Rating of the best rubber mallets for 2025

Probably the first tool created by man was a hammer. It has undergone significant changes over the millennia. Currently, a variety of devices are used in various fields of activity. A mallet, the impact element of which is made of different materials, is used to manipulate products that are too susceptible to squeezing.

Content [Hide]

What is needed for

It is practically not used in everyday life, but it is especially popular with craftsmen who deal with structures that are afraid of mechanical damage during significant impacts. The main area of use is straightening sheet metal. The simplest example is the straightening of car bodies.

Roofing work, especially on complex types of roofs, where it becomes necessary to process numerous joints and edges at the intersection of seam joints, cannot be carried out without this device. The actual folding of the metal is carried out by means of a hammer.

With the help of a mallet, furniture elements are padded, it is involved in the assembly process. An indispensable assistant for laying laminate. Carpenters use the device paired with a chisel and a chisel.

Design features

All mallets have a striking part (strike) and a handle. A variety of products are used in the manufacturing process of the striker. It all depends on the scope. The holder is inserted into the hole of the striker and fixed so that there is no breakdown during operation.

Manufacturing materials

Most of the handles are made of hard wood species, including birch. Popular models have rubber coatings at the holding points.Less common are plastic, metal and fiberglass handles. The striker is produced from the following raw materials:

- hard rubber;

- wood of viscous and hard breeds;

- fluoroplast.

Striker shape

Products are produced with the following head shape:

- Rectangular. It is used when carrying out slotting manipulations, folding and roofing works.

- Round. Helps to carry out straightening, installation, used for laying paving slabs.

- Square. The main area of use is in folding and roofing.

The shape of the head is wedge-shaped or straight.

Weight and parameters

The variety of areas of use for hammers also implies a difference in weight devices. The mass of equipment ranges from 225 to 450 grams (light models), 450 - 900 grams (medium), over 900 grams (heavy).

It is worth remembering that the size of the device does not always correspond to its weight. So, small devices can be of considerable severity and vice versa.

The variety of handle lengths is impressive. A long handle means a strong blow. The classic model weighs 300 g and has a 30 cm handle.

Areas of use for a rubber mallet

A mallet is a fairly serious instrument, so strict requirements are imposed on its manufacture. Holders are made exclusively from solid wood species. It is assumed that the wood is both viscous and heavy. This guarantees the strength and comfort of the product. The rubber part is made of black or white rubber. The white head leaves no marks on smooth and light surfaces. In addition to rubber, PTFE options are available.

Another feature is the installation of the handle exactly in the center of the striker in a cone-shaped hole. This ensures that the rubber part does not break off during operation.

Often a rubber mallet is used for laying tiles. The presence of shock-absorbing quality and bulge of the rubber element does not allow damage to the laid tiles. It is intended for a precipitation of a tile in solution.

An indispensable tool for carpentry work. The rubber striker with a wooden handle makes it possible to keep other equipment safe and sound: a chisel and a chisel.

What are

Standard devices are of the following types:

| Type of | Description |

|---|---|

| Wooden | The scope of application is the molding of raw materials and structures during assembly and dismantling. |

| Rubber | It is supposed to work with products that are too sensitive to pressure. The handle is made of metal or wood. Popular with roofers. |

| Construction | It is used in the installation of structures related to soft metal-plastic and metal. Equipped with rubberized head. |

| Inertialess | It is used for manipulations with structures in which it is necessary to maintain the integrity of the surface, for example, the assembly of furniture sets. The inner part of the striker has an elongated cavity in which there is metal shot or balls that prevent it from bouncing. |

| Locksmith | Used for folding and straightening material, or when working with sheet metal. There is a rectangular striker and a round wooden handle. |

| carpentry | Differs in wide and flat sides. Slotting work is not complete without it. Suitable for adjusting planer attachments. |

| Turning | The scope of use is identical to the metalwork, only all its parts are made on lathes. |

| Plastic for roofers | Can be found where double standing seam technology is used.In the manufacture of the striker, impact-resistant polyethylene is used. |

| For the tiler | There is a rubber head with a round heel. To lay paving stones, use a 400 g device. For paving slabs, you need to choose a product weighing from 600 to 800 g. |

| "Cutter's Hammer" | It looks like a hand bell or a one-handed rolling pin. Designed for woodcarving. Made from solid wood species. Can be used to create sculptures. |

| Textolite | It has electrical insulating qualities. Jewelry and body work cannot do without it. Helps where it is impossible to prevent the formation of sparks from impacts (gas tanks and so on). |

How to choose

Mallets differ in design, functionality, average price, material of manufacture, parameters. Experts recommend carefully approaching the choice of this product. Everyone has different selection criteria. To avoid mistakes when choosing, you need to pay attention to the following technical parameters:

- Length. The run-up in the length of the handle can be significant. Which is better to buy depends on the preferences of users. It is worth remembering: the longer the grip, the greater the impact force.

- Material. It is desirable that the elements are made of different types of wood. This will soften the recoil force.

- The weight. A heavy tool has an increased impact force. It should be borne in mind that working with a heavy tool implies the presence of not hefty physical strength. A person can quickly get tired, and the process will drag on for a long time. Sometimes they make the device heavier due to lead.

- Head size. Rough work involves the presence of a large percussion element, delicate actions are performed by a small percussion element.

- Derzhak. Popular models are produced where this component is made of fiberglass.Belongs to the category of durable, over the years the shape is not lost, there is protection from drying out, despite the interaction with various organic solvents.

The rating of quality goods is headed by German models. Where can you buy them? There are several options. They are sold in specialized stores. How much it costs depends on the model. The best ones are sold at a price of over 1000 rubles. The budget option can be purchased for 350 rubles.

You can order goods online in the online store. But first, you should review the products, choose the best ones, carefully consider the proposed photos. Which is better firm, the user is determined independently. It will not be superfluous to get acquainted with the opinion of buyers on this matter, to listen to the advice of specialists. Much will depend on what it is supposed to be used for.

There is a third option - to make a mallet with your own hands at home. The procedure is as follows:

- Pen preparation. The workpiece is turned on a lathe, it is given a round shape for ease of holding in the hand. A special protrusion is made in the middle of the handle. There will be a head.

- We prepare materials for the impact element. We take rubber (you can skin). Cut out circles of the required diameter. The number of circles depends on the thickness of the selected material. There may be more than fifty of them. Round holes are cut in the center so that it becomes possible to string them on the holder. All circles are glued together with PVA glue. For quality gluing, the circles must be placed under a press or placed in a vise until the glue is completely dry.

- We fix the head. To prevent the possibility of falling off, a wooden or metal washer is attached to the top of the handle.It should fit under the handle in size so that cracking does not occur. The striker should sit tightly on the handle.

The resulting design is quite suitable for homework. Its main characteristics: reliability, noiselessness, practicality. With a significant impact, the head will not crack. For the purpose of additional fastening, the protruding edges of the percussion element can be intercepted with twine or small carnations can be driven into the end.

Inexpensive fixtures

Sparta, 680g

votes 2

As a basis, black raw materials (rubber) are used, the hardness of which is 80 units. A little different from the traditional design due to the attachment of the striker to the pull. The holder is two-colored, covered with a colorless varnish, which prevents the wood from drying out. The total weight of the device is 825 g, including the round head - 680 g. Made in China.

The average price is 175 rubles.

- comfortable;

- light;

- practical;

- functional;

- inexpensive;

- good feedback.

- missing.

Bartex Euro, 450 g

votes 0

The product belongs to the category of hand percussion instruments. The main feature is the presence of a long wooden handle, varnished with the function of protecting it from drying out. The impactor is black rubber with a hardness of 80 Shore. Used in conjunction with a chisel, chisel and crimp ring.

The average cost is 162 rubles.

- reliability;

- long service life;

- functionality;

- practicality;

- convenience;

- used to work with products that are sensitive to pressure.

- not installed.

Stayer "Standard", 225 g

votes 0

The black fixture is used when performing assembly and installation work. It is often used in the process of laying tiles on sidewalks.Equipped with a cylindrical head with flat heads, which is qualitatively attached to the holder with a special epoxy adhesive.

You can buy goods at a price of 130 rubles per unit.

- excellent damping of vibration;

- build quality;

- reliability;

- durability;

- practicality;

- comfort in use;

- affordable price.

- not identified.

Bartex, 340g

votes 0

Model with a long lacquered wooden handle. There is protection against drying out. The head has a black color, rubber, strength index - 80 units. Faithful companion of such devices as a chisel, a chisel and a ferrule. It is often used in relation to products that are extremely sensitive to pressure.

It is sold at a price of 120 rubles.

- lasts long enough;

- comfort in operation;

- practicality;

- reliability;

- universality;

- functionality.

- missing.

Sparta 111405

votes 0

An inertial-type product with a rounded striker and a 28-cm wooden holder is very convenient for assembly and other work. Light weight (340 g) allows you to work tirelessly with the tool for a long time. The manufacturing process uses innovative production technology and high-quality rubber and wood.

The average cost is 176 rubles.

- quality materials;

- ease of use;

- comfort;

- reliability;

- perfectly fulfills the duties assigned to him;

- acceptable price.

- not installed.

Sparta 111305, 225g

votes 0

A handy hand tool at a ridiculous price. The product is produced in China.It attracts builders with its light weight, which allows you to work with such a product for a long time, while your hands will not get tired. The hardness of the rubber is 80 Shore. It differs from the traditional product by the principle of fastening the head to the holder - “on a pull”. The wooden handle is painted in two colors. There is protection against drying out. Coating - colorless varnish.

Sellers offer goods at a price of 87 rubles.

- German brand;

- light weight;

- rubberized handle;

- toe - round;

- reliability;

- is included in the rating of quality goods;

- comfort;

- durability.

- not identified.

Tools of the middle price segment

Hammer 1250 g 15109295

votes 0

The head is black and white, made of high-quality rubber, without all kinds of impurities and fillers. Attached to a wooden handle. The tool belongs to the category of universal. It is used in the process of straightening, helps with laying paving slabs, assembling furniture, straightening sheet metal. The handle is lacquered.

Sold in all specialized outlets at a price of 756 rubles.

- ergonomic handle;

- unlimited service life;

- material quality;

- practicality;

- reliability;

- comfort;

- price-quality ratio;

- positive reviews.

- missing.

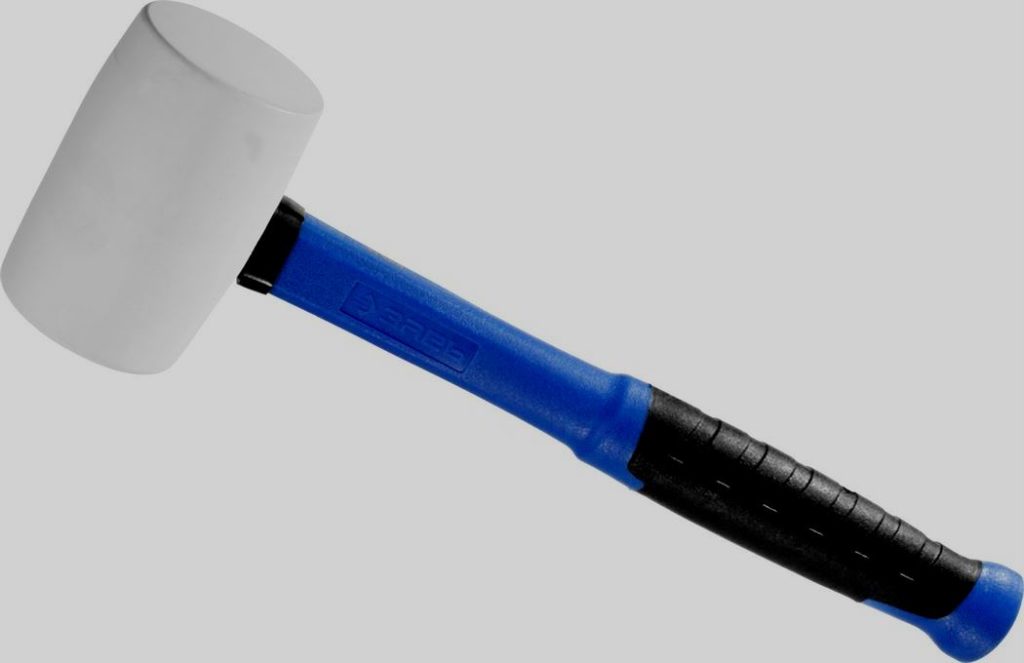

Professional, 900 g

votes 7

Russian-made products are produced by the Zubr company. For little money, you can get high-quality hand tools. Belongs to the category of professional products. Cylindrical white rubber head. Anti-vibration handle with anti-slip coating. Fiberglass is used in its manufacture.The product is intended for carpentry, construction, roofing and carpentry, where you need to interact with very "delicate" materials. A distinctive feature - with proper use, damage to the processed materials is practically excluded.

The average price is 634 rubles.

- eternal;

- quality;

- reliable;

- professional;

- universal;

- comfortable;

- anti-slip coating;

- produced in full compliance with the requirements of GOST;

- does not damage the processed materials;

- leaves no traces;

- elasticity;

- increased strength;

- does not dry out;

- not afraid of organic solvents;

- anti-vibration technologies;

- optimal settings.

- not installed.

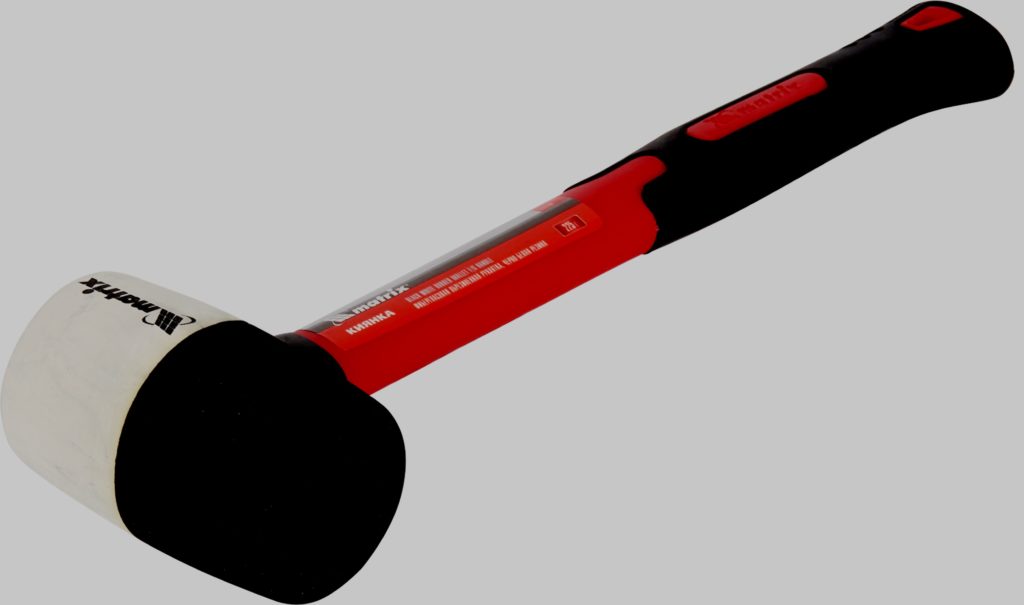

Mallet with fiberglass handle, 900 g

votes 0

A novelty from the best Russian manufacturer Zubr. Considered professional equipment. The impact element is made of high quality rubber, two-tone (white and black), cylindrical shape. The presence of an anti-slip coating on the fiberglass handle helps to perform work efficiently without fear of dropping the tool. With her participation, roofing, joinery, construction and carpentry work is carried out. Excellent for pressure sensitive materials.

The average cost is 592 rubles.

- long service life;

- excellent performance;

- reliability;

- universality;

- comfort;

- functionality;

- wear resistance;

- practicality;

- handle elasticity;

- does not swell and does not dry out;

- resistance to organic compounds;

- use of anti-vibration technology.

- missing.

Hammer 15109308, 680 g

votes 0

The device with a rubber impact element weighing 680 g, a wooden handle is very popular among assemblers and installers. Often used by paving, wall and floor tiles. Boyok has a black and white surface. The handle, made of high quality wood, is able to dampen vibrations.

The average cost is 582 rubles.

- strength;

- elasticity;

- quality;

- durability;

- practicality;

- functionality;

- positive user reviews;

- acceptable price;

- compliance with the requirements of GOST.

- not installed.

Rubber mallet with fiberglass handle, 680 g

votes 0

High-quality Russian-made goods are distinguished by reliability, durability and practicality. In the manufacture of the company strictly complies with the requirements of GOST. The head is two-tone - white and black, made of durable rubber. The fiberglass handle has anti-vibration properties. Ideal tool for roofing, carpentry, construction and carpentry work. Indispensable where you have to interact with materials that are too sensitive to pressure.

The product can be purchased at the store at a price of 504 rubles.

- full compliance with GOST;

- quality factor;

- reliability;

- long service life;

- price-quality ratio;

- does not damage the processed materials;

- wear resistance;

- anti-vibration technologies;

- elasticity;

- strength;

- functionality;

- universality;

- not afraid of organic solvents;

- qualitatively held in the hand;

- does not slip.

- missing.

Hammer 15109316, 450 g

votes 0

A product with a black and white percussion element and a wooden holder. It is used where it is necessary to deal with "delicate" materials that are afraid of significant pressure. With its help, you can process iron, adjust road or curb stone or brick, as well as masonry. It can often be found in the implementation of tin manipulations. The constant companion of a chisel and a chisel. Prevents damage to cutting tool handles.

The average cost is 552 rubles.

- ergonomics;

- reliability;

- does not leave dark spots on a light surface;

- contributes to the quality performance of tasks;

- convenient sizes;

- durability;

- universality;

- functionality;

- quality factor;

- profitable price.

- missing.

Expensive hand tools

M 11045 Jonnesway 47814 (0.52 kg)

votes 0

The birthplace of the brand and the country of manufacture are the same - Taiwan. The series includes special hammers with a hollow head, inside which steel shot is contained in a certain amount. The shot continues to move forward even when the tool stops, and then it abruptly slows down due to the presence of an obstacle. In this case, the hammer does not bounce. The mallet itself is steel, covered with synthetic rubber of special density. Thanks to this coating, the surface is completely protected from damage. Product length - 28.6 cm, weight - 493 g, the shape of the striker is round.

The average price is 1630 rubles.

- reliability;

- indestructibility;

- functionality;

- practicality;

- ease of use;

- price-quality ratio.

- not installed.

M 11055 Jonnesway 47815, 1.05 kg

votes 0

Quality product from Taiwan.Differs in a hollow shock part in which steel shot is filled up. It is used when carrying out various manipulations where adjustment or alignment is necessary. The steel handle is covered with thick rubber, which makes the tool more comfortable to use. Head diameter (round) - 55mm.

The average cost is 2310 rubles.

- multifunctional;

- practical;

- good;

- comfortable;

- durable;

- reliable.

- significant cost.

Hans 5702 - 16, 470 g

votes 0

Brand and country of manufacture - Taiwan. The products are reliable and of good quality. Professional builders have no complaints about it. The hammer is made of polyurethane. There is no return. Light weight allows you to work with it for quite a long time. At the same time, a person does not feel tired, and his hands do not hurt. Round rubber striker.

The product can be purchased at a price of 1350 rubles.

- multifunctional;

- practical;

- long service life;

- universal;

- positive reviews.

- not identified.

Zubr Expert, 700 g

votes 0

Russian brand, but the country of origin is China. The hammer belongs to the category of multifunctional tools. Made for professional use. Suitable for installing plastic windows. Conforms to all requirements of GOST. Impact element - rubber, diameter 30 mm, weight - 0.315 kg, ash handle.

Sellers ask for 1096 rubles for the goods.

- warranty period - one year;

- comfortable;

- functional;

- good;

- qualitative;

- reliable.

- missing.

Rubber mallet, black and white, 450 g, 81968472

votes 0

Impact head - rubber.Suitable for processing tiles, wood and laminate. It is widely used in roofing and tin work, laying tiles, both floor and paving, for car repair. Works in tandem with a chisel and a chisel. Qualitatively adjusts parts when assembling furniture, without damaging or deforming them. Leaves the paint layer intact. The weight of the structure is 450 g, the head is 6 cm wide. The length of the handle is 260 mm.

The average price is 888 rubles.

- long service life;

- universality;

- quality factor;

- practicality;

- functionality;

- does not harm the material.

- missing.

Mallet with fiberglass handle 82356519, 225 g

votes 0

The model is widely used in assembly and installation work, when laying curb, paving, wall and floor tiles, paving stones. It can process sheet metal. The handle is ergonomic, two-component, has a length of 250 mm. Made from red fiberglass. It has rubber inserts to prevent slipping of the hands. The ellipsoidal cross-section on the handle improves the grip, allows you to strike accurately, while regulating the force. Equipped with a rubber head weighing 225 g and with a diameter of 5.1 cm, a width of 7.9 cm. The striker is black. Despite the Chinese production, the product is quite reliable and durable.

The average cost is 1005 rubles.

- used for processing colored material;

- quality factor;

- universality;

- ease of use;

- ergonomic handle;

- functionality.

- a black head may leave traces on a light background.

Conclusion

Not all hand percussion instruments are used for destructive purposes. Some are designed for creative moments and a gentle approach to the material. It is impossible to straighten metal plates, assemble furniture, carry out roofing, carpentry and construction work without a mallet, especially if tools such as a chisel and a chisel are involved. People began to use such hammers even before our era. And now they have not lost their relevance, although they have changed and improved a little.

In appearance, the mallet looks like a hammer and it belongs to the same class. The main difference is that the enlarged striker is made of rubber, wood or metal, has a cylindrical, round or rectangular shape. The purpose is also different. It is necessary to hammer something with a hammer, while they work carefully with a mallet so as not to damage the “delicate” material.

Modern designs differ in the shape of the impact element and the material used in its manufacture. Wooden models are indispensable in the implementation of roofing, disassembly and assembly of furniture, molding of non-ferrous metals. Tools with rubber heads are used when laying slabs, straightening metal.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127688 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124516 -

The best men's sneakers in 2025

Views: 124030 -

The Best Complex Vitamins in 2025

Views: 121937 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2025

Views: 113393 -

Ranking of the best wood paints for interior work in 2025

Views: 110317 -

Rating of the best spinning reels in 2025

Views: 105327 -

Ranking of the best sex dolls for men for 2025

Views: 104363 -

Ranking of the best action cameras from China in 2025

Views: 102214 -

The most effective calcium preparations for adults and children in 2025

Views: 102010