Rating of the best septic tanks for giving without pumping for 2022

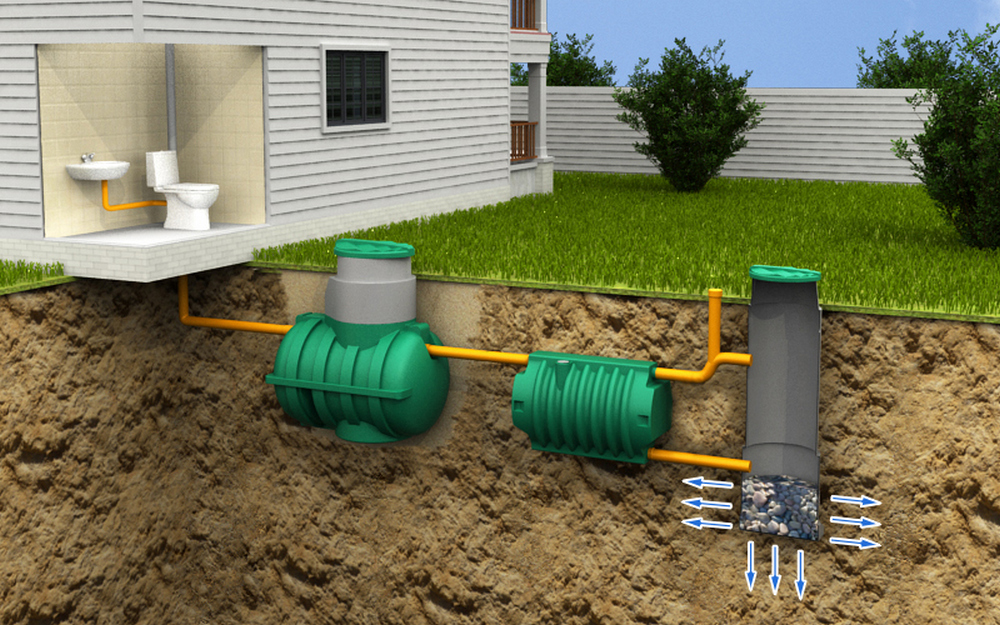

In many private properties in the city (and even in summer cottages outside the city), there is often no possibility of direct connection to public utilities of the central type. The reason for this may be the remoteness of the sewer route itself, or the connection to it is associated with technical difficulties. In such a situation, residents have to install autonomous septic tanks (large capacities), where sewage will flow.The septic tank itself (aka the purifier) is a structure of two (or more) tanks that are located in the ground and communicate with each other by connecting sewer pipes.

Content

- 1 Septic tanks without pumping - features and benefits

- 2 Differences between a septic tank and a cesspool

- 3 Volatile and independent cleaners - differences

- 4 The principle of operation and design of an autonomous cleaner

- 5 Selection of the best material for a septic structure

- 6 Rules for the installation of an autonomous septic sewer

- 7 Building a septic tank with your own hands

- 8 Legislative requirements for equipment and installation of a septic tank

- 9 Rating of the best septic tanks for giving without pumping for 2022

- 10 Afterword

Septic tanks without pumping - features and benefits

Wastewater treatment is carried out according to the following technology:

- Waste fluids enter Tank 1, where they begin to decompose through the action of anaerobic bacteria (i.e. bacteria that do not require oxygen to sustain life). Solid and heavy particles at the same time settle on the bottom surface and, as they accumulate, are pumped out using a drainage pump.

- As a result, organic waste during fermentation is transformed into elemental substances (acids, alcohols, etc.), which is accompanied by the release of gas. Thus, the colony of bacteria is restored autonomously, and if there is a risk of its death, then biologically active additives are used.

- Tank No. 2 is designed for complete processing of the liquid substance, freeing it from the lightest impurities and fatty films. Therefore, during the fermentation process, stable sludge is created and carbon dioxide (methane or other gaseous substances) is released.

- The substance thinned out in this way is transferred to the drainage well / filtration field, where it is oxidized (with the participation of aerobic bacteria), then it is absorbed into the ground.

If we compare the described system with the available alternative methods, then its undoubted features and advantages include the following:

- These septic tanks are more in line with sanitary standards than the same cesspool.

- They do not need to be connected to the sewerage system, which significantly reduces financial costs.

- Factory-made models are completely sealed, which eliminates contamination of nearby groundwater.

- There is no need to change the location of the tank every 10-20 years.

- Their operation is absolutely not affected by quicksand.

- There are almost no unpleasant odors.

- The entire system can be used without the necessary constant checks for up to six months.

- They use a system of emergency notification of violations in the work.

IMPORTANT! Septic tanks without a pumping mode are also allowed to be used in the water protection area.

Differences between a septic tank and a cesspool

The main task of each septic tank is the process of disinfecting waste and draining water after cleaning. Solid elements make up only a small part of the total volume of the purified substance. In the septic tank, they are separated into liquid and solid parts, and in the cesspool they simply mix with water. Polluted water in the septic tank is perfectly cleaned and constantly removed, and sedimentary parts in the form of silt accumulate on the bottom surface over time. This shows that the cesspool requires permanent cleaning, but the septic tank does not.

Design differences

In fact, a cesspool is a reservoir dug into the ground. If it is made with impermeable walls, then it can quickly overflow and the waste liquid will pour out over the edges. Therefore, the inner walls on the sides of the pit are made in a draining form (capable of passing liquid) - a solid substance lingers at the bottom of the cesspool, and water seeps into the ground. It is necessary to pump out the sewerage in the area with a pit at the moment it is filled to the brim.

The septic tank works and is arranged differently. It consists of two or more tanks, which are interconnected by sewer pipes. Before the entire system begins to work, it is filled with clean water to such a level that it reaches the lower base of the pipe. At the outlet of the septic tank, a well for filtration or a drainage ditch is mounted, in which the final decomposition of sewage will be carried out through interaction with oxygen.

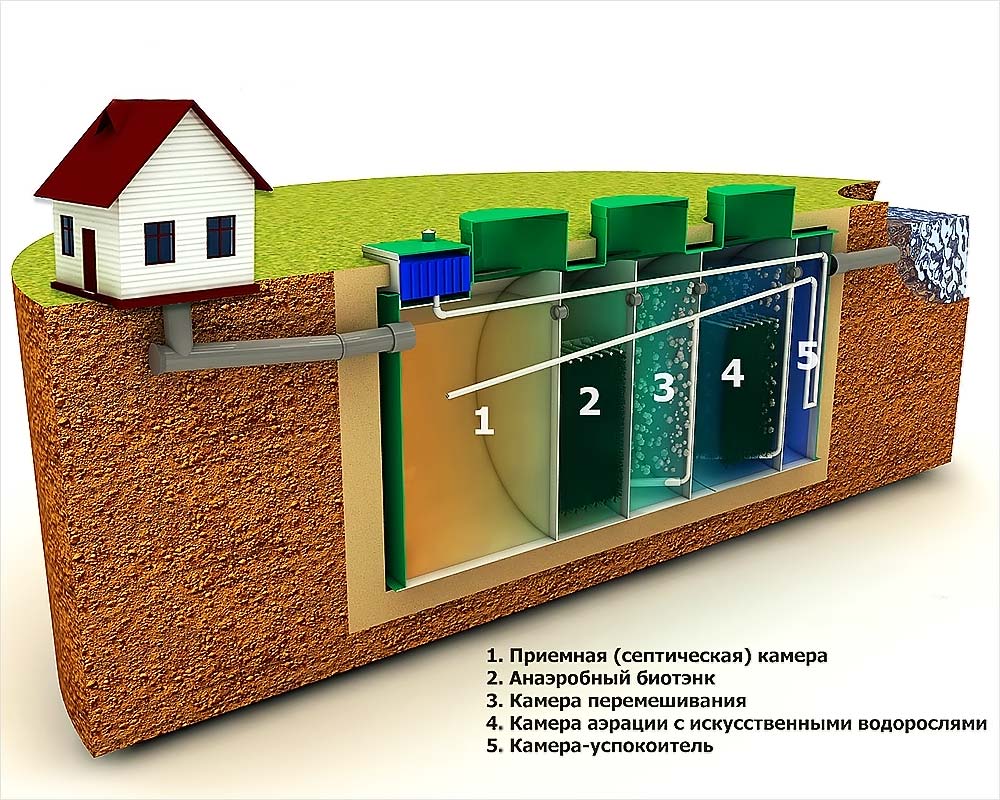

A traditional type of septic tank with two tanks can be called a station for deep biological treatment. The process of disinfection of substances is carried out inside one chamber, which is divided into several sections.The main role in the cleaning process is played by oxygen and special bacteria.

Types of modern autonomous septic systems

At the moment, there are three types, the differences between which lies in the principle of operation:

- Cumulative - are made in the form of sealed chambers for the accumulation of wastewater. During their maintenance, there is a need for periodic pumping.

- Settling tanks with fermentation without oxygen - the effluents are settled in them, and the sedimentary substance undergoes a process of fermentation by anaerobic bacteria. With a similar method, it is possible to purify from 60 to 70% of harmful impurities. At the end of the cleaning process, the water is drained into the soil.

- Stations operating on the principle of deep cleaning using biocomponents - in them, aerobic bacteria join the work of anaerobic bacteria, which increases the efficiency of the production process.

NOTE: It is inappropriate to compare these systems in terms of efficiency, because each of them has its own significant pluses and minuses. The choice will depend only on the capabilities and wishes of the user.

Volatile and independent cleaners - differences

Non-volatile systems are used to purify water up to a set limit, after which they direct the purified liquid into the ground. Their main differences from energy-consuming systems can be called:

- Cost - A cleaning system that does not require power supply will be much cheaper. The reason for this is the absence of energy consumers in the design, such as: special fittings, pumps, compressor, automatic hoses and valves.

- The main task - a non-volatile system is designed to purify water only to the established level of purity, and then it is drained into the ground.Energy-powered systems purify water to the maximum - up to a level of 98%, and then it can be used for irrigation or as process water.

- Necessity of care - for a non-volatile treatment plant, such indicators are of little importance that are necessary for the normal maintenance of the life of bacteria, for example: a certain temperature, air and water quality, etc.

The principle of operation and design of an autonomous cleaner

Often, they are an ordinary plastic container, divided into three chambers. At the top of the tank there is a hole designed to get drains inside. A pipe for draining the purified liquid is installed on the bottom surface. The chambers themselves communicate with each other using special holes located in the upper parts of the walls. Each compartment is equipped with ventilation to remove gases. The principle of operation of the system is quite simple. The sewage is drained through the pipes into the first chamber, where they are settled. Solid fractions then fall into the sediment, and the liquid flows into the second chamber, in which it is additionally cleaned and clarified. Then, all the treated water is drained into the third chamber, where, under the influence of fermentation, silt is formed from it, and the remaining water goes into the soil.

Post-treatment - two effective ways

There are two important ways to carry out additional water purification - using filtration or drainage systems:

- Drainage is carried out using a well, which is the last tank in the purification system. This tank does not have a sealed bottom and the water that enters it immediately seeps into the ground. However, at the bottom there is a filter pad made of sand or gravel.A similar method can be used if the groundwater in the serviced area lies quite deep. At the same time, if the soil is overflowing with clay in the area, then the number of drainage wells should be increased.

- Filtration is carried out using a special field through which the liquid passes in order to fully cleanse. Compared to a drainage well, the filtration field occupies a large area. This method is used if the aquifers are located close to the surface. The peculiarity is that the field must first be covered with a filter cloth sprinkled with gravel or sand.

IMPORTANT! When calculating the area required for a filtration field, it is worth considering the number of consumers, the diameter of the conductive pipes and the average annual air temperature in the area.

Selection of the best material for a septic structure

First of all, the material from which the septic tank is made must meet the requirements of strength and tightness, because the main task of the entire structure is to prevent environmental pollution. The most popular materials are:

- Concrete monolith - for such a design, the installation of formwork will be required.

- Reinforced concrete rings - this design is very resistant to corrosion and is characterized by increased strength. However, the material itself is quite fragile, so installation and transportation must be done with care.

- Structures made of foam blocks and bricks - they are erected from the bottom of a dug pit. The bottom surface and walls must be sealed with clay or special putty.

- Fiberglass - characterized by special strength with a rather light weight. Due to their chemical neutrality, they are highly practical and durable.

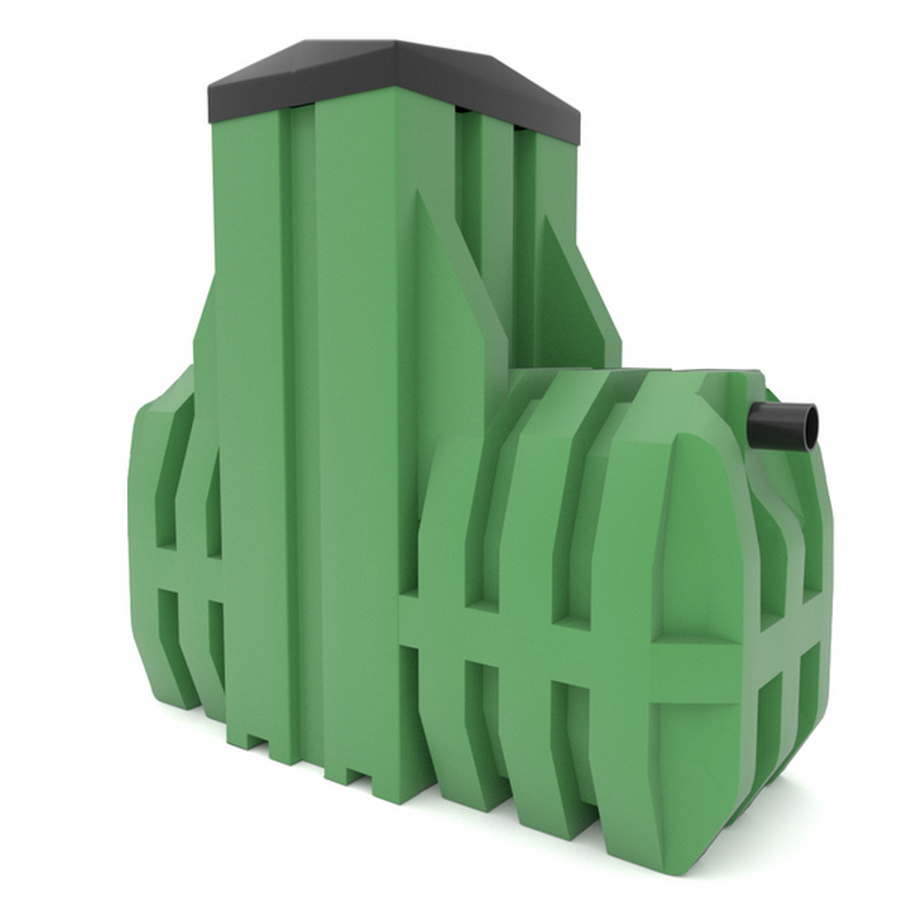

- Polymer - they are distinguished by a budget price, a relatively small mass, however, at low temperatures they can crack. Also, polymer bases are vulnerable to rodents.

- Steel is the cheapest option. Despite their overall mechanical strength, they are extremely susceptible to corrosion. However, this problem can be solved by installing waterproofing.

Rules for the installation of an autonomous septic sewer

The described type of septic tank cleaner is able to function without unpleasant odors and does not require pumping, and is also the only type of cleaner allowed for installation in areas that are limited in area or located within the city. However, in this case, certain conditions must be met:

- The required distance from the base of the foundation must be at least 5 meters, in special cases (with an excessive lack of space) it can be reduced to 3 meters.

- There should be at least 2-4 meters to the border of the adjacent area or to the fence.

- Maintenance of several houses at once and installation in the city limits is allowed.

IMPORTANT! The installation of a septic tank should be carried out only by organizations accredited by the manufacturer of the treatment system, or directly by the manufacturer's employees. The future owner is allowed to independently carry out only excavation and preparatory work.

Choosing a place for a pit

The installation pit must be dug with a deep margin - this is necessary to form a solid bottom. Then, the bottom surface is poured with mortar, plates are mounted on it and sand is poured over the crushed stone cushion. The base itself must be strictly flat and horizontal.

The place for the pit itself is selected in such a way that the sewer pipes from the house pass with a minimum of high-altitude differences and different turns. In general, it is desirable to lay the entire connection in a straight line. It is worth remembering that the installation of the pipe must be carried out at an angle - this is done so that the liquid can drain freely into the receiving tank. The standard pipe diameter is 100-120 millimeters, it is preferable to use pipes made of polypropylene or made of PVC.

Rules for care and maintenance

Usually, in the documentation supplied by the manufacturer of the septic system, an exhaustive list and terms of preventive maintenance are indicated. However, for any systems there are general rules:

- A weekly inspection of the drain and checking the transparency of the liquid and monitoring for the presence of strong odors is required (the water at the outlet of the autonomous sewer system should not have any color shades, the smell should be absent, as well as any impurities).

- If the system is equipped with a special trash catcher, then the waste baskets should be removed once every one to two months (access through the hatch).

- If chlorine is used for disinfection, then the tablet in the module intended for this is replaced once every two weeks.

- Complete cleaning of the chambers from solid fractions should be done every 3-5 years, because the amount of accumulated waste during this time is insignificant - from 60 to 90 liters. In extreme cases, a powerful drainage pump can be used for these purposes.

- Spare parts and consumables are usually replaced ten years after the start of operation.

Building a septic tank with your own hands

The most common options for a home-made design of a treatment plant are variations from monolithic concrete and from eurocubes

Monolithic Concrete Cleaner

Such samples of structures are distinguished by increased strength indicators and a long service life. Their obvious advantages include:

- High practicality;

- Extended service life;

- Easy accessibility of the material used for manufacturing;

- Greater degree of waterproofing.

At the same time, monolithic structures have a number of the following disadvantages:

- Labor intensity and total cost of construction;

- The need to install a reinforcing base;

- Formwork structure integration as a mandatory task;

- Reduced throughput.

The process itself can be described as follows: before concreting, a reinforced mesh is laid at the bottom of the chambers. Further, in order to prevent corrosion processes, a thick layer of concrete is applied to the metal, the minimum thickness of which over the mesh should not be less than three centimeters. The next step will be the arrangement of formwork and general reinforcement. Then it is necessary to concrete the walls of the chambers and build partitions between them. The final stage will be the pouring of the floors with a concrete solution. The total drying period of the structure will be about fourteen days. At the same time, it is desirable to cover the finished system with a film to ensure uniform drying of the concrete over the entire area.

Eurocube cleaner

Eurocubes are containers made of plastic. To install cameras from this material, you first need to prepare a thick concrete base, on which the septic tank itself will subsequently be installed.Such manipulation aims to prevent the displacement of the entire structure as a whole under the influence of groundwater moving close to the soil surface. And in general, the rise of groundwater upwards is also capable of displacing the entire structure if it is poorly fixed. Before installation, plastic containers must be insulated with foam, and only then mounted in the pit itself. After that, it is necessary to fill the tanks with water and concrete it on the sides. It will be nice to insulate the entire sewage treatment plant from above. A pipe system should be brought to the surface, which will provide ventilation processes. A septic tank from eurocubes will also require the use of additional elements to improve and fully clean the drains to an acceptable level. Here the best solution would be to use a filtration field or filter cassettes.

Legislative requirements for equipment and installation of a septic tank

The main document regulating this area of construction in the Russian Federation is the Construction (SNiP) norms and rules of 1985 for No. 2.04.03 “Correct arrangement of sewerage systems without pumping”. This document contains an exhaustive list of legal requirements for the structures described.

Separately, it is worth pointing out some of the features established by the above rules and regulations:

- Possibility of connecting the septic tank to the home system by concealed installation;

- There must be a distance of at least 50 meters from the septic tank to the source of clean water;

- It is forbidden to install septic facilities in areas where there is a large vegetation with a strong root system - over time, the roots can destroy the integrity of the tanks.

Rating of the best septic tanks for giving without pumping for 2022

Economy class

3rd place: "Microbe - 450" (Trademark "Triton")

A stationary septic tank, although focused on small amounts of processing, does its job well. Suitable for both seasonal and permanent use. Perfect for a family of 4-5 people. The manufacturer in the package of additional services offers delivery and installation on its own throughout the Russian Federation.

| Name | Index |

|---|---|

| Dimensions, mm | 810x810x1430 |

| Weight, kg | 35 |

| Productivity, l/day. | 150 |

| Total volume, liters | 450 |

| Price, rubles | 12500 |

- Budget price;

- Simplified installation;

- Long service life.

- Requires winter insulation.

2nd place: "Rostok-mini"

Universal unit with increased production capacity. Suitable for large families. It can be used both outside the city and in a frequent residential building within the city. The tanks themselves are made of heavy-duty plastic, which can provide operation for up to 50 years. The dimensions of the model are quite compact and allow you to quickly build a pit for it.

| Name | Index |

|---|---|

| Dimensions, mm | 1760x1100x1275 |

| Weight, kg | 70 |

| Productivity, l/day. | 300 |

| Total volume, liters | 1000 |

| Price, rubles | 28000 |

- Absence of extraneous odors during operation;

- Large capacity;

- Excellent performance.

- Not detected.

1st place: "Biofor 2.0 Profi"

The manufacturer specifically positions this sample as a country model and recommends it for summer residents who live in summer cottages until the first cold weather. It is very easy to install, does not require special preparatory work and is characterized by high performance. The hull base is reinforced with a special pallet.

| Name | Index |

|---|---|

| Dimensions, mm | 2720x2000x1000 |

| Weight, kg | 125 |

| Productivity, l/day. | 300 |

| Total volume, liters | 1000 |

| Price, rubles | 34000 |

- The presence of an additional pallet;

- Does not require special training during installation;

- Reliability.

- Big mass.

Improved Models

3rd place: "Aquatek LOS 5 M"

It is intended for cleaning household sewage from dachas and cottages, it is able to serve a family of up to 5 people. Purification is carried out by settling the substance under anaerobic conditions using the method of multi-stage biology. The case is made of polyethylene of increased rigidity, which allows it to be placed in different types of soil.

| Name | Index |

|---|---|

| Dimensions, mm | 1525x1525x 2275 |

| Weight, kg | 230 |

| Productivity, l/day. | 1200 |

| Total volume, liters | 3000 |

| Price, rubles | 58000 |

- Does not require a concrete base.

- An innovative cleaning method is applied;

- The case of the increased rigidity.

- High price.

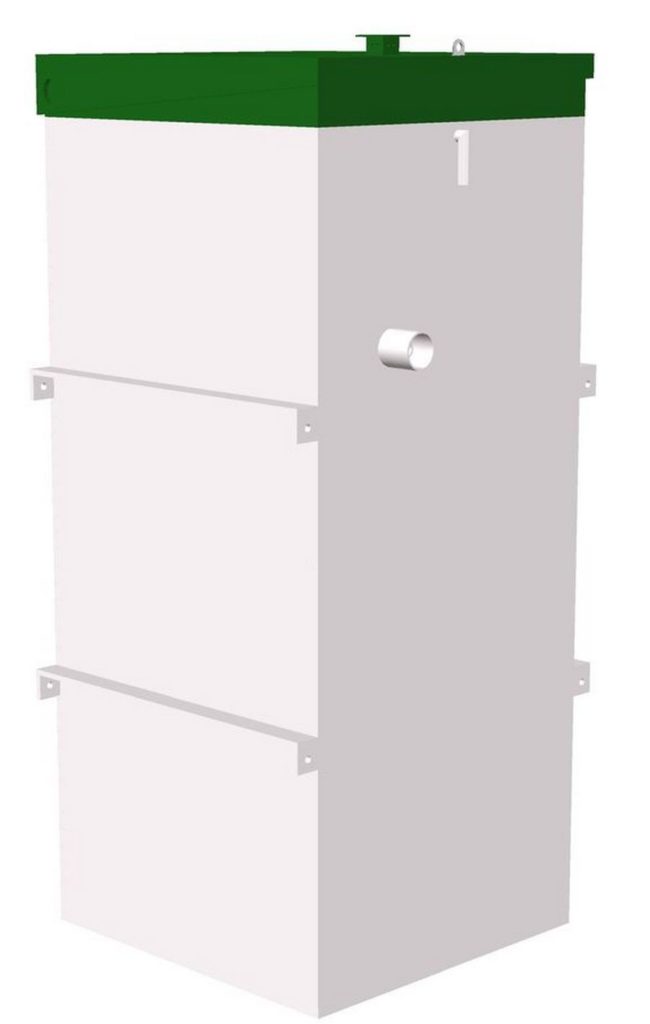

2nd place: Alta Bio Lite-5

The sample is not an independent septic structure, but is a superstructure for a home-made septic tank made of concrete rings. Installation can be done independently, which will not be difficult. After integrating this add-on, the throughput of the septic tank increases three times.

| Name | Index |

|---|---|

| Dimensions, mm | 2182x630x1220 |

| Weight, kg | 50 |

| Productivity, l/day. | 250 |

| Total volume, liters | 630 |

| Price, rubles | 69000 |

- Service life - at least 50 years;

- Easy integration;

- Extended functionality.

- It is just an add-on.

1st place: Topas-S 5 Pr

This model is characterized by ultra-high performance: the cleaning efficiency ratio is 98%. Serves a family of 4 to 6 people. Volley discharge reaches 220 liters. Installation "on a turn-key basis" forces of the manufacturer is possible.

| Name | Index |

|---|---|

| Dimensions, mm | 2182x630x1220 |

| Weight, kg | 260 |

| Productivity, l/day. | 220 |

| Total volume, liters | 630 |

| Price, rubles | 94000 |

- Completely autonomous system;

- High degree of purification;

- Protection against corrosion and mechanical damage.

- Overcharge.

Afterword

Before making a choice in favor of a septic tank for a suburban area without pumping out, it is worth deciding on the conditions for its placement - whether there is enough territory, whether regulatory indents will be observed, how deep the groundwater lies, etc.

The main thing is to understand that septic tanks are intended only for putrefactive wastewater treatment, that is, roughly speaking, the cleaning process in them is carried out by nature itself.

They cannot cost more than 100,000 rubles, moreover, they cannot be automated or volatile. Everything that falls under the above requirements is already autonomous sewers or biological treatment plants. In addition, the fermentation process in the purifier can always be helped by pouring a special chemical preparation into the container - the chemical industry is actively developing today.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131650 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127689 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124518 -

The best men's sneakers in 2022

Views: 124032 -

The Best Complex Vitamins in 2022

Views: 121938 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114979 -

The best paint for gray hair - top rating 2022

Views: 113394 -

Ranking of the best wood paints for interior work in 2022

Views: 110318 -

Rating of the best spinning reels in 2022

Views: 105328 -

Ranking of the best sex dolls for men for 2022

Views: 104365 -

Ranking of the best action cameras from China in 2022

Views: 102215 -

The most effective calcium preparations for adults and children in 2022

Views: 102011