (petal at the end of the workpiece, blacksmith's foot) - this action can be performed with the preliminary heating of the object being processed and the subsequent formation of the end in a forging die or on a rolling machine with a mandrel according to the desired configuration.

- Rolling and bending profile pipes - bending at an angle in blacksmithing for the furniture industry or along a radius (in the manufacture of barbecues, arbors, canopies and arches), requires the use of special profile benders or pipe benders. The molding of profile pipes is carried out for the subsequent execution of curls (both procedures are carried out on electromechanical machines).

- Forging leaves and flowers - these procedures can be carried out with or without heating. Today, such elements are made with an automated forging die, however, a blacksmith with a high level of qualification and sufficient experience can also make them manually (even by chasing).

- Decorating connecting points (connecting blacksmith elements) - as a rule, these actions are carried out by welding or stripping the junctions themselves, or using rivets. It is allowed to decorate such places with various clamps (they are made using the method of rolling from steel strips).

- Rolling assortment (decorative) - this operation can also be carried out with or without heating. It is carried out on rolling equipment for stamps with different patterns-decorations. Hand chasing is also allowed.

Difficulties of choice

By manufacturer

This is one of the main points to which you should pay attention. You can buy a cheap device that will not be able to last even a month of intensive work on metal. It’s worth mentioning right away that all the equipment in question is far from cheap. Experts advise that it is better to spend money on a quality unit once than to constantly repair a cheap sample. The leaders in this market segment are European manufacturers - their companies have been operating there for more than 70 years and their equipment is characterized by quality and durability.

By working method

The machine can be electric or manual. For a domestic workload, a hand-held device is naturally the best and most economical option. It is perfect for learning, it allows a leisurely style of work. An electric machine is suitable for experienced blacksmiths who carry out orders on an industrial scale. Moreover, electrical samples with greater power and productivity are able to handle large objects.

By type of equipment

Machine tools can be directional (that is, their functionality is qualitatively limited to a certain range of operations) or universal.The latter are adapted for a variety of tasks. For homework, most likely, you will only need a couple of functions, so for a small workshop it does not make sense to spend money on an expensive unit. If a streaming style of working with large workpieces is expected, then the universal machine will be the best choice.

Features of the operation of cold forging machines

It should be noted right away that most of the work with cold forging machines does not differ in any increased injury risk (the biggest threat is electric shock - and that applies to electric models, for example, damage to the electrical circuit of the device), however, a number of simple rules to follow when working need:

- It is always necessary to carefully check the strength of the fixing of the workpiece in the grooves of the device, because the object being processed may turn out to be of an irregular shape or even damage the device itself;

- A small dose of warming up the workpiece before starting work can simplify the whole process, while giving the metal additional useful qualities;

- Sharp movements of the processed object in the grooves should be avoided, for which it is necessary to control each stage of the production process. Failure to comply with this requirement may lead to premature wear of the equipment;

- All rollers and rollers, other rotating components of the unit, periodically require lubrication with engine oil (in order to maintain overall smooth operation).

Equally important is the proper sequence of production steps when forging technological/decorative objects. Each machine has its own operating procedure, which is described in its instructions.

Rating of the best cold forging machines for 2022

Budget segment

3rd place: "Stancraft Gnutik 110123"

This machine is a special equipment for artistic cold forging. It allows you to perform complex types of products with minimal effort. The unit has a welded structure, rigid connections are additionally painted and protected against corrosion. The use of samples and templates speeds up the process of creating three-dimensional products from a metal profile. The machine for cold forging "Gnutik" bends the rod at any desired angle and is designed for the manufacture of arcs, rings with different diameters (with a thickness of 17 cm or more). The recommended cost for retail chains is 7900 rubles.

- Rugged construction;

- The need to apply a minimum of effort;

- Variety of final products.

- Not detected.

2nd place: "Stancraft Torsion + Basket 110122"

This unit is designed to produce more complex volumetric art products in the "forge basket" and "torsion" formats. Simple and intuitive to operate. Recommended for use in home workshops. The device is reliably welded, and all its working units and mechanisms are additionally painted over and protected from corrosion. The recommended cost for retail chains is 8200 rubles.

- Anti-corrosion protection;

- Ability to perform complex artistic elements;

- Adequate cost.

- Somewhat large sizes.

1st place: "For bending curls Blacksmith M3-V1"

Such machine equipment is intended for the manufacture of various forged products (window bars, fences and railings) at home and in small private workshops.A special functional lever, with three long handles, makes it easy and comfortable, with minimal effort, to make various curls and hem ends on the workpiece. The device is characterized by ease of operation and the strength of the basis of the entire structure. The maximum curl size is 26 cm, and the processed material can be: St3 steel, copper, aluminum and other softer metals. The recommended cost for retail chains is 9500 rubles.

- Long service life;

- Ease of use;

- Increased operational stability.

- Some weakness of the support bolt (with intensive use it will be necessary to replace it with a stronger one).

Middle price segment

3rd place: "For the rental of the Blacksmith M06-LX strip"

This equipment is used in the manufacture of various forged products in blacksmithing. A metal strip, with dimensions up to 20x2 mm, is rolled through special figured rollers to obtain a decorative component for clamps. Convenient functional levers with optimal length facilitate the rolling procedure. All components of the device are mechanical, which means safe operation and long service life. The recommended cost for retail chains is 12,500 rubles.

- Stability during the work process;

- Simple control;

- High quality and simple design.

- Not detected.

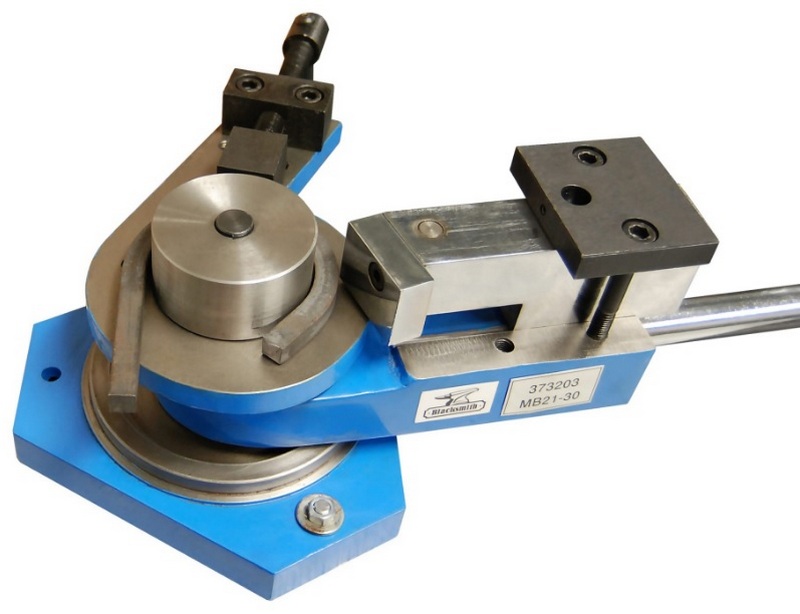

2nd place: "For bending metal and curls Blacksmith MB21-30"

This machine is characterized by ease of operation, it is widely used in blacksmithing for making all kinds of forged elements (fences and gratings, railings and other curly elements). The robust cast construction of the device is covered with paint that prevents corrosion. This sample is also perfect for use by craftsmen at home. The machine is characterized by high-quality workmanship, ease of maintenance and versatility of use. The recommended cost for retail chains is 15,800 rubles.

- Build quality;

- Small dimensions;

- Adequate cost.

- The small size of the working "snail".

1st place: "Universal bending machine TRIOD SBG-30 241034"

Such a universal machine is used for bending curls when creating artistic products of cold forging. Used by blacksmiths or craftsmen to make decorative objects in the manufacture of railings or fences. Has the strong wearproof case which provides high quality of the performed works. The recommended cost for retail chains is 17,000 rubles.

- Small dimensions;

- Quality construction;

- Intuitive operating principle.

- Not detected.

Premium class

3rd place: "Bending machine Proma UO-30 25404000"

This equipment is perfect for bending plates with a small width and thickness. The plate is securely clamped in a vice, and, by means of the rotary part, a bend occurs at a certain angle. A guide rod with an end plate for a stop is installed at the back, which helps to set the processed object in size.When the heated plates are bent, the maximum thickness of the workpiece increases. The recommended cost for retail chains is 27,900 rubles.

- Possibility of bending at a right angle;

- The ability to install almost any radius;

- Working with heated material.

- Not detected.

2nd place: "Universal bending machine TRIOD FBM-120 241022"

A similar device is used for bending rectangular, round and other solid profiles with low hardness. The harder the metal, the smaller the profiles can be bent. Before starting work, the machine must be securely fixed on a stable base. The recommended cost for retail chains is 32,600 rubles.

- Ease of use;

- sustainability;

- Low degree of fatigue for the operator's hands during operation;

- High quality and reliable installation.

- Over time, the bending foot may shift.

1st place: "Forging machine Master Universal 380V in the configuration" Optima ""

This electromechanical machine is designed to perform a wide range of functions of classical and artistic forging (including the cold method). The model is used for the production of most elements (volute and monogram, curl and ring, torsion bar and basket cone, as well as an arc) and decorative rolled products - embossing on a profile pipe and strip, squares and circles. The equipment allows work for twisting and forging with solid rolled products with a cross section of up to 22 mm and with a profile pipe (with dimensions of 40x20 mm), and for rolling - with pipes with a cross section of up to 50 mm, as well as solid rolled products up to 24 mm.The recommended cost for retail chains is 363,000 rubles.

- Completely universal device;

- Production of all classic forging elements;

- Drawing invoices on a profile pipe, a strip, a square, a circle;

- The equipment is characterized by increased power;

- Simplicity and convenience in use.

- Too high cost.

Conclusion

It cannot be said that cold forging machines are very complex equipment - it is possible to learn how to work on them even at home. However, to obtain the proper skills, you should understand the principles of their work, study the material part and strictly follow the recommendations on the production process from the manufacturer. In any case, such machines will be useful both for beginners in blacksmithing, and for private entrepreneurs with a professionally oriented activity, and metal design masters.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131651 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127690 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124519 -

The best men's sneakers in 2022

Views: 124033 -

The Best Complex Vitamins in 2022

Views: 121939 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114980 -

The best paint for gray hair - top rating 2022

Views: 113395 -

Ranking of the best wood paints for interior work in 2022

Views: 110318 -

Rating of the best spinning reels in 2022

Views: 105329 -

Ranking of the best sex dolls for men for 2022

Views: 104366 -

Ranking of the best action cameras from China in 2022

Views: 102216 -

The most effective calcium preparations for adults and children in 2022

Views: 102011