Ranking of the best high pressure hoses for 2025

The sleeve is a reinforced hose, which is equipped with all kinds of transitional connections, thanks to which it can be mounted to various units, hydraulic systems and mechanisms. In most cases, it is installed on bends and in the presence of mobile elements, for example, to raise the bucket of an excavator.

Content [Hide]

- 1 What are and how they differ

- 2 Rules for the manufacture of goods

- 3 Technical features of flexible pipelines

- 4 Scope of use of RVD

- 5 How to choose the right option

- 6 Use and repair at home

- 7 High pressure hose rating for 2025

- 8 Conclusion

What are and how they differ

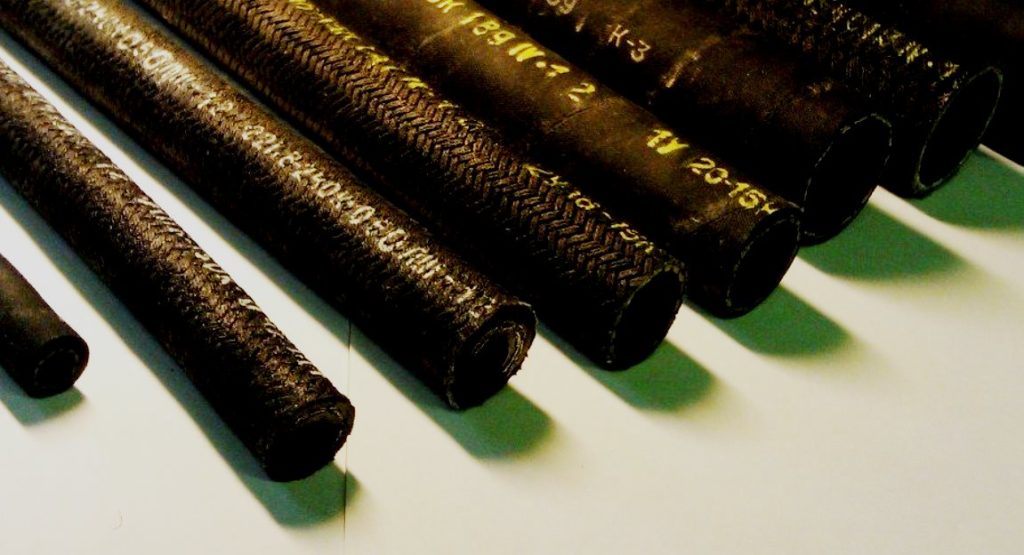

Such devices, regardless of the popularity of the models, are similar in their design features, despite the variety of manufacturers. They are a structure consisting of several layers:

| Layer view | Description |

|---|---|

| Internal sealing rubber | In the manufacture, rubber is used, which has a special composition, thanks to which the hose becomes airtight, perfectly copes with aggressive environments, does not stretch or deform. |

| Metal reinforcing | The main manufacturing materials are wire and high-strength synthetic threads. The number of layers may vary depending on the scope of use of the device. |

| Outer protective rubber | The main task is to protect the product from external negative influences, to ensure the strength, durability, and reliability of the hose. |

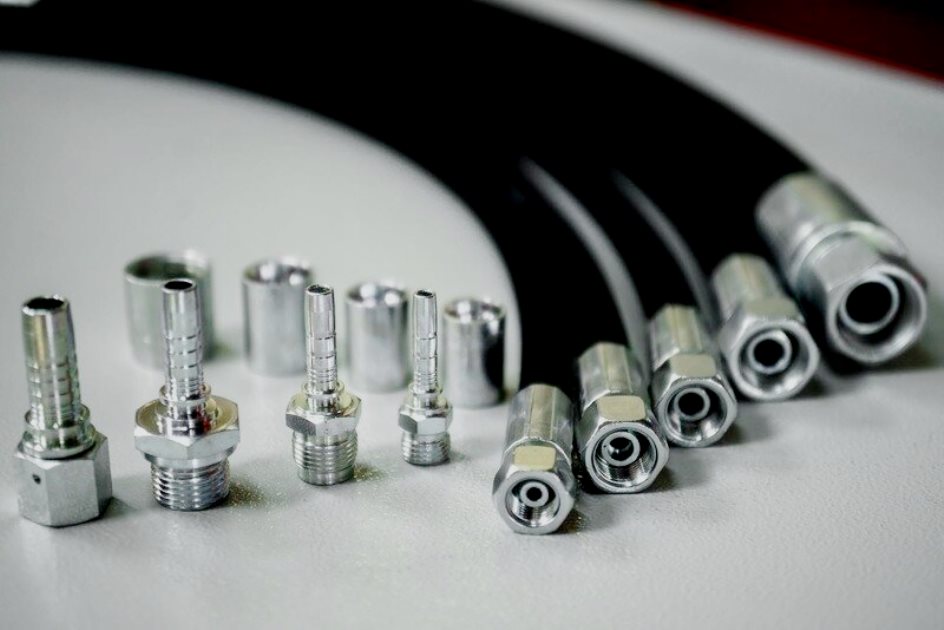

Despite the varieties, the products are equipped with metal fittings, thanks to which they are connected to various systems.

RVD are of the following types:

- with winding;

- with braid.

The most popular in Russia is braided models due to the fact that winding turns are prone to divergence when bent, therefore they have a larger bending radius than braided ones.

It is worth noting that winding structures withstand increased performance, since in their manufacture the maximum number of layers reaches six pieces, while the braid involves only three layers.

Rules for the manufacture of goods

For the manufacture of high pressure hoses, innovative production technologies are used. The process itself involves the passage of the following technological stages:

- The length of the product is determined. A specific calculation is needed in order to distribute a uniform load throughout the device. Cutting is carried out using a special cutting machine, which makes it possible to make the pipeline clean and durable.

- Processing of the fixture with the help of a debarking machine. It is not always necessary to remove the rubber outer layer. Type 2 SN hoses are stripped.

- Pressing and assembly. The hose on each side is equipped with couplings and fittings up to the stop. Care must be taken to lock the fitting, which must exactly match the coupling. After that, the finished product is pressed.

- The final step is labeling and packaging the product. It must be remembered that RVD has a certain shelf life, so you need to take the packaging technology seriously and follow the storage rules. The packaging displays the technical characteristics of GOST, which were used in the manufacture of a particular batch of products.

Technical features of flexible pipelines

Products differ from each other in parameters that affect their categorization. The main selection criteria are:

- Operating temperature range;

- bend radius;

- operating pressure indicator.

The temperature indicator at which the product is able to function qualitatively is determined by International Standards and ranges from -40 to +100 degrees Celsius.

The value of the bend radius plays a significant role, since the usability of products depends on it. The larger it is, the less functional the pipeline will become. The requirements regarding the bending radius are specified in GOSTs and depend on the category of the product.

Absolutely all popular hose models from the best manufacturers, whether coiled or braided, have their own limiting operating pressure. They are displayed in European standards and in GOSTs used on the territory of the Russian Federation. Many manufacturers have launched the production of hoses for work in extreme conditions, where the temperature reaches -50 or -55 degrees Celsius.

Scope of use of RVD

Products are used in almost all high-performance hydraulic systems. Practice shows that the use of this type of product is more efficient and justified than working with rigid metal tubes.

HPH is actively equipped with modern complex equipment, in which there are both pneumatic and oil drives. This is about:

- Systems of gas supply and water supply.

- Excavators, asphalt pavers, tractors of various brands and other similar mechanisms.

- Road construction, municipal and other specialized equipment.

- Devices with the function of transporting various working fluids and liquid fuels.

- All kinds of equipment that is used in mechanical engineering, metallurgy, oil production and oil refining industry.

- Drilling rigs.

- Lifting equipment.

- Machine tool equipment.

- In enterprises related to logging, food processing, mining, woodworking and so on.

- Agricultural machinery and units.

- Trucks and cars.

Modern designs of this type guarantee complete tightness during the transportation of all kinds of liquids. The need for auxiliary seals is completely eliminated. The functional hose is selected taking into account the scope of its use and types of systems.

The peculiarities of flexible pipelines are that they have such unique properties that they can function efficiently under any increased loads and in the most aggressive environment.

How to choose the right option

It should be noted that such devices are developed and produced taking into account increased strength, reliability and long service life. Mistakes in the selection can cause a breakdown of the system, its failure, which will lead to significant financial costs, and possibly to injury to the employees of the enterprise.

The main and sufficient characteristics of the product are determined at the stage of designing a specific system. Any hose has an individual purpose and its misuse will lead to breakage of the entire product.

The main point is to accurately determine the length of the unit. It should be borne in mind that depending on pressure surges, this indicator may vary. When using the product in hydraulic installations, the sleeve will constantly bend and unbend, as well as perform certain movements. The result of such actions is the constant friction of the parts against each other. With rare contact, this equipment will withstand such loads. With frequent friction, it is necessary to replace the sleeve with a shorter one.

The recommendations of experts boil down to the following: determine for yourself which company's product is better, and try not to change the manufacturer. According to buyers, this applies not only to hoses, but also to other components.

What else is worth paying special attention to? The indicator of the maximum allowable pressure in the system. It is necessary to pay attention not only to the value of constant loads, but also to variables that occur due to the turbulence of the system, including jumps of an impulsive plan. It is best to take products with a certain margin.

Which one is better to buy depends on many factors, including the scope of use, as well as the indicator of the aggressiveness of the environment. The best products are included in the rating of high quality and reliable. There are several options for where to buy the necessary equipment. It is best to visit a specialized outlet, get acquainted with new products, understand for yourself what it costs, get advice from a sales manager. If you decide to order products online in the online store, then you should carefully review the proposed photos, read the reviews.

Use and repair at home

The main scope of hoses is hydraulic and pneumatic structures. They are also widely used in the automotive industry. All drivers know how, thanks to the presence of a built-in hydraulic booster, you can turn the steering wheel without much effort. But with significant operation, deformation of the sleeve and tube may appear, which will lead to instability in the operation of the assembly itself. It is possible to correct the situation on your own or by contacting a service station to specialists.

Motorists are constantly faced with problems in the operation of hydraulics, which inevitably leads to the replacement of the product.The main reasons for the occurrence of an emergency situation are:

- Development of an operational period. Mechanical damage appears due to the natural wear of the equipment. Main problems: frayed areas, cuts and broken cord. They appear, as a rule, due to the wrong sleeve length.

- Marriage in the manufacturing process. As a rule, this concerns the purchase of an inexpensive device from a little-known manufacturer. Possible poor-quality crimp fitting or hose joint. The cause may also be incorrectly configured or debugged equipment.

- Incorrectly selected technical characteristics or temperature indicator. If the main indicators of the product do not match the actual environment of its use, then this will negatively affect the quality of functioning and durability of use.

- Structural inconsistencies. Troubles arise if the installed equipment does not meet the parameters specified by the manufacturer. This is fraught with a wire break, a breakdown of the fittings, if the provided indicator is lower than the actual one (in the system).

That should be paid attention

It is strictly forbidden to operate the car if the following problems occur:

- the sleeve is completely or partially clogged;

- there was a significant kink in the hose;

- corrosion has appeared on the fittings;

- the outer part of the sleeve is too worn;

- joints pass liquid;

- the fitting fell off the landing diameter;

- connections are depressurized;

- overestimated temperature and significant pressure led to damage to the inner surface of the sleeve.

If the above breakdowns occur, it is worth replacing the sleeve.If you have never done this yourself, step-by-step instructions posted on the Internet will come to the rescue. It clearly and clearly spells out the steps, how to remove, how to replace the device, how to put it back, what accessories will be needed for this.

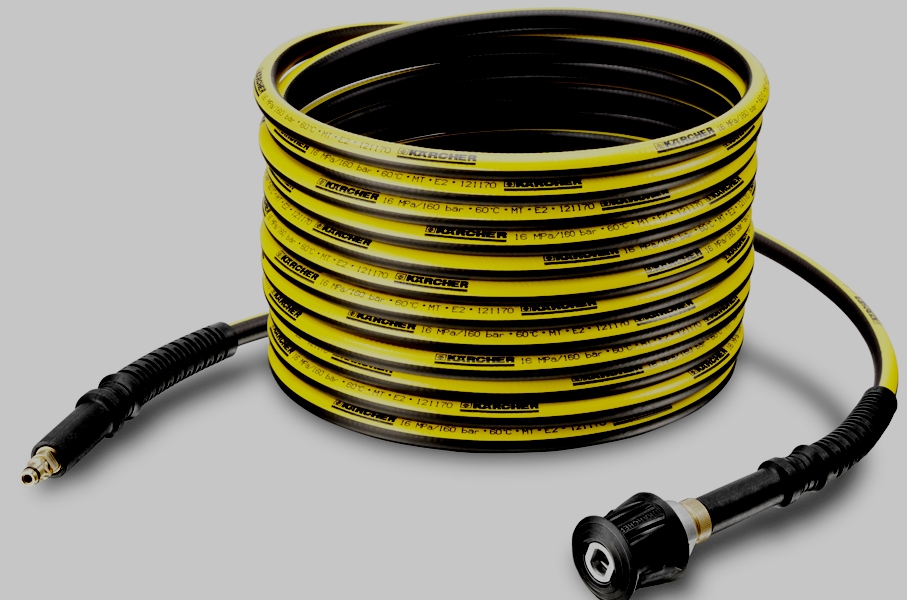

You can not carry out a complete replacement of the product, but try to repair it. It all depends on the maintainability of a product. A damaged area with scuffs, cuts and cracks can be replaced with a new one. As for the repair of high-pressure hoses at Karcher, experts believe that this matter is almost hopeless. If damage occurs in a straight section, the material is crushed or chopped, then it is quite difficult to purchase a double-sided Christmas tree branch pipe and compress it with your own hands.

High pressure hose rating for 2025

for hydraulics

KVT 60068 RVD - 2

votes 0

Russian brand product, but produced in Taiwan. Used along with hydraulic equipment. Operates at an indicator of 700 kgf / sq. mm. Withstands a maximum value of 900 kgf / sq. mm. Main characteristics: weight - 93 g, length - 30 cm, height - 2 cm, width - 20 cm.

The average price of the goods is 2775 rubles.

- multifunctional;

- reliable;

- quality assembly;

- withstands high rates;

- optimal combination of price and quality.

- not installed.

High pressure hose 12 - 2 SN S 27 DK (M 22 x 1.5), 27.5 MPa

votes 0

The product is of excellent quality, there are metal braids, the ends are equipped with crimped fittings. It is widely used in industries where high and medium pressure hydraulic systems are installed and working fluid is supplied through hydraulic distributors to actuators.The fittings on the hose are equipped with a spherical nipple (so-called "apple") and a union nut.

The sealing angle on the cone is 37 degrees. Thread metric cylindrical type. Withstands the temperature of the working environment from -40 to +100 degrees (motor and hydraulic oils, kerosene), from -40 to +25 degrees (gasoline), +5 - +93 degrees (water-oil emulsion and water). The hose is crimped with fittings on both sides, the inner part is a two-layer metal braid. The goods are produced in the territory of the Celestial Empire, but the crimping is carried out in Russia. Not subject to certification.

The main characteristics are:

- length - 145 cm;

- diameter (outer and inner) - 2.22 cm and 1.2 cm, respectively;

- discontinuity index - 110 MPa.

- weight - 1.055 kg.

Sellers offer to purchase products at a price of 386 rubles. Discounts are available for bulk purchases.

- quality;

- reliability;

- long service life;

- practicality;

- ease of use;

- significant working life - 350 cycles or more;

- a budget option;

- functionality.

- not identified.

Portotecnica D – 8 mm, 345900315

votes 0

Products of excellent quality are ideal for professional grade sinks such as Karcher, Comet, Kranzle, Portotecnica. The number of braids inside the product is 2 (2 SN). At the inlet and outlet there is a nut M 22 x 1.5. The length of the structure is 15 meters, the weight is 1.4 kg, it can withstand an indicator of 400 bar.

The average price is 4500 rubles.

- used for professional equipment;

- quality worthy of attention;

- multifunctionality;

- long service life;

- reliability;

- comfort in use.

- not installed.

For water

1SN-06

votes 0

The ten meter single-braided hose is designed for use with devices of this type, which are equipped with an inlet with an external thread M 22 * 1/5. The maximum indicator is 350 bar. It can function in the temperature range from -40 to +150 degrees Celsius.

The average cost is 1716 rubles.

- suitable for mini-sink;

- equipped with protection against kinks;

- multifunctional;

- comfortable in using;

- practical;

- optimal length;

- long service life;

- will fit any pistol.

- missing.

2SN-06

votes 0

A high-quality two-braided model is produced for work with devices operating under high pressure. Mandatory presence of inputs with external thread M 22 * 1/5. Main parameters: tensile strength - 1600 bar, while working - 450 bar. Indicators of minimum and maximum temperatures - from -40 to +150 degrees.

You can buy goods at a price of 2028 rubles.

- reliability;

- multifunctionality;

- comfort;

- practicality;

- durability;

- protected from kinks;

- large temperature range;

- optimal combination of price and quality.

- not installed.

Z-II-25-14.0

votes 0

Belongs to the category of non-reinforced hoses with a metal braid. Full compliance with the requirements of GOST 6286 - 73. It is used as flexible pipelines mainly in agricultural vehicles.As for road and construction specialized mechanisms, such devices are used as hydraulic drives that supply motor oils, kerosene and gasoline under high pressure.

Designed for operation in tropical and temperate climates. Withstands temperature range -50 - +70 degrees. In cold climates, operating temperatures range from -60 to +70 degrees. The whip is available in lengths from 10 to 50 meters.

You can buy products at a price of 200 rubles per linear meter.

- convenient to use;

- functional;

- qualitative;

- reliable;

- durable;

- safe;

- bends well;

- withstand heavy loads.

- missing.

RVD - 2 (KW)

votes 0

Sufficiently durable model, which enjoys well-deserved popularity at professional service stations. Belongs to the category of durable and reliable. Has steel reinforcement. The improved novelty is equipped with end sleeves that minimize the possibility of breakage.

The average price is 1951 rubles.

- working (optimal) indicator - up to 70 MPa;

- improved design;

- quality;

- strength;

- operational period;

- compatible with KBT hydraulic equipment;

- repairable.

- missing.

For car washes

Rubber RVD GOST 6286 - 73

votes 0

An unreinforced product equipped with a metal braid. Produced in accordance with the requirements of GOST 6286-73. It has found wide application in hydraulic systems of equipment used in agriculture as flexible hoses. It is also installed in construction and road cars in order to supply gasoline and kerosene engine oils.Able to work at temperatures from -62 to +70 degrees.

The average cost is low - only 75 rubles per meter.

- affordable price;

- multifunctionality;

- reliability;

- quality;

- ease of use;

- maintainability.

- not installed.

X – TRA Nilfisk 128500654 (9 m)

votes 0

The model can often be found not only in small, but also in modern service stations. It is used for washing any machines, including long ones. Quickly and efficiently cleans the contaminated surface under significant pressure, without causing mechanical damage to the equipment.

You can buy goods at a price of 3988 rubles per unit.

- reliability;

- long service life;

- ease of use;

- high quality of the material used;

- light weight - only 1.2 kg;

- optimal length - 9 meters;

- elastic;

- not damaged when bent.

- missing.

5 XY 462.175

votes 0

High quality products of a domestic manufacturer are sold at any specialized outlet. If desired, you can place an order online on the manufacturer's website. It is an integral part of car washes. It is very convenient to use due to its low weight - 500 g. Main parameters: length - 16.5 cm, width - 13.5 cm, height - 4 cm.

The average price is 2140 rubles.

- quality;

- safety;

- wear resistance;

- acceptable cost.

- not identified.

For air

Mighty Seven SD-23315

votes 0

The Taiwanese manufacturer has launched the production of pneumatic spiral hoses designed to work with inflated performance.Manufactured using high quality polyurethane. Its main task is to bring compressed air to pneumatic devices, connect pneumatic equipment, and conduct air lines to the place of operation. Mainly used in car services, car repair shops, service stations. Product length - 15 meters, diameters 0.1 and 0.15 cm (internal and external, respectively), fitting with thread M 3/8 inch, weight - 1.9 kg, operates at a maximum rate of 17.8 bar.

Sellers offer products at a price of 3630 rubles per package.

- quality;

- multifunctionality;

- long service life;

- comfort in use;

- reliability;

- safety.

- not identified.

Air hose with fittings (Enkor-Plast)

votes 0

A transparent reinforced three-layer hose is produced for use as flexible pipelines for transporting air masses under significant pressure. In the manufacture, a 24-thread counter-diagonal reinforcement is used, thanks to which the product practically does not break and does not twist, knots and kinks do not appear during operation. The length of the set is 7.5 m, the diameter is 8 mm, it withstands a voltage of 20 bar.

The product can be purchased at a price of 620 rubles.

- resistant to pressure of air masses;

- increased flexibility;

- light weight;

- maximum convenience during operation;

- complete safety for both humans and the environment;

- no harmful toxic components;

- resistance to ultraviolet radiation;

- reliability;

- durability;

- does not twist and does not create knots;

- in the manufacture of high-quality polyvinyl chloride was used;

- optimal combination of price and quality.

- missing.

ACH 8 – 10 Concorde 6619281

votes 0

The air hose is made of high quality and durable PVC. Produced in the territory of the Middle Kingdom. The manufacturing company guarantees the high quality of the goods. Reinforced, straight shape, withstands an air pressure of 20 bar, length - 10 meters, inner diameter - 0.8 cm, weighs 1.26 kg.

The average price is 750 rubles.

- comfortable in using;

- functional;

- practical;

- qualitative;

- safe;

- inexpensive.

- missing.

for compressor

Pneumatic spiral hose

votes 0

The manufacturer produces a product specifically for supplying compressed air to the compressor. Made in the form of a spiral. It has excellent resistance to various oils, gasoline and various solvents. When working at low temperatures does not lose elasticity. Has quick release tips. It is produced with a length of 10 meters, an inner diameter of 1 cm, can withstand a maximum pressure of 60 atm, a temperature range of -40 to +70 degrees.

The average cost is 3890 rubles.

- made of high quality polyurethane;

- reliable;

- long service life;

- safety;

- ease of use;

- not afraid of active environments.

- missing.

Wester 814-012

votes 0

High quality product withstands 20 bar, is available in lengths of 10 meters, inner diameter is 1 cm. Equipped with quick-release adapters. It perfectly copes with its main task - the supply of compressed air to hydraulic devices.

The average cost is 1400 rubles.

- high build quality;

- reliability;

- long service life;

- not afraid of aggressive environments;

- works under considerable pressure;

- optimal combination of price and quality.

- not identified.

Mastak 681 – 08100

votes 0

The domestic company has launched the production of high-quality pneumatic polyurethane hoses, thanks to which compressed air is supplied to various pneumatic tools, and pneumatic devices are brought into working condition. Excellent interaction with gasoline and oils. Produced with a length of 100 m, withstands 60 atm, operating temperature range - from -40 to +70 degrees Celsius.

The average cost is 13,000 rubles. Discounts are possible.

- reliability;

- reinforced polyurethane was used in the manufacture;

- quality;

- durability;

- practicality;

- functionality.

- not installed.

Conclusion

This product is considered the main element of any hydraulic system. Depending on how well the project will be completed, the choice of goods and its installation, the durability and reliability of the entire system depends. There are certain rules that must be followed when using this product:

- Observe the temperature regime.

- When used for transporting gas, choose an appropriate permeation rate.

- Choose the optimal diameter.

- Do not twist or deform.

- Do not overload.

- Carefully treat the fastening, prevent interaction with moving mechanisms.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131655 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127695 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124522 -

The best men's sneakers in 2025

Views: 124040 -

The Best Complex Vitamins in 2025

Views: 121943 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114982 -

The best paint for gray hair - top rating 2025

Views: 113399 -

Ranking of the best wood paints for interior work in 2025

Views: 110323 -

Rating of the best spinning reels in 2025

Views: 105333 -

Ranking of the best sex dolls for men for 2025

Views: 104371 -

Ranking of the best action cameras from China in 2025

Views: 102220 -

The most effective calcium preparations for adults and children in 2025

Views: 102014