Rating of the best silencers for ventilation for 2022

In the process of operation of supply and exhaust ventilation devices, production noises necessarily occur. This is especially true for industrial installations, because they are equipped with a large number of valves, fans and other elements responsible for air distillation. Accordingly, in order to increase the efficiency of work and reduce the discomfort of the surrounding people, such installations need to dampen such noises using a variety of silencers.

Content

- 1 General information

- 2 Modern types of ventilation noise absorbers

- 3 Industrial silencers for ventilation

- 4 Mounting Recommendations

- 5 Features of pricing for silencers

- 6 Difficulties of choice

- 7 Rating of the best silencers for ventilation for 2022

- 8 Conclusion

General information

The principle of operation of any noise-absorbing unit is based on the fact that during operation it is able to change the parameters of the moving air flow in a special way. This happens when the air mass passes through several layers of special materials, which reduce sound vibrations.

Such sound filters are still considered an innovation, because they were developed relatively recently. However, even today they have become an indispensable and popular element in large ventilation ducts. They also proved themselves well when working in closed private small systems. The installation of such sound absorbers still cannot completely remove noise, but they can significantly reduce its level, which will qualitatively affect the comfort of people staying in a protected room.

It should be noted that for some categories of premises and ventilation systems, the installation of such devices is not mandatory. These, first of all, include spaces in which people are not present on a permanent basis or their presence is very short-lived.In other cases, especially at production facilities, the presence of such devices is highly desirable, since they will immediately prove their effectiveness, their cost is not very high, and integration even into a ready-made system does not present any particular difficulties.

Modern types of ventilation noise absorbers

The current market of the considered segment of devices is quite wide and allows you to choose the right model for almost any air pumping system. Most professionals prefer to classify these devices according to their purpose and technical parameters.

- Flexible.

Such samples are used for those cases when it is not possible to apply standard rigid models. The flexible housing is most often installed in heat supply units or in air pre-treatment centers. Their design consists of the following components:

- Protective layer made on the basis of aluminum foil;

- Polyester/glass wool inner layer;

- The outer layer is made of steel wire twisted into a spiral (it can also be made of fiberglass).

The noise-absorbing power of elastic devices will mostly depend on their dimensions, the location area and the thickness of the soundproofing layer in the structure.

- Tubular.

They have a special design, which consists of two pipes inserted into each other. These pipes may vary in their shape. In any case, their dimensions must correspond to the cross section of the air flow channel where the device will be integrated. Their outer layer may have a perforated type surface, with the help of which a high-power passing stream will be broken into several weaker ones.In the voids between the two shells, there is sound-absorbing material, which is responsible for the overall reduction in the degree of noise in its section of the system. To enhance this working quality, the inner surface of the device can be coated with special polymers. For tubular units, the length parameter is extremely important and it ranges from 60 to 90 centimeters in standard values. Focusing on this parameter, it is possible to choose a specific model for a specific type of supply and exhaust ventilation. There are also such tubular models that can independently reduce / increase their length, which is achieved by pushing / moving the moving parts of the structure. It should be noted that such samples are not recommended for installation in ventilation systems where the channel cross section exceeds 50 centimeters.

- Round.

They are intended exclusively for those channels that are built on the basis of round pipes or have the shape of a cylinder or tube. Their main difference lies in the versatility of their purpose: they work in supply, exhaust, and supply and exhaust combined lines. They are made of galvanized steel, their inner layer is also soundproof, for which mineral fiber material is used.

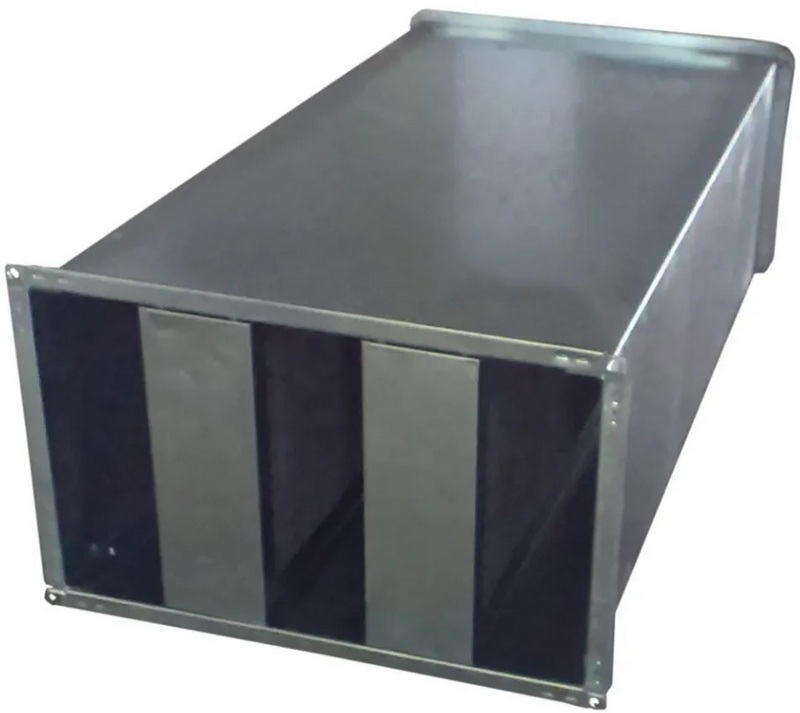

Industrial silencers for ventilation

These samples are used on large and powerful ventilation systems used in manufacturing enterprises. The standard model of such a device consists of a body made of galvanized steel sheet with a thickness of at least 1 millimeter. The dimensions of the housing must always correspond to the cross section of the channel where it is supposed to be installed.Its inner layer is a set of thinnest plates divided into cells, between which a soundproof material is laid. Such material can be glass wool, mineral wool or felt. This group has a clearer classification and includes six main modifications of devices.

- "GTP".

The silencer is a tubular rectangular structure, which is integrated into the working space by means of flanges. These flanges can be made of a solid tire or a metal corner. Designed for rooms with ventilation, which is not focused on the active pumping of flows, including a large amount of flammable / toxic impurities. If it is intended to use especially harmful air media for the transfer, then all internal parts of the GTS must be made of hardened steel.

- "GP".

The most standard industrial sound filter. Manufactured from galvanized steel with perforated surface.

- "GTK".

This modification belongs to the tubular type, equipped with bandage or flange fasteners. It is used ONLY for highways that distill a relatively clean air stream (without toxic compounds).

- "Plate EUROstandard".

The sample is of the flexible type and is suitable for rectangular ducts. It is easy to mount it in exhaust and supply systems. It is made on the basis of galvanized steel, and the sound vibration filtering layer is made of mineral fibers.

- "Tubular EUROstandard".

It is essentially the same design as the previous modification, but it is intended only for channels with a circular cross section. Works on all types of ventilation.

- "GTPi".

An extremely productive modification designed for large networks where many air distillation devices are installed: fans, air conditioners, air regulators, coolers, etc. It is able to effectively suppress the strongest aerodynamic noise to a minimum percentage. Under the conditions of production necessity, even the installation of two devices at once on one serviced area is allowed. There is a technical limitation: before and after the silencer, there must be a completely empty space 1 meter long.

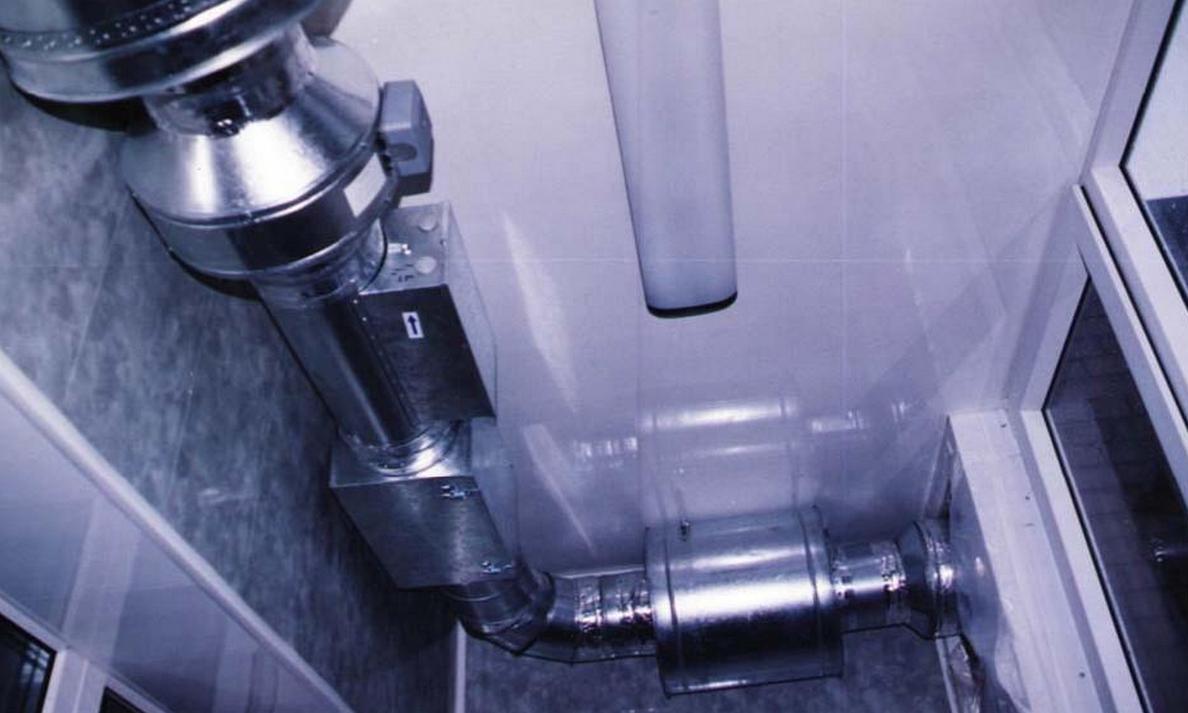

Mounting Recommendations

The design of ventilation silencers is not particularly complicated, so it is also possible for a non-professional to install them. However, the mounted model must fully comply with the technical parameters of the served channel. There are no special requirements for the process itself. However, the following guidelines must be followed during installation:

- The place of integration of the device can be chosen even empirically (experimentally), and this can positively affect its further work. By simply running the unit loose in different areas and measuring the level of noise reduction, it is much easier to find the best place to place it. If you put the unit at random, then it is quite possible to place it in a place where it will simply be inefficient.

- When choosing a model, one should take into account the speed of the flow along the highway. This indicator should not exceed the value that the selected unit is able to process.

- Standard silencers must not be installed in networks in which air masses with elevated temperatures pass and which carry aggressive impurities and toxic substances in their flow.

It is quite easy to measure the efficiency of work - for this you should use a specialized device with a sensor. If, after installation, the noise at the output does not exceed 15 decibels, then the installed device fully copes with its task and its integration has been carried out properly.

It is possible to install the considered types of devices both in the supply, and in the exhaust, and in the combined ventilation. Experts still recommend placing them in the area where the exit from the main shaft to the fan is carried out. Another possible installation site can be a platform located directly behind the wall of the serviced premises. Installation is also permissible in the immediate vicinity of the nodes where the separation of air currents is carried out. For domestic use, the best place is the area located immediately behind the hood grate.

To obtain the maximum soundproofing effect, the unit must be located in relation to the fan in such a way that the flows passing through the filter have the lowest speed. To enhance the work of the silencer, you can even build an additional layer of sound insulation from the appropriate material, simply by placing it on top of the device. This operation is simple, you just need to attach a piece of canvas in the right place to the unit and fix it with a simple, but reliable, adhesive composition. To increase the service life of the “jammer”, it is advisable to install a coarse filter at an acceptable distance from it, which will prevent large and solid foreign fragments from entering the system.

As for household ventilation systems, universal small models of noise absorbers are more suitable for them.Installation is best done in a place that immediately meets two requirements: the availability of installation and the highest level of current noise.

Features of pricing for silencers

The cost of the products in question is formed on the basis of their modification type and production material. The most budget options on the Russian market start at 1,500 rubles. The price will increase as the properties of the device improve, such as: better material, overall dimensions, thickness of the soundproofing layer and the availability of additional features. As a result, the most reinforced industrial version can cost as much as 20 times more than a standard household one (about 20,000 rubles).

Difficulties of choice

Before buying a ventilation noise suppressor, there are several important points to consider. For example, if we are talking about a household appliance for extracting hoods in the kitchen, then first of all you should pay attention to the maximum temperature of the air flow that the sound filter can pass through. At the same time, it is necessary to clarify the maximum possible flow rate to pass. Primary information about this can be obtained from the instructions for the kitchen hood, and then you need to compare only the numbers with the capabilities of the "jammer".

If we are talking about the acquisition of industrial models, then it is better to immediately choose a more durable sample. It is no secret that industrial exhaust air in most cases can carry aggressive and toxic substances that can damage the soundproofing coating. Also, you should pay attention to the position recommended by the manufacturer for installing your product. This is especially important when you need to mount the device in a channel in a hard-to-reach place.Moreover, not all industrial models have the properties of versatility and it is possible to install them both vertically and horizontally.

It should be noted that the most important parameter influencing the choice of product, both for industrial and for household units, remains the size of the channel section. It must be fully compatible with the cross-sectional size of the "jammer" itself. A model that is too large simply will not fit into the shaft, and there will simply be no effect from too small. It must be understood that the effect of the product comes only when the noise level in the serviced area does not exceed 10-15 decibels.

Rating of the best silencers for ventilation for 2022

Budget segment

3rd place: "Sonodec GLX25, 102 mm x 1 m, Dec International"

This flexible model is made of laminated aluminium/polyester, insulated with 25 mm sound absorbing material and provided with an extra strong outer shell. The internal air duct is protected by a special layer of acoustically transparent polyester. This increases the strength of the duct and stops the penetration of foreign particles into it, as well as improves acoustic performance, reduces the risk of cold bridges, and reduces leakage / pressure loss. The outer sleeve on the frame is made of a highly stretched helix based on high-strength steel. Special joints based on reinforced aluminum, which are installed at both ends of the "sleeve" type, allow you to easily connect to any device or duct. The connection point must optionally be fixed with aluminum strong tape, which is necessary to ensure tightness. Installation is carried out on round connecting elements.The recommended cost for retail chains is 1720 rubles.

- Operating temperature from -30 °C to 140 °C;

- Maximum pressure +2500 Pascals;

- The maximum flow rate is 25 m/s;

- The minimum bending radius is 0.54 * +25mm.

- Not detected.

2nd place: "DSV 200/600 mm Diaflex UV-00034426"

The sample is designed to reduce turbulent noise and aerodynamic noise in ventilation ducts. Manufactured from a solid sheet of galvanized steel with a special sound-absorbing material. The sound absorption coefficient of sound insulation is NRC=0.9. Acoustic tests are confirmed by the building acoustics laboratory of the NIISF RAASN of Moscow. Fully comply with the current GOST and SNiP. The recommended cost for retail chains is 3800 rubles.

- Double case with special perforation;

- Noise-absorbing material is made on the basis of mineral wool;

- Mounting is possible in any position;

- The maximum flow temperature is 60°C.

- The body is equipped with round pipes, has rubber seals for attaching to other elements of the system.

- Not detected.

1st place: "GPP 400×200/1000 mm NOIZZLESS 2000000297286"

This industrial design is made of galvanized steel with a special sound-absorbing material. Mounted in rectangular ducts. It has connecting flanges for comfortable installation. Easily absorbs turbulent swirls and aerodynamic noise in rectangular ducts, which significantly reduces the noise level in the duct.The silencer is used in conjunction with a soundproof fan in the case when the requirements for reducing the noise level are imposed not only on the mine, but also on the equipment in general. The recommended cost for retail chains is 6690 rubles.

- Rugged housing;

- Convenient connecting flanges;

- Light weight.

- Not detected.

Middle price segment

3rd place: "GKR 315x600 mm jav5 NOIZZLESS 2000000295503"

The product is used to absorb aerodynamic noise in round ducts. Significantly reduces the noise level in the duct. It is used together with a soundproof fan to reduce the noise level in the serviced premises as a whole. Made of galvanized steel, there is a special sound absorption. Mounted in round ducts. Equipped with connecting flanges for ease of installation. For maximum noise reduction, a silencer should be installed directly after the fan. The recommended cost for retail chains is 7300 rubles.

- Housing made of durable galvanized steel;

- Good value for money;

- Powerful noise reduction effect.

- Not detected.

2nd place: "SonoDFA-SH-356 (1 m; 356 mm) Diaflex UV-00000132"

The model is designed for air conditioning and ventilation systems. It consists of a micro-perforated duct of patented DFA technology, wrapped with a polyester film, which prevents glass wool fragments from entering the duct.The thermal insulation layer is 25 mm, has a density of 12-14 kg / m3 and an outer protective shell made of multilayer aluminum foil with a reinforced helix based on steel wire. Basic tasks: reduction of noise level from fans and other sources, work on ventilation and air conditioning lines, where the use of standard silencers is unacceptable. The recommended cost for retail chains is 10,870 rubles.

- Flexible body;

- Reinforcement with a reinforced layer;

- Sufficient density.

- Not detected.

1st place: "GPP 600 × 350x1000 mm jav13 NOIZZLESS 2000000297590"

The product is made on the basis of galvanized steel, equipped with a special sound-absorbing material. Mounted in rectangular ducts. Equipped with connecting flanges for ease of installation. For maximum noise reduction, a silencer should be installed immediately after the fan. The recommended cost for retail chains is 11,650 rubles.

- Relatively simple installation;

- Strong fasteners;

- Designed for rectangular channels.

- Not detected.

Premium class

3rd place: Arktos CSA 355/900

The model is designed to reduce aerodynamic noise in air ducts with a circular cross section. The product is installed regardless of the direction of air flow. The body is made entirely of galvanized steel. Inside the case there is a layer of sound-absorbing material based on mineral fiber. The recommended cost for retail chains is 18,600 rubles.

- Reinforced hull;

- Effective sound absorption;

- Designed for round channels.

- Somewhat overpriced.

2nd place: Arktos RSA 600x350/1000M1

The product is used to reduce dynamic noise in rectangular channels. Can be mounted regardless of the direction of air movement. To obtain the maximum noise reduction effect, it is recommended to provide a free straight section with a length of at least a meter before the silencer. The body is made of galvanized steel. Sound-absorbing plates based on mineral fiber are installed inside. The recommended cost for retail chains is 21,540 rubles.

- Maximum noise reduction;

- Work is independent of flow direction;

- Dampenes most dynamic vibrations.

- It is necessary to observe the meter indent.

1st place: "SRSr 900*500/1000"

The sample is needed to reduce the noise from the fan in the duct, both on the supply and on the exhaust, when directly installed in the duct of ventilation and air conditioning systems. The transported air must not contain solid, sticky or aggressive impurities. The maximum operating air temperature is 60°C, the maximum allowable speed is 10 m/s. The product is made of galvanized steel with mineral fiber absorbent material. To achieve maximum noise suppression efficiency, it is recommended to provide a free straight section of at least 1.5 m in front of the silencer. The recommended cost for retail chains is 26,000 rubles.

- Ability to work with high-speed flow;

- Versatility of the tasks performed (exhaust / supply / air conditioning);

- Durable production material.

- It is necessary to observe a one and a half meter indent.

Conclusion

Before purchasing a silencer, it is always better to take a clean noise measurement directly in the ventilation shaft. Permissible standards for such noise are established by the Construction Norms and Rules of the Russian Federation No. 23-03 of 2003. Based on the indicators obtained, it will already be possible to select the desired model of the "jammer", while not overpaying for its excessive power.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127688 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124517 -

The best men's sneakers in 2022

Views: 124030 -

The Best Complex Vitamins in 2022

Views: 121937 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2022

Views: 113393 -

Ranking of the best wood paints for interior work in 2022

Views: 110318 -

Rating of the best spinning reels in 2022

Views: 105327 -

Ranking of the best sex dolls for men for 2022

Views: 104363 -

Ranking of the best action cameras from China in 2022

Views: 102214 -

The most effective calcium preparations for adults and children in 2022

Views: 102010