Rating of the best grinding machines for 2022

In our review you will find a description of the best grinding machines. We will provide recommendations on which company to buy a product, how to choose the right one, consider the best manufacturers, popular models, determine their characteristics, and orient by price.

Content [Hide]

How do the machines work?

Grinding removes some of the material from the workpiece in order to shape it according to your needs. Processing takes place using an abrasive wheel consisting of quartz grains, silicon carbide, carborundum.

In fact, grinding is an operation that requires certain tolerances, a high class of accuracy, complex measurements (longitudinal or angular), observance of geometric dimensions (concentricity, parallelism, perpendicularity). Also grinding is intended for surface finishing, removal of roughness, scratches.

Apparatus types

There are many types of grinding equipment available. Here we will look at what it is like, define the criteria necessary when choosing the functionality you need, list tips that will draw attention to errors that may occur during the purchase, which is not unimportant for the effective implementation of any project you have conceived.

1. Surface grinding

Thanks to the simple design of such a machine, consisting of a longitudinal carriage, it is very easy to operate it. Depending on the position of the abrasive element, two types of products are distinguished:

- In devices with a vertical mounting of the grinding wheel on the spindle, the workpiece moves in a straight line, adhering tightly to the abrasive. Such machines are usually used for rough machining of planes, although individual models can achieve high precision.

- The active element of the tangential apparatus rotates horizontally, works along the edge of the workpiece, moves in a circular, pendulum stroke. Such machines are used, as a rule, for high-tech processing of bell-shaped, inclined, mating surfaces, grooves, for performing complex profile-, internal grinding operations.

Such equipment can be used in conjunction with other, turning, milling. Workpieces are positioned using a magnetic pressure plate, moved manually or mechanically.The product is equipped with a pump for automatic recirculation and application of coolant to parts.

Scope of use:

- stamps;

- guides;

- plates;

- ordinary or piston rings;

- Press forms;

- pins;

- tool profiles.

The dimensions of the blanks can vary from 40-80 cm to 6 meters. The machine can work with a high degree of reliability on metal, wood, it is possible to install brushing brushes.

2. Cylindrical grinding

These machines can work with workpieces of various shapes, however, the part must have a central axis of rotation: a cylinder, cone, ellipse, cam or crankshaft. We distinguish several subtypes of aggregates:

- On a two-drum machine, the part rotates synchronously with the abrasive.

- The size of the workpiece processed by the internal grinder is always smaller than the width of the circle.

- Centerless grinders work with small-sized, cylindrical products, their scope, bolts or pins. The mechanism consists of two circles that rotate in the same direction, a workpiece is placed between them, without a clamp (hence the mechanism is called "centerless"), which rotates in the opposite direction to the abrasive. The driving wheel is inclined at a certain angle, from 1 to 5 degrees, depending on the hardness, size of the material to be processed.

3. Universal

One of the best machines with excellent performance. On these machines, you can grind at home the outer, inner surfaces of camshafts, crankshafts, cylinders, cones, liners.

The longitudinal carriage, which is part of the design of the unit, provides translational movement of the workpiece, and the hydraulic mechanism gives the wheel the opposite rotation.The characteristic of the processed products determines the speed of the shaft with the help of regulators.

4. Special

These machines are used for parts with complex mechanical geometries that cannot rotate on their own. A vertical spindle (sometimes called planetary) is built into their design, in addition to rotation, it performs circular movement.

Machines are used for processing gears, their profiles, threads, rolling cylinders, bed guides, brake shoes, splines, bearings, turbine blades, aircraft landing gear.

The grinding wheel has many different shapes, grain sizes, and meets international standards.

5. With CNC system

Technological progress has led to the emergence of numerically controlled products on the market, for example, grinding and calibrating. Such machines are used both in large-scale production and in small enterprises, they will help make your project a success, they have a number of advantages over conventional ones:

- unification of workpiece processing (top, front, bottom) on one machine;

- full automation, minimal operator intervention;

- the dimensions of the unit allow grinding large parts;

- magnetic clips;

- improved performance, accuracy;

- with the function of turning on servo motors for each axis, which allows you to effectively position the part;

- automatic control of the condition of the wheels;

- the possibility of programming Cartesian coordinates;

- air purification system from chips, dust.

After studying this review, you yourself will be able to rank the popularity of models. Decide which equipment is better to buy for effective work.

Where could I buy

You can buy inexpensive, low-cost novelties in electrical equipment stores, managers will orient you at an average price, tell you how much this or that product costs, and provide step-by-step instructions for working on machines of this type. You can also order them online, in the online store, with a guarantee of fast delivery.

Rating of quality grinding machines for 2022

This list of circular grinding, combined aggregates is based on real reviews, it takes into account the opinions of customers who have purchased this product.

Combined

Such machines can work with workpieces using an abrasive belt or circle.

Record Power BDS150-EP

votes 0

The BDS150-EP combined woodworking machine has a 5-seat position and is suitable for placement in a small, medium-sized production hall or a tool shop. The design of the unit provides grinding by a tape, a disk. A level is integrated into the design, which regulates the installation of the most important angles.

The product does not require high-tech maintenance, has a compact size, which is useful when space is limited.

The tape effectively works with flat parts, and the disk successfully copes with irregularities on the ends or protruding parts of the workpiece;

Technical indicators:

| Options | Characteristics |

|---|---|

| Manufacturing firm | Great Britain |

| Rotational speed | 2850 rpm |

| R-r circle | 0.152 m |

| Table size | 0.225*0.158 m |

| Power consumption | 0.4 kW |

| output power | 0.25 kW |

| Dimensions, m | 0.36*0.44*0.245 |

| The weight | 19 kg |

| Tape size | 1.01 m |

- the versatility of the machine allows you to combine grinding methods;

- the ability to change the slope of the working area expands the functionality of the equipment;

- with the help of a special protractor provided for by the design of the product, you can control the angle relative to the circle;

- ease of use.

- not detected.

Einhell TC-US 400

votes 0

The Einhell stationary machine, used for working with wood, plastic in medium-sized workshops, takes 4th place. An important advantage of the TC-US 400 is its safety, the tape is securely fastened, so the operator performing the task on the equipment can feel confident.

The case, which covers the inner part of the mechanism from dust, grinding waste, is protected by an anti-corrosion coating. The equipment is resistant to vibrations, mechanical damage.

Technical indicators:

| Options | Characteristics |

|---|---|

| Voltage | 220 V. |

| Max. power | 375 W/30 min. continuous work |

| The weight | 15.5 kg. |

| Processing material | wood, plastic |

| Circle speed | 1450 rpm |

| Belt speed 276 m/min. | |

| Disk size | 150 mm. |

| Tape length | 0.915 m |

| Tape width | 0.1 mm. |

| Substrate | + |

| Dimensions, m | 0.523*0.320*0.249 |

- increased accuracy;

- the marking on the protractor is easy to read, so the part is positioned at the right angle;

- wide functionality;

- simple control;

- vibration immunity due to damping pads;

- increased security;

- wear resistance;

- reliable isolation of electrical contacts;

- ease of maintenance;

- guarantee period.

- no visible flaws found

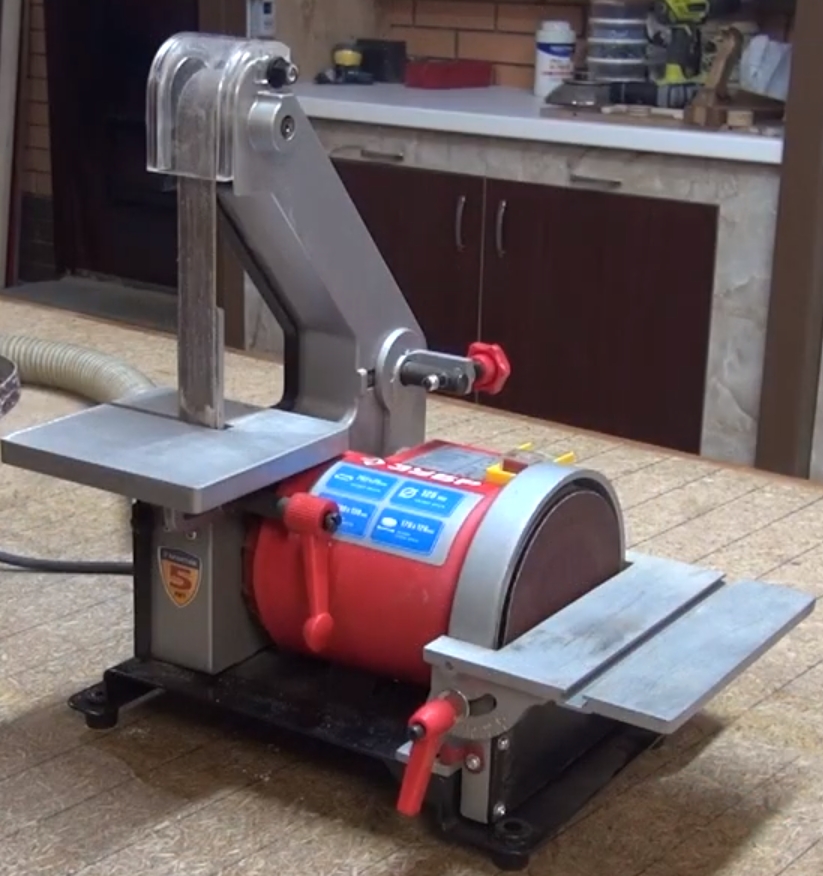

ZUBR ZSHS-330

votes 0

3rd place was won by a functional apparatus that performs various types of work. Its design provides for the presence of a grinding wheel, a belt that can easily cope with any workpiece.

A switch with an electromagnet will prevent accidental start during a power surge. The part can be fed at an arbitrary angle, which allows you to work in any plane. A vacuum cleaner can be connected to the device, which will effectively remove dust and keep the workplace clean.

In general, the ZSHS-330 is a reliable, versatile machine, easily customizable for various types of processing, thanks to Velcro fasteners. Mobile, productive, wear-resistant - it will certainly be a reliable assistant for many years.

Technical indicators:

| Options | Characteristics |

|---|---|

| Machine type | plate-belt |

| Purpose | wood |

| Power | 330 W |

| Voltage | 220 V |

| Circle size, m | 0.125 |

| Circle speed | 2950 rpm |

| Revolutions (rpm) | 2950 |

| Belt speed | 810 m/min |

| Guarantee | 60 months |

- high efficiency;

- due to the size of the circle, increased processing area;

- nozzle for a vacuum cleaner;

- working area size 178×126 mm, tilt angle up to 45°;

- valve for pulling the tape;

- vibration resistance.

- not detected

Record Power BDS150

votes 0

2nd place at the tape-disk machine BDS150, which is a useful addition for workshops. By changing the speed of rotation of the belt, disk, increasing the pressure on the workpiece, you can achieve good quality processing, molding of the part.

Record Power is a compact machine equipped with an asynchronous motor for quiet operation and a cast iron base for stability.

The kit includes an inclined table, which improves the processing of bevels, ledges. It is used for horizontal and vertical grinding.

Technical indicators:

| Options | Characteristics |

|---|---|

| Rotational speed | 2850 rpm |

| R-r circle | 0.152 m |

| Working area solution | 0.225x0.158 m |

| Power consumption | 0.4 kW |

| output power | 0.25 kW |

| Dimensions, m | 0.36*0.44*0.245 |

| The weight | 19 kg |

- stable bed;

- high performance;

- tilt table included.

- not detected.

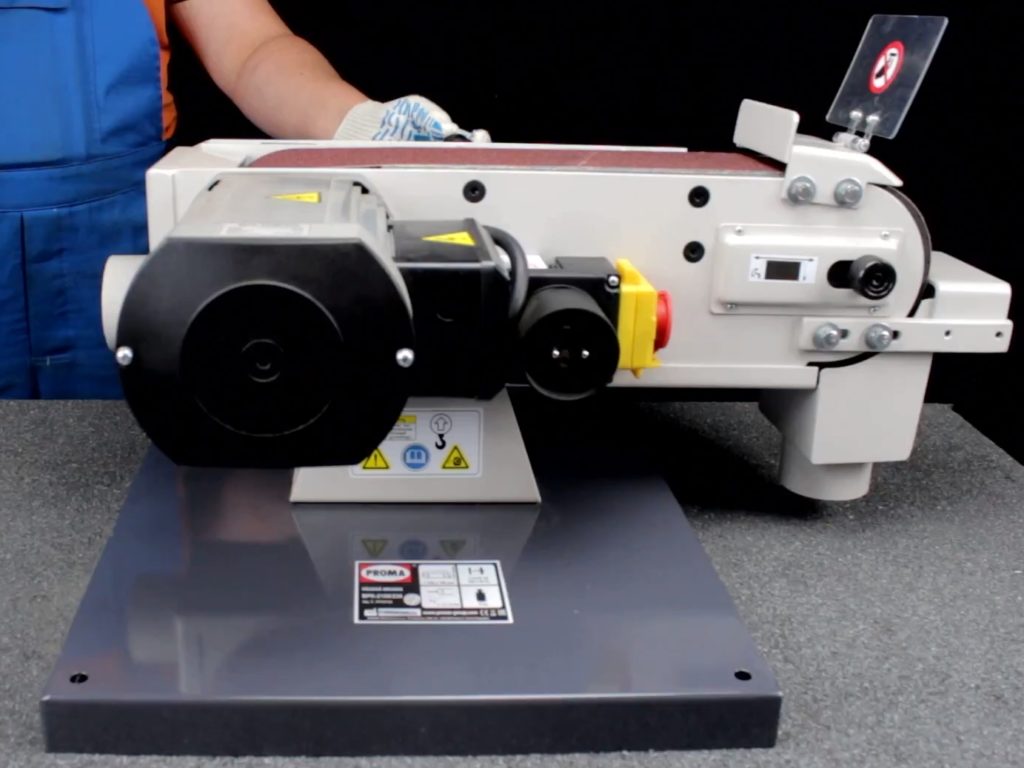

PROMA BPK-2100/400

votes 0

1st place is occupied by a universal device, which is a professional product for grinding metal parts (pipes and profiles). If you increase the belt speed from 23.5 to 47 m/s, the power of the device increases from 2.5 to 3.3 kW.

The stable base protects the internal mechanism from damage. The design is equipped with a tape 10 cm wide.

Technical indicators:

| Options | Characteristics |

|---|---|

| Rotation modules | 1 PC |

| work item | ribbon |

| Mains voltage | 380 V |

| Engine power | 3300 W |

| sharpening | Universal |

| Tape length | 2 m |

| Tape width | 0.1 m |

| Rotational speed | 2840 m/min / 1410/2840 m/min / |

| Rotation speed adjustment | + |

| Stand/cabinet | + |

| The weight | 159 kg |

- you can install additional rollers;

- the ends of the blanks are processed at an angle of 30 - 90 °, 0 - 60 °;

- performance;

- wear resistance;

- build quality;

- the transparent screen protects the operator from sparks, dust;

- the design assumes easy change of a tape;

- the possibility of grinding small workpieces;

- convenient management;

- clear key labels;

- the emphasis provides an opportunity to reliably position the part;

- the equipment can be anchored to the workbench, providing stability.

- not detected.

Cylindrical grinding

These machines work with workpieces that must have a central axis of rotation: cylinder, cone, ellipse, cam or crankshaft.

3L141VF2

votes 0

5th place - at the machine 3L120VF2, a series of these models gained popularity back in the USSR, established itself as high-level equipment. A distinctive feature of the machine is the accuracy in positioning the workpiece during operation. The design of 3L141VF2 incorporates new technological ideas of engineers - machine builders, increasing the productivity of all elements of the apparatus: headstock, ball screw, PU system.

The product of the universal type 3L141VF2 is used for processing:

- internal parts of cylindrical blanks;

- external elements of conical surfaces;

- ends.

The part can be mounted in cam chucks, collets, centers, on a faceplate, as well as in other ways. The accuracy class of the machine corresponds to GOST 8-82.The equipment is suitable for placement in areas with a cold, temperate climate, according to the UHL4 standard, GOST 15150.

Numerical control, created by Delta Electronics, has a logic controller.

Technical indicators:

| Options | Characteristics |

|---|---|

| Distance between centers, m | 0.75 |

| The largest processing solution, m | 0.32 |

| The largest mass of the installed part, kg | 50 |

| Type of | 1 |

| Dimensions (GOST R 52781), m | 0.4x0.4x0.203 |

| Rotation frequency, rpm | 1720 |

| Maximum cutting speed, m/s | 45 |

| Headstock grinding: | |

| Installation angle, hail. | 90 |

| Speed of movement of the grinding grandma, m/min | 2.5 |

| Infeed stroke, m | 0.15 |

| Minimum feed, mm | 0.001 |

| Grandma front: | |

| Rotation frequency, rpm | 30-300 |

| Morse taper size, No. | 4 |

| Quill travel, m | 0.023 |

| Table travel speed, m/min | 0,1-3,5 |

| Minimum feed, mm | 0.001 |

| Rotation angle, degrees | ±6 |

| Size of the smallest hole, m | 0.013 |

| Depth of smallest hole | no more than 3 diameters |

| Size of the largest opening, m | 0.08 |

| Depth of the largest hole, m | 0.125 |

| Machine net weight, kg | 3100 |

| Dimensions (LxWxH), m | 3.510x1.65x 1.4 |

| Permissible deviation from roundness when processing in the centers, microns | 1.6 |

| Constancy of diameter in longitudinal section, microns | 6 |

| The roughness of the outer surface when processing in the centers, microns | 0.16 |

- the presence of a kinematic chain in the design;

- it is possible to move the desktop in a reciprocating direction;

- conical parts are finished manually on a turntable;

- high cost of equipment.

3L10SF2

votes 0

The machine, which occupies the 4th place in our list, is used for grinding the internal, external cylindrical, end, conical parts of workpieces. Parts are fixed, motionless, in collets or a three-jaw clamp. 3L10VSF2 will be more effective in a factory engaged in piece, small-scale production.

The model has a programmable controller, a touch interface, two servos and a converter from Delta Electronics.

Technical indicators:

| Options | Characteristics |

|---|---|

| The largest size of the installed product, m | 0.01 |

| The largest size of the sanded outer surface, m | 0.01 |

| The largest size of the hole to be ground, m | 0.040 |

| The greatest length of the installed product, not less than, m | 0.22 |

| The greatest length of grinding of external surfaces, m | 0.2 |

| The greatest length of the hole to be ground, m (with a hole diameter of more than 20 mm and a frequency of rotation of the internal grinding spindle of 40,000 rpm.) | 0.05 |

| The largest mass of the installed product, kg | 6 |

| Center height above table, m | 0.08 |

| Dimensions without attachments (length x width x height), m | 1.47x1.5x1.8 |

| Dimensions with attached equipment (length x width x height), m | 1.47x1.9x1.8 |

| Machine weight without attachments, kg | 1550 |

| Machine weight with attached equipment, kg | 1850 |

| The greatest movement of the table, m | 0.23 |

| Table automatic movement speed, m/min (stepless regulation) | 0,01…1 |

| The smallest automatic table travel at minimum speed, mm | 1 |

| The largest angle of rotation of the upper table, degrees: | |

| Clockwise | 6 |

| Counterclock-wise | 7 |

| Manual movement of the table in one revolution of the handwheel (electronic handwheel) | 0,1; 1,0; 10,0 |

| The value of the rapid approach and withdrawal of the grinding headstock, m | 0.015 |

| The largest angle of rotation of the sled of the grinding headstock, degrees: | |

| Clockwise | 30 |

| Counterclock-wise | 30 |

| Grinding wheel solutions according to GOST R 52781-2007, m | 0.25x0.02x0.076 |

| The greatest wear of the circle on the radius, m | 0.04 |

| Spindle end diameter according to GOST, m | 0.032 |

| Spindle speed, rpm | 2690 |

| Circumferential speed of the grinding wheel, m/s | 35 |

| Movement of the grinding head per one turn of the handwheel (electronic handwheel), mm / diameter | 0,1; 1,0 |

| Movement of the grinding headstock by one division of the flywheel (electronic handwheel), mm / diameter | 0,001; 0,01 |

| Infeed feed speed, mm/min (stepless regulation) mm/turn of the product | 0,001…0,01 |

| Automatic periodic giving (at the moment of a table reverse). mm/stroke | 0,001…0,01 |

| Grandmother of the product: | |

| Product rotation frequency, rpm | 100…1000 |

| Spindle bore taper according to GOST 25557-82 | Morse 3 |

| The largest angle of rotation of the headstock of the product, degrees: | |

| To the grinding wheel | 90 |

| From the circle | 30 |

| Quill travel, m | 0.015 |

| Quill hole cone according to GOST SEV 174-75 | Morse 2 |

| Internal grinding spindle: | |

| Spindle speed, rpm | 40000…96000 |

| Geometric accuracy of the machine: | |

| Straightness of the trajectory of the table in the horizontal plane, microns | 2 |

| Radial runout of the headstock spindle hole, µm | 2.5 |

| Roundness when processing in the centers, microns | 0.4 |

| Roundness when machining in a chuck, µm | 0.6 |

| Constancy of diameter in longitudinal section, microns | 1 |

| End surface flatness, µm | 3 |

| Surface roughness Ra, µm: | |

| Cylindrical outer | 0,04 |

| Cylindrical inner | 0,04 |

| flat end | 0,16 |

- intuitive control system;

- automatic mode of longitudinal, plunge grinding.

- not detected.

3L142

votes 0

3rd place for a model that performs all-round machining of cones, cylinders, as well as flat flanges.

The equipment is adapted for operation in cold climatic zones, according to the UHL4 standard, GOST 15150. The part can be attached to the machine using a faceplate or a cartridge.

The unit will be effective in any workshop, but for large-scale production it is better to look for more powerful equipment.

The DVP-SA2 CNC controller manufactured by Delta Electronics is integrated with a touch panel from the DOP-B line.

Technical indicators:

| Options | Characteristics |

|---|---|

| The largest R-r of the installed product, m | 0.4 |

| The greatest length of the installed product, m | 1 |

| Center height above table, m | 0.24 |

| The largest mass of the installed product, kg: | |

| When the quill is not clamped | 200 |

| in cartridge | 32 |

| In a chuck with a steady rest | 150 |

| Headstock grinding: | |

| A circle | GOST r 52781-2007 |

| type of | 1 |

| External solution, m | 0.6 |

| Inner diameter, m | 0.305 |

| Height, m | 0.063 |

| Spindle speed of the grinding headstock, rpm | 1590 |

| The largest angle of rotation of the grinding headstock, degrees | ±30 |

| Grinding hole diameter, m | |

| least | 0.03 |

| greatest | 0.2 |

| The greatest length of the ground hole, m | 0.125 |

| Product rotation frequency (adjustable steplessly), rpm | 30...300 |

| The largest angle of rotation of the headstock, degrees | |

| Clockwise | 30 |

| Counterclock-wise | 90 |

| The largest angle of rotation of the upper table, degrees: | |

| Clockwise | 3 |

| Counterclock-wise | 6 |

| Overall dimensions of the machine, m: | |

| length | 5 |

| width | 2.5 |

| height | 2.22 |

| Machine weight with electrical equipment, hydraulic unit, lubrication station, cooling unit and accessories, kg | 7900 |

- kinematic chains;

- all spindles are spinning;

- the table, like all moving parts of the machine, can be positioned manually or hydraulically;

- not enough capacity for mass production.

3D4230

votes 0

On the 2nd place there is a machine used for processing connecting rod, main journals of the crankshaft. The equipment is made in accordance with the regulations UHL4.2, GOST 15150.

3D4230 is used for grinding:

- cylindrical parts,

- conical surfaces with an angle of not more than 3°30'.

The workpiece is fastened with the help of cartridges, or "centers". The equipment has an accuracy level of "B", according to GOST 8-82, in addition, equipment with a class "A" can be ordered.

Technical indicators:

| Options | Characteristics |

|---|---|

| The largest dimensions of the workpiece to be installed, m. | 0.58 |

| Rotation diameter length, m | |

| in the centers | 1.6 |

| In cartridges | 1.45 |

| Grinding diameter, m.: | |

| Largest without lunette | 0.2 |

| Largest with lunette | 0.1102 |

| Smallest with lunette | 0.025 |

| Smallest taper surface (at the tailstock) | 0.05 |

| The largest crank radius of the crankshaft to be ground, m | 0.11 |

| The largest angle of adjustment of the position of the crankshaft with clamped cartridges, deg. | 2 |

| The largest mass of the installed workpiece, kg | 160 |

| The height of the centers above the table, m | 0.3 |

| The greatest displacements, m.: | |

| Table (manually and hydraulically) of the grinding headstock | 1.6 |

| By screw | 0.175 |

| Tailstock quills | 0.035 |

| Speed of movement of a table from a hydraulic drive, m/min. | 0,2...5 |

| Spindle speed of the grinding headstock at idle, rpm. (permissible deviation - 10% | 740 |

| Workpiece rotation frequency (adjustable in steps), rpm | 30;60;85;174 |

| Grinding wheel size, m.: | |

| R-r outer | 0.9 |

| R-r internal | 0.305 |

| height | 0.063 |

| Circumferential speed of the grinding wheel, m/s no more | 35 |

| Infeed value per diameter, not less than (including all feeds) | unlimited |

| Overall dimensions of the machine (at the extreme position of the moving parts), m .: | |

| long | 5.6 |

| width | 2.6 |

| Height (without lamp), m | 1.9 |

| Machine weight, kg | 7500 |

- kinematic chains;

- you can twist the workpiece, abrasive;

- position the grinding headstock in a position convenient for processing;

- table with hydraulic drive;

- the quill moves along the axis of the tailstock;

- clamps move vertically.

- high price.

Spitzen SOG-2040

votes 0

The 1st place is deservedly occupied by an apparatus that allows for high-precision processing of workpieces in the form of cones, cylinders (shaft, bushing, axis, flange, cover).

The design of the machine involves the supply of parts manually, hydraulic or servo, depending on the model of the unit. Due to the movable headstock, the workpiece is ground from all sides, and its accuracy complies with European regulations.

The equipment is produced in several versions:

- the displacement of the table in the longitudinal direction is carried out by hydraulics, and the transverse movement of the headstock is carried out manually;

- all elements of the apparatus are controlled by CNC, in automatic mode;

- machine with numerical control, servo drives.

Technical indicators:

| Options | Characteristics |

|---|---|

| Rotating workpiece diameter above the table, m. | 0.2 |

| Distance between centers, m. | 0.4 |

| Maximum grinding diameter, m. | 0.16 |

| Maximum workpiece weight in centers, kg | 60 |

| Minimum movement of the grinding headstock, mm | 0.001 |

| Grinding wheel size, m. | 0.305 x 0.038 x 0.127 |

| Angle of rotation of the headstock, ° | -30 ~ +90 |

| Front speed, rpm | 10 - 600 |

| Table rotation angle, ° | 10 |

| Grinding wheel drive power, kW | 2.2 |

| Drive power | 0.37 (inverter) |

| Length, m. | 2.370 |

| Width, m. | 1.45 |

| Height, m. | 1.73 |

| Machine weight, kg | 2000 |

- magnetic filter;

- spare wheel with flange;

- adjustable 2-point, 3-point fixed steady rests;

- abrasive dressing device;

- lighting of the working area;

- tank with hydraulic pump;

- carbide centers.

- except for the price, there are no visible flaws.

All machines presented in the review are time-tested, they have shown themselves only from the best side. We hope that our information will help you in starting a successful project.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131654 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127694 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124521 -

The best men's sneakers in 2022

Views: 124037 -

The Best Complex Vitamins in 2022

Views: 121942 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2022

Views: 113398 -

Ranking of the best wood paints for interior work in 2022

Views: 110320 -

Rating of the best spinning reels in 2022

Views: 105332 -

Ranking of the best sex dolls for men for 2022

Views: 104370 -

Ranking of the best action cameras from China in 2022

Views: 102218 -

The most effective calcium preparations for adults and children in 2022

Views: 102013