Ranking of the best self-priming pumps for 2022

If there is a drilled well in the summer cottage or home plot, then in order to organize the irrigation of household plots and to meet the needs of home water supply, you will need to use a special self-priming pump. Before purchasing it, you should learn more about the principles of operation of such equipment, familiarize yourself with the advantages / disadvantages of the models on the market, study the installation and connection procedures. This information will be useful not only for amateur gardeners, but also for residents of private houses who have problems with water delivery.

Content

- 1 The structure and functionality of a surface pump

- 2 Main Differences Between Peripheral and Centrifugal Pumps

- 3 Rules for a competent choice

- 4 Ranking of the best self-priming pumps for 2022

- 5 Instead of an epilogue

The structure and functionality of a surface pump

Self-priming pumps lift liquid from a depth due to the pressure difference formed during its differences. The maximum effective depth of such a pump is about 10 meters, but usually domestic wells do not reach such depths, but only 8-9 meters, so the power of the device, as a rule, is more than enough. The mechanism of operation is based on blades rotating inside the apparatus, which create areas of low pressure, which it rapidly tries to fill with liquid.

Such units consist of an electric motor, a working chamber that pumps liquid through a pumping mechanism, which, in turn, is driven by a special rotor. All active elements are located around the shaft passing through the seal, and it also prevents liquid from entering the electrical parts of the device.

There are two types of seals - end seals and seals. The first option is not often found due to its high cost and reliability, but the second is provided by most existing models.

IMPORTANT! In "nature" there are models that are generally devoid of seals. They are replaced by magnetic couplings in the design. Such a decision often indicates a greater reliability of the device, but it significantly reduces its performance. The reason for this is the reduction in torque during transmission from shaft to shaft.However, such equipment is considered the most expensive.

According to the type of suction force, pumps are divided into vortex and centrifugal. Both designs use an impeller (impeller for water treatment equipment).

Centrifugal pumps

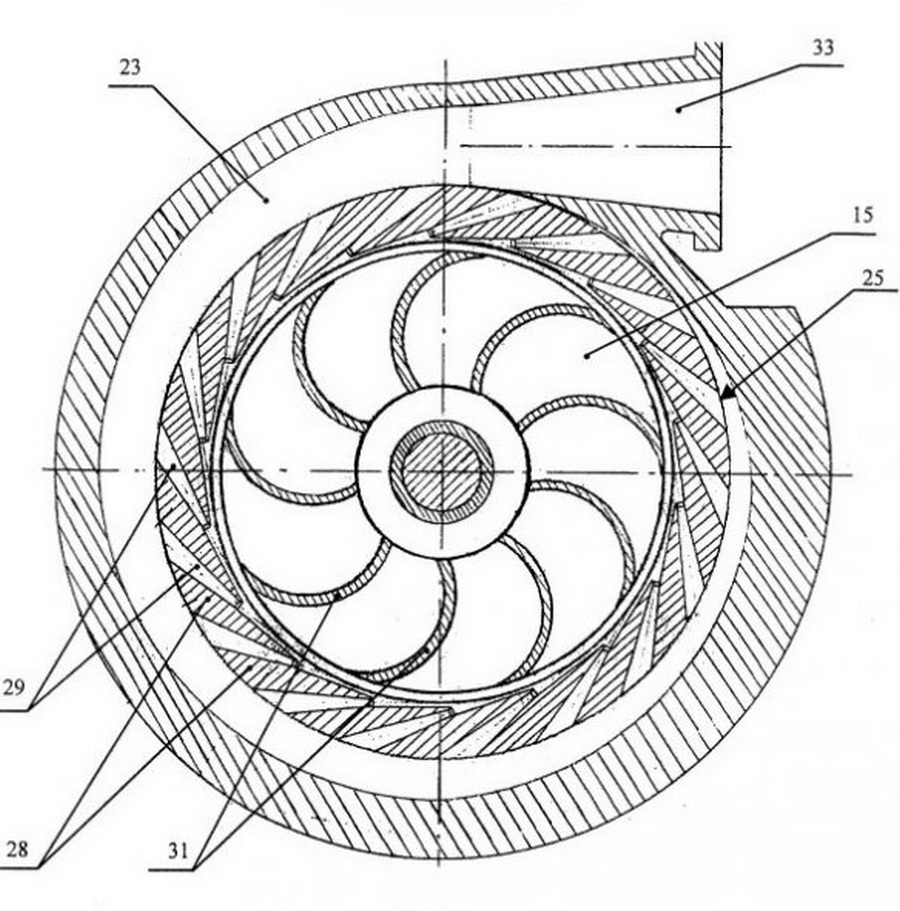

The working chamber of such a pump at first glance is a snail shell. Blades are installed in its center, which make up the water wheel. The wheel may be in a single copy (single-stage pump), or there may be several (multi-stage form). Accordingly, the first will always work with the same power, and on the second it (power) can be changed.

The blades are located in such a way that they diverge from the shaft and at the same time are bent in the direction opposite to rotation. During the rotation of the wheel, the blades repel water from themselves, press it against the chamber sides, while creating a centrifugal effect. The liquid seeps through the diffuser - the minimum distance from the tips of the blade to the wall. Thus, a high pressure arises on the diffuser, due to which the liquid goes up, twists according to the “snail” principle, after which it is transferred towards the outlet pipe.

At the same moment, a reduced pressure arises in the central part of the chamber, which draws water along with it through the inlet pipe. From it, the highway goes either into a well or into a reservoir. This process cannot even be called cyclic - it is simply endless, because it occurs permanently while the electric motor is running and the shaft is spinning.

In general, this method of pumping liquid is quite effective, however, it has a significant drawback - if the system is filled with air, then reduced pressure cannot be created.The device will run idle, which will inevitably lead to overheating and breakdown. In order to avoid such a situation, when the equipment is first started, water is poured into it in order to fill the working chamber and the supply line. The water will no longer be able to drain back, because the check valve will prevent this. It is equipped with a coarse filter, located at the end of the inlet line, which is immersed in the source.

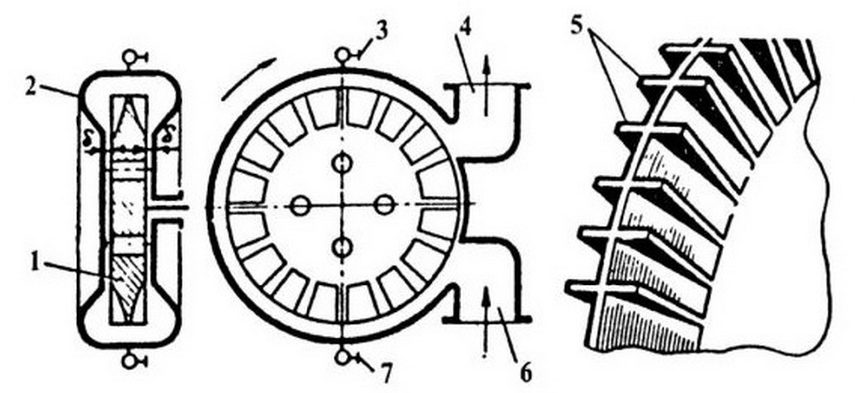

Rotary pumps

They have a slightly different principle of operation. The main difference is that the impeller has a different shape - the blades on it are located on both sides at once, they are radial and straight. Such a structure is called an impeller. The design of the working chamber is arranged in such a way that the wheel is in tight coverage, and only the side partitions have a large gap.

The rotation of this wheel makes the water move. Due to centrifugal force, the liquid is pressed against the chamber walls and moves along it. And when touching the second side of each blade, it receives another portion of acceleration, which is why it twists in the form of a vortex. All this action forms a vortex flow, which gave the name to this design.

By the way, this system creates a pressure 5-7 times higher than that of centrifugal pumps of similar power. This system should be used in cases where it is necessary to provide high pressure with low water consumption. Peripheral pumps can create an area of reduced pressure even when partially filled with air, so dry running and overheating are extremely rare in such equipment. The mixture of water and air will not affect either the performance or the power of the machine. Therefore, at the first start, the chamber can only be partially filled with water.The disadvantage of vortex models is the high consumption of electricity, so such equipment is used where the water flow is relatively small.

Ejector - a device for raising water from great depths

An ejector is used to solve the issues of water intake from a great depth. It is a special-shaped tube that has one inlet and two outlets - the lower expanded inlet is used to draw fluid from the well, and the other, which narrows inside, is used to recirculate water received from the pump. Then, through the outlet, both streams are mixed and rush back to the unit.

All this works on the provisions of Bernoulli's law. Water, passing through a narrow pipe, creates the effect of a turbine, while, having received additional acceleration, it creates a low pressure area in the ejector. These voids are instantly filled with liquid, which enters through the main nozzle. As a result, the pressure in the well itself increases many times, its difference with the pressure on the wheel of the unit also increases, so the water begins to move quickly upwards.

The disadvantage of the ejector is that it will reduce the efficiency of the equipment by 35-38% (water will have to be constantly returned to the well), but the lifting depth increases from 10 to 40 meters. Usually an ejector is included with any pump.

Additional characteristics of pumping equipment

- The performance of pumps, as a rule, is 3-5 cubic meters of water per hour, which is enough for a house with a decent number of residents;

- The pressure in the system is approximately 4 bar - it is sufficient for all plumbing fixtures;

IMPORTANT! The performance of the pump will depend not only on the depth of the well, but also on the length of the water supply and the number of water points.

- Pumping equipment is quite noisy in itself, so it should be installed away from living quarters.

Main Differences Between Peripheral and Centrifugal Pumps

Centrifugal models are much superior to vortex ones in size and weight, however, they work somewhat quieter. In addition, the simplicity of their design without fear can allow pumping liquids with foreign inclusions - such as fecal and drainage aggregates. Vortex pumps are quite sensitive, so they are specially equipped with filters;

Centrifugal units are considered more reliable - their service life can be up to 20 years. In repair, they are also quite simple, if desired, the problem can be fixed independently. Vortex units are considered thinner equipment that conducts scrupulous cleaning and high-speed pumping of liquid - it is unlikely that they will be able to repair them themselves;

The energy consumption of vortex pumps is 40% higher.

Rules for a competent choice

Before buying, you should read the information contained in the product data sheet. You need to be interested in the following data:

- Power and productivity - this indicator must be compared with the distance of the well from the house, the number of water distribution points and the maximum volume of water required at any given moment. Naturally, this will require precise mathematical calculations. However, by correctly calculating the required power of the pump, you can extend its service life, as well as avoid premature breakdowns and overheating;

- The minimum output pressure - it should be 0.3 bar. Otherwise, household appliances connected to plumbing communications may fail.

- It is also necessary to correlate the capabilities of the pump with the diameter of the casing that is installed in the well.With this question, it is better to contact the specialists who carried out the drilling.

Ranking of the best self-priming pumps for 2022

The models of pumps presented below are sorted by increasing price index.

The best self-priming pumps worth up to 10,000 rubles

5th place: ZUBR NPG-M1-400

The device has an automatic on / off function, a thermal fuse to protect the motor. It is used for pumping clean and contaminated liquids, indispensable for dewatering, as well as for drainage and aeration.

Specifications:

| Name | Index |

|---|---|

| Lifting height, m | 6 |

| Productivity, l/min | 125 |

| Dry run protection | There is |

| power, kWt | 0.4 |

| Suction depth, m | 7 |

| price, rub. | 1940 |

- The body is made of reinforced plastic;

- Ease of transportation (the presence of a special handle);

- Universal fitting.

- Performance fluctuations.

4th place: AL-KO Drain 20000 HD

Designed for pumping liquids with foreign inclusions. Able to work in extreme conditions. Also suitable for draining basements and swimming pools. The impeller has a funnel shape, which increases the efficiency of the apparatus. The kit includes a universal nipple.

Specifications:

| Name | Index |

|---|---|

| Lifting height, m | 5 |

| Productivity, l/min | 720 |

| Dry run protection | There is |

| power, kWt | 0.43 |

| Suction depth, m | 6 |

| price, rub. | 3590 |

- Special wheel technology;

- Increased size of foreign grain - up to 30 mm;

- Rugged housing.

- Big weight.

3rd place: Metabo P 2000 G

The model belongs to the line of budget pumps and is designed exclusively for the intake of clean water.Has some internal rubberized details that allows to reduce working noise at operation. Has excellent throughput. Afraid of low temperatures

Specifications:

| Name | Index |

|---|---|

| Maximum depth, m | 8 |

| power, kWt | 0.45 |

| Productivity, l/h | 2000 |

| Maximum height (with ejector), m | 30 |

| price, rub. | 4400 |

- Democratic price;

- Increased pumping distance - 30 meters;

- Quality build.

- Reduced power;

- Inability to work in low temperature conditions.

2nd place: Gilex Jumbo 70/50 P 3701

Model from a Russian manufacturer. It has an increased immersion depth - 9 m. An ejector is included in the kit. The electric motor is characterized by extremely economical energy consumption. Due to the use of special treatment to which the elements of the running gear have undergone, the operational life has been significantly increased (the pump is designed for at least 5 years of continuous operation).

Specifications:

| Name | Index |

|---|---|

| Lifting height, m | 5 |

| power, kWt | 1.1 |

| Dry run protection | Missing |

| Productivity, l/min | 70 |

| Suction depth, m | 9 |

| price, rub. | 6940 |

- Ease of use;

- Acceptable cost;

- Quality build.

- High noise level.

1st place: GARDENA 8500 Comfort

All parts of the pump are made of high-strength materials, they perfectly resist both chemical and mechanical influences. It has a high level of liquid pumping speed. The power cable is significantly increased - up to 10 meters. The maximum diving depth is 8 m.

Specifications:

| Name | Index |

|---|---|

| Lifting height, m | 8 |

| Productivity, m3/hour | 8.3 |

| Dry run protection | there is |

| power, kWt | 0.38 |

| Suction depth, m | 7 |

| price, rub. | 9300 |

- Reduced noise level;

- Quality assembly;

- Extended functionality.

- High price among analogues.

The best self-priming pumps worth over 10,000 rubles

2nd place: Calpeda MXHM 205/A 230/50 Hz

A very popular model due to its high-quality and uninterrupted operation at low temperatures. It has a very compact size. The case is made according to the principle of a monolithic type and has special moisture / dustproof properties. It is equipped with a safety lock against an overheat at interruptions in water supply.

Specifications:

| Name | Index |

|---|---|

| Suction depth, m | 8 |

| power, kWt | 0.75 |

| Productivity, l/h | 4800 |

| Weight, kg | 12.5 |

| Suction system | multistage |

| price, rub. | 24105 |

- Long service life (monolithic body);

- Increased reliability;

- Availability of accessories (universal nozzles).

- Used for clean water only.

1st place: Grundfos JP 6 46811202

Designed exclusively for pumping liquids from wells, wells, reservoirs. It has a filter with carbon brushes, which allows you to get water of almost drinking quality at the outlet. It can be used as a water supply equipment for small residential buildings, and as a small fire extinguishing installation.

Specifications:

| Name | Index |

|---|---|

| Lifting height, m | 6 |

| Productivity, m3/hour | 55 |

| Dry run protection | Not required |

| power, kWt | 1.4 |

| Suction depth, m | 5 |

| price, rub. | 34000 |

- Increased power;

- Rugged housing;

- Multifunctionality.

- Extremely high price.

Instead of an epilogue

When choosing a suction pump, you must always remember that it is a complex technical equipment, so before buying, you should clearly establish the purposes for which it is purchased. Using a pump that is not adapted to a particular type of work will invariably lead to its failure. You should also pay attention to the warranty period: does it correspond to the type of equipment purchased? As a rule, it is larger for centrifugal ones, and less for vortex ones. It is better to buy a pump through online trading platforms, thus saving yourself from unnecessary retail "cheats".

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131653 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127693 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124520 -

The best men's sneakers in 2022

Views: 124036 -

The Best Complex Vitamins in 2022

Views: 121941 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2022

Views: 113397 -

Ranking of the best wood paints for interior work in 2022

Views: 110320 -

Rating of the best spinning reels in 2022

Views: 105331 -

Ranking of the best sex dolls for men for 2022

Views: 104369 -

Ranking of the best action cameras from China in 2022

Views: 102217 -

The most effective calcium preparations for adults and children in 2022

Views: 102012