Rating of the best flooring restoration products for 2022

Each floor covering wears out naturally during long-term use, scratches or other more severe damage form on it. However, there are also many ways and means by which you can return the former presentable appearance. As a rule (but not always), methods are understood as actions aimed at the physical replacement of large elements of the floor covering, and with the help of means, surface elimination of defects is allowed.

Content

- 1 Modern types of floor coverings

- 2 Recovery methods

- 3 Means for removing minor defects and scratches

- 4 Painting products

- 5 Means to combat creaking

- 6 Anti-Stain and Darkening Products

- 7 Floor care after restoration

- 8 Restoration of marble flooring as a complex process

- 9 Rating of the best flooring restoration products for 2022

Modern types of floor coverings

All existing options can be divided into two large groups:

- Rolled - these include carpet and linoleum;

- Modular - this group includes coatings laid in separate parts - tiles or dies.

The main problem of restoring roll samples is that it is impossible to replace a single fragment in them. Naturally, if you do not find fault with the aesthetic appearance of the floor, then it is quite possible to apply a patch to the damaged area on the linoleum.If the appearance should play a primary role, then even with minor damage it will have to be completely redone.

Modular ones are significantly easier for restorative procedures, and these include:

- Laminate is a free-standing interlocking floor covering. Its installation takes place according to the type of constructor, when the connection of one part of the fragment is installed in the groove of the other;

- Quartz-vinyl - its installation is carried out either by a lock type (connection in grooves), or on an adhesive basis;

- Parquet board (or parquet) - like the previous model, they can be mounted on an adhesive basis or by means of groove joints;

- Porcelain stoneware (or tile) - different types of glue are used for application - polymer, dispersion, epoxy or cement. However, it will often be necessary to trim the tile elements in order to properly position them in the area (for example, to cover corner joints).

Recovery methods

For laminate

It is very rare for the average homeowner to think that small scratches on a laminate floor need to be repaired. This is fundamentally wrong, because a small scratch can subsequently grow greatly and lead to serious deformation of the floor. In general, the laminated melamine layer is considered an element of its decorative pattern. If this layer is damaged, then, accordingly, this manifests itself in the figure itself. In production, the pattern is applied to paper, which is then glued to the plate. Thus, if there is a scratch, moisture (for example, when washing the floor) will penetrate the paper drawing and simply blur it. In addition, moisture-absorbed paper, as well as fiber-wood flooring, can swell and deform the floor area.

In order to combat cracks in the laminate, special wax pencils, putties or wax are used. The recovery process looks like this:

- It is required to clean the crack (as well as a small space around) from dirt and dust;

- Dry the damage site (you can even use a household hair dryer);

- Apply putty with a small spatula;

- Wait for complete drying and polish with a soft cloth.

With severe damage, this method (like any putty) will not work. As a rule, a laminate mounted on a softened substrate is at greater risk. Such a floor is easily pressed through with studs from women's shoes or legs from furniture. In this case, the only way to restore is a complete replacement of the spot floor element. It is worth noting that it is impossible to remove the lamella from the middle - you will have to sort through the entire close-fitting. And in such a process, the main drawback of the laminate can be revealed - the fragility of its connecting locks, which can break during parsing, after which they can no longer be inserted back.

For parquet boards and parquet

Parquet is considered a durable floor covering, although it was invented a long time ago, it is still popular. However, even with the most careful operation, the material in question wears out. Special methods will help restore the original freshness and appearance of the parquet. For example, with the help of special varnishes it is possible to give the floor a new shine or remove small spots that have formed, or repair small cracks.

Methods and means for repairing parquet

Both parquet and parquet board can last up to one century if they are properly installed and properly cared for.At the same time, the selection of means and methods of recovery must also be carried out very carefully. Recovery procedures are performed by applying special substances to problem areas, which include:

- Lacquer parquet;

- Decorating mastics;

- Construction oils;

- Special wax.

With the help of special oils, it is even possible to restore the parquet board, where the oils will replace the protective layer. The newly created layer will allow the board to “breathe”, and its wear resistance and strength will increase several times.

Parquet care

For quality care, wax putties are often used, which give a natural wood color to the parquet floor along with excellent gloss. The wax itself has excellent water-repellent properties and can be used for pre-treatment purposes and in the restoration of old floors.

Modern types of mastic are used as independent substances for floor care, but can also be used for restoration work. When rubbing parquet flooring with mastic, it will give them a shiny look, while endowing them with protective functions. Thus, the process of wear and rapid contamination is significantly slowed down.

Tips for restoration parquet work

This work will still require certain knowledge and experience. All restorative materials must be used in strict accordance with the instructions. For example, oil can only be used on a parquet board or piece parquet, and it should be applied exclusively with a spatula. Mastics are usually diluted with water, and it is applied by an ordinary mop (or brush) dipped in an appropriate solution.

It is quite possible to remove small scratches with the help of a retoucher pencil made on the basis of alcohol stain. Such pencils are available in a wide range of colors, which eliminates any difficulties in selecting a specific floor color.

Difficult repair work is carried out using hard wax - with its help, even significant dents and chips are successfully eliminated, and its color palette exceeds a hundred variations.

If the repair of the parquet base occurs due to the fall of a heavy object on it or after the leakage of a large amount of moisture, then in this case a special polyurethane adhesive will become indispensable.

IMPORTANT! Any work on the restoration of the parquet floor must be carried out in a timely manner, until individual elements have undergone more significant deformation. Timely repair will not allow a complete replacement of the parquet covering.

For porcelain stoneware and tiles

Particularly vulnerable to damage is the glossy front surface of the tile, which over time is scratched, becoming faded and satin in appearance. In addition, chips can form on the top layers of the glaze. Usually, a tile that has significant damage cannot be repaired and is simply replaced.

However, when you need to remove a small scratch or chip, then there is no need for dismantling. For repairs, you only need epoxy paint (matching the color of the tile), a primer and putty, as well as sandpaper. The process will look like this:

- It is necessary to treat the damaged area with sandpaper;

- Then carefully putty it;

- After the putty dries - primed;

- In the end - paint with epoxy paint to match the tiles.

For adhesive quartz-vinyl

This material is highly dependent in the processes of its recovery on the severity of damage and their nature. It is very easy to remove cuts from above along the protective layer. Such damage can be formed from the blade of a sharp object, such as a skate, which has passed over the surface. With such a defect, the edges of the protective layer will be slightly raised, which will even be visible. To eliminate it, you just need to walk with an effort along the incision with some rounded object, for example, a hammer handle. Small scratches can be easily removed with special mastics, however, this method will not be able to completely eliminate the problem, but will only mask the incision. The banal replacement of tiles will remain the right way to restore.

Means for removing minor defects and scratches

Small scratches, chips and dents that occur on any floor covering can be repaired with special products suitable for the type of floor required. The most popular is hard wax, which may have an additional name - "melt putty". After its application and hardening, its hardness becomes akin to wood, especially since it is excellent for restoring floors treated with both oils and varnishes. The application is carried out by means of an electric or gas wax melter. At the end of the application, the excess must be carefully removed with a spatula or a well-sharpened chisel. The final step will be grinding.

The pencil-retoucher is also quite popular. You can use it on a whim, the main thing at the end of the work is to polish the problem area with a soft cloth.

Painting products

Only areas that are completely free of dirt and dust should be painted.The restored surfaces without paint are puttied and covered with drying oil, after which they need to dry for at least two days. The process goes like this:

- The selection of funds for options from MDF or wood should be carried out among alkyd, oil or acrylic paints. If the floor is made of synthetic materials, only acrylic paint will do. To apply, use a small brush.

- The surface for applying paint must be strictly even, then the coating will turn out to be similar;

- For restoration, the paint is applied at least two layers, each of which should be allowed to dry;

- You can fix the finish with varnish.

Means to combat creaking

Squeaking can occur not only with wood floors, although it is not very common in other variations. Creaks can be caused by a number of reasons:

- Drying of the floor due to the low level of humidity in the room;

- Numerous physical damage to the surface (breakage of grooved joints, delamination/split of individual plates, etc.);

- Detachment of bearing plates from the base;

- Offset of parts of the coating relative to the lag.

If the surface not only creaks, but even bends under a person, then most likely the logs or the mounting base itself have also been destroyed. In such a situation, it is hardly possible to avoid a major overhaul, which will consist of both a rough finish and a fine coating. If things are not so bad, then you can apply two methods:

- Sprinkling with talc - it simply needs to be poured into the cracks formed so that the floor elements do not rub against each other, making unpleasant sounds;

- Filling with polyurethane glue - a reasonable amount of polyurethane glue must be pumped between the dies.

The download process will consist of only four steps:

- Masking tape is glued onto the damaged areas of the floor (it will prevent the glue from spreading and will not allow it to rise through the cracks to the surface);

- Using a drill, you need to make several holes at an angle, the distance between which should be about 15 centimeters. In this case, it is necessary to pay attention to the fact that the base must remain intact;

- In the interplate space, you need to pour the adhesive composition with a syringe;

- After an hour, the adhesive tape can be removed, and traces of glue that have appeared on the surface must be removed using a special cleaner.

Anti-Stain and Darkening Products

Over time, almost any floor covering can darken or stain. Often this is due to a poor-quality finishing layer, which was chosen incorrectly, and therefore foreign substances easily penetrated into the structure. In this case, scraping can help, i.e. surface leveling through scraping. Also, a special tinting agent will help hide traces of darkening, but the overall tone of the floor will have to be made darker. In some cases, the use of oil mixtures will be justified.

Removal by grinding

After sanding, in which the top layer will be removed, it will be necessary to carry out grinding activities. However, the scraping step can be skipped if the damage is not very significant. Grinding itself is the removal of a thin woody layer no more than one millimeter in size. The grinding process is carried out with special tools and it occurs from the center of damage and in all directions. The main tasks are to accurately obtain an optimally flat surface, while removing a layer with damage.

Application of decorative coating

Stains and blackouts are finally removed during the final stage of repair work. The drawing can be applied with special paints or varnish. So it will be possible to paint over local spots or darkening areas. Experts recommend applying a decorative coating in several layers in order to increase the protective properties and give the floor a more presentable appearance. At the same time, it is not recommended to achieve a decorative effect by applying multiple layers of varnish or oil composition, because such substances very easily penetrate the structure of the base and do not leave a shiny film on the surface. At the same time, deep penetration can improve wear resistance.

Floor care after restoration

In order to keep the result as long as possible, you need to follow a few simple rules:

- The room must maintain the proper degree of humidity;

- Avoid, if possible, a long and direct exposure of the repaired area under the influence of ultraviolet rays;

- Do not allow sand or other substances containing fine fractions to get on the floor;

- When walking, it is preferable to use soft slippers, rather than shoes with sharp heels;

- Put special soft pads under the legs of furniture and chairs.

Nevertheless, it is worth noting that the restoration process, in comparison with the installation of a new coating, is not so costly. Especially when it comes to porcelain stoneware - you don’t have to tear off the old coating and buy and apply a new one. All issues can be quickly and cost-effectively resolved through competent grinding. Finishing treatment should be selected from the general interior of the room, because for a strict office style, a method of decorative removal of stains and blackouts is hardly suitable.It is always worth remembering that if the flooring is made according to the mosaic principle, then it is easier to remove a certain area and lay new mosaic elements than to delay the repair, waiting for the moment when one part of the floor becomes much darker than the neighboring one. In the end, it should be remembered that sealant is the best solution for repairing possible cracks that have arisen after restoration work.

Restoration of marble flooring as a complex process

Restoring a marble floor is a very complex and lengthy process. Moreover, it will not be possible to carry it out with improvised means. Such types of work are subject only to professionals.

In cases where the marble is slightly deformed or has small differences, then the problem can be eliminated by rough grinding (you will need a special technique). In any case, one pass will not be enough, so the final step should be repeated, less aggressive sanding. Double grinding will provide the marble surface with perfect evenness.

To return the marble floor to its original luster, a crystallization process is carried out.

To eliminate small chips, special compounds are used, with which the cracks are simply smeared.

In any marble restoration procedure, the final step should be the application of protection to prevent future damage. For each type of damage, specially designed compounds are used.

It is worth mentioning that at the beginning of any restoration work on marble, first of all, it is necessary to conduct a thorough inspection of the premises, assess the level of damage, and calculate the amount of necessary tools and materials.If the decision is made to carry out rough sanding, then the professional must determine the thickness of the layer to be removed so that the result looks potentially renewed. A mandatory step before the start of repair work should be the washing of marble floors and their complete cleaning of dirt. In addition, before the start of restoration and after washing - the marble flooring must dry. Great attention must also be paid to interplate cracks and seams. They must be treated with acetone and, upon completion of processing / grinding, painted over to look like a marble.

Rating of the best flooring restoration products for 2022

Wax crayons and markers

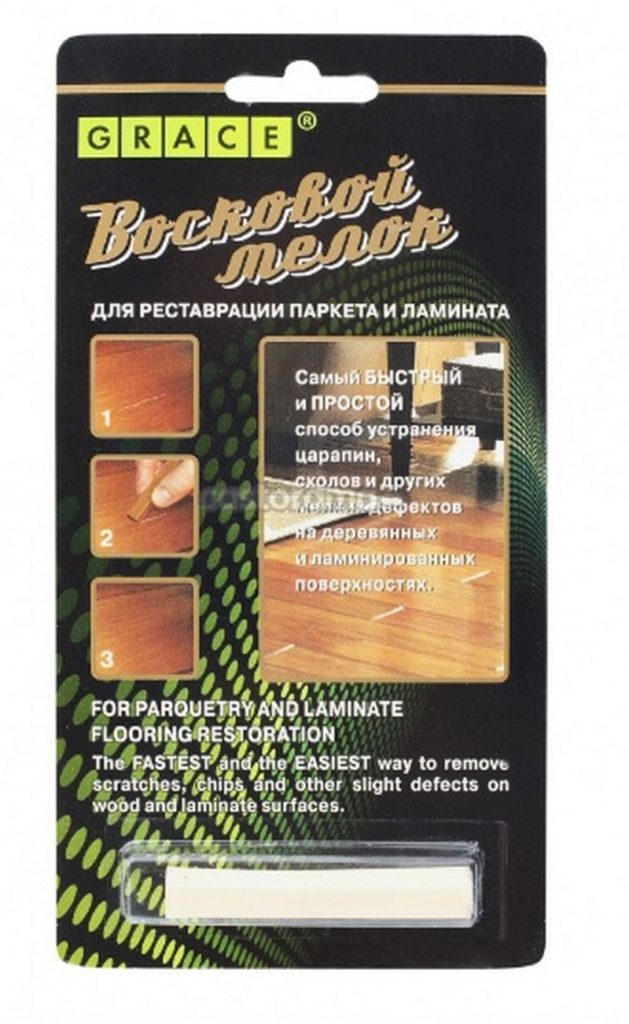

3rd place: "Mel Grace (white)"

This chalk is designed to quickly eliminate chips, cracks and scratches that are clearly visible on the floor. Use on a laminate and wooden surfaces (parquet and a parquet board) is possible. Easily available in Russian networks and shows high-quality results. The birthplace of the brand is Russia. It measures 18.9x9.8x2.7 centimeters. The recommended retail price is 95 rubles.

- Reliable masking of floor defects;

- Does not require special handling skills;

- Made from non-toxic materials.

- It might end quickly.

2nd place: "Mel Pine"

Another representative of wax chalk from a Russian manufacturer. It is a very simple and affordable solution for both mild and moderate injuries. Designed for use on parquet and laminated surfaces. Perfectly eliminates dents, chips, large scratches and other defects. To obtain the desired shade, wax crayons can be mixed with each other.To increase the service life of the restoration result, the applied substance should be fixed with a protective varnish for wax chalk. The homeland of the manufacturer is Russia, the chalk has dimensions - 18.9x9.8x2.7 centimeters. The recommended retail price is 150 rubles.

- Adequate price;

- Ease of use;

- Possibility of getting your own color variations.

- Requires fixing the result with a special varnish.

1st Place: Marker Oregon

This valve marker is able to remove small scratches and scuffs, as well as other defects without indentations, on laminated, plastic and wood surfaces (including windows, doors and furniture). Can be used to darken edge scratches or restore texture after waxing. The volume of paint inside the marker is 7 milliliters. The homeland of the brand is Russia, the declared retail price is 160 rubles.

- Increased tightness of the composition;

- Retains properties under the action of sunlight;

- Does not leave smudges after application;

- Wide color palette;

- Frost-resistant;

- Capable of instant drying.

- Not detected.

Restorative correctors

3rd place: "Correction varnish translucent semi-matt"

This varnish is exclusively corrective in nature and is used for local restoration of small damages. Works great on laminate or parquet. It is characterized by good ability to hide cracks, chips and scratches. The volume of the container is 30 milliliters, the birthplace of the brand is Russia. The recommended price for retail chains is 115 rubles.

- Budget price;

- Sufficient capacity;

- Semi-matte shade.

- It dries for a relatively long time - about half an hour.

2nd place: "Proofreader restoration for MDF"

This corrector is designed to eliminate minor defects with small indentations on the floor covering. Able to process wooden, laminated and plastic surfaces (including skirting boards and architraves, including furniture, windows and doors). The volume of the container is 40 milliliters, the birthplace of the brand is Russia. The recommended retail price is 150 rubles.

- Frost-resistant;

- Sufficient volume of liquid in the vial;

- Wide application.

- The composition contains toxic substances.

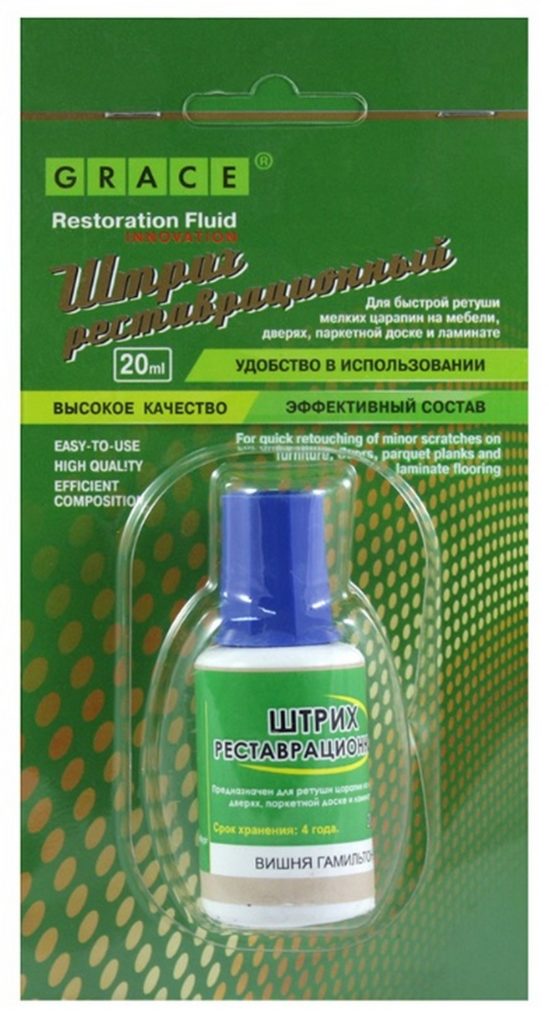

1st place: "Hamilton Cherry Stroke for the restoration of laminate and parquet"

This stroke is used to quickly fill medium and small damage on laminate and wood floors - MDF, cork, plastic, plywood, solid wood and chipboard. Poor resistance to low temperatures - the working limit is -25 degrees Celsius. With prolonged non-use, it may thicken, however, its properties can be restored simply by adding water. Allows you to get the desired shade by mixing several colors of a similar brand. The birthplace of the brand is Russia. The volume of the container is 40 grams. The recommended retail price is 200 rubles.

- Variety of colors and materials;

- Renewable work;

- Treatment of significant damage.

- Temperature restrictions.

Polyurethane restoration varnishes

2nd place: "Petri Diamond Hard glossy PC1711101"

This restorative substance is used only for interior work.Perfectly prevents the recurrence of cracks and scratches, while protecting the entire coating. Perfect for working on a parquet board, especially for places with intensive systematic loads. The homeland of the brand is the USA, the capacity is 3.5 liters, the recommended price is 5000 rubles.

- Safe for children;

- It is applied to coverings with big loadings.

- Not detected.

1st place: "Tikkurila Parketti-Assa 20 semi-gloss"

High-quality restoration varnish on an acrylate-polyurethane base. Able to form a durable coating with a semi-matte finish. Possesses the high decorative properties emphasizing structure of a tree. The homeland of the brand is Finland, the capacity is 5 liters, the recommended retail price is 9200 rubles.

- Reliable brand;

- High quality.

- Limited specialization (wood only).

In general, it can be concluded that the market for restorative products is completely dominated by a domestic manufacturer. However, for large-scale work, you will have to use goods from foreign brands.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131651 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127690 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124519 -

The best men's sneakers in 2022

Views: 124033 -

The Best Complex Vitamins in 2022

Views: 121939 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114980 -

The best paint for gray hair - top rating 2022

Views: 113395 -

Ranking of the best wood paints for interior work in 2022

Views: 110318 -

Rating of the best spinning reels in 2022

Views: 105329 -

Ranking of the best sex dolls for men for 2022

Views: 104366 -

Ranking of the best action cameras from China in 2022

Views: 102216 -

The most effective calcium preparations for adults and children in 2022

Views: 102011