Rating of the best grinding stones and blocks for 2025

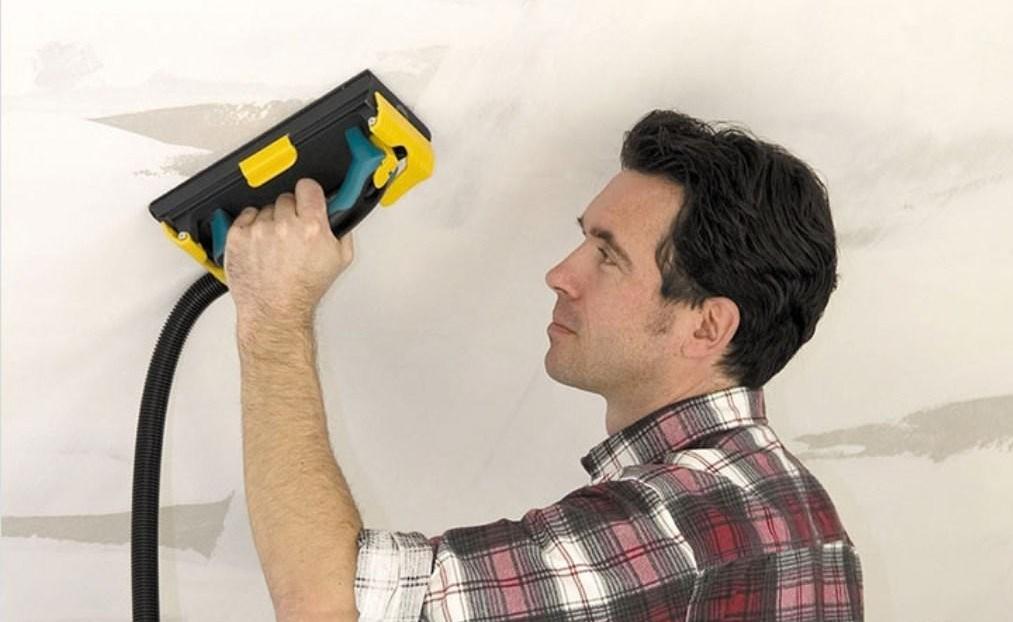

Any person is familiar with the situation when, during repairs, before starting to apply varnish or paint, the surface to be painted needs to be cleaned of old coatings. In this case, a grinder with various nozzles can come in handy. But not everyone has the opportunity to purchase this device, so it is quite possible to get by with abrasive (grinding) blocks or bars. They can not only effectively clean the surface, but even polish it if necessary.

Grinding stones are used as rotary grinding stones - they are convenient for grinding grooves, removing roughness, or giving a rounded outline to a particular surface. Grinding stones are fine-grained sharpening stones with an extremely high level of hardness. They may also include knife sharpeners and abrasive cleaning sticks and other items that have abrasive potential.

Content [Hide]

Varieties of grinding blocks

There are just a huge number of them on the modern market, so you can choose the right block for any job. Specifically, they can be used for grinding, machining or cleaning the following materials:

- Leather;

- Dye;

- Metal;

- Glass;

- Plastic;

- Stone;

- Tree, etc.

To correctly determine which block will need to be used, you need to know what it will be used for:

- Standard abrasive block - it is a regular handle-holder to which the abrasive itself is glued. Fastening is also possible with bolts or screws on wing nuts. Thanks to this mount, the working part of the tool is excellent and holds and is stable in operation, and this is the main thing. Such tools are used for grinding large areas, such as walls.

- Abrasive block equipped with a latch - this twisted product is characteristically different in that instead of bolts and nuts, the block is fixed with springy handles that support the abrasive;

- Rubber abrasive block - a grinding block is attached to it by means of special spikes. Such a tool is not very convenient, because, unlike bolted and snap-on blocks, it does not have a handle-holder.

- Grinding block - in this design there are no handles or fasteners at all, but it is an ordinary cube or parallelepiped. However, due to the fact that all surfaces are working, it can be used from different sides, and this indicates a fairly long service life. In addition, it can even be washed, which also prolongs the life of the tool. Depending on its size, it can be used for different surfaces - both small and large. Moreover, some models also have flexibility properties, so they can be used on profiled bases. As a result, such a block is most often used in repair work to clean surfaces from putty, traces of varnish and paint, and to eliminate irregularities on wood.

- The trapezoid abrasive block is one of the subspecies of the grinding block with a special shape in the form of a trapezoid, due to which it can be used in hard-to-reach places, for example, at inner corners.

- Velcro sanding block - as a standard, it is plastic and is attached with a special Velcro. A similar product is used for processing small areas in the furniture and automotive industries.

- Foam block - as a rule, it is made of an elastic material. As standard, it can be equipped with a special insert that prevents deformation of the working area. Such blocks are used in the automotive industry for grinding car body parts, both on a dry and wet basis.

- Cork sample - it is made on the basis of natural cork, to which ordinary sandpaper is attached. The main advantage of this design is its durability, because it does not crumble and is able to maintain its working properties for a long time, including during wet grinding.

- Contour grinding pad - this item has a small thickness, it is used for detailed grinding of kinks and contours.

- Sanding block with a special suction - a special connection is attached to its design, which is designed to remove dust that collects during the grinding process. The connection can have several suction holes (the more the better). It can also be equipped with an adapter to which the suction arms are connected.

When using a specific model of a sanding block, it is necessary to pay attention to its main characteristics. For example, pads coated with abrasive material must be properly gritted, as this will determine how fine grit was used to make the sanding surface. Thus, it can be argued that fine grit is suitable for more precise operations. With weak granulation and large grains, the abrasive is used to remove large spots and entire coatings. At the same time, the size of the sanding block itself is considered an important parameter.

Top manufacturers and price of tools

Professionals from various fields of activity who use the grinding process in their work clearly name three leading companies that produce abrasive blocks:

- "TOPEKS";

- "3M"

- "Klingspore".

The products of these manufacturers are time-tested and adapted to perform many tasks.

Ordinary sanding blocks are inexpensive, usually ranging from 80 to 100 rubles. The same applies to snap-on, screw or elastic models - their price starts at 150 rubles and rarely exceeds 200 rubles. The most expensive are tools equipped with a dust removal mechanism, but their cost is never more than 500 rubles. However, there are also industrial models used in production - they are large in size and are not used in everyday life.

Grinding blocks (bars) diamond for working on metals

They are distinguished by the presence of a high degree of abrasiveness, which is a consequence of the concentration. Concentration refers to the number of carats (grains) in a diamond bond. With an increased degree of concentration, the grinding performance of the bar increases. Thus, the higher the percentage concentration, the slower the bar will be consumed, and its productivity will increase. With a lower level of concentration, the work will be done more slowly, but generally softer. It is the diamond concentration on the surface that is considered the most important characteristic of the efficiency of a diamond grinding block. It should be noted that in order to increase the rigid bond, in addition to diamond powder, other grinding powders can be added to the working surface, for example, boron carbide, which will also enhance the quality of work.

Bonding species in diamond in diamond bars

The carrier diamond layer in the bar includes grains of industrial diamonds, a special binder and a special filler (not in every case). A binder is a substance that connects abrasive grains and on which the durability of the operation of the bar depends, as well as its effectiveness.In organic-type bonds, fillers create mechanical and chemical, as well as physical properties of the diamond layer:

- grain consumption rate;

- Wear resistance;

- Resistance to temperature extremes;

- Strength.

In addition, they are an excellent base and are able to securely fix diamonds in their composition. The filler grit is selected so that it affects the surface treatment procedure as little as possible, while all the main work should be done by the diamond base.

Today, there are 3 main types of bonds for diamond-based sanding blocks.

Galvanic (diamond-coated bars, three-layer or Blitz diamond plates) is a special application method in which diamond particles are attached to the working base and precipitate a layer of a metal bond from the electrolyte, which fixes and covers the diamond grains. For a galvanic bond, it is characteristic that it holds diamond grains only due to mechanical adhesion, therefore, grains must be inserted into the bond to a height of approximately 65-75% of the dimensions of the grain itself. The metal base capable of properly fixing the diamond grain is nickel. Diamond plates on a similar basis are perfectly capable of sharpening the cutting part of a knife, even if it has serious mechanical damage in the form of chips or jams. Such tools are able to work much more efficiently than bars produced on an organic or metal base. This effect is achieved by means of bulging diamond grains, while in an organic or metallic binder, the grains seem to “drown” in a binder substance or mix with it. The concentration of the dimensions of diamond grains in the layer quite reaches 100%.However, it is worth noting that in terms of the duration of their operation, these bars will certainly yield to bars on other types of ligaments, which is due to the thin coating, which will be actively erased during sharpening. Nevertheless, in order to extend the service life, a coating is usually applied in 2-3 layers, which allows not only to extend the service life, but also to carry it out faster. It is especially important to work with a galvanic bond on soft metals with a hardness of up to 58HRC. It should be noted that when sharpening hard steels, the galvanic bond will be consumed faster. In general, the diamond inserts discussed above are good in that they do not require special preparation for sharpening such as “cheering” / leveling. As a result, they are a budgetary and effective way to quickly sharpen.

metal (CBN bars) is a solid type of bond, characterized by increased productivity of metal removal. Such a bundle does not have a filler, but represents diamonds and metal mixed into one substance. Typically, abrasive bars on such a bundle are marked with the letter "M" and have a clarified gray tint. For example, a bar with the M2-01 brand is suitable for the production of a diamond-based working tool used for grinding carbide products or for sharpening tools with many blades. By itself, such a bar represents a structure in which a hardened tin solution is present in copper (an additional name is copper-tin bars).

organic (diamond bars Venevskie, including "Premium" in the same number) has a more viscous structure, which means easier application. This is its main advantage over the metal bond.For example, a fat layer is not formed on it so quickly and it is better renewed (manually when opening and trimming with carbide powder). Regarding the advantages over galvanic, the organic one differs in that the diamond substance is applied not in the thinnest layer on the bonding surface, but is located throughout the entire thickness. In addition, it has an increased degree of plasticity and viscosity, which means that a diamond on such a base will crumble less. Accordingly, the service life of such a bar will be increased. From this we can conclude that this bundle has the best wear resistance.

whetstones

One of the most important items in any kitchen is a knife. This appliance is used daily for cutting various products. Over time, its blade gradually dulls, and re-sharpening will require the use of a whetstone with better abrasive properties. Bars can be made from various materials, so you should carefully consider their choice, paying close attention to performance.

A whetstone is a small-sized tool that is designed for processing objects that have a cutting edge. These items are based on hard abrasive materials that are capable of destroying molecules in the steel substance. It is thanks to these properties that it is possible to quickly sharpen a dull blade, and this process does not require any special skills. As a rule, a manual whetstone (whetstone, stone) can vary greatly in size, but most often it is made with a special handle with an anti-slip coating.

The advantages of this tool can be called:

- Strength - most of the samples endure mechanical damage and do not break upon impact;

- Convenience - for the bar to work, only a special oil is required, but ordinary water can also be dispensed with;

- Practicality - many samples are resistant to clogging with steel particles; after sharpening, they only need to be washed in running water and wiped dry;

- Efficiency - the turning process itself takes place efficiently and quickly, this is especially true when using hard bars.

However, whetstones also have a few disadvantages. First of all, we are talking about an increased risk of injury. Most of all, the risk of injury increases if the whetstone does not have a handle and a protective frame. It is also worth mentioning natural abrasives, although they have increased efficiency, but have a short service life.

Classification of whetstones

All whetstones intended for the care of tools with a cutting edge can be conditionally classified according to their abrasive characteristics (grit) and material of manufacture. These important parameters must be taken into account when choosing a stone.

Types by material of manufacture

The bar can be made from various materials. The natural ones include "Japanese water stone" or "Arkansas", and the artificial ones include ceramics and diamond. Each of the mentioned materials has its own "pluses":

- Arkansas - it contains quartz crystals that do an excellent job of sharpening various razors. When performing the sharpening process, you will have to use oil, because the pores of the grinding material may become clogged.

- Japanese water stone - it is characterized by an increased quality of processing, such products themselves are softer in comparison with "Arkansas".

- Ceramics - they are intended for finishing the cutting edge, because they contain the smallest particles of abrasive material. During processing, it is necessary to lubricate the touchstone, in order to avoid smoothing its surface.

- Diamond is the most popular material for whetstones; almost all sharpening household tools are made on its basis, because it is of high quality and budget cost.

It is worth mentioning that modern manufacturers use synthesized materials for the production of bars. Among this category, corundum and carbide are the most popular. However, the use of such whetstones requires some experience, as there is a risk of damaging the blade being sharpened.

Grain types

The grit size of whetstones means the parameters of the particles and their quantity that is part of the product. With overestimated indicators, the whetstones will more intensively and coarser remove the metal layer from the sharpened blade. If the user has little experience, then scratches and burrs can remain on the blade. Soft ones are intended for final sharpening. There are three types of samples:

- Coarse grain - 120 grit, such abrasives are necessary for turning dull blades. With their help, chips with notches are easily removed. Bars can be produced in mechanical and manual form, and may even be part of electrical devices.

- Medium grit - 1000 grit, usually presented in the form of flint or diamond stones for turning knives. They do an excellent job of smoothing out frivolous roughness and give the knives the necessary sharpness.

- Fine grain - 2000 grit, not used in everyday life, most often used for grinding and polishing manicure tools. These stones are made in the form of additional nozzles. It is good to process ceramic objects with such soft bars, however, the quality of sharpening will be somewhere at a slightly above average level.

Rating of the best grinding stones and blocks for 2025

Budget options

2nd place: "Caliber 00000060715"

votes 0

This bar has a collapsible design. The upper part is made in the form of a rounded shape, which provides a comfortable grip during processing. Also, the holding surface is equipped with special ribs that will prevent the tool from slipping out of your hand. The collapsible design is good because the device is convenient to store, clean and transport.

| Name | Index |

|---|---|

| Manufacturer country | China-Russia |

| Material | Plastic |

| Fastening | clamp |

| Dimensions, mm | 67x30x125 |

| Weight, kg | 0.22 |

| Price, rubles | 115 |

- Comfortable grip;

- Possibility of connection to the vacuum cleaner;

- Ease of transportation.

- Not detected.

1st place: "MATRIX 125 mm 76242"

votes 0

Sanding pad with rounded velcro. Supplied as standard with a ceramic whetstone. Excellent for processing large surfaces. The elastic is conveniently located on the hand, and thanks to the small size, using the device is easy and pleasant. Does not cause any particular complaints in the work.

| Name | Index |

|---|---|

| Manufacturer country | Germany |

| Material | Rubber/ceramic |

| Fastening | Velcro |

| Dimensions, mm | 125x125x40 |

| Weight, kg | 0.24 (with bar) |

| Price, rubles | 150 |

- Variability of replacement of a working sole;

- Ease of management;

- Small dimensions.

- Somewhat poor-quality firmware (the threads stick out visually, but this does not affect the work).

Middle price segment

2nd place: "Gigant 230x105 mm SPT 045"

votes 0

Great sandpaper holder. Supplied with a piece of fine-grained sandpaper. You can also use a grid. The design is made of durable plastic, has a fastener with screws that provide the closest fit to the workpiece/surface.

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| Material | plastic/sandpaper |

| Fastening | screw |

| Dimensions, mm | 235x105x80 |

| Weight, kg | 0.21 |

| Price, rubles | 290 |

- Closed handle;

- Light weight;

- Comfortable grip.

- A little dusty when working.

1st place: STAYER 3569-08

votes 0

Excellent grater with a reliable metal lock. The manufacturer positions this tool as a final grouting device. The design is made of impact-resistant material. The abrasive material is attached to the rubber base. Supplied with a trial cut of grout paper.

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| Material | plastic/sandpaper |

| Fastening | screw |

| Dimensions, mm | 235x105x80 |

| Weight, kg | 0.19 |

| Price, rubles | 300 |

- Reliable fastening;

- Light weight and dimensions;

- Impact resistant material.

- Not found.

Premium options

2nd place: "MATRIX 125 mm 75812"

votes 0

Good hand tool. Production material – hard plastic that provides softness and elasticity in work. The manufacturer claims this device as "a tool for thin fingers." It has an ergonomic shape and special Velcro for a more secure fit.Great for body work.

| Name | Index |

|---|---|

| Manufacturer country | Germany |

| Material | plastic/bar |

| Fastening | Velcro |

| Dimensions, mm | 125x60x60 |

| Weight, kg | 0.7 |

| Price, rubles | 360 |

- Holds the work item well;

- Supplied with trial diamond bar;

- Ergonomics at work.

- Slightly slips in hand due to very smooth plastic.

1st place: "COLOR EXPERT 212mm x105mm 93310002"

votes 0

A manual grinder is used for repair and finishing work. Perfectly cleans walls and other flat surfaces. The holder is made of durable plastic and has a metal mounting clip. The manufacturer positions this product as universal.

| Name | Index |

|---|---|

| Manufacturer country | Germany |

| Material | plastic/bar |

| Fastening | clamps |

| Dimensions, mm | 570x470x360 |

| Weight, kg | 0.25 |

| Price, rubles | 420 |

- Convenient and reliable clips;

- Multifunctionality;

- Ease of use.

- Not found.

Instead of an epilogue

Summing up, we can confidently say that the modern market is able to provide many different types of sanding blocks and whetstones. They can come in handy everywhere - from sharpening knives to grinding walls and ceilings. Moreover, the price of them is not so high.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127687 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124516 -

The best men's sneakers in 2025

Views: 124030 -

The Best Complex Vitamins in 2025

Views: 121937 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2025

Views: 113393 -

Ranking of the best wood paints for interior work in 2025

Views: 110317 -

Rating of the best spinning reels in 2025

Views: 105326 -

Ranking of the best sex dolls for men for 2025

Views: 104363 -

Ranking of the best action cameras from China in 2025

Views: 102214 -

The most effective calcium preparations for adults and children in 2025

Views: 102010