Rating of the best height gauges for 2025

Caliper tools are a group of metalwork measuring instruments characterized by high accuracy. However, their high accuracy is by no means hindered by a relatively simple device and ease of use. The most common caliper tools are calipers, depth gauges and calipers. The latter device will be discussed in this article.

Content [Hide]

- 1 Features of height gauges

- 2 Scope of use

- 3 Types of height gauges

- 4 Accuracy classification and measurements

- 5 Measuring and evaluating results

- 6 Possible sources of errors and their elimination

- 7 Rules for handling the height gage

- 8 Rating of the best height gauges for 2025

- 9 Instead of an epilogue

Features of height gauges

First of all, it is worth mentioning some features of the tool:

- Due to the fact that the term came from the Norman dialects, the device can be referred to in two ways - both “shtangenreismAs” and “shtangenreismus”, which will be true in both cases;

- Visually, it is somewhat similar to a caliper, but it is used to set dimensions along horizontal planes in a vertical position;

- It is quite possible to compare the principle of its operation with the work of a caliper;

- Its main task is to measure objects in height, measure the depth of holes, coordinate the location of various parts on the plane of the object relative to each other, as well as the implementation of various marking procedures;

- Due to the fact that the device is essentially a measuring tool, it has its own normatively fixed methodology for making measurements and verifying the results;

- The technical conditions of this device are regulated by the State Standard No. 164 of 1990 (164-90).

Device design

As mentioned above, the height gauge is a measuring tool for the plumbing industry and is used to measure the heights of objects, the depth of holes, and to mark the body of various parts.Its design features include the presence of special marking devices (sponges and legs), as well as the base base used to install the measured object on the plane. The standard measurement accuracy of the device is +/- 0.5 millimeters and is easy to achieve even for an inexperienced user.

The entire design of the height gage can be divided into basic elements and additional ones. The first ones include:

- Massive base-base;

- The bar is vertical, with the main millimeter scale applied to it (popularly called the “ruler” for its similarity to a school instrument);

- main frame;

- An additional scale with micrometric markings (aka nonius);

- Measuring leg.

- The second elements, which play an auxiliary role, carry either a fixing or an adjusting function, and they include:

- A nut with a screw used to move the main frame;

- Frame for micrometric feed;

- Retainer for replaceable tips on the measuring leg;

- Drawing tool.

Design features

In the device under consideration, the rod with the main measuring scale, as it were, is “pressed” into the base of the instrument strictly at an angle of 90 degrees to the plane of its support. On the bar itself there is a moving frame with a micrometer scale that protrudes to the side. The protrusion is equipped with a lock with a screw, on which the marking / measuring leg is fixed (which will depend on the task being performed - marking or measuring).

Scope of use

This type of measuring and marking tools is used in turning / metalwork workshops in order to establish geometric linear dimensions for objects of various types, and it is also possible for them to measure the depth of a groove or hole or mark parts and elements when carrying out repair / assembly operations in the necessary industrial sectors (automotive industry). , mechanical engineering, metalworking, etc.). Among other things, the height gauge can be used to accurately measure the height of workpieces that are already placed on the measuring plane. It is worth remembering that the measurement technique and instrument verification are exact categories that are defined by the relevant state standard.

Types of height gauges

In total, there are three main types of the considered device. The traditional vernier height gauge was invented over 100 years ago and has been successfully used ever since. Its main users are engineers who need to accurately calculate data to confirm the correctness of the indicators. There are also special altimeters that have a circular pointer in the form of a dial, which serves to set altitude measurements. And the third variety is digital height gauges that can directly read the height or determine zero marks, regardless of the test plane.

INFORMATION! Even today it is possible to add a small motorized controller to the instrument and connect the resulting system to a computer. Thus, it is possible to achieve automation of work and make the measurements made as accurate as possible.

If we talk about the axes of gage measurements, then they can be made both vertically and horizontally.Diagonal measurements are also possible, but require an additional module.

As a result, using the marking established by the state standard, the existing three types of height gauges must be correctly named as follows:

- "SHR" (nonius) - determination of linear measurements on a micrometer scale;

- "SHRK" - having a circular reading scale;

- "SHRC" - digital devices with electronic indicators.

IMPORTANT! There are digital models up to 40" in size, usually equipped with a motor/handwheel that works to speed up movement when making a mark or taking measurements. Some electronic samples have a rapidly adjustable spreading servo mechanism, which makes it possible to quickly move the measured point to the desired location before initiating the measurement system.

Additionally, the considered caliper tools may differ in the maximum height (length) of the measured objects. This parameter is expressed as a numerical value, which is added to the letter marking in the tool name. For example, a device called "SHR-250" performs manual measurement functions for parts with a height of no more than 250 millimeters. The maximum possible height of the measured part today is 2500 millimeters.

Accuracy classification and measurements

Any height gage must be categorized according to the accuracy class, which is included in the marking of the device. This class is indicated numerically and is the last group of numbers in the name. For example, the last three digits in the name "SHR-250-0.05" will mean that the device has a measurement error of 0.05 mm.

Thus, accuracy classes are divided into the following categories:

- First class (the most accurate and best) - from 0.05 to 0.09 millimeters;

- The second class is from 0.1 mm and above.

For electronic devices, accuracy can also be added to the step of discreteness - from 0.03 to 0.09 millimeters - the first class, everything above is the second.

Before using the instrument, it is necessary to verify its accuracy, and the measurements themselves should be carried out in accordance with the conditions of MI 2190-92 and GOST 164-90.

It is possible to check the zero point on the work plane in the following way:

- The tool is fixed on a flat base;

- The main frame is lowered down to the stop (until it touches the base);

- Next, there is a reconciliation of the scale on the main ruler and vernier - they must match in their zero risk values;

- If a match is achieved, the instrument is capable of making accurate measurements.

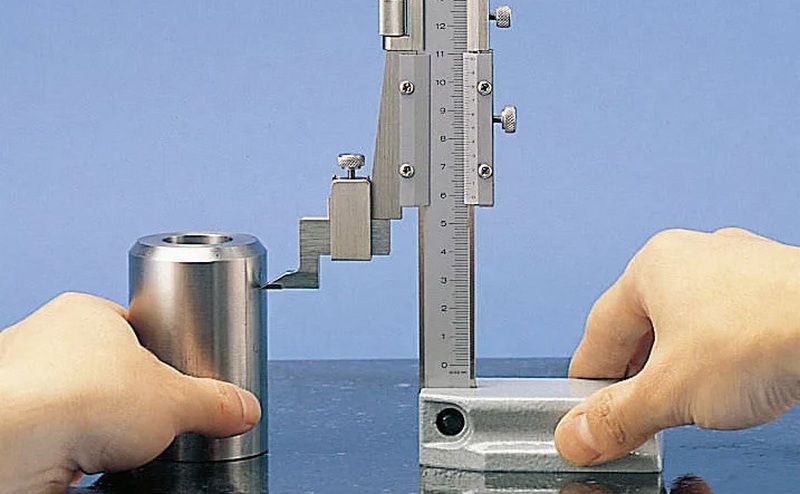

Measuring and evaluating results

The measurement algorithm itself consists of several stages:

- The measured object is fixed on a smooth, even base;

- Further, the device and the object are combined;

- The main frame of the device moves down until it touches the object;

- Then the micrometric mechanism moves until it is in full contact with the measured part;

- The screws fix the position of the instrument frames;

- The result is evaluated.

The results are evaluated in the form of determining the full number of millimeters according to the indicators of the main scale and by fractions of an incomplete millimeter on a micrometric scale. On the latter, it is required to find such a division that would coincide with the corresponding division on the rail. When a match is found, it is required to calculate how many strokes of the vernier ruler remain from zero to it - this will become the micrometric value of the measured height.

Optimization of measurement processes

The device in question is extremely sensitive to operating temperature. Therefore, it should be touched during operation only in specially designated places, such as: a toggle switch that activates the air bearings, a platform for supporting the rod and a control handle. In order to obtain more accurate results, it is forbidden to touch other elements of the measuring circuit.

The primary stage of the measuring process includes the marking of the processed object according to the sample. Usually, for this, a test platform is used, a thickness gauge with a scriber or dial indicator and a gauge with a wide range. In this case, the test platform, which is the main plane, is used simultaneously for the reference point both for the object and for the height gauge. The latter is used to fix and determine the height on the object being processed. In any case, you should always follow a few simple tips:

In cases where the height gauge is used simultaneously with the test plate, the efficiency of its work is directly determined by the evenness of the plate, which ensures the binding of the reference point both to the object and to the device;

- The efficiency of the altimeter is qualitatively affected by the actual state of the base of the granite test tile and the presence of foreign formations on it (a layer of dust and dirt);

- Any, even the smallest defect in the base between the height gage and the object of measurement, can increase the measurement inaccuracy by several times.

Possible sources of errors and their elimination

Regardless of its type, any height gage has the same problem - the greater the height it is able to measure, the more likely it is to get an erroneous result. This circumstance is due to the fact that the resulting height is not valid.It is only a relation to the foundation. As an example, it is possible to cite a similar situation in physical mechanics: the longer the arm of a mechanism with a lever, the greater its multiplied force becomes.

A qualitative error may also lie in the design of the base height gage. For example, a tool designed to measure only 12" heights can be upgraded by simply lengthening the stand to, say, 36". At the same time, proper changes in the design features of the base or in the cross section of the measuring rack are not properly made. With such an increase, the stand naturally begins to bend and sway. The resulting deviation of about 0.001 inches will not be noticeable, but it will qualitatively affect the final results, and this, in turn, will increase the size of the measured part.

To improve the measuring performance, it is necessary to try to fix the stand in a position that would eliminate the risk of bending. However, this move is unlikely to completely solve the problem, because the rack may begin to bend already at the top. A radical solution could be to increase the base area and add massiveness to it - this will already have a great effect on the stability of the tool. It is also worth looking at the presence of dust and dirt on the measuring site, which also entail a deviation from the exact results.

Rules for handling the height gage

For any precision measuring device, the correct use of the tool and its careful adjustment by the operator is very important. As a rule, gauges are used in the lower aisles of their working ranges, which is 300 millimeters or 12 inches.Regardless of the measurement system used (metric or inch), the accuracy of the result will always decrease as you move away from the control point. In the case when the measurement is made in the upper part of the ruler, then it is possible to increase the correctness of the results by slightly approaching the zero mark to the center of the object being processed.

Due to the fact that the device in question is categorically afraid of high temperatures (due to the fact that when heated, the metal expands and, accordingly, thereby increasing the distance on the measurement scale), the following rules must be observed:

- It is forbidden to place the height gage in places where it will be exposed to direct ultraviolet rays, as well as strong air currents;

- It is forbidden to install the device in the immediate vicinity of working radiators or heaters;

- It is forbidden to take the object of measurement with bare hands immediately before its processing - for this you need to use gloves;

- It is forbidden to measure those objects that have recently been moved from a cold space to a warmer one and vice versa;

- To achieve results with increased accuracy, the part under test is first placed on the support plate and left to adapt to the current conditions (for 15 minutes and up to 8 hours - depending on the size of the sample).

Practical Tips

- As a general rule, air bearings should only be used for instrument positioning purposes immediately prior to measurement. If, however, there is a need for them precisely during the measuring process (this applies, for example, to massive objects), then the control point should also be measured again with their help.

- Instruments with an electric motor perform best if the applied force is constant when measuring an object.When using the instrument with manual control, it is necessary to apply a uniform force each time the sample surface is touched.

- It is always worth remembering that when two elastic bodies (in this case, the instrument and the object of measurement) come into contact, they oscillate for some time. Therefore, during the named time, the measured values will also fluctuate, i.e. oscillate. To obtain an accurate result, it is necessary to wait for the stabilization of both bodies, for which the “settlement time” is taken into account.

- Long contact probes, especially those with small contacts and narrow protrusions, can be bent when in contact with the sample being measured. Thus, it is quite possible that there will be a need for the formation of jumpers between sensors, in the event of the aforementioned deviation.

Rating of the best height gauges for 2025

ATTENTION! It is always worth remembering that height gauges, like any high-precision measuring instruments whose use is regulated by government regulations, are high-value goods. Therefore, "super-budget" models, with a price below 3,000 rubles, capable of performing accurate measurements at a sufficient level, simply do not exist. Any cheap "handicrafts" (precisely "handicrafts", and not counterfeit or fake) from the countries of the Asian part of the world are not trustworthy!

Budget segment

3rd place: "MEGEON 80900"

votes 0

This model is digital and is a typical sample of the "ShRTs" type instrument. The chassis base uses a composite composition interspersed with carbon fiber, thanks to which the manufacturer was able to reduce the weight of the device, while increasing its wear resistance and strength.More reliable fixation is provided by magnets, and the liquid crystal display clearly shows the accuracy of the results. The model itself is used for marking parts from dissimilar materials in the range from 0.5 to 150 millimeters. There is a built-in relative sizing feature that allows you to automatically check tolerances. Perfect for visually impaired people who find it difficult to see small risks on a micrometer scale. The weight is - 150 grams, the brand's homeland is Russia, the cost for retail chains is 3600 rubles.

- Good value for money;

- Sufficient step of error;

- The very budget price in the vastness of the Russian Federation.

- Warranty for the electronic component - 1 year.

2nd place: "CALIBRON 96529"

votes 0

This sample is directly intended for linear measurements and marking work in the engineering industry. The movement of the frame is very easy, which makes it easy to set the device to the required size. All components of the structure have an anti-corrosion coating, and due to the use of hard alloy in the structure, the service life is significantly extended. The weight is 500 grams, the home of the brand is Russia (manufactured under license in China), the recommended cost for retail stores is 7500 rubles.

- Anti-corrosion coating;

- Increased stability;

- Directed Specialization.

- Large mass for its measured caliber.

1st place: SHAN SHR-200

votes 0

This device is (again) recommended by the manufacturer for industrial use only.Perfectly copes with marking and measuring products for the needs of mechanical engineering. Measurement by micrometric indicators is carried out using a special screw, providing the most accurate step. The entire structure of the device is treated with an anti-corrosion coating. Both scales for measurements have a matte layer that does not glare in the sun, which creates additional convenience for the user. Comes with a secure carrying case. The mass of the device is 5 kilograms, the birthplace of the brand is China, the price set for the retail network is 9500 rubles.

- Convenient case with compartments for auxiliary modules (purchased separately);

- Massive base (reduces error);

- Anti-corrosion coating.

- Not detected.

Middle price segment

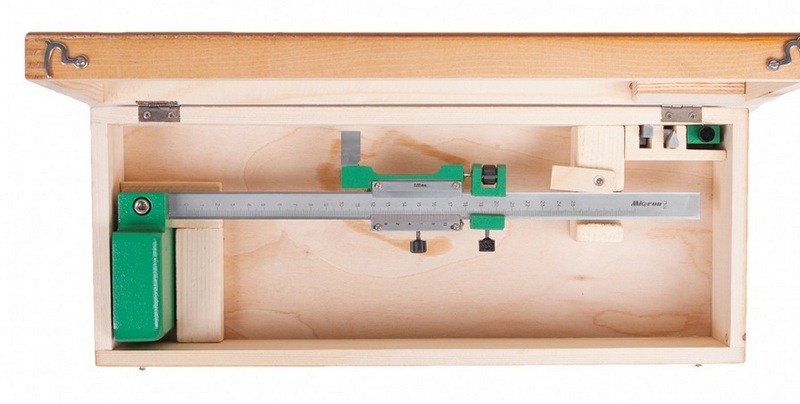

3rd place: "Micron PRO 100837"

votes 0

In principle, this device can be called an elite classic device, yet focused on production purposes. The measurement step is maintained in standard values - up to 0.05 millimeters. The total measuring range is up to 200 millimeters. The vernier scale is coated with a matte finish to prevent glare. At the same time, the entire structure is made of industrial strength steel, which means durability. The package includes a high-quality wooden case that can provide long-term storage. The total weight of the device is 300 grams, the home of the brand is the Czech Republic, the recommended price for retail chains is 20,900 rubles.

- Matte finish that eliminates glare;

- Appropriate level of error;

- Reliable case for transportation.

- Too high price.

2nd place: "Micron ShRK-200 0.01 MIK 26264"

votes 0

This model, which has a pointer dial, is perfect for accurate measurement of heights and drawing marking marks on the established dimensions of the measured samples. Removal of numerical indicators occurs according to the exact data of the dial. The accuracy division price is extremely high and amounts to 0.01 millimeters, which refers the device to the first accuracy class. The most extreme limit is 200 millimeters. The total weight of the device is 2.3 kilograms, the brand's homeland is the Czech Republic, the recommended retail price is 25,200 rubles.

- Large base provides increased accuracy;

- Measurement variability;

- Quality assembly;

- Carbide drawing tip.

- Not detected.

1st place: TekhnoStal 035022

votes 0

This model is a high-precision specialized tool aimed at determining the external boundaries of the dimensions of the machined parts. More adapted to the establishment of high-altitude indicators. It is a heavy and durable equipment, with a characteristic fixing of the stable properties of any structures. However, in order to obtain highly effective results, correct fixation is required, which generally implies the absence of any convergent properties. In any case, a pre-prepared clear surface allows you to achieve the desired result. The mass of the goods is 19 kilograms, the birthplace of the brand is China, the price determined for retail chains is 33,000 rubles.

- Maximum accuracy (on the cleaned surface);

- Structural stability;

- Extended measuring range.

- Not detected.

Premium Samples

2nd place: CHIZ 41989

votes 0

An excellent copy from domestic Chelyabinsk manufacturers. Able to determine the height with an error of 0.05 millimeters. The device is equipped with heavy and durable parts that give the overall structure with the measured object full stability. The markings on all scales are made by a laser method, which makes it impossible to erase them over time. The weight of the device is 6.3 kilograms, the manufacturer's brand is Russia. The recommended retail price is 16,800 rubles.

- Massive base;

- Measuring accuracy;

- Adequate cost (for the height of the bar).

- Not detected.

1st place: "INSIZE SHR-1000"

votes 0

An excellent model for the production of ultra-high measurements. The working area is made of carbide materials, which allows you to withstand temperature changes (adaptation occurs faster). All parts are made of stainless steel, which is coated with a layer that can repel small metal fragments. The working temperature is adapted to differences, thus the process of "calming down" of materials is made minimal. The total weight of the device is 29 kilograms, the birthplace of the brand is China, the price for stores is 195,000 rubles.

- Massive device;

- Accuracy of measurements;

- Specialization.

- Extremely overpriced.

Instead of an epilogue

An analysis of the current market has shown that the gage gauges in question (not to be confused with standard thickness gauges) are highly specialized tools that are unlikely to be needed in domestic conditions. However, the existing wide product range suggests the great popularity of this type of device.Accordingly, market indicators, as soon as they are considered the determining factors, which say that the leaders are European manufacturers, form the current demand. From this it is clear that the companies listed in the rating have long established their quality products, with which it is difficult for a manufacturer from the Russian Federation to compete. This is also evidenced by consumer demand.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131660 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127698 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124526 -

The best men's sneakers in 2025

Views: 124042 -

The Best Complex Vitamins in 2025

Views: 121946 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114985 -

The best paint for gray hair - top rating 2025

Views: 113401 -

Ranking of the best wood paints for interior work in 2025

Views: 110327 -

Rating of the best spinning reels in 2025

Views: 105335 -

Ranking of the best sex dolls for men for 2025

Views: 104374 -

Ranking of the best action cameras from China in 2025

Views: 102222 -

The most effective calcium preparations for adults and children in 2025

Views: 102016