Rating of the best plastering buckets for 2025

In the process of building structures, when finishing and repairing premises, in most cases plastering of walls and ceilings should be carried out. This is done so that with the help of a layer of plaster it is possible to level a certain surface for its subsequent decoration or finishing. This process is laborious and time consuming, so the need to facilitate it is fully justified. Since ancient times, plasterers have had special tools for these purposes, for example, spatulas and trowels - but they are effective only in small areas and where the plaster layer should be thinner. For throwing a large amount of plaster mass, more capacious tools are used - for example, Ilyukhin's scoop or Shaulsky's plaster ladle.If the first one is quite difficult to meet today, then the second one has not lost its relevance.

Shaulsky's ladle, in fact, is a bowl with thin metal walls (from 0.4 to 1 mm) with a volume of 0.75 to 1 liter. A plastic or wooden handle is also attached to it.

The shape of the bowl could vary:

- Truncated funnel;

- Hemisphere with a truncated bottom;

- Standard hemisphere;

- With mixing funnel towards the handle.

Modern plaster buckets are not far from their ancestors and have several options for holding handles. They can be:

- Ergonomic;

- oval;

- Cylindrical.

The process of throwing plaster itself is quite simple, however, certain skills will be required. The mixture is scooped from the container with a bucket and splashed in a semicircular motion over the surface, which was moistened or primed before starting. In this case, the impact of the mixture on the surface should be light in order to ensure the best grip. Then, with a special rule or an elongated spatula, the plaster layer is leveled. Nevertheless, any plasterer who performs large volumes of work on an ongoing basis is interested in mechanizing his activities. In this, a pneumatic plaster ladle, powered by a compressor, will come to his aid. It can also be called a plaster shovel or a hopper (from the English "hopper" - "jumper"). Thus, the plaster will automatically “jump out” easily from the container onto the desired surface.

Content [Hide]

- 1 The principle of operation of the hopper

- 2 Existing types of hopper buckets

- 3 Features of the technology of use

- 4 Required compressor specifications

- 5 Using a hopper: requirements for a plaster mortar

- 6 Arguments in favor of using hopper buckets

- 7 Questions of competent choice

- 8 Rating of the best plastering buckets for 2025

- 9 Instead of an epilogue

The principle of operation of the hopper

The hopper bucket consists of its own bucket (functional container), into which a tube is inserted, and on which an air gun with a special valve is installed. By pressing the trigger, the compression air enters the container with the mixture, from where it squeezes it out through the nozzle located on the front of the tool. With the help of a manual valve actuator, you can instantly start / stop the air supply to the container with the plaster mix, which, unlike the ball valve, significantly saves the consumption of the solution. Air ducts usually have a diameter of 2 to 5 millimeters, and mixture outlets are made with a diameter of 10 to 25 millimeters. The distance between the back and front walls of the bucket (in its lower part) should not exceed 250 millimeters, while the ideal distance would be 160 - 200 millimeters. For optimal operation of the entire pneumatic system, a compressor designed for 4-5 atmospheres is suitable.

IMPORTANT! The increased distance between the working and outlet nozzles can lead to insufficient pressure, which means that a more powerful compressor must be connected!

Structurally, the device consists of several elements that are necessarily present in any of its modifications:

- Spray nozzle - sprays the plaster mixture, giving it the desired speed;

- Bunker-capacity - is intended for storing the solution (the performance of the apparatus depends on the shape of the bunker and its dimensions);

- Pneumatic control valve - responsible for the flow of the mixture into the nozzle;

- A fitting equipped with an exit nozzle - is responsible for firing a solution at the desired speed;

- Handle - is responsible for the direction and movement of the device, its tilt to the desired angle.

NOTE. Factory-made hopper buckets are immediately equipped with special compressors for working with various mortars - lime, gypsum, cement, etc.

Depending on the type of solution used, the nozzles must be changed, because each of them has its own dispersion angle (between 30 and 90 degrees). In addition, the bucket hopper has a closed part located on the side of the compressor connection and is responsible for preventing spillage of the mixture during operation.

For the full operation of the bucket, you may also need:

- High capacity compressor - it must be installed if the bucket has several large nozzles;

- Couplings "Gek" - they connect the device to the air supply device;

- An elongated hose - it is responsible for the passage of air under pressure (must be particularly durable and reinforced);

- The manometer is a very important element, because with the help of it it is necessary to constantly monitor the level of pressure. Otherwise, the pressure distribution will be uneven, which will affect the quality of work. For example, a pressure of up to 6 atmospheres will be optimal, and a pressure of 8 atmospheres will lead to excessive impact force and dispersion (and in general is fraught with an explosion).

"Pros" and "cons" of the functionality of the pneumatic bucket and working with it

- Its most significant disadvantages include:

- The need to equip the device with a compressor;

- A relatively large mass of the device - about 10 kilograms, despite the fact that it will have to be kept on weight.

The undoubted advantages are:

- High plastering speed (the hopper is able to throw out 50 kilograms of mortar in 3 minutes);

- Ease of management;

- Ability to work with various decorative and plaster mixtures (paints, liquid wallpaper, cork, sand-cement, gypsum, concrete);

- Increased savings in material mixtures;

- High adhesion to the treated surface, which is achieved due to the ejection force;

- Possibility of using decorative mixtures containing granules/fibers.

IMPORTANT! When working with a structural plaster mortar containing mica, wood fibers, pebbles and granules, it is necessary to ensure that they do not break up into smaller fractions in order to avoid clogging of the nozzles and damage to the device!

Existing types of hopper buckets

In total, there are two types of the considered devices, which is due to the fact that the surface to be treated can be located differently in relation to the operator:

- Ceiling models;

- Wall models.

Between themselves, they differ only in the angle of the handle and the location of the nozzles. The nozzles of the ceiling hopper are at an angle of 45 degrees to the vertical axis and look directly upwards, while those of the wall hopper are located at an angle of 90 degrees to the same axis of the hopper.

Features of the technology of use

Before starting, it is necessary to install "beacons" at a distance of 150 - 300 centimeters from the end to the beginning of the wall.For convenience of markup, additional ones can be fixed between them. The distance between them is filled with a solution from the pneumatic bucket in such a way that it would minimally go beyond the boundaries of the "beacons". At the same time, the solution should not be too liquid so as not to spread over the surface, and not too thick so that the compressor can cope with splashing. Then, with a rule of one and a half meters, with gentle movements, the mixture is distributed from the bottom up along the wall, removing excess mortar and not touching the “beacons”.

IMPORTANT! In the process of work, the bucket must be kept at a distance of 5-6 centimeters from the surface! If you remove the tool at a distance of 10 centimeters, you can already get an unnecessary “fur coat” effect.

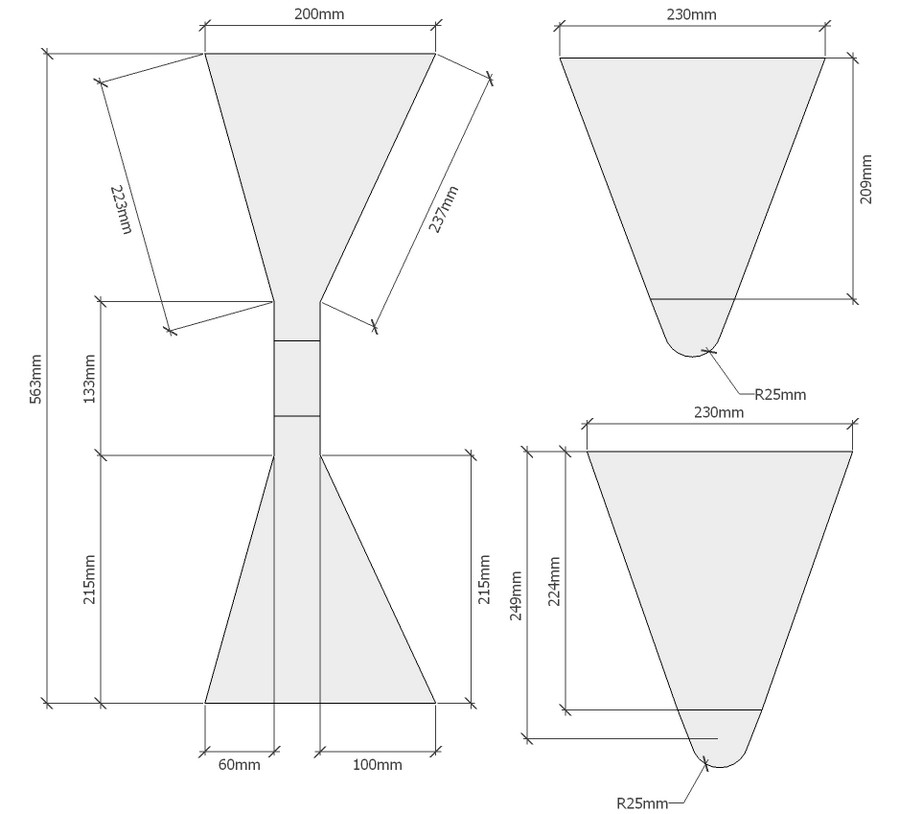

Self-made hopper bucket

It is quite easy to make this device yourself, although its retail price is relatively low. If an air gun and a compressor are available, then only a hopper-capacity will need to be made. “For everything - about everything” will take no more than 2-3 hours, and “any” finances will still be saved.

Necessary materials:

- Tin (steel, aluminum) sheet is thin, from 0.4 to 1 mm thick;

- Directly airgun;

- 6 washers for 3 nozzles size M10-14;

- Welding or riveting machine;

- Drills (10-14 mm) and a drill;

- A grinder with a cutting wheel or scissors for metal.

Step by step manufacturing process:

- It is necessary first to make allowances of 20-30 millimeters, if riveting is supposed to be connected;

- Transfer the split diagram drawn on whatman paper or thick cardboard to a metal sheet;

- Cut, bend at the seams, rivet or weld the resulting template;

- In the front part, it is necessary to drill three holes and strengthen them on both sides with washers of the required diameter using rivets.

- On the back wall, on the contrary, make a hole for the air gun nozzle;

- Mount the air gun;

- Attach the handle to the upper part of the hopper tank with rivets;

- Connect the entire structure to the compressor by means of the "Gek" coupling.

Required compressor specifications

The main element of the working design of the entire tool under consideration is the compressor. The quality and speed of processing will directly depend on its characteristics. In many situations, the hopper makes increased demands on the volume and pressure of the supplied air, which is incomparable with a conventional cartridge pistol. It is worth noting that the compressor must be selected based on the characteristics of the remaining elements of the apparatus in order to create the optimal variation of the instrument, which will be fully operational. Thus, the average characteristics can be called:

- Working pressure of 6 atmospheres;

- Exhaust capacity (minimum) is 350 liters per minute;

- The number of active cylinders - two pieces;

- The volume of the receiver (minimum) is 50 liters.

For a cartridge pistol, these requirements will be somewhat lower:

- Working pressure of 4 atmospheres;

- Exhaust capacity (minimum) - 160 liters per minute;

- The number of working cylinders - 2 pieces;

- The volume of the receiver (minimum) is 25 liters.

Using a hopper: requirements for a plaster mortar

With the help of a hopper bucket, it is possible to apply various types of plaster.At the same time, according to the provisions of Building Code 7.1.7, the strength of the surface on which the plaster is applied must be higher than the strength properties of the plaster itself. Thus, the following example can be given: only lightweight types of mortars are applied to the surface of aerated concrete - cement-sand or gypsum interspersed with polystyrene granules

The choice of the mixture used will depend on the type of premises:

- For external walls and rooms with high humidity, whose surfaces constantly undergo temperature changes and where condensation occurs constantly, cement-based plaster mixtures should be used;

- In dry rooms, where there is a need for the walls to "breathe" - gypsum or lime mortars should be used;

- If you need to apply a base for laying tiles, then you should use a sand-cement mortar.

- At the same time, additional properties must be imparted to plaster mortars by introducing special additives into their composition:

- Fiber is added to cement compositions in order to give them increased strength properties, because this fiber minimizes the manifestation of cracks and shrinkage deformations;

- In order to increase the plasticity of sand-cement mixtures, PVA, initial plasticizers or detergents are added to them. Plasticizing inclusions help prevent delamination of the hardened mortar, prolong its life, and provide the possibility of long-term work with it. Particularly noteworthy are the plasticizing additives "TsemStone" and "TsemAkva", which save cement, increase its water-repellent properties, increase strength, reduce shrinkage, and actively fight the manifestation of cracks.The TsemStone ingredient fully replaces lime in the mixture, because it has plasticizing characteristics and can extend the life of the solution up to 300 minutes. It is very easy to introduce "TsemStone" (unlike lime, because it must first be extinguished, spending some effort and time), there is no need to comply with special safety requirements. The additive "CemMix" can simply be poured into the mixture and stirred, and in addition to increasing plasticity, it will add additional properties against stratification of the solution and accelerate curing;

- In order to obtain plaster with special waterproof properties, water-repellent additives are used - they work with cement mortars;

- In order to increase the strength of the coating of gypsum compositions, the TsemStone plasticizer is used, which fully involves gypsum in the hydration process and the plaster turns out to be self-compacting.

Arguments in favor of using hopper buckets

In addition to the above advantages, there are additional advantages of buckets:

- They notably save the solution, which equals financial savings;

- Significantly reduce the time spent on work;

- They have increased accuracy and accuracy of applying the solution;

- Able to work with almost any type of mortar and liquid finishing materials;

- They have high productivity of the process itself both on complex surfaces and on smooth bases;

- The adhesive qualities of the applied plaster will be increased several times;

- You can work both indoors and outdoors.

Even a novice can use the device in question - the device itself does not differ in complexity, and the instructions for the factory models are intuitive. The cost of models is usually low, especially true for those samples that are sold without a compressor.And if necessary, even a car compressor can be attached to a homemade bucket.

The device will last a long time, however, do not forget about its cleaning and regular maintenance. A hopper made of metal will be easier to clean. It is easy to find a device in a retail network - they are available in a sufficient assortment and are variable in relation to their technical characteristics.

Nevertheless, it is worth remembering that if plastering work is carried out in several layers, then it is better to use the manual method of applying plaster so that the casting occurs much faster. At the same time, the cleaning of excess solution must be removed immediately, otherwise it may freeze tightly.

Questions of competent choice

First of all, you need to decide how often and for what purposes the device will be used. It is desirable for a professional plasterer to purchase expensive and reliable equipment, the service life of which is significantly extended. Of particular importance is the performance of a cartridge pistol in liters per minute - for domestic use, an indicator of 170 liters is enough, and for professional workshops this value is too small.

It is extremely important to pay attention in advance to various defects, chips and cracks on the case. Also, interchangeable nozzles should be screwed in without much effort, the trigger in the gun should be pressed smoothly, there should be no backlash. In cases where the gun is equipped with an air cock, this is a positive thing that allows you to adjust the pressure and improve the quality of work.

This shows that the main points when buying a hopper will be:

- Its purpose is ceiling, wall, or universal with different nozzles;

- Ease of use - the material of the hopper capacity, the size of the nozzles, the ergonomics of the handle;

- The volume of the container - you do not need to choose too large, since, accordingly, the volume of the placed mixture and the weight of the apparatus will increase. However, a small bunker will have to be replenished more often;

- The presence of replaceable nozzles - most buckets are equipped with nozzles for spraying the solution at different angles (and this already speaks of the versatility of the device);

- The quality of the material of manufacture - the optimal device should be made of stainless steel. However, there are also budget models on the market that will not last long - the surface coating will peel off quickly, the metal will easily corrode. This is especially true for tin buckets.

Rating of the best plastering buckets for 2025

Budget models

2nd place: "Zitrek SN-01"

votes 0

A good example of an Eastern European brand, although it is considered a budget option. More positioned as a model for wall work. The volume of the bunker is sufficient, but it is difficult to call it very large. The output nozzles have 4 pieces, and the solution is able to be applied to the surface with a layer of 5 millimeters. It has a long and ergonomic handle, high-quality body with anti-corrosion coating.

| Name | Index |

|---|---|

| Producing country | Czech Republic |

| Bowl volume, liters | 3.5 |

| Number of nozzles, pieces | 4 |

| Required pressure, atmospheres | 2021-05-04 00:00:00 |

| Price, rubles | 2800 |

- A bowl of sufficient capacity;

- Low price;

- Long handle.

- Anti-corrosion is provided only by coating.

1st place: "Zitrek SN-02"

votes 0

This model is designed specifically for ceiling work. The body is made of stainless steel. Using this tool, it is quite possible to achieve a uniform distribution of the entire solution over the treated surface with a minimum layer of 5 millimeters.Included for the hose is a "European adapter"; with its help, the ceiling surface is perfectly processed with an average performance of 4 atmospheres with an exhaust of 320 liters per minute. The device is capable of working with a fine-grained mixture of 6 millimeters.

| Name | Index |

|---|---|

| Producing country | Czech Republic |

| Bowl volume, liters | 3.5 |

| Number of nozzles, pieces | 4 |

| Required pressure, atmospheres | 2021-06-04 00:00:00 |

| Price, rubles | 2900 |

- Cast stainless steel body;

- Productive compressor;

- Hose with a diameter of 18 millimeters.

- A somewhat loose handle - you will have to strengthen it additionally (with rivets).

Middle price segment

2nd place: "PROFMASH KSh-4"

votes 0

Excellent device for processing vertical surfaces. It requires a slightly increased pressure with a limit of 8 atmospheres, however, it has four nozzles with an increased width of up to 18 millimeters. It is characterized by a high application speed - approximately 60 square meters per hour. Although it is considered a semi-professional model, it has become popular due to its ease of use and affordable price. Requires good mixing of the solution, especially with the content of granules (i.e. it makes sense to strictly observe the consistency). Similarly, we can talk about the need for quality service - nozzles must be cleaned with special care.

| Name | Index |

|---|---|

| Producing country | Russian Federation |

| Bowl volume, liters | 3.6 |

| Number of nozzles, pieces | 4 |

| Required pressure, atmospheres | 2021-08-06 00:00:00 |

| Price, rubles | 4100 |

- High processing speed;

- Increased nozzle diameter;

- The best ratio in terms of "price-quality".

- Requires careful and meticulous maintenance.

1st place: "HYVST 07-OMG-II"

votes 0

This pneumatic bucket is made of high-grade stainless steel, which indicates an increased operational life of the device. It is positioned by the manufacturer as the best device for applying the composition to vertical surfaces. Experienced experts advise this model to be used for applying liquid wallpaper. The kit comes with several nozzles at once, providing variability of application and excellent performance. The hopper does not have a large volume, however, this affects the usability. Plastering must be done from a distance of approximately 5 centimeters.

| Name | Index |

|---|---|

| Producing country | People's Republic of China |

| Bowl volume, liters | 3.5 |

| Number of nozzles, pieces | 4 |

| Required pressure, atmospheres | 2021-08-06 00:00:00 |

| Price, rubles | 4500 |

- Increased length of the complete hose - 15 meters;

- Productivity - about 40 kilograms of dry mix per hour;

- The holes are optimized for 90 degree angles.

- The need to work at close range.

Professional Samples

2nd place: "TeaM K350"

votes 0

This wall hopper is specially designed to work on wall surfaces. Produced by the world famous Italian brand "Team-M". The case is completely made of the strongest stainless steel. By itself, it is a compact device, which is not difficult to use. The performance is quite high. The connection to the compressor has the “Geka” standard, which means that it can even be connected to a car compressor. In general, most elements can be completely replaceable, although this is not declared by the manufacturer. The nozzle diameter has been increased to 20 millimeters.

| Name | Index |

|---|---|

| Producing country | People's Republic of China |

| Bowl volume, liters | 3.5 |

| Number of nozzles, pieces | 4 |

| Required pressure, atmospheres | 2021-08-06 00:00:00 |

| Price, rubles | 4500 |

- Extremely light weight - only 2.6 kilograms;

- Increased nozzle diameter;

- The handles do not have a common defect - no play is observed, additional reinforcement is not required.

- Not found (for its segment).

1st place: "Pegas 2721"

votes 0

Bucket hopper from the Russian manufacturer Pegas Pnevmatika - it specializes exclusively in automatic equipment in the field of construction. The connection with the compressor is made according to the universal scheme "Gek ½". The manufacturer insists that the equipment is adapted for the use of GENERALLY (!) all known building mixtures, including compositions with unsifted sand. General reviews say that the device is of very high quality and is suitable for any type of finishing and construction work. At the same time, excellent work with adhesive mixtures is declared. The working distance can be varied from 5 to 25 centimeters.

| Name | Index |

|---|---|

| Producing country | Russian Federation |

| Bowl volume, liters | 3.5 |

| Number of nozzles, pieces | 4 |

| Required pressure, atmospheres | 6 |

| Price, rubles | 7200 |

- Versatility;

- Increased performance;

- Ability to work with fractions of 1 centimeter.

- Not found.

Instead of an epilogue

After analyzing the domestic market of the equipment in question, we can safely say that the domestic manufacturer confidently occupies a niche “above average” in this segment, moreover, its products are quoted at a fairly high level.However, this again can only be attributed to the products of the "Professional" level. Otherwise, household consumer demand is clearly not fixated on the purchase of high-end equipment and is limited only to the budget or mid-price segment. This circumstance is largely due to the reluctance of the average consumer to perform such work on their own.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127688 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124517 -

The best men's sneakers in 2025

Views: 124030 -

The Best Complex Vitamins in 2025

Views: 121937 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2025

Views: 113393 -

Ranking of the best wood paints for interior work in 2025

Views: 110318 -

Rating of the best spinning reels in 2025

Views: 105327 -

Ranking of the best sex dolls for men for 2025

Views: 104363 -

Ranking of the best action cameras from China in 2025

Views: 102214 -

The most effective calcium preparations for adults and children in 2025

Views: 102010