Rating of the best drywall planers for 2022

Nowadays, a particularly popular building material used for interior decoration, wall cladding and partitions is drywall. By itself, this material is quite simple, but for its proper and high-quality installation, the use of special tools will be required. These include special planers, which are useful only at some stages of working with drywall, but their absence can stop all finishing work. Thus, every finisher needs to know the features and be able to use such tools.

Content

- 1 Scope of planers for drywall

- 2 Planer technical parameters

- 3 Modern varieties of planers for plasterboard

- 4 The ability to create planers for processing drywall yourself

- 5 Difficulties of choice

- 6 Fittings and equipment planers for drywall

- 7 Rating of the best drywall planers for 2022

- 8 Instead of an epilogue

Scope of planers for drywall

Plasterboard sheets (abbreviated as GKL) are a rather fragile material and therefore their edge parts are prone to various chips or coloring. From this it can be seen that although the sheets are far from small in their formats, they require careful treatment. For the highest quality and smooth joining between individual sheets, they must be properly processed. It is for these purposes that planers are used, which, in fact, are one of the varieties of rasps.

In addition, this tool will be needed at the final stage of work, so that at the end of laying and when finishing surfaces, the seams can be puttied without any problems. To do this, a chamfer is removed along the edges of the sheet with a planer, which forms a recess, which is subsequently filled with putty, which will eliminate the risk of bulges and cracks at the seams in the future.

Planer technical parameters

In order to carry out the highest quality and efficient cleaning process, it is necessary that the tool meets the following technical parameters:

- The length of the working platform - it will determine the speed of cutting work. The length of the handle for different models can be different and range from 15 to 24 centimeters. A large platform is not an objective indicator of the best working results - first of all, the planer must be convenient for the user himself and suitable for those GKL sheets that are supposed to be processed.

- The width of the cutting part - this parameter can vary from 1.4 to 4.3 centimeters. Its choice depends entirely on the thickness of the processed sheet.

- Blade - this element of the tool can be made of various types of steel. Blades made from tool steel grades are of great quality. They are considered stronger to work with and are able to produce smooth edges.

- Case - it can be made of both metal and plastic. Naturally, a tool in a metal case has a longer service life, because it can withstand mechanical stress better.

Modern varieties of planers for plasterboard

In total, there are two types of them - it is peeling and edging

Peeling planer - features of the device and use

Such a planer is a tool used to level the edges of a drywall sheet. With its help, it is possible to create a smooth and flawless edge, which will serve as a good help when installing drywall sheets and their finishing.A feature of the peeling planer is its appearance - the working platform is located on the lower part of the device and has many cutting pointed holes on its surface (these are blades for the edge model). The very structure of the peeling model is very simple:

- Handle for holding;

- Working platform - grater;

- Housing for fixing structural elements.

Using this type of device is also not difficult: the sheet of drywall must be held tightly by running the device along its edge and removing all irregularities and roughness. It is worth remembering that, unlike wood, gypsum does not shrink, but grinds off. To achieve the best effect from the peeling operation, it is preferable to place the sheet itself with the edge up and evenly drive the planer along the entire length. The pressure on the sheet should not be excessively strong - a light and tight pressure is sufficient. For some types of drywall, it is better to repeat the peeling operation several times (2-3 times).

IMPORTANT! Professionals believe that the optimal parameters of a peeling planer will be the following: the width of the working platform is no more than 3 centimeters with a total length of no more than 25 centimeters.

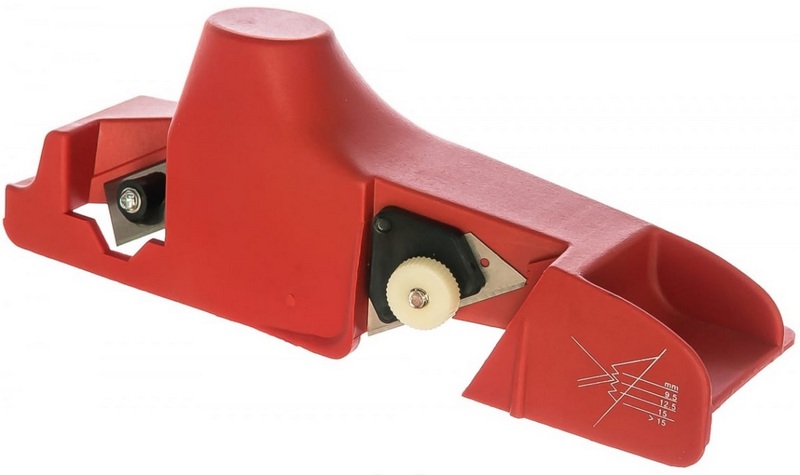

Edge planer - features of the device and use

This planer is also used for trimming the edges of drywall and chamfering, which can have a bevel angle of 45 degrees. The blades of this tool are made in the form of a trapezoid, amenable to displacement by the user in order to achieve the required depth of processing.

The edge planer consists of:

- Steel blade mounted on the side of the device;

- The screw with which this blade is fixed in a fixed position;

- The body holding all the structural elements.

IMPORTANT! An edge planer, the blade of which is made of high-quality and durable steel, is quite possible to use even for processing soft woods.

The very design of the device allows you to replace the blades as their cutting edge wears out. In principle, there are no difficulties with finding and purchasing such parts in retail chains of specialized stores in the Russian Federation, but their cost is not high.

It is worth noting that the use of an edging tool is significantly different from a peeling tool and looks a little more complicated. In general, the whole process comes down to the following steps:

- The gypsum board to be processed is installed with an edge in relation to the master;

- Along the edges, they initially pass once with a planer for chamfering;

- Further passages will form a recess with a width of 5 to 11 millimeters;

- When moving the tool, you should slightly press on the rear handle so that the front handle acts as a guide and with its help it is possible to maintain a single size of the layer to be removed;

- Then the sheets are applied as tightly as possible to each other;

- The final step will be filling the resulting grooves between the sheets with putty.

Thus, with strict observance of all stages of work with edging tools, the joints between the sheets turn out to be strong and inconspicuous.

IMPORTANT! To obtain the desired performance when using an edge planer, its blade must be made of durable steel, preference is given to tool grades. The process of replacing the blades should not cause problems and be difficult on the part of the device body.

The ability to create planers for processing drywall yourself

It is easiest to make a peeling model at home.For this you will need:

- Guide profile based on durable metal (it is possible to use spare parts from other tools, it is preferable that the profile be made of metal);

- A small piece of board or bar;

- Several screws;

- Scissors for working with metal;

- Screwdriver;

- Hammer small (if necessary).

Step by step, the entire process of manufacturing a peeling device is as follows:

- On the profile, it is necessary to measure the total length of the future tool (this parameter should be twice the length of the desired cutting part);

- Next, the sides are cut in such a way that when the profile is folded in half, a box-like shape is obtained;

- Facial, i.e. the working part of the profile must be laid on a wooden piece and drill holes in it with a screwdriver - the more they are drilled, the better the platform-grater of a homemade planer will turn out;

- Further, the sides are bent and a kind of box should be obtained;

- With the help of self-tapping screws, the sides are fixed on the platform;

- Using a hammer, too sharp edges of the holes are eliminated;

- For the convenience of holding a homemade tool in your hand, the part that will be intended for grip is wrapped with electrical tape.

Regarding self-manufacturing of an edge planer at home, this process will be very problematic, because you will need to find a suitable frame, make a blade mount and choose a reliable screw to fix it. All such actions will require not only the presence of certain knowledge and experience, but it will also be necessary to use special tools that are not available to every master.Thus, it is easier to buy a device for edging drywall work in a specialized store.

Difficulties of choice

Regarding the competent selection of a peeling planer for drywall, first of all, you should pay attention to what its peeling platform is made of and what sharpness of the cutting holes it has. Naturally, cheaper models are adapted to work with soft material - the sharpness of their holes is not great and leaves much to be desired, and the sole itself is made of soft material (up to thick sandpaper). If the roughing sole is made on a metal base, then you should check how much it can resist corrosion. At the same time, if the peeling holes are extremely sharp, they will cause the drywall material to crumble and notch. Professional craftsmen are advised to purchase a small-sized peeling device, no more than 15 centimeters in length, so that it fits comfortably in the hand.

For an edge device, in order to carry out its correct selection, it is necessary to pay attention to the following parameters:

- The length of the working platform - it can be from 15 to 24 centimeters, which will depend on the length of the edge of the sheet to be processed. Also, the length of the platform will directly affect the speed and overall productivity of the work.

- The width of the working platform - as a standard, it can vary from 15 to 42 millimeters. The value of this indicator should increase as the thickness of the drywall boards is supposed to be processed. Some edge planers allow you to manually adjust this setting, allowing you to use the device on drywall panels of any thickness.

- Blade material - as mentioned above, blades made from tool steel are preferred, because it is more durable and strong, and, accordingly, will last longer. At the same time, if a single work with sheets of small thickness is supposed, then the blade can be chosen from ordinary steel so as not to incur additional financial costs.

- It is also worth paying attention to the handles - they must be securely held in the hand. Using the front handle, the tool must be comfortably controlled, and the rear handle must provide the proper degree of pressure.

Fittings and equipment planers for drywall

By and large, the issue of configuration and additional fittings concerns only edge models, because peeling ones, in fact, are a one-time monolithic device.

Some edge models are provided with removable handles - it can be either only the front or rear, or both together. They can be adjusted in such a way as to provide the desired support on the back and at the same time provide comfort in the direction of the front handle. To do this, the front handle is set to a position slightly below the conditional "zero", and the rear should be slightly higher (depending on the thickness of the material). If you do not observe the uniform distribution of the load between the handles, this will affect the accuracy of the cut.

Also, the edge device may have a side limiter and a ruler. This kit will help you trim the edges of a drywall sheet without going beyond the desired angle.

Optionally, a special sharpener may also be present in the set, with which a blunt blade is undermined. However, this applies only to models whose blade is made of tool steel.Nevertheless, a sharpener may not be needed - some blades have double-sided sharpening and when one side is ground, it is simply turned over to the other. But when both sides are ground off, the manufacturer believes that the blade has already become completely unusable and simply recommends replacing it with a new one.

Expensive kits, as a rule, have spare blades in their set, although they can be of different sizes, which is quite convenient when processing sheets of various thicknesses. Also, the kit may include a special mount that turns the planer into a jointer.

Rating of the best drywall planers for 2022

Peeling Models

4th place: "STAYER Surform 140mm, medium 1881"

A good and budget option for a peeling device. It is intended for processing not only drywall sheets, but also softwoods, including products made from pure gypsum. The handle is a one-piece construction. And the sole is made of standard steel. The total length of the planer is 140 millimeters. The country of origin is Germany, the recommended cost for retail chains is 420 rubles.

- Manufacturing quality;

- Medium firmness of the sole;

- Monolithic construction.

- Relatively weak sharpness of the working platform.

3rd place: "TOPEX 250 mm 11A411"

Although this sample is intended for roughing wood products, it also copes well with plasterboard panels and even plastic products. The sole has a good grit, the body-handle is made of reliable plastic, the working platform can be adjusted with a screw.The overall design is characterized by strength and durability. The cutting platform can be replaced, however, it lasts for a long time. The handle is made in compliance with all conditions of ergonomics, which ensures the comfort of work. Country of origin - Poland, recommended price for retail chains - 540 rubles

- Ergonomic control;

- Replaceable working sole;

- Adequate cost;

- Excellent graininess.

- Not detected.

2nd place: "STAYER Surform 250mm, large 1882"

This model is focused exclusively on plasterboard surfaces and softwood. It has a durable body made of environmentally friendly plastic, which means a long service life of the tool. The peeling blade itself is made from high quality tool steel. Also, the blade is provided with a large number of cutting holes, which ensures high performance. The country of manufacture is Germany, the recommended cost for retail chains is 580 rubles.

- Durability;

- High productivity is achieved by a large number of cutting holes;

- Lightweight and durable body.

- Not detected.

1st place: "SANTOOL 250 mm 030751"

Excellent model for household and for large-scale works. The working sole itself is maximally enlarged, which allows processing long sheets. Chamfering and subsequent layers are done in a quality manner. The case itself is made of metal, which means an extended margin of safety for the tool. The guide handle is made of durable plastic and can be adjusted.The country of origin is Israel, the established retail price is 790 rubles.

- Long working sole;

- Rugged housing;

- Adjustable guide handle.

- Not detected.

Edge models

5th place: Anchor 51660

The simplest model of an edge planer for processing drywall. In general, it is characterized as a convenient device that is not loaded with unnecessary functions. Able to process the edge of the GKL panel at angles from 22.5 to 45 degrees. The sample can be adjusted to the thickness of the processed material: 9.5, 12.5 and 15 millimeters. The device is made of durable tool steel grades. The country of origin is Russia, the recommended cost for store chains is 310 rubles.

- budget cost;

- Variability of processing angles and material thickness;

- Blade made of tool steel.

- If the adjustment for material thickness is not followed, the resulting edges may be torn.

4th place: "FIT 15025"

This model is characterized by a comfortable and streamlined body, providing a comfortable grip when working. It is possible to adjust the angle and thickness of the processed material. The blade is doubled, which is made for proper quality when chamfering. The cutting element is made of tool steel, which guarantees a long service life of the planer. The country of origin is Canada, the established cost for retail stores is 530 rubles.

- Quality steel on the double blade;

- Streamlined and durable body with a comfortable grip;

- Adjustment of work parameters.

- Requires very smooth handling.

3rd place: "MTX 879055"

This model is structurally simple and is intended exclusively for cutting sheets on plasterboard panels. It is possible to set the working cutting angles - from 22.45 to 45 degrees. At the same time, it is possible to adjust the working thickness of the material, which will vary from 9.5 to 15 millimeters. The blade will ensure long operation of the device due to its production from tool steel of the 45th grade. The country of manufacture is Russia, the established cost for store chains is 690 rubles.

- Variability of setting the angle and thickness of the work;

- The case is made of high quality and durable plastic;

- Adequate price.

- In order to maintain the quality of the blade, it must be thoroughly cleaned and stored.

2nd place: "MATRIX 250x42 mm 879165"

This metal planer can be used not only for processing plasterboard and plastic panels, but also for working on fiberglass. The sample has an adjustable handle that can be fixed at different angles. It is equipped with special mounts that allow you to change the blades to work with different materials. Directly in the body design there are special holes designed for chip removal. The outsole has maximum elongation. The country of origin is Germany, the established cost for retail chains is 810 rubles.

- The model has numerous settings and options;

- Maximum length of the working sole;

- Metal case;

- Reversible handles.

- Not detected.

1st place: STAYER 18855

This model is distinguished by the amazing strength of the entire structure.It is used for chamfering and finishing edges in the processing of plastics and drywall, as well as softwoods. The planer itself is small in size, which means that it is comfortable and tireless to work with such a device. Structurally, the planer is adapted to install the blade at the angles desired by the user. The pressure plate will allow quick and easy blade changes, apart from the usual changing of its position. Two replaceable A-24 blades are supplied with the device. The country of manufacture is Germany, the established cost for the retail network is 920 rubles.

- Quick change and position and the blade itself;

- Ergonomic shape;

- 2 spare blades included.

- Not detected.

Instead of an epilogue

The analysis of the market of the instruments under consideration has established that most of the instruments located on it are of foreign origin. Moreover, an unpleasant trend is revealed, when even models from famous brands, primarily Western European ones, have a lot of negative reviews. This circumstance is most likely due to the fact that some of the production facilities of these companies are located in China, and the Russian consumer has little confidence in everything Chinese. At the same time, although the Russian manufacturer is poorly represented in this segment, the price-quality ratio for its planes is the most optimal.

If we talk about the direct cost of planers, then this parameter depends weakly on the technical characteristics. If the design uses a working platform based on tool steel, then the price for different brands will not vary much. Another thing is when it comes to packaging.It is the presence in the set of additional blades, removable handles, rulers and corner stops - these are the elements that can significantly increase the total cost of the product.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131652 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127693 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124520 -

The best men's sneakers in 2022

Views: 124034 -

The Best Complex Vitamins in 2022

Views: 121941 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114981 -

The best paint for gray hair - top rating 2022

Views: 113396 -

Ranking of the best wood paints for interior work in 2022

Views: 110320 -

Rating of the best spinning reels in 2022

Views: 105330 -

Ranking of the best sex dolls for men for 2022

Views: 104368 -

Ranking of the best action cameras from China in 2022

Views: 102217 -

The most effective calcium preparations for adults and children in 2022

Views: 102012