Rating of the best rotary cutters for excavators for 2022

In many sectors of construction and industry, the use of the cold milling process is becoming in demand. It is used in cases where it is impossible to perform various kinds of work using the usual methods. For example, if it is not possible to dig a ditch with a simple bucket, a rotary unit comes to the rescue. This tool is able to overcome even hard rocks or reinforced concrete. At the same time, it is no longer necessary to equalize the bottom or side walls of the resulting trench, and the cleaning of the crushed material will take much less time than when using a hydraulic hammer.

Content [Hide]

What it is

Rotary cutter for an excavator - a mounted hydraulic tool for crushing and loosening rocks, dismantling and demolition of structures, laying trenches, profiling vaults, removing old coatings, dredging or other works.

For each task, its own solution method is selected with the definition of the type of cutters and equipment.

Design

The main elements of standard equipment are:

- drum with scoring (at the edges) and main tool holders;

- cutters with hard-alloy tips;

- blades collecting cut material;

- high torque hydraulic motor;

- mounting frame;

- set for wetting the treated surface (tank, electric pump);

- hydraulic cylinder for displacement in a horizontal plane.

The device allows quick replacement of worn cutters.

The cutter drum is driven by a high-torque rotary piston hydraulic motor. Cutting force and torque are optimized by the gearbox. Operator comfort is improved by reducing vibration and noise by adjusting the cutter speed.

Applications

The use of rotary mechanisms is advisable for:

- trenching in rocks;

- digging pits in frozen soils or rocks;

- digging up soil or backfilling in difficult conditions;

- development of permafrost or rocks with rock crushing;

- tunneling;

- profiling of bridge supports, concrete walls;

- cutting reinforced concrete;

- removal of "hats", analysis of "goats";

- vaulting and surface leveling;

- demolition of building structures with grinding of material;

- pier construction.

Features and benefits

The use of a rotary unit allows you to get a number of significant advantages:

- compactness;

- manufacturability and increased volume of production with a simultaneous reduction in costs during the extraction of rock and its transportation;

- high performance;

- high-speed driving on fractured and frozen soils;

- accurate positioning and stable operation;

- grinding materials to fractions of established sizes;

- good waterproofing with the possibility of operation in the aquatic environment for the construction of berths;

- simple convenient maintenance with easy access to the main structural elements;

- comfortable conditions for the operator with a minimum level of noise and vibration;

- ensuring high reliability in difficult conditions thanks to the safety valve system;

- versatility for solving the problems of excavation, grinding and soil filtration;

- use in cramped conditions when installed on mini-excavators;

- reduction in electricity consumption.

Along with the advantages, there are disadvantages:

- service life depends on careful attitude, competent maintenance and care;

- the difficulty of replacing consumables (cutters) depends on the type of equipment.

Varieties

Universal

Equipped with interchangeable drums and cutters. It is used to perform a large volume of diverse cases, incl.removal of old asphalt or concrete pavement, milling of soil in the permafrost zone, chopping of wood or rock.

transverse

Equipped with a 360 degree swivel mechanism. Designed for tunneling and trenching, quarrying, dismantling of structures, as well as earthworks.

Longitudinal

It is used when cleaning piles, digging ditches.

Disk

Better efficiency in solving specialized tasks, incl. laying of communication trenches, dismantling and disposal of building structures.

chain

Designed for narrow trenches with smooth contours without the need for expansion in soft soil.

planning

It is used when removing road surface or dirt, as well as when planning areas with the possibility of adjusting the depth.

Criterias of choice

In order not to make mistakes when choosing, experts advise paying attention to the goals of upcoming events, taking into account the technical characteristics of the base machine - an excavator.

- Type of excavator for mounting attachments: weight, dimensions, load capacity, hydraulic characteristics, downforce level.

- Volume and productivity to perform calculations of the required cutters and the number of teeth.

- Analysis of the class and strength of the processed material or soil in megapascals (MPa).

- The need to install a separate rotary hydraulic line.

Where could I buy

Popular models and new attachments for excavators can be purchased directly from the manufacturers of these products or at the warehouses of dealers of such bulky goods.Consultants will assist with competent recommendations and valuable advice - how to choose, which ones are available, which company is better to buy, how much it costs.

In addition, a suitable unit is available for ordering online in the online store, where you can always get acquainted with customer reviews, read the description, study the technical specifications, parameters, and see photos. Typically, retail aggregators present goods in different categories - from inexpensive budget to premium, for which you will have to pay many thousands of rubles.

The price of the proposed "hitch" is influenced by various factors, which include:

- purpose and processed material - for soft soil, structures are cheaper;

- dimensions - the smaller, the cheaper;

- trade mark - products of well-known manufacturers are much more expensive.

TOP 7 best rotary cutters of transverse type for excavators

The rating of high-quality units is based on customer reviews who left reviews on the Internet. The popularity of models is due to technical characteristics, functionality, performance, service life, cost.

The obor presents the lines of rotary units of the world's best manufacturers, represented on the domestic market of special machinery and equipment.

ROCKWHEEL

votes 3

Brand - ROCKWHEEL.

Producer: Rokla GmbH.

Rokla GmbH, headquartered in Germany, developed the first rotary cutter more than 25 years ago. Today, the company's product range includes universal attachments that are installed on excavators, loaders, and robots.ROCKWHEEL mounted rotary cutters are characterized by a wide range of applications, the ability to combine operations, as well as high productivity and long service life. At the same time, maintenance costs are minimal. It should be noted that the key elements of the equipment are made of HARDOX high-strength alloy, which is a guarantee of durability.

Mounted milling cutters ROCKWHEEL on the excavator are presented in various models. There are road mounted cutters, trench cutters, vertical models, as well as chain and cross cutters.

Characteristics of the transverse rotary cutters of the brand - in the table:

| Model | Carrier weight, t | Milling cutter weight, kg | Rated power, kW | Oil consumption, l/min |

|---|---|---|---|---|

| C2 | 1 to 3 | 66 | 9.5 | 30-60 |

| G5 | 2,5-6 | 181 | 22 | 40-65 |

| G5 TWIN | 5 to 10 | 200 | 44 | 80-100 |

| D10 | 8 to 12 | 426 | 29 | 60-112 |

| D15 | 12 to 18 | 595 | 41 | 120-132 |

| D20 | from 18 to 25 | 1.17 | 70 | 220-320 |

| D30 | 26-38 | 1.444 | 110 | 320-460 |

| G40 | 30-50 | 1.8 | 140 | 360-540 |

| G50 | 42-50 | 2.458 | 140 | 360-540 |

| G60 | 50-65 | 2.478 | 220 | 540-680 |

| G125 | 65-125 | 5.42 | 400 | 800-1000 |

- Easy to connect to excavators and robots;

- Moderate dimensions of the equipment;

- Balanced weight;

- Wear-resistant actuator with safety valve;

- In operation, the equipment is characterized by low noise and low vibration;

- Bearings and seals are durable;

- Some cutters can be used for underwater work;

- The equipment is convenient to store and transport;

- There are extensive opportunities for modernization;

- Possibility to use the equipment in various climatic zones due to well-thought-out engineering solutions.

- No.

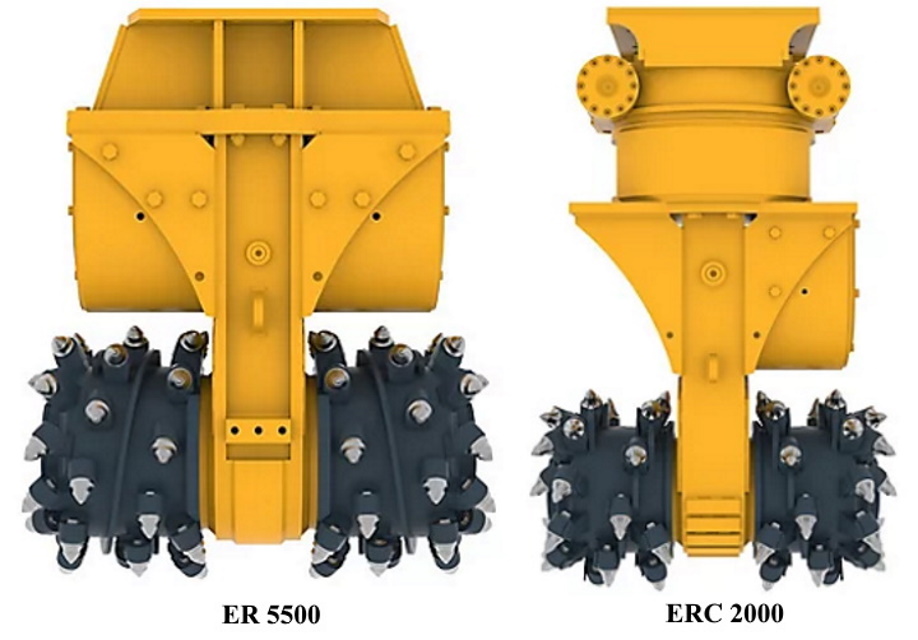

Epiroc ER/ERC series

votes 1

Brand - Epiroc (Sweden).

Producer - Epiroc GmbH (Germany).

A wide range of more than 30 hydraulic models of different sizes and types, with a transverse cutting head for construction, road, mining and other works.Attachments are placed on the boom of a caterpillar excavator having the appropriate weight.

The ER series is commonly used in soft rock mining, trenching, tunneling, stone or concrete surface profiling. In cramped conditions, small products can be used on mini-excavators. Units with a curb weight of up to seven tons for installation on excavators weighing 70-125 tons are excellent for laying road or railway tunnels. At the same time, oil and cutters should be changed regularly in the gearbox, which wear out quickly during active operation.

ER Series Specifications:

| Model | Carrier weight, t | Milling cutter weight, kg | Rated power, kW | Oil consumption, l/min |

|---|---|---|---|---|

| ER40x | 0,6-2 | 110 | 13 | 17-22 |

| ER50x/50 | 1-3 | 170/200 | 18 | 25-38 |

| ER 100x/100 | 3-7 | 330/350 | 30 | 41-62 |

| ER 250x/250 | 8-15 | 520/570 | 45 | 60-85 |

| ER600 | 10-18 | 900 | 65 | 120-150 |

| ER650 | 15-25 | 1200 | 80 | 140-190 |

| ER 1500х/1500хl | 20-40 | 2000/2100 | 120 | 205-300 |

| ER1700 | 30-50 | 2450 | 120 | 290-360 |

| ER 2000x/2000 | 35-55 | 2700/2900 | 160 | 300-390 |

| ER 3000 | 50-70 | 4000 | 200 | 350-450 |

| ER5500 | 70-125 | 7000 | 400 | 700-950 |

The ERC series has a built-in hydraulic rotation mechanism to increase productivity, reliability and accuracy of the work performed.

ERC Series Specifications:

| Model | Carrier weight, t | Milling cutter weight, kg | Rated power, kW | Oil consumption, l/min |

|---|---|---|---|---|

| ERC50 | 1-3 | 340 | 18 | 25-38 |

| ERC 100 | 3-7 | 530 | 30 | 41-62 |

| ERC 250 | 8-15 | 950 | 45 | 60-85 |

| ERC600 | 10-18 | 1280 | 65 | 120-150 |

| ERC650 | 15-25 | 1760 | 80 | 140-190 |

| ERC 1500x/1500xl | 20-40 | 2700/2800 | 120 | 205-300 |

| ERC 1700 | 30-50 | 3240 | 120 | 290-360 |

| ERC2000 | 35-55 | 3600 | 160 | 300-390 |

| ERC3000 | 50-70 | 5700 | 200 | 350-450 |

Price on request.

- versatility of application;

- high performance;

- strength of the structure, covered with wear-resistant material;

- reliable transmission of torque by durable cylindrical gears of the gearbox;

- optimal positioning in difficult conditions;

- resistance to heavy loads;

- equipped with a dust cover;

- precise spraying of water on the area of the cutting head;

- possibility of use for underwater work.

- the need to agree with the manufacturer of any modifications.

Gypsum mining ER 2000:

Delta RDC series

votes 0

Brand - Delta (Republic of Korea).

Manufacturer - Delta Engineering Group, Co, Ltd (Republic of Korea).

A range of universal transverse-type machines for continuous work with concrete or rocks both on land and under water. Demonstrate good results in trenching, surface profiling, mining operations in mine or open pit. Indispensable in confined spaces, mines, trenches or in water. They have high productivity when processing materials of medium complexity - asphalt, concrete, gypsum, limestone, permafrost.

The power of manufactured products varies from 18 to 140 kW, depending on the installation on mini-excavators or powerful tracked vehicles weighing from two to 60 tons. Due to the modular design, they are well adapted to perform highly specialized tasks.

Specifications:

| Model | Carrier weight, t | Milling cutter weight, kg | Milling width, mm | Cutting force, N | Number of cutters | Working pressure, atm. | Oil consumption, l/min |

|---|---|---|---|---|---|---|---|

| RDC 25 | 4–6 | 250 | 500 | 2800 | 48 | 375 | 30-65 |

| RDC 60 | 9-14 | 420 | 630 | 5500 | 48 | 375 | 70-120 |

| RDC 100 | 12-20 | 850 | 750 | 9900 | 56 | 350 | 100-190 |

| RDC 150 | 18-30 | 1400 | 900 | 14000 | 56 | 350 | 120-210 |

| RDC 250 | 25-35 | 1460 | 900 | 24100 | 56 | 350 | 240-340 |

| RDC 400 | 30-45 | 2550 | 1200 | 36100 | 64 | 350 | 250-500 |

| RDC 450 | 40-60 | 2800 | 1400 | 43500 | 80 | 350 | 360-550 |

Price - by agreement.

- universal functionality;

- high performance;

- recycling of materials after excavation;

- low vibration level;

- good tightness during underwater work;

- simple maintenance with minimal cost;

- the possibility of use in case of collapse threats.

- not detected.

Simex TF series

votes 0

Brand - Simex (Italy).

Producer - Simex Engineering srl. (Italy).

Universal models for excavation and dredging, tunneling or trenching, profiling concrete and stone walls, demolition of various structures. They show good results where conventional methods are not effective enough, and the use of shock or explosive means is impractical. The low noise level allows them to be used in close proximity to residential areas, hospitals, schools, bridges and other sensitive infrastructure. The heavy-duty transfer shaft is not stressed by cylinders supported by wear-resistant bearings.

Specifications:

| Model | Carrier weight, t | Milling cutter weight, kg | Milling width, mm | Max. pressure, bar | Oil consumption, l/min |

|---|---|---|---|---|---|

| TF200 | 2,5-7 | 300 | 565 | 350 | 45-80 |

| TF400 | 6-12 | 470 | 625 | 350 | 65-120 |

| TF600 | 9-16 | 640 | 700 | 350 | 90-150 |

| TF850 | 14-22 | 1140 | 800 | 350 | 130-190 |

| TF 1100 | 20-34 | 1465 | 850 | 350 | 170-250 |

| TF2100 | 28-45 | 2410 | 950 | 380 | 240-340 |

| TF2500 | 40-55 | 2700 | 1000 | 380 | 280-400 |

| TF 3100 | 50-70 | 3650 | 1250 | 380 | 350-500 |

Price - by agreement on order.

- increased performance in extreme conditions of low or high temperatures, at 100% dust content, in mud, up to 30 meters underwater;

- wide matrix of cutters, drums;

- noiselessness;

- high accuracy;

- hermetic capsule of the hydraulic motor;

- balanced design with the exception of vibration, impact and without causing harm to the seats of the handle of the base machine;

- proprietary rotation mechanism for rotary cutters;

- possibility of use for longitudinal or transverse modes when laying ditches or processing complex surfaces.

- not identified.

Rotary cutters Simex TF:

LST series SC

votes 0

Brand - LST (Germany).

Producer - LST Group (Germany).

Classic models for performing a wide range of earthworks, uprooting trees, laying trenches, dismantling buildings.Structural strength is enhanced by the use of Hardox steel. The drive is carried out by a low-speed hydraulic motor. Thanks to interchangeable tips, the cutting force can be adjusted depending on the hardness of the materials. Completion of all products is possible with various hydraulic motors based on the installed power of the excavator. For dismantling, profiling and breaking, installation of different nozzles is provided.

Specifications:

| Model | Carrier weight, t | Milling cutter weight, kg | Cutting head diameter, mm | Milling width, mm | Drive power, kW | Oil consumption, l/min |

|---|---|---|---|---|---|---|

| SC 45/C | 12-20 | 815 | 550 | 750 | 45 | 120 |

| SC 100/C | 25-35 | 1450 | 615 | 900 | 90 | 240 |

| SC 120 | 20-40 | 1550 | 650 | 850 | 90-190 | 180-320 |

| SC 125 | 20-45 | 1750 | 670 | 1000 | 90-190 | 170-320 |

| SC 130 | 20-45 | 1850 | 670 | 1200 | 90-190 | 170-320 |

| SC 160 | 30-50 | 2200 | 680 | 1200 | 150-230 | 300-410 |

| SC 200 | 45-70 | 3300 | 805 | 1330 | 150-300 | 350-600 |

| SC 240 | 70-110 | 5500 | 910 | 1600 | 230-350 | 350-795 |

| SC 500 | 70-110 | 8000 | 1200 | 1600 | 400-1200 | 700-1600 |

Price - by agreement upon request.

- versatility of application;

- high performance;

- structural strength;

- resistance to external influences;

- long service life;

- equipment with various types of cutting heads;

- low vibration and noise levels.

- not detected.

MB Crusher

votes 0

Brand - MB (Italy).

Producer - MB S.p.A. (Italy).

Italian-made universal products are suitable for excavation and dredging, profiling concrete walls and surfaces, dismantling buildings, digging ditches and trenches in urban areas and mine workings. It is easy to use and facilitates construction work that requires high precision. To reduce the transverse load on the excavator boom, it is equipped with the NoTorsion system. If necessary, the power of the milling head can be increased by the Power Boost amplifier. The high temperature of the oil in the system is reduced by a special proprietary device.

Specifications:

| Model | Carrier weight, t | Milling cutter weight, kg | Milling width, mm | Cutting force, kN | Oil consumption, l/min |

|---|---|---|---|---|---|

| MV-R500 | 3,5-11 | 300 | 450 | 19.6 | 60-120 |

| MB-R700 | 6-13 | 600 | 890 | 19.6 | 110-180 |

| MV-R800 | 10-22 | 1000 | 1015 | 33.9 | 200-300 |

| MV-R900 | 19-35 | 1400 | 1130 | 40 | 250-350 |

Price - as agreed when ordering.

- versatility of application

- high performance;

- positioning accuracy;

- adjustable power;

- possibility of application in water;

- reduced noise and vibration levels;

- simple control;

- increased comfort for the operator.

- the choice is limited to four models.

Operation of MB-R900:

Kinshofer KDC series

votes 0

Brand - KINSHOFER (Germany).

Producer - KINSHOFER GmbH (Germany).

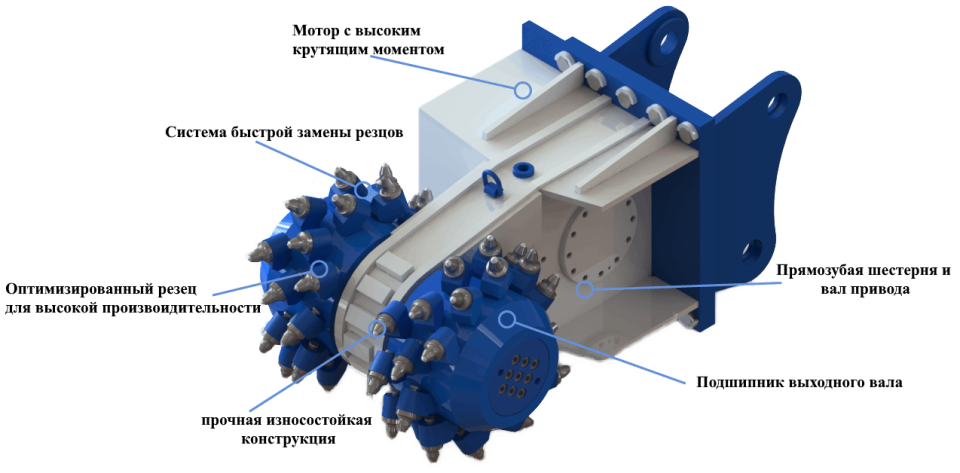

The universal model range of the leading German manufacturer for placement on excavators when performing excavation and dredging, trenching, profiling walls and surfaces, demolition of structures and structures. The units have a strong spur gear driven by high torque motors. To increase the cutting force, they are equipped with gearboxes. High productivity is guaranteed by the optimal choice of cutters and drum. Reliable tightness allows the use of equipment at a depth of up to 25 meters. It is possible to use three variants of the drum - for excavation, profiling of surfaces and demolition of structures.

Specifications:

| Model | Carrier weight, t | Milling cutter weight, kg | Milling width, mm | Rated power, kW | Oil consumption, l/min |

|---|---|---|---|---|---|

| KDC04 | 2-4 | 250 | 500 | 18 | 30-65 |

| KDC06 | 4-6 | 250 | 500 | 18 | 40-65 |

| KDC08 | 5-8 | 250 | 500 | 22 | 50-65 |

| KDC15 | 9-14 | 420 | 630 | 30 | 70-120 |

| KDC20 | 12-20 | 850 | 750 | 45 | 80-190 |

| KDC30 | 18-30 | 1400 | 900 | 60 | 120-210 |

| KDC35 | 25-35 | 1460 | 900 | 90 | 240-340 |

| KDC45 | 30-45 | 2550 | 1200 | 120 | 250-500 |

| KDC60 | 40-60 | 2800 | 1400 | 140 | 360-560 |

Price on request.

- high performance;

- wear resistance;

- low noise level;

- reliable tightness with the ability to perform work at a depth of up to 25 meters;

- ease of management and maintenance;

- comfortable conditions for the operator;

- a wide range of cutters and drums;

- precise positioning.

- difficult to find on sale;

the guarantee is issued after the submission to the manufacturer within a month of the report on the commissioning of the unit.

Demo of Kinshofer KDC:

TOP of the best chain rotary cutters for excavators

Kemroc EK series

votes 2

Brand - Kemroc (Germany).

Producer - KEMROC Spezialmaschinen GmbH (Germany).

Line of models for excavators from two to 50 tons for rock milling with compressive strength up to 100 MPa. It demonstrates high efficiency in conditions when drilling and blasting is impossible for the extraction of medium-hard rocks with a compressive strength of 15 to 60 MPa.

The units are well suited for laying narrow trenches from 480 mm wide with an optimal wall profile. The continuous chain, which is driven by drums with cutters, automatically removes the crushed material from the space between them. Digging a trench with a minimum width saves on unnecessary transportation costs for the removal of crushed fractions and reduces the cost of bulk material.

The use of EK series products reduces the wear of the excavator slewing device. In addition, compared with a simple rotary product without a central chain, the energy expended is saved by 40% at the same performance. The high tightness of the equipment allows it to be used in underwater operations.

Specifications:

| Model | Carrier weight, t | Milling cutter weight, kg | Milling width, mm | Rated power, kW | Oil consumption, l/min |

|---|---|---|---|---|---|

| EC 15 | 1,5-3 | 90 | 370 | 15 | 15-30 |

| EC 20 | 2-4 | 170 | 480 | 22 | 20-40 |

| EC 40 | 5-10 | 900 | 500 | 44 | 70-90 |

| EC 60 | 10-17 | 1600 | 500 | 60 | 130-160 |

| EC 100 | 18-30 | 2400-2600 | 600/700/800 | 100 | 180-240 |

| EC 110 | 25-32 | 2400-2600 | 600/700/800 | 110 | 210-260 |

| EC 140 | 30-45 | 3600-3800 | 800/900/1000 | 140 | 260-300 |

| EC 150; 160 | 35-50 | 3600-3800 | 800/900/1000 | 150 | 280-330 |

| EC 220 | 50-70 | 6000-6500 | 920 | 220 | 420-550 |

In the domestic market, units with similar parameters are presented under the HammerMaster trademark from HAMMER RUS. Price - on request when ordering.

- high performance;

- good orientation accuracy;

- the possibility of choosing the width of the milling;

- fine-grained material after processing;

- increased wear resistance of the rotary mechanism;

- low level of vibration and noise;

- mates well with any modern excavators;

- saving up to 40% of energy costs.

- not suitable for digging wide trenches.

Demonstration of the capabilities of KEMROC EK equipment:

Simex TFC series

votes 0

Brand - Simex (Italy).

Producer - Simex Engineering srl. (Italy).

Patented branded units for use on small excavators up to 12 tons. Equipped with an innovative system with no gaps in the center or sides. Suitable for trenching and flat surfaces. They are used for crushing tree trunks and roots, milling asphalt and concrete pavements, opening gypsum deposits.

Specifications:

| Model | Carrier weight, t | Milling cutter weight, kg | Milling width, mm | Max. pressure, bar | Oil consumption, l/min |

|---|---|---|---|---|---|

| TFC 50 | 1,2-3 | 90 | 370 | 250 | 20-40 |

| TFC 100 | 2,5-4,5 | 170 | 430 | 300 | 30-60 |

| TFC 400 | 6-10 | 400 | 440 | 300 | 65-115 |

| TFC 600 | 9-12 | 670 | 490 | 300 | 90-150 |

Price - on request when ordering.

- versatility of application;

- continuity;

- low noise level;

- high precision of material processing;

- deep and narrow works.

- no.

Video review of Simex TFC:

Thus, rotary cutters are multifunctional, high-performance and efficient attachments for excavators, which are widely used in various fields - from forestry and agriculture to road construction and mining.Unfortunately, such high-tech products are manufactured practically only abroad and supplied to the domestic market exclusively on order, which significantly affects pricing.

Happy milling. Take care of yourself and your loved ones!

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131655 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127696 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124523 -

The best men's sneakers in 2022

Views: 124040 -

The Best Complex Vitamins in 2022

Views: 121944 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114982 -

The best paint for gray hair - top rating 2022

Views: 113399 -

Ranking of the best wood paints for interior work in 2022

Views: 110323 -

Rating of the best spinning reels in 2022

Views: 105333 -

Ranking of the best sex dolls for men for 2022

Views: 104371 -

Ranking of the best action cameras from China in 2022

Views: 102221 -

The most effective calcium preparations for adults and children in 2022

Views: 102015