Rating of the best thicknessing machines for 2022

Why do you need a thicknesser? Not a single building of a capital structure can do without it, including residential buildings, utility rooms, garages, and so on. The equipment allows you to cut the board to the required length, make it even and smooth. Such high-quality wood is used for the construction of log cabins, laying plank floors, and making furniture.

Content [Hide]

What are

If a person has to deal with a tree, then with a significant amount of it, the question arises of how to quickly and accurately plan the boards. You can do it manually, but it's too long and too hard. To speed up and facilitate the process will help special units with knife shafts, where the workpieces are fed automatically.

What is it and what options are available? The best manufacturers have saturated the market with a variety of products, presenting various types of machine tools to the public. Their distinctive features can be viewed in the comparative table:

| Planer type | Description |

|---|---|

| Unilateral | Belong to the household category. Plane one side of the workpiece. Used for home. There are many popular models. |

| Bilateral | considered professional. Treat both the bottom and top surfaces. They have great power and great speed. |

| Three-, four- and multi-sided | Industrial options that process wood on both sides. Used to give parts the correct geometric shape, provide the edges with the necessary texture. Differ in significant parameters, weight and complexity in operation. The main benefit is performance. |

Design classification

Wood processing devices are:

- Mobile. They are distinguished by their low weight, small size, as a rule, they are installed on top of a working workbench and process small parts at home.

- Stationary. Bigger and heavier than their counterparts. Used for processing large workpieces.

Regardless of the popularity of the model and its structure, the devices are equipped with automatic feed.The existing roller system presses the wood against the shaft and “transports” it until it is on the working surface.

The units have the following features:

- power varies from 1.5 to 8 kW;

- maximum planing width - 38 cm;

- depth - 3 mm.

Models differ not only in functionality, but also in shaft speed, energy consumption, number of knives, characteristics, average price, and so on.

The difference in functionality

In order not to make mistakes when choosing, you need to have information about which machines manufacturers produce and what functions they are endowed with. Consider the main options:

- Household. Main characteristics: compact, weigh a little, can be installed in a small room. They have low to medium power. Inexpensive for the price. They are used for processing small workpieces and sawing to a shallow depth (from 1 to 1.5 mm). In most cases, the filing is done manually. Unable to master deep cutting surfaces. Working with them requires significant physical effort. Not applicable for work with workpieces on an industrial scale.

- Industrial. The best models have high speed and significant power, the possibility of deep cuts. Takes up a lot of space in the room. There is an automatic feeding function. It is connected to the mains at 380 V. High power requires its own cooling system. Blades can be installed on one side or on both sides. Main structural elements: double rack, movable drum, knives. There is the possibility of adjusting the depth of cut, thanks to the presence of the control unit.

- Slicing - planer.They are used if there is a need to turn parts, products and other accessories made of wood with your own hands as accurately as possible. Able to provide a perfectly flat surface, reduce the thickness using a longitudinal method, eliminate various defects, such as splinters, cuts, bulges and more. Some manufacturers provide for the possibility of reciprocating movements of the device. Which company is better to buy depends on the preferences of the masters. The product is produced by both foreign firms and domestic companies. New products are produced annually, leading the rating of quality products of this kind.

- Jointing - planer. Milling is performed by processing the base base by means of a knife shaft installed under the table. There are two-sided and one-sided. The first option is used more often both for self-processing at home and in industrial conditions.

Scope of application

All woodworking enterprises have such equipment. It helps to solve the following tasks:

- Align the thickness of the workpieces.

- Precisely cut boards and boards designed for floor and wall finishing.

- To make a wooden surface perfectly smooth.

- Perform flat work.

Before starting work on the thicknesser machine, it is necessary to carry out a thorough adjustment. What to pay special attention to:

- The machine on the desktop is installed clearly and correctly, without distortions.

- Avoid low placement of the corrugated roller.

- Adjust the pressure of the rear pressure pad on the surface to be treated.

- Make sure that there is no very high pressure on the lower rollers, due to which the wood is fed above the level of the table.

- Check the operation of the extractor.If it fails, the chips will end up in the rear main roll.

- Look at the installation of the cap.

How to choose

Thicknessing aggregates belong to the category of high-performance for woodworking. Ease of operation is as follows: adjustment is carried out once and a batch of goods is of high quality and with the same parameters. Which one is better to buy depends on many factors, including the scope of its use and the installation location. It is worth listening to the recommendations of experts.

Everyone has different selection criteria. Some pay attention to the material of manufacture, the second - to the rating, the third - to the manufacturer, the fourth - to the cost. For home production, you can choose budget options. Before purchasing, it is worthwhile to review the proposed product, read the reviews.

Each master decides for himself where to buy the device. Many people prefer to visit a specialized outlet, see the products offered with their own eyes, talk with a sales manager, and listen to his advice. Some people order the model they like online in the online store. But, according to buyers, this method of acquisition has its drawbacks. The item may be defective or damaged.

If a person has “golden” hands, then the unit can be made independently at home. How to do it will tell you step-by-step instructions, which are easy to find on the Internet. First you need to calculate how much the spare parts for the device will cost and how long it will take to manufacture it. However, there is no guarantee that the machine will operate without vibration. This deficiency will adversely affect the quality of manufactured products.

Rating of the best thicknessing machines for 2022

Inexpensive models

Caliber SSR - 1600

votes 59

The product is produced in China. Belongs to the category of the lightest. It is able not only to make blanks according to the set parameters, but also to level the surfaces by switching to the jointing mode. Processes wood with a thickness of 6 to 120 mm. The number of revolutions of the cutting shaft is 8000 rpm. Roller rollers make it easy and simple to feed workpieces. When switching to planer mode, manual feed can be used. Table parameters - 746 x 210 mm. The collector plan engine is able to work continuously for about 20 minutes, after which it should be turned off for 5 to 7 minutes to avoid overheating.

The average cost is 16550 rubles.

- copes with various processing thicknesses;

- equipped with a parallel stop with fasteners;

- able to change the angle from 90 to 120 degrees;

- stable due to the presence of rubberized legs;

- minimum vibration;

- optimal performance;

- acceptable cost;

- reliability;

- durability.

- significant have not been identified.

Stark CWM-2500

votes 19

Combined device that qualitatively processes wood in order to give the required size and configuration. Performs the following actions:

- planes on a plane using a clamping device;

- cuts fibers across and at an angle;

- cuts along the ribs;

- uses end mills for milling and drilling;

- cuts fibers lengthwise and across;

- cuts straight.

Equipped with:

- protective cover;

- asynchronous motor with a power of 2.5 kW;

- connector for connecting a vacuum cleaner;

- RCD electronic unit that starts the machine.

Sellers offer goods at a price of 36,200 rubles.

- assembly;

- reliability;

- operational period;

- built-in overheating protection;

- the electronic unit;

- optimal combination of price and quality;

- high-quality work of the thickness gauge and jointer.

- difficulty in installing and adjusting the sawing table.

Makita 2012 NB

votes 58

If we review similar models, then this one is ergonomic. Japanese equipment is produced in China. Differs in accuracy of processing of wooden surfaces. Able to work with a maximum height of 155 mm and a width of 304 mm. The portable device is considered high-performance, the auto-feed speed is 8.5 m / min. Depth of planing - 3 mm, with maximum accuracy. Can be installed on various surfaces. Handles both large and small parts.

The average cost is 44,990 rubles.

- slight noise;

- compactness;

- ergonomics;

- processing accuracy;

- autofeed speed;

- changing blades is quick and effortless;

- quality of sharpening of the cutting element;

- Comes with detachable drawer for storing small tools.

- safety;

- operational period.

- not identified.

Kraton WMT 318

votes 26

The Russian installation is manufactured in China. The main feature is a monolithic body and a folding table. Differs in ease and compactness. Qualitatively planes and processes timber in home workshops. Due to the solidity, the design is well installed and quickly adjusted. A comfortable handle makes it easy to move the machine from place to place. High shaft speed - up to 8000 rpm. Automatic feed is carried out at a speed of 8 m/min.

The average price is 25950 rubles.

- monolithic structure;

- mobility;

- compactness;

- build quality;

- reliability;

- durability;

- ensuring the accuracy of processing;

- smooth adjustment of cut parameters;

- sharp knives;

- broaching mechanism;

- the presence of additional videos.

- not installed.

Hitachi P 13 F

votes 32

High quality Japanese equipment. The best option for craftsmen engaged in semi-professional activities. Able to master the processing of any wood. An excellent machine for use in small-scale production. Planing depth range - 0 - 2.4 mm. The presence of the thickness gauge scale allows you to set the height of the cut, with a maximum allowable log width of 152.4 mm. Parameters are set with a convenient knob. Equipped with a 1800 W motor, providing a shaft rotation speed of 8000 rpm. Material feed speed - 7.5 m / min.

The average price is 31,900 rubles.

- the parameter control knob can be installed both on the right and on the left;

- quality of work;

- reliability;

- high performance;

- there is protection against overheating;

- equipped with top rollers to ensure comfortable material feeding;

- operational period;

- affordable cost.

- significant were not found.

Zubr SR - 330

votes 58

Russian compact equipment with an electronic indicator. Place of manufacture - China. Differs in simplicity in management and compact dimensions. Refers to the portable type. It can handle medium volumes while maintaining the quality declared by the manufacturer. A millimeter scale and an electronic indicator allow you to control the indicator of the accuracy of observing the processing width. The rotary knob allows you to adjust the planing depth from 1 to 3 mm.

The average cost is 25390 rubles.

- it is equipped with the switch of the modes of automatic giving of wood;

- the possibility of the choice of speed in the range from 4 to 6 m/min. is given;

- the ability to connect a dust collector;

- table can be extended

- ease of use;

- safe;

- reliable design;

- made of high quality materials;

- operational period.

- not identified.

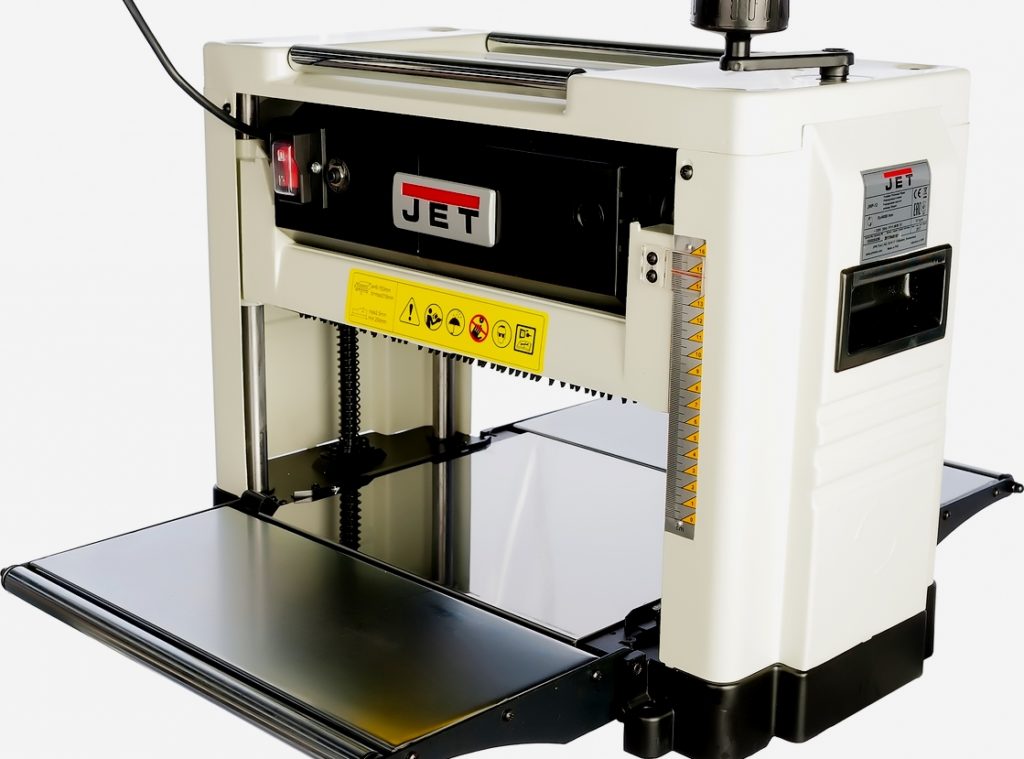

Jet JWP-12

votes 41

The equipment is characterized by the presence of an optimal performance indicator. Time-tested Swiss quality, despite the country of manufacture - China. It is characterized by compact dimensions and low weight of 30 kg. It features a high power rating of 1800 W and productivity, as well as noteworthy quality of work. The maximum rotation speed of the cutting shaft is 9000 rpm. The maximum dimensions of wood for processing are 153 x 318 mm. The processing speed is 7 m/min, which is the optimal indicator. Equipped with a control button, a handle for adjusting the height of the table and a millimeter scale.

The product can be purchased at a price of 26,000 rubles.

- intuitive control;

- folding tabletop;

- compactness;

- light weight;

- good combination of price and quality;

- performance;

- convenience of storage;

- mobility;

- reliability;

- durability.

- missing.

Models of the middle price segment

Proma HP - 250/2 - 230

votes 4

The Czech development is made in the territory of the Celestial Empire. Differs in existence of a broach and a heavy bed. It is popular with craftsmen who are engaged in leveling and subsequent milling of wood. Suitable for home use, as well as installation in a small production hall.Rotation speed - 4000 rpm. Due to the presence of a planer shaft with thin steel knives in the amount of three pieces, it qualitatively removes chips up to 5 mm. The unit is characterized by stability due to the presence of a smooth cast-iron frame.

The average cost is 89,500 rubles.

- there is a pulling mechanism;

- ease of operation;

- cleanliness in the workplace due to the ability to connect a vacuum cleaner;

- the quality of the material used in the manufacture;

- reliability;

- productivity;

- operational period.

- not installed.

Metabo HC 260 DNB

votes 9

The German company has launched the production of narrow-profile products for woodworking, guaranteeing the high quality of the goods. A distinctive feature is a high performance indicator. It is used for jointing and planing of wooden surfaces measuring 160 x 260 mm. It has a stable gearbox that feeds wood at a speed of 5 m / min. The body is aluminum, the table is cast iron. Height of processing is regulated in one touch.

The average cost is 83,500 rubles.

- three-phase motor;

- shaft rotation speed - 6500 rpm;

- the effectiveness of a double-sided knife;

- build quality;

- increased wear resistance;

- ease of operation;

- the presence of a protective bar in order to protect the operator;

- restart lock.

- not identified.

Record Power PT 260

votes 0

The device is manufactured by a British company with a worldwide reputation, whose products are distinguished by reliability, safety and excellent performance. The machine is used in small production shops. Power - 1900 W, weight - 80 kg, mobile. Equipped with a protective cover for operator safety.In the manufacture of two beds, cast iron was used. Able to work with different types of wood. Planing occurs evenly, with a maximum depth of 3 mm. Operating speed - 5 m / min.

The average price is 91608 rubles.

- the quality of the proposed product;

- ease of use;

- reliability;

- safety;

- productivity;

- processing accuracy;

- efficiency;

- multifunctionality;

- compactness.

- not detected.

Proma T-400 65400000

votes 2

A professional thicknessing machine that planes any wooden surfaces to a depth of 4 mm. Transported by stacker. Connected to a single-phase power supply. Workpieces are fed at a speed of 13.5 m/min. Equipped with a rotating knife shaft, which is responsible for working with flat surfaces.

The Czech manufacturer offers products at a price of 79,000 rubles.

- the table is made of cast iron, which is not afraid of corrosion;

- durability;

- reliability;

- material feed rate;

- high performance engine;

- exact installation of knives is carried out by means of adjusting bolts;

- lack of vibration;

- stability;

- there is an emergency stop button;

- millimeter measuring scale;

- equipped with a large flywheel that raises and lowers the tabletop;

- warranty period - one and a half years.

- not installed.

premium models

Dewalt D 27300

votes 0

The universal model of the American manufacturer enjoys well-deserved popularity among professionals due to its reliability, quality of work performed and long service life. Differs in a high rate of productivity.Equipped with a 2100 W motor, which makes it possible to work with wood of any density with a thickness of 160 mm, but no more. Performs thicknessing and jointing work of various levels of complexity and in any volume. In the manufacture of knives, high-speed steel was used, which makes it possible to increase the material feed rate up to 5 m/min.

The average cost is 124,000 rubles.

- high quality knives;

- optimal performance indicator;

- two tables of different designs;

- built-in dust removal function;

- stable emphasis;

- the operator and the engine are reliably protected;

- durability.

- not installed.

Jet JWP-208-3

votes 2

The device has an excellent indicator of power and performance, which allows it to be installed both in private workshops and in production workshops with a large amount of upcoming work. Massive unit weighing 300 kg, with a rigid and stable design, comes standard with a planer unit equipped with a motor and a fixed feed mechanism. The thickness of the wood is adjusted by moving the table up and down the columns. There is a two-stage feed rate adjustment, a roller system, the ability to install a helical cutter shaft and other functions.

The goods are sold at a price of 210,000 rubles.

- the body is made of high-strength cast iron;

- planing height adjustment;

- power indicator;

- excellent performance;

- reliability;

- operational period;

- excellent combination of price and quality;

- safe;

- easy to operate and maintain.

- missing.

Powermatic WP 2510

votes 0

The multifunctional thickness gauge is designed to work at large manufacturing enterprises. High-class modern equipment, characterized by ease of operation, high service life, performance and reliability. Helical shaft included. Differs from similar designs with knives. Equipped with carbide segments with radius edges arranged helically in several rows. The elements have four cutting sides, which significantly increase the declared resource. All elements are subject to replacement, but only in the sequence declared by the manufacturer.

Products can be purchased at a price of 730,000 rubles.

- universality;

- noiselessness;

- quality of work;

- electronic control system;

- simplified reconfiguration;

- lack of marriage;

- accurate digital control of operating parameters;

- ease of management;

- feed shaft sectional metal;

- four hooks for transportation.

- overpriced.

Powermatic 209

votes 1

Belongs to the category of powerful and massive thicknessing machines. The manufacturer declared a three-phase connection. Planing width reaches 500 mm. The shaft is equipped with the usual straight blades. Equipped with a segmented helical drum with carbide blades. The cast-iron construction is strong and vibration-free. The height of the table can be adjusted using the steering wheel. The model is produced with all the necessary settings and functions that allow you to work stably for a long time and comfortably.

The average price is 245,000 rubles.

- high quality products;

- power;

- reliability;

- multifunctionality;

- able to work with wood of various densities;

- the main and secondary (auxiliary) functions thought out by the manufacturer;

- the wheeled chassis is equipped with a brake for easy movement around the workshop;

- height adjustment;

- performance;

- convenience in operation.

- not installed.

Jet JWP-16 OS HH

votes 0

The high-quality unit is designed for professional use for a long time and with a significant load. Equipped with a powerful motor and a planing drum, 90 square carbide cutting segments, the rounded shape of which makes it possible to carry out fine planing. The knives operate at a certain slope and alternately, which completely eliminates shock loads. Sufficiently successful design, characterized by rigidity and massiveness.

The average price is 190,000 rubles.

- minimal noise;

- lack of vibration;

- knots are cut off;

- high intensity of exploitation;

- significant resource;

- ease of maintenance;

- the possibility of reversal of damaged segments;

- no need for further adjustment.

- used in production line;

- copes with wood of any hardness;

- durable;

- safe;

- the ability to adjust the speed;

- reliable;

- universal.

- significant have not been identified.

Conclusion

Those whose activities are related to the processing of wooden surfaces, the production of parts and other accessories, know how important it is to have a high-quality, reliable, safe and functional thicknessing machine in their arsenal. The equipment is designed for planing, adjusting the thickness of the boards, giving them the necessary shape.

For automatic feeding of workpieces, a special mechanism is provided, thanks to which the work of the operator is greatly facilitated and efficiency is increased. The main structural elements of the machines are the knife shaft and engine, work surface and rollers.

Models are produced in industrial and domestic designs, differing in functionality, material of manufacture, power, reliability, parameters and cost. The product can be purchased in specialized retail stores. It should be borne in mind that when placing an order online for an industrial machine with a significant weight through an online store, there may be problems with delivery.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2022

Views: 131656 -

Rating of the best soundproofing materials for an apartment in 2022

Views: 127696 -

Rating of cheap analogues of expensive medicines for flu and colds for 2022

Views: 124523 -

The best men's sneakers in 2022

Views: 124040 -

The Best Complex Vitamins in 2022

Views: 121944 -

Top ranking of the best smartwatches 2022 - price-quality ratio

Views: 114982 -

The best paint for gray hair - top rating 2022

Views: 113399 -

Ranking of the best wood paints for interior work in 2022

Views: 110324 -

Rating of the best spinning reels in 2022

Views: 105333 -

Ranking of the best sex dolls for men for 2022

Views: 104371 -

Ranking of the best action cameras from China in 2022

Views: 102221 -

The most effective calcium preparations for adults and children in 2022

Views: 102015