Ranking the best tile leveling systems for 2025

Installing tiles on the floor or walls always requires careful marking, fitting and trimming consumables. Any inaccuracies in the calculation will be easily noticeable. At the same time, it is necessary to carefully align the lines between adjacent modules, because by laying just one tile at an angle, you can get a whole oblique row. It is to prevent such problems that master finishers use tile leveling systems (abbreviated as “SVP”). For the first time they began to be used in the west, and this method can significantly speed up the work on laying porcelain stoneware or tiles.

Content [Hide]

- 1 General information

- 2 Necessary tools and algorithm of work

- 3 Features of use

- 4 A brief overview of the leading manufacturers of SVP

- 5 Issues of selection and calculation of SVP

- 6 Self-manufacturing of SVP

- 7 Ranking the best tile leveling systems for 2025

- 8 Conclusion

General information

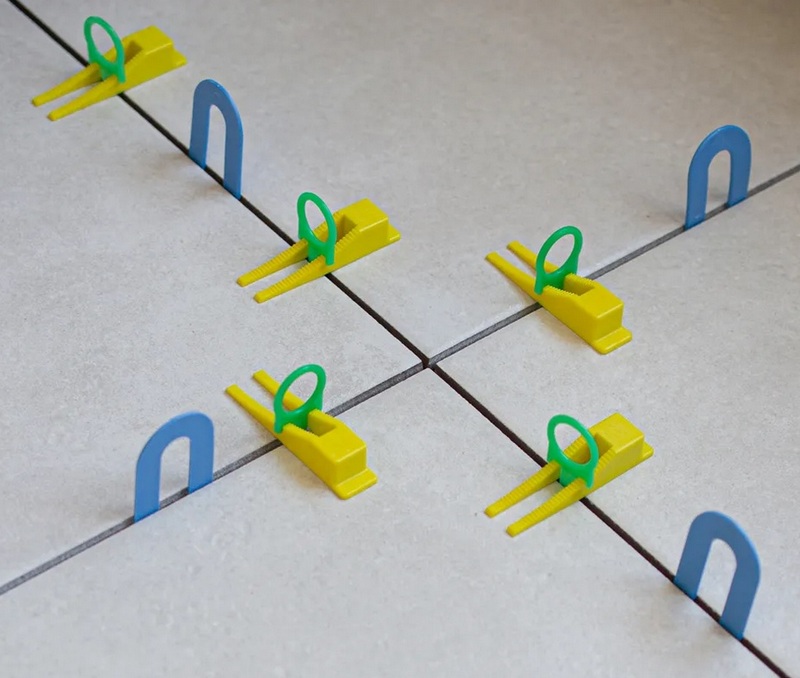

It is possible even for a non-professional to use the tile leveling system. It consists of sets of two elements - these are clamps and wedges. Despite its solid name, its design and fixtures are not technically complex. However, such sets do an excellent job with the task of even laying out.

This innovation was invented in the West, therefore, in the construction segment of the Russian market, the corresponding goods are presented in 90% of cases by a foreign manufacturer. Russian variations can be typed, at most, a dozen. Nevertheless, both domestic and foreign samples are adapted mainly for leveling tile modules with a thickness of 3 to 20 millimeters.

As standard, the system consists of a set of wedges and clamps that can be used repeatedly. Also, the kit may include anticipatory petals that increase the accuracy of the calculation, and you need to work with them with special tongs.

In principle, SVP is an improved alternative to crosses, which were used to align seams in the CIS.The main working element is now wedges-spacers, through which it is possible to adjust the location of the tile modules on the plane and fix the desired position with special clamps. As a result, wedges-spacers give direction, and fixation is carried out by wedges-clamps.

Depending on the material of manufacture, the type of auxiliary tools under consideration can be divided into:

- Metal - they are rare and have a higher cost. They are the object of the use of professional masters when laying out large areas with a fragmentary image. The increased price indicates a long service life, greater intensity of possible use and professional orientation;

- Plastic - they are made from a variety of types of polymers. They have sufficient strength and durability, but are more focused on periodic use, so they cannot be compared in service life with metal ones. Focused on small scale projects.

As a result, the system in question is suitable for both working with tiles and porcelain stoneware, and the result of its use will be even and clear rows of laid out tiled base.

Advantages and disadvantages of SVP

Of the undoubted advantages of floor leveling systems, the following can be distinguished:

- Obtaining an almost perfectly smooth surface finish. The coating will always become smoother and even, while the aesthetics of its appearance will increase significantly. An even coating will also become a guarantee of durability and performance in general. In addition, the entire workflow will be accelerated, and individual operations will become simpler and easier.

- All inter-seam distances will become visually uniform and it will be possible to detect any discrepancies only with the help of precise instruments.

- The adhesive mass will also be evenly distributed over the entire tile, and with its help it is possible to better level the bearing surface. All small internal voids will close completely and will not interfere with further facing work.

- The use of SVP will allow in the process of further operation to slow down or completely prevent subsidence of the slab base.

- Fixing each module with fasteners will have a better laying effect than when the master performs such an operation manually. With manual holding, sagging and displaced areas are more likely to appear, which, often, can only be detected after the adhesive solution has dried. As a result, the SVP will hold the modules in the correct position until completely dry.

If we talk about the shortcomings of the system, then these can include:

- Expansion of the work budget in the form of purchasing a SVP kit, as well as wasting time on installing / removing its individual elements;

- During use, all seams must be filled with adhesive, so pre-cleaning of gaps will be required before filling;

- SVP may not justify itself (in terms of time and financial costs) when finishing small areas.

Necessary tools and algorithm of work

Before starting finishing work, you should prepare tools and consumables, which make up a not so big list:

- Directly tiled modules made of porcelain stoneware, tiles or ceramics;

- adhesive solution;

- Set of wedges and ties, i.e. SVP;

- Mallet with a rubber chipper;

- Construction level;

- Spatula with teeth.

The process itself includes the following steps:

- Cleaning and drying of the supporting base before applying a layer of glue;

- Applying glue to the base, while the applied solution should not be either very thick or very liquid, but have an average level of consistency;

- The overlay of the first module, which must be manually aligned as accurately as possible, because all the others will be oriented along it, the alignment is checked using the building level;

- Two clamps are installed on each side of the first module, indented from the edges by 50 millimeters;

- The next tile is applied tightly and exactly to the leg of the installed clamp;

- The wedge is installed in such a way as to ensure its snug fit to the surface of the next module;

- Waiting for the glue to dry;

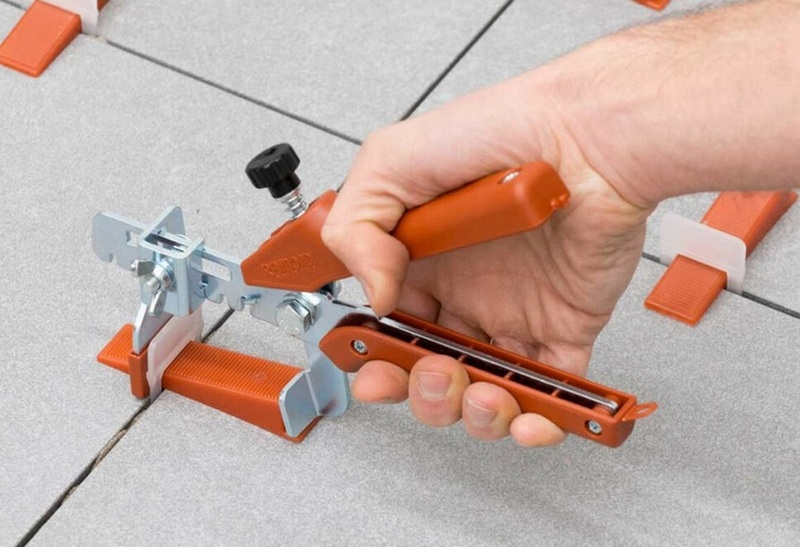

- The clamp is removed by striking with a mallet in an area parallel to the seam. In doing so, the top side of the clip will break, allowing the wedge to be removed, while the bottom side will remain under the module.

The whole process is then repeated from step 4 to step 8 for each chip.

Features of use

When performing flooring finishing using the system in question, some nuances should be taken into account:

- The considered method of laying out shows the greatest efficiency when the differences in the bearing base do not exceed 1 centimeter;

- It should be understood that if the end result is used incorrectly, even the use of SVP technology will not save the cladding from cracking. In this case, the quality material of the modules and a good adhesive solution will play a decisive role;

- If it is required to create a hole in the cladding to be mounted, then an additional element called a “ballerina” will be required (due to the similarity of the device with a tutu);

- If large modules are laid out, then the glue layer should be double;

- The use of the system is possible only at an ambient temperature of +10 degrees Celsius and in the absence of drafts;

- Professionals recommend purchasing foreign kits, because for the domestic industry, SVP is still considered a rather poorly mastered product for release.

A brief overview of the leading manufacturers of SVP

Among the foreign kits that are widely represented in our modern market, it is necessary to highlight the Spanish brand "Rubi Tili Level". These accessories are of excellent quality. The role of the clamp in these sets is performed by a cap endowed with flexible petals. These samples can be applied to any modules (wall and floor) with a thickness of 3 to 20 millimeters, and a fairly small thickness of the screed, which is only 0.8 millimeters, allows you to form the thinnest seams.

The next most popular brand can be designated "LITOLEVEL". Its products are almost completely identical to those described above, but its use is associated with the need to perform some actions. For example, a mandatory 30-minute soak will be required before laying nylon ties. Also, the manufacturer recommends installing and dismantling all guides and fixing elements with special tongs, since they are included in the kit by default.

Issues of selection and calculation of SVP

It is always worth choosing exactly such a set, in which there are elements of the right size that can work with the thickness of the existing tile chips. In one set there can be elements of different sizes, and they will differ from each other in color (in terms of size). Standard manufacturers prefer the following colors:

- Yellow, white and orange colors are intended for tiles with a thickness of 3 to 16 millimeters;

- Gray (and any other cool) colors are designed for thicker modules with a thickness of 12 to 21 millimeters.

Also, the elements of the set may differ in the size of the joints, which can be from 1 to 3 millimeters. Accordingly, each working component will have on its body the corresponding digital designation "1", "1.5", "2" or "3".

If we talk about making calculations, then for their implementation you will need to know the required number of clips and the format of the modules themselves - this way you can calculate the number of fixtures needed to cover one square meter. Further, the resulting number should only be multiplied by the total footage of the area to be lined.

For clarity of calculations, the following examples can be given:

- With dimensions of one module of 1200 * 600 millimeters per square meter, approximately 7 pairs of wedges with clamps will be needed;

- With dimensions of one module of 1200 * 295 millimeters per square meter, approximately 14 pairs of wedges with clamps will be needed;

- 600 * 600 millimeters - 11 pairs;

- 600 * 300 millimeters - 22 pairs;

- 300 * 300 millimeters - 44 pairs.

From this it is clear that when finishing large areas (or when working with small modules), you should immediately purchase sets with a large number of work items. Also, it is worth taking care of the presence of special forceps in the kit, which will definitely be needed for operations with small fragments. In principle, when using SVP, other tools will not be needed anymore, although, in the absence of tongs, the use of small pliers is allowed.

Self-manufacturing of SVP

Modern prices for the systems in question may not seem very high, however, no one needs extra spending when it comes to doing a one-time job that does not require the use of a full-fledged kit. Accordingly, you can make several elements of this system yourself. This will require only metal rectangles and some aluminum wire. The latter will perform a fixing function, and the former will become guide stops.

First, using wire cutters, you need to cut a few pieces of wire and bend it into rectangular clips. Next, under them you need to trim the existing metal stops. Then the following steps are performed:

- A plate is inserted perpendicularly into the clamp;

- A tiled module is superimposed on it;

- A wedge is installed in the wire clamp;

- For better fixation and fit, a small piece of fiberboard is inserted between the wedge and the clamp.

Ranking the best tile leveling systems for 2025

Budget segment

3rd place: "Flag" + Wedge (1.4 mm; 40 pcs.) DECOR 339-4040 "

votes 1

The kit is used when laying ceramic or porcelain stoneware tiles with a thickness of 4-14 mm. With it, it is easy to ensure the alignment of the surface on the plane. Thanks to the use of such a system, an extremely even seam is formed, not exceeding 1.4 mm. There are 40 pieces in total in the set. The recommended cost for retail chains is 210 rubles.

- Good geometry;

- Strength;

- Durability.

- Not detected.

2nd place: "Gate" SVP (white; 50 pcs.) DECOR 559-2050 "

votes 1

This product is used when laying ceramic tiles or porcelain stoneware with a thickness of 4-14 mm. Perfectly provides a snug fit to the surface of two adjacent modules. The set includes 50 items. It is designed for medium-sized tiles - 800 * 200 millimeters. The recommended cost for retail chains is 250 rubles.

- Simple laying work;

- Acceleration of the lining process;

- Great for thick adhesives too.

- Not detected.

1st place: "Plastic Rusi Plant" - PROFIMINI 0.7 mm, 100 pcs."

votes 1

The set consists of two elements - a tile trimming wedge and clamps for fixing. The wedge can be used several times, but the clamp is a consumable and after applying the tile it remains inside the seam. When using lines, a uniform tile joint is guaranteed over the entire area to be lined. A uniform adhesive layer is also formed under the coating. The set is perfect for any porcelain stoneware or ceramic coating. This SVP allows you to achieve high-quality lay-out results, with its help you get beautiful rows and uniform seams. Working with the kit does not require special skills and special devices. Set - 50 wedges + 50 clamps. The recommended cost for retail chains is 333 rubles.

- Quality;

- Democratic price;

- Sufficient filling.

- Not detected.

Middle price segment

3rd place: "IVK group 1.5 mm, 300 pcs."

votes 2

This innovative leveling method is used when tiling walls and floors.It is suitable for working with ceramic and porcelain stoneware chips with a thickness of 6 to 12 mm. The SVP consists of two elements - a clamp and a wedge. Wedges can be used several times, and clamps are consumables, since after installation their lower part will remain inside the seam. Included: clamps 1.5 mm. - 200 pieces, wedges - 100 pieces. The presented version of the clamp has an ergonomic shape, which provides an extremely comfortable grip when tightening the wedge. The width of the tile joint is 1.5 mm. The recommended cost for retail chains is 420 rubles.

- Comfortable grip;

- Orientation for domestic use;

- Sufficient durability - 6 cycles.

- Not detected.

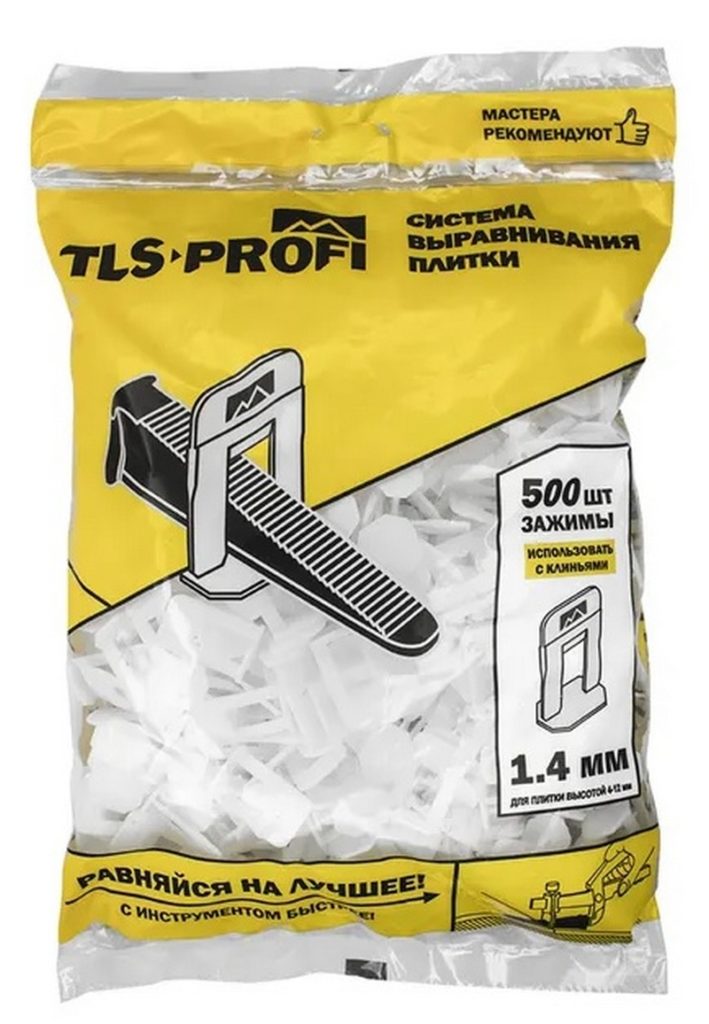

2nd place: "TLS-Profi, 1.4mm, 500 pcs."

votes 1

The product provides a flat surface when tiling walls or floors. The alignment process is reduced many times in time. With the help of this SVP it is possible to form seams suitable for working with "warm floor" networks. The elements are slightly prone to fracture during installation and are easily beaten off with a rubber mallet. They have a thinner support of 1.7 mm, which means less glue consumption. The possibility of installation with wall cladding is assumed. The recommended cost for retail chains is 730 rubles.

- Proper elasticity;

- Convenient installation;

- Excellent value for money and quality.

- Not detected.

1st place: "Newly born" reusable 50 pcs.

votes 1

This SVP is reusable and differs significantly from the standard tile leveling system, where the design consists of only a wedge and a base. During operation, a minimum joint width of 1.5 mm is formed.The height of the working leg is only 2 mm, so it is permissible to use a minimum adhesive layer. As a result, the product simplifies and greatly facilitates the work. During operations, a special key is used, which is supplied in the kit. Both a beginner and a professional can work with the kit - both of them will be able to get perfect results very soon, i.e. surface without irregularities. Moreover, now it is not required to pre-place the base of the SVP along the edge to the already laid row. This operation is performed after laying. Contents: 50 pieces of elements + key. The recommended cost for retail chains is 800 rubles.

- Truly reusable;

- Strong screwing;

- Tight fit.

- There is not enough intermediate washer, which is why sand can get under the base of the mount.

Premium class

3rd place: "3D KRESTIKI, 200 pieces"

votes 1

The product is a complete SVP and consists of a set of wedges and clamps. Through it, it is easy to obtain perfect seams, the size of which will not exceed 2 millimeters. With such devices, it will be easy to form dense rows of tiles, in which the edges will converge flush. At the same time, it is possible to provide a perfectly flat surface, which, even after the glue has dried, will not shrink. Approximate acceleration of facing works - 4 times, in relation to the usual pace. Quite low cost allows the use of the kit for 50 cycles. The recommended cost for retail chains is 830 rubles.

- Quality performance;

- Ease of use;

- Reusable use.

- Not detected.

2nd Place: "Delta by Rubi, 100"

votes 1

This kit is ideal for laying large-format ceramic tiles using the reverse overlay method. In this way it is possible to prevent unintentional movement of the individual modules during the adhesive drying phase. The pressure that will be applied to the wedges will be moderately sufficient and will give the newly created surface the most even appearance. Supplied in 3mm strips for chip sizes 6 to 15mm and 2mm strips for chip sizes 11 to 20mm. By default, the set includes pliers with clamp height adjustment up to 6 positions and ergonomic handles. The recommended cost for retail chains is 1300 rubles.

- Pincers included;

- Supply variability;

- Possibility of using the reverse overlay method.

- Not detected.

1st place: "RAIMONDI, 200 pieces"

votes 0

While working with this SVP, the tiles will only "push", but not "rise", which will create their stronger adhesion to the base. The work will not present any particular difficulties, since the fixing clips and wedges reliably prevent deformation and settling of the chips when moving from one to another. The resulting joint size is 1.5 millimeters with a tile thickness of 3 to 12 millimeters. The kit comes with special tongs that support the three-stage process - setting the support, driving in the wedge and removing the support. The recommended cost for retail chains is 1540 rubles.

- Multipurpose forceps in a set;

- Special procedure for fixing;

- Maximum chip slip prevention.

- Somewhat overpriced.

Conclusion

Aligning tiles is a very important nuance, which will depend on the final appearance, external presentability and quality of the cladding. SVPs can greatly facilitate the entire workflow, both for professionals and novice craftsmen, especially when it comes to large format modular tiles. On the modern market, for the most part, there are foreign samples of the goods in question: they are characterized by the best quality, but their price may seem somewhat “biting”. If we talk about Russian samples, then their price is more affordable, but they are represented only by sets that can withstand five, at most six, cycles of use.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131650 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127689 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124518 -

The best men's sneakers in 2025

Views: 124032 -

The Best Complex Vitamins in 2025

Views: 121938 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114979 -

The best paint for gray hair - top rating 2025

Views: 113394 -

Ranking of the best wood paints for interior work in 2025

Views: 110318 -

Rating of the best spinning reels in 2025

Views: 105328 -

Ranking of the best sex dolls for men for 2025

Views: 104365 -

Ranking of the best action cameras from China in 2025

Views: 102215 -

The most effective calcium preparations for adults and children in 2025

Views: 102011